Page 1

Baler Belt Skiver

Safety and Operating Manual

is manual contains important information about product function and safety. Please read

and understand this manual BEFORE operating this tool. Please keep this manual available for

other users and owners before they use this tool. is manual should be stored in a safe place.

www.flexco.com

www.flexco.com

CAUTION!

Page 2

Table of Contents

General Safety Rules ....................................................................................................................... 2

Main Components .......................................................................................................................... 3

Tool Specications .......................................................................................................................... 3

Adjust the Clamping Lid ............................................................................................................... 4

Position Blade Holder, Belt and Hold-Down Sha .................................................................... 5

Tes t Skiv e ......................................................................................................................................... 6

Skive the Belt ................................................................................................................................... 7

Changing the Blade ........................................................................................................................ 8

Maintenance .................................................................................................................................... 9

Troubleshooting ............................................................................................................................ 10

Replacement Parts ........................................................................................................................ 11

General Safety Rules

–Save ese Instructions–

Signal words:

“DANGER” indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury. e signal word is

limited to the most extreme situations.

“WARNING” indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

“CAUTION” indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. It may also be used to

alert against unsafe practices.

Safety Symbol

is international safety symbol is used

to identify and call attention to specic

!

safety matters.

Safety Information

To Avoid Severe Personal Injury or Property

Damage, read carefully and understand the

following Safety Precautions.

1. WORK AREA

!

CAUTION

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

2. PERSONAL SAFETY

!

CAUTION

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used

for appropriate conditions. Wear cut resistant

gloves.

!

WARNING

Keep your hands and ngers away from all

moving parts, e.g. the blade, at all times. Do

not allow hair or loose clothing near the skiver,

particularly rotating components including the

user supplied drill motor.

