Safety and Operating Manual

Alligator® Staple Gold Class™ Plus

is manual contains important information about product function and safety. Please read and understand

this manual BEFORE operating the tool. Please keep this manual available for other users and owners

before they use the tool. is manual should be stored in a safe place. Also available online at exco.com.

www.flexco.com

www.flexco.com

WARNING

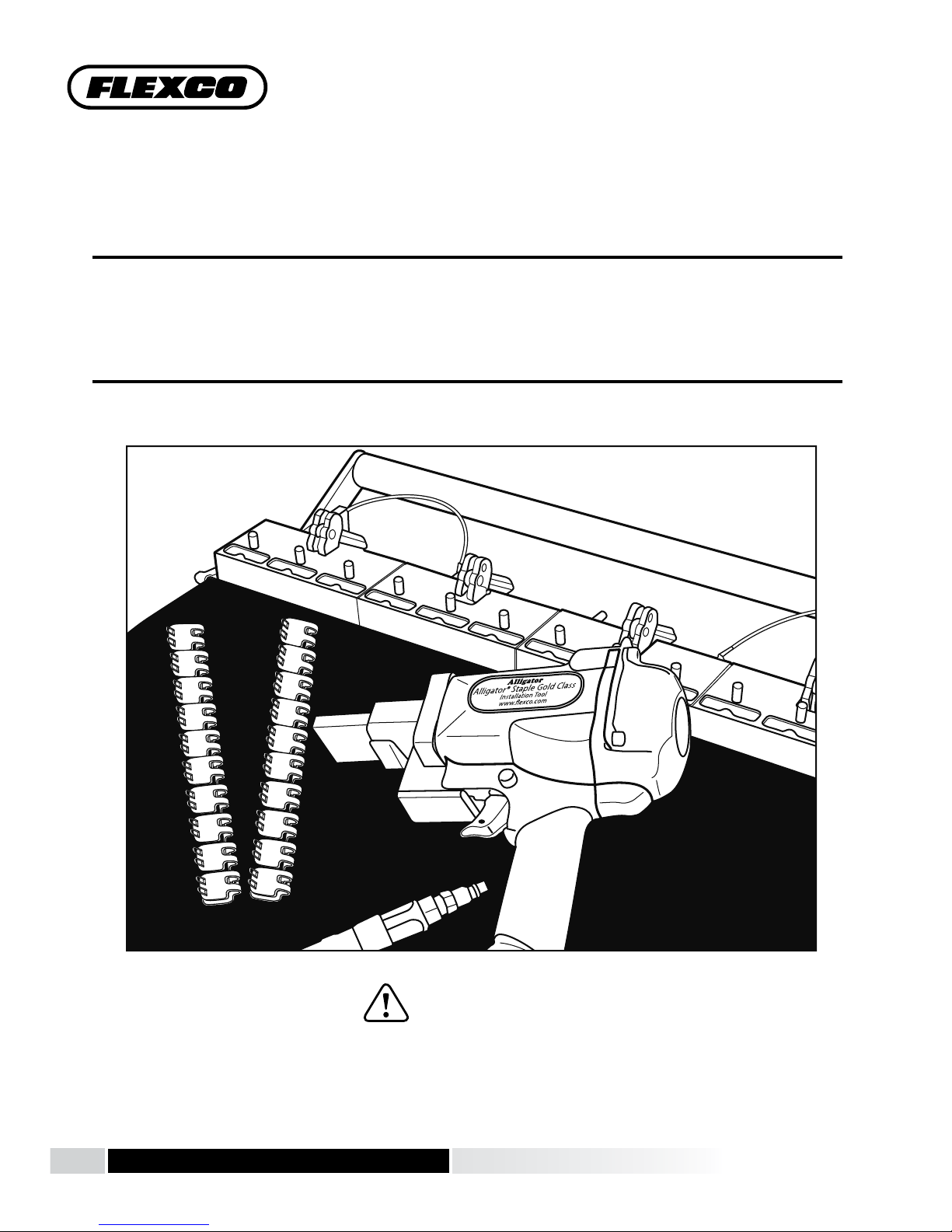

Alligator® Staple Gold Class™ Plus

Table of Contents

Introduction ............................................................................................. pg. 3

Main Components ...................................................................................pg. 3

General Safety Rules .......................................................................... pgs. 4-5

Maintenance and Instructions for Installation .............................. pgs. 6-7

Spare Parts ................................................................................................ pg. 8

www.flexco.com

—2—

Alligator® Staple Gold Class™ Plus

Introduction

e Alligator® Staple Gold Class™ Plus tool is designed to be used in conjunction with the

Alligator® Gold Class Power Driver. Together these tools will install the complete line of Flexco

Alligator® Ready Set™ Staple fasteners.

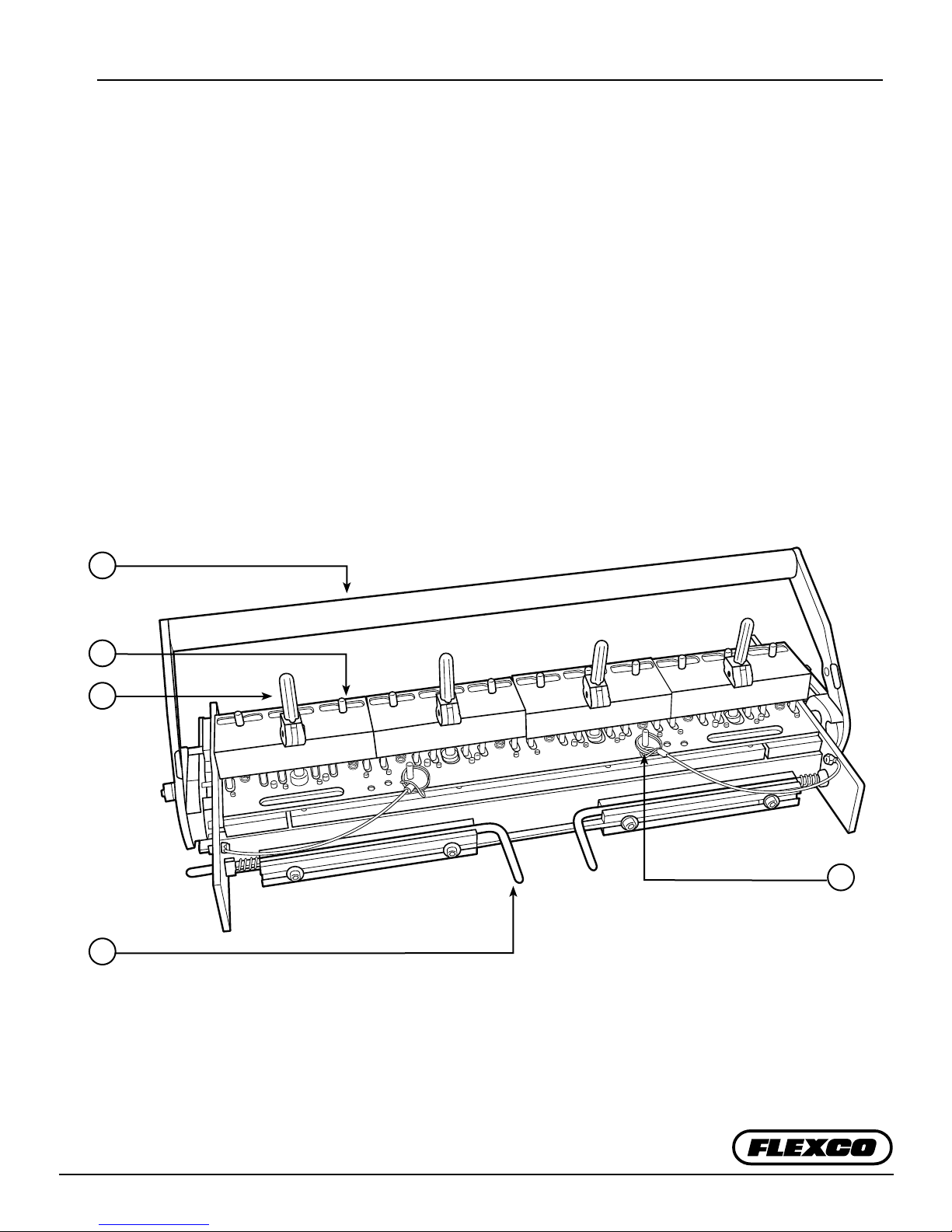

Main Components

1. Handle

2. Guide Block (4)

3. Cam Lever (4)

4. Release Handle (2)

5. Fastener Size Pin (2)

1

2

3

5

4

—3—

Alligator® Staple Gold Class™ Plus

General Safety Rules

–Save ese Instructions–

Signal words:

“DANGER” indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury. e signal word is

limited to the most extreme situations.

“WARNING” indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

“CAUTION” indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury. It may also be used

to alert against unsafe practices.

Safety Symbol

!

is international safety symbol is used to

identify and call attention to specic safety

matters.

Safety Information

To Avoid Severe Personal Injury or Property

Damage, read carefully and understand the

following Safety Precautions.

1. WORK AREA

!

CAUTION

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

2. PERSONAL SAFETY

!

WARNING

Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use tool while tired or under the

inuence of drugs, alcohol, or medication. A

moment of inattention while operating power

tools may result in serious personal injury.

!

WARNING

Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be

caught in moving parts.

!

WARNING

Do not overreach. Keep proper footing and

balance at all times. Proper footing and balance

enables better control of the tool.

!

CAUTION

Use safety equipment. Always wear eye

protection, dust mask, non-skid safety shoes,

and hard hat. Hearing protection must be used

for appropriate conditions.