ww w.flexco.com

—2—

Page 3

Baler Belt Skiver

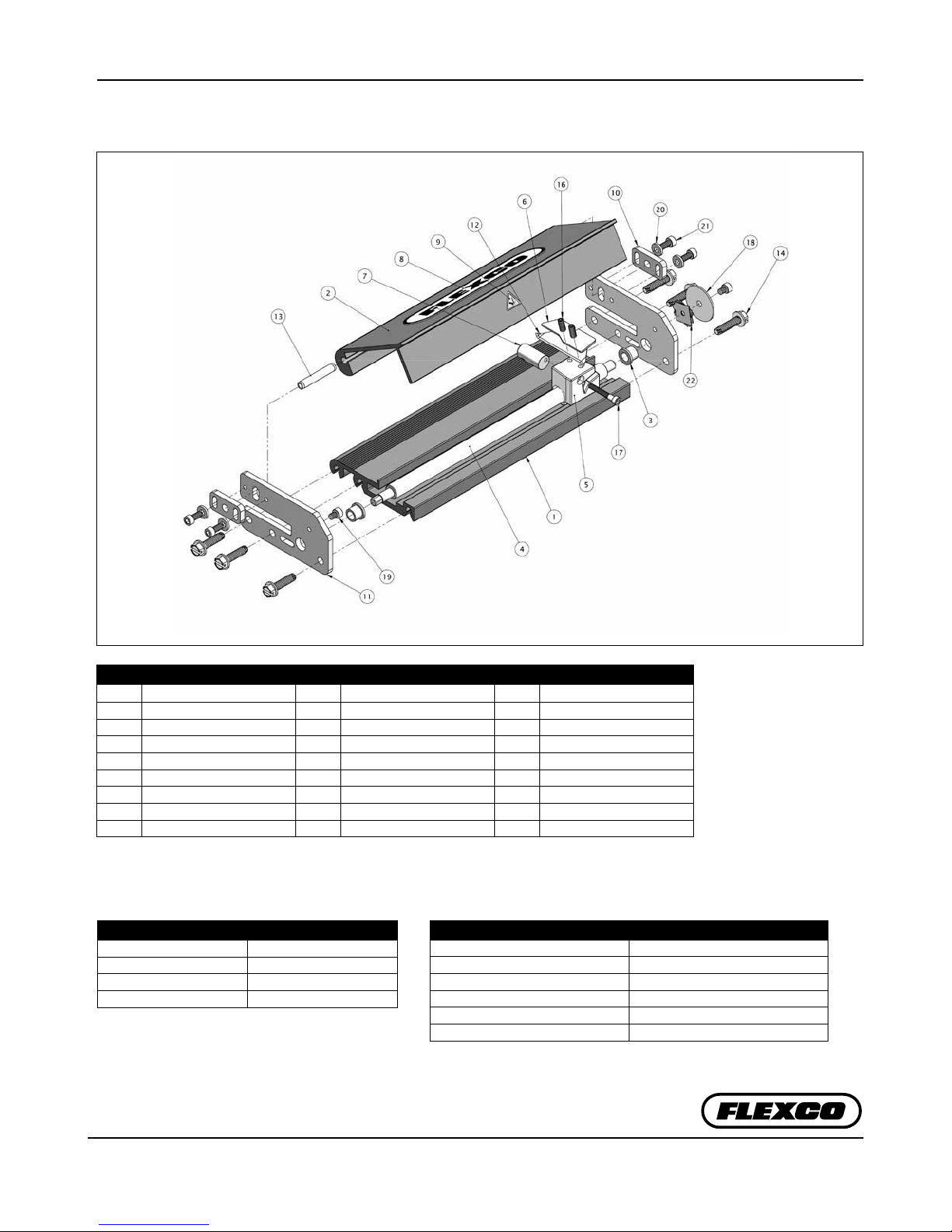

Main Components

Parts

Item Description Item Description Item Description

1 Base Plate 8 Flexco Label 15 Position Pins (not pictured) (2)

2 Clamping Lid 9 Cut Hazard Decal 16 Blade Set Screws (2)

3 Spindle Bushings (2) 10 Adjuster Plates (2) 17 Shaft Screw

4 Spindle 11 Side Plates (2) 18 Shim Storage Cover

5 Blade Holder 12 Blade 19 Shim Storage/Stop Screws (2)

6 Blade Backer Plate 13 Lid Hinge Pins (2) 20 Clamp Adjusting Washers (4)

7 Hold-Down Shaft 14 Base Screws (6) 21 Clamp Adjusting Screws (4)

22 Shims (5)

Tool Specifications

Tool Specifications

Maximum Belt Width 7.5 inches

Unskived Belt Thickness Range 0.200 to 0.400 inches

Skive Depth (Reach Back) 1.0 inches

Skived Belt Thickness Range 0.190 to 0.240 inches

Note: Other skived belt thicknesses may be achieved by providing

a shim beneath the belt.

Material

Side Plates, Blade Holder, Adjuster Plates Zinc-Plated Steel

Blade Backer Plate Stainless Steel

Lid and Base Hard Coat Anodized Aluminum

Spindle, Blades Steel

Spindle Bushings Bronze

Shims Polyester

—3—

Page 4

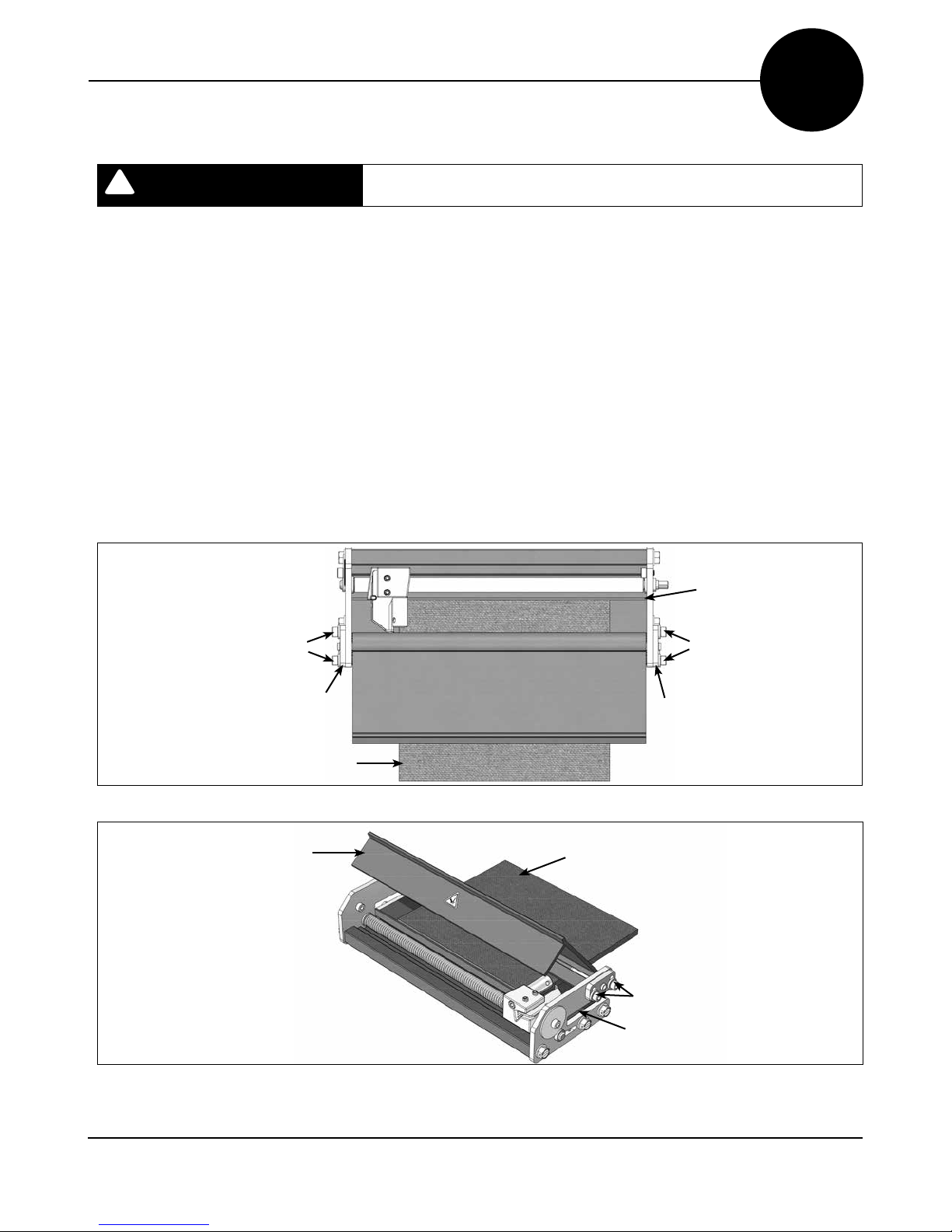

Adjust the Clamping Lid

A

!

WARNING

For best results: Store skiver in a clean dry area. Do not throw or drop tool.

1. Using the 5/32" hex key (included) loosen the four clamp adjusting screws at the adjuster plates (Fig. 1).

2. Insert belt to be skived, positioning it at against the belt stop.

3. Hold lid at 45° angle from the belt and apply downward pressure (Fig. 2).

4. Tighten four clamp adjusting screws and close lid.

5. Clamping pressure is correct when clamped belt cannot easily be pulled from skiver and belt end to be skived

does not curl away from base when clamped (check for correct belt position by looking through slot of

sideplate).

6. If tighter clamping force is required, hold lid at between a 45 and 90° angle while applying downward pressure

and tighten screws.

7. Remove belt from skiver.

Keep ngers and hands away from blade cutting edge.

Belt Stop

Fig. 1

Fig. 2

Clamp Adjusting Screws

Adjuster Plate

Baler Belt

Clamping Lid

Clamp Adjusting Screws

Adjuster Plate

Baler Belt

Clamp Adjusting Screws

Side Plate

Slot

ww w.flexco.com

—4—

Page 5

Position Blade Holder, Belt and Hold-Down Shaft

Avoid contact with blade cutting edge.

!

CAUTION

1. Taking care not to touch the cutting blade, slide the blade holder to the right end of the spindle. (Fig. 3).

2. Using the 9/64" hex key (included) loosen the sha screw and rotate the sha to its maximum belt clearance

position. Temporarily tighten the sha screw.

3. Insert squared belt end into skiver ensuring that it is butted against the belt stop.

4. Position the belt so that the edge is against the cutting blade (Fig. 4).

5. Loosen the sha screw, insert suitable tool into sha adjustment hole (Fig. 3) and rotate sha to the le

(away) from the blade. Hold it against the belt surface with light pressure.

6. Tighten the sha screw.

7. Push on the position pin (Fig. 3) to engage blade holder and spindle. e position pin is also an aid in determining the location of the blade holder.

8. Close lid.

Before operation ensure spindle threads are free of dirt/debris to allow proper function of

blade holder release system.

B

Fig. 3

Fig. 4

LEFT

Belt Stop

Spindle Hex

Drive

RIGHT

Hold Down Shaft

Shaft Adjustment

Hole

Cutting Blade

Position Pin

Blade Holder

Blade Set Screws

Shaft Set Screw

Belt Edge Against

Cutting Blade

Spindle Threads

—5—

Page 6

C

Test Skive

For multiple skives, use of power drill is recommended to avoid fatigue from use of ratchet.

Operate only with clamping lid in place and fully closed.

!

CAUTION

1. Keep hand on closed lid to ensure adequate clamping force and to hold the skiver in place while skiving.

2. Use a hand-held power drill with a 1/4" extra deep bit on the spindle hex drive to rotate the spindle and skive the

belt (Fig. 4). A ratchet can be used in place of the drill.

3. Position the belt so that the edge is against the cutting blade (Fig. 4)

4. Measure the skived belt thickness.

5. Using the 3/32" hex key loosen blade set screws on top of blade holder.

6. Using the 5/32" hex key remove the shim screw and shim storage cover located on the right side plate to access the

shims(Fig. 5).

7. Insert the required number of shims under the blade to prevent belt carcass damage. Each shim is 0.010" thick, so

addition of each shim will result in the skived belt thickness being 0.010" thicker.

8. Tighten blade set screws.

Use hand drill with a clutch mechanism set to the minimum required to skive the belt.

Do not exceed 600 rpm when skiving.

Do not permanently ax a motorized drive device to this equipment.

Fig. 5

Shim Storage Screw

Shim Storage Cover

Right Side Plate

ww w.flexco.com

—6—

Page 7

Skive the Belt

1. Disengage the blade holder from the spindle and slide it to the right end of the spindle. Ensure blade holder

moves freely on spindle. Clean spindle if binding or grinding occurs.

2. Insert squared belt end into skiver ensuring that it is butted against the belt stop.

3. Position the belt so that the edge is against the cutting blade.

4. Close lid.

5. e clamping action may move the belt away from the belt stop. Verify that belt is against the stop by looking

though the slot of the side plate.

6. Using the hand drill, skive the belt.

7. Li lid and remove belt.

8. Measure the skived height to verify proper belt thickness for your fastener.

NOTE: Between skives, keep the interior of the base and the slot that guides the block free from belt material

and dirt. Store skiver with hold down sha in position to aid in guarding blade edge.

D

E

—7—

Page 8

Changing the Blade

E

!

WARNING

1. Loosen the blade set screws.

2. Carefully remove the blade and backing plate from the blade holder leaving the shims in place.

3. Insert a new blade on top of the previously installed shims. Ensure that the slot in the blade is seated around

the pin on the blade holder. When properly installed, the opposite end of the blade farthest from the belt is

seated and is completely recessed in the blade holder.

4. Replace the backing plate on top of blade ensuring that the slot is seated around the blade holder pin.

5. Replace shims under blade.

6. Tighten blade set screws.

7. Carefully dispose of old blade.

Backing

Plate

Keep ngers and hands away from blade cutting edge.

Blade

ww w.flexco.com

Correct Notch

Blade Holder Pin

—8—

Page 9

F

Maintenance

• Store blade adjusting shims behind shim storage plate when not in use.

• Lubricate spindle threads frequently. Spindle threads are initially coated with a semi-dry graphite / molybdenum

grease. Application of a high pressure molybdenum grease every 20 skives is recommended. It is also

recommended to lubricate the base blade holder surfaces shown (see image). For eld applications, use a hard

wax or other high pressure dry lubricant on threads and base blade holder surfaces, to avoid entrapment of dirt.

• If the skiver is used outdoors in eld applications, remove dirt from belt end and from skiver threads, blade and

blade holder rubbing surfaces. Dirt / grit will reduce blade and skiver life.

Lubrication Locations

Spindle Threads

Lubrication Locations

Blade Holder

Guide Slot

Blade Holder

Bearing Surface

—9—

Page 10

Troubleshooting

Symptom Possible Cause Possible Solution

Blade holder does not engage

with spindle threads

Belt moves during skive Inadequate clamping force

Inconsistent skive thickness

Carcass exposed

Inadequate skived belt thickness Shim selection

Inadequate skive depth (reach back)

Flap not separated down belt length

Flap not completely removed at skive end Normal Remove manually

Blade holder binding during skive

Blade holder does not release at end of

skive

Belt not positioned against blade

and hold down shaft

Blade holder beyond spindle threads Use position pin to aid engagement

Hold down shaft too tight or too loose

Blade dull Replace with new blade

Blade backing plate damaged or missing Replace blade backing plate

Shim selection

Blade dull Replace with new blade

Blade positioned incorrectly

Belt moved during skive Increase clamp force.

Belt too thick Remove with utility knife

Blade tip damaged Replace with new blade

Dirt present on spindle threads or blade

holder bearing surfaces

Blade dull Replace with new blade

Blade positioned incorrectly

Dirt or debris interfering with movement of

blade holder

Worn spindle or blade holder threads

Reposition belt

Readjust clamping lid for increased

clampforce

Loosen shaft screw and reposition hold

down shaft. Retighten screw

Add shim(s) to increase skived belt

thickness

Add or remove shim(s) to achieve desired

thickness

Ensure that blade is properly positioned

on the blade holder pin

Clean dirt from skiver and re-lubricate as

necessary

Ensure that blade is properly positioned

on the blade holder pin

Clean dirt and debris from skiver

Check threads for wear. Replace spindle

or blade holder as required.

G

ww w.flexco.com

—10—

Page 11

Replacement Parts

H

5

1

4

3

4

2

3

4

4

Replacement Parts List

Item Description Ordering Number Item Code

1 5 replacement blades BLADE-KIT-5-BALER-SKIVER 04990

2 5 replacement shims SHIM-KIT-5-BALER-SKIVER 04991

3 Spindle and 2 bushings SPINDLE-BALER-SKIVER-7IN 04992

Blade holder, hold-down shaft & set

4

screws, blade set screws

5 Blade backer BLADE-BACKER-SKIVER 04998

6 Bench mounting kit BENCH-MOUNT-KIT-BALER-SKIVER 04994

BLADE-HOLDER-KIT-BALER-SKIVER 04993

6

—11—

Page 12

2525 Wisconsin Avenue • Downers Grove, IL 60515-4200 U.S.A.

Telephone: (630)-971-0150 • Fax: (630)-971-1180 • E-mail: info@exco.com

Visit www.flexco.com for other Flexco locations and products.

©2016 Flexible Steel Lacing Company. 04-20-16. For reorder: X4138

Loading...

Loading...