!

WARNING

Never alter or remove safety devices.

!

WARNING

Keep hands and ngers away from all moving

parts at all times.

www.flexco.com

—4—

Alligator® Staple Gold Class™ Plus

General Safety Rules

3. TOOL USE AND CARE

!

WARNING

Always use tool on a level, rm surface.

!

CAUTION

Do not force tool.

!

WARNING

Store idle tools out of reach of children and

other untrained persons.

!

CAUTION

Maintain tools with care. Properly maintained

tools are less likely to bind and are easier to

control.

!

CAUTION

Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may aect the tool’s operation. If damaged,

have the tool serviced before using. Many

accidents are caused by poorly maintained tools.

4. SERVICE AND MAINTENANCE

!

CAUTION

When servicing a tool, use only Flexco

or equivalent replacement parts. Use of

unauthorized parts or failure to follow

maintenance instructions may create a risk

of injury.

!

CAUTION

Do not wipe plastic parts with solvent. Solvents

such as gasoline, thinner, benzene, carbon

tetrachloride, and alcohol may damage and

crack plastic parts. Clean tool with brush only.

!

WARNING

NEVER use a tool which is defective or

operating abnormally. Stop using it immediately

and arrange for repairs when operating

unusually, making strange noises, vibrating

excessively, or emitting odor.

!

WARNING

Do not remove regulator whip assembly from

Alligator® Staple Gold Class™ Driver.

!

CAUTION

is tool weighs 51 lbs. (23.1 kg)

—5—

!

WARNING

Do not exceed 120 PSI incoming air pressure.

!

WARNING

Do not depress tool trigger before tool is seated

completely down on top of guide block. Oil air

line on Alligator® Staple Gold Class™ Driver with

one to two drops prior to use.

Alligator® Staple Gold Class™ Plus

Operation

UNLOCK

PUSH

LOCK

5

1. Do not remove regulatory whip assembly.

Connect the Alligator® Staple Gold Class™

Driver to a clean, dry air line with a

maximum incoming pressure of 120 PSI.

e driver regulator will bring air source

down to 70 PSI. Oil air line with one to two

drops prior to use.

4. Make sure the tool is in initial position.

is position is when the handle is all the

way back and locked.

2. (a) Square belt ends.(b) Cut belt using a

Flexco belt cutting tool.

5. To change fastener size setting, pull both

pins from the tool base.

3. (a) Skive rough-top belt using Flexco

skiving products. Select correct fastener size

by using the chart on page 7.

R8 187

R8 125

R8 62

6. Move template so corresponding

fastener size matches the base hole. en

reinsert both pins.

7. Center fastener strip in the tool.

Fastener Strip should be tight against tool.

(a) Cam lever(s) should be up. Center belt

in installation tool, equal distance between

belt ends.

www.flexco.com

8. (a) Belt end should be tight against

the fastener belt stops. (b) Depress cam

lever(s).Fastener top should lean forward.

If not, tighten handle clockwise to increase

pressure and repeat. To prevent damage to

the tool, do not overtighten cam levers.

—6—

9. Starting with the center fastener plates,

insert the nose of the Alligator Staple Gold

Class Driver into the guide block. Note: the

driver must be rmly seated into the pin

to activate safety switch. DO NOT depress

tool trigger before tool is seated completely

down on top of guide block, as this will

damage the tool. Apply adequate number

of trigger pulls to produce sucient staple

leg fold. Refer to chart on page 7. Drive

remaining staples as follows.

Alligator® Staple Gold Class™ Plus

22

133

10. Follow the sequence shown above to

drive all remaining fasteners. Staples will be

partially clinched.

13. Return the handle into the initial position

and lock it down. Release Cam Levers and

remove belt from the tool.

AVERAGE TRIGGER PULLS

Average

Fastener

Size

RS62 1-2 1-2

RS125 2-3 2-3

RS187 3-4 3-4

Note: Number of trigger pulls will

vary depending on belt thickness and

durometer. Do not overdrive staples.

Trigger Pulls for:

Initial

Drive

Final

Set

11. Squeeze both release handles to allow the

tool to change position.

14. Using Belt Nippers, notch corners of

trailing edge. Notch at an angle as shown.

12. Move the handle from initial position

into nal position to move anvil into

nishing position. Repeat steps 9 & 10.

Refer to chart below for average trigger pulls.

15. Bring belt ends together and insert hinge

pin. If retaining washer is used, crimp with

pliers. Splice is complete.

Alligator® Ready Set™ Staple Fasteners Selection Chart

Operating

Fastener

Size

RS62 100 17 1/16-1/8 1.5-3.2 2 50 nylon .080, steel .080 nylon 2.0, steel 2.0

RS125 160 28 1/8-3/16 3.2-4.8 3 75 nylon .141, steel .141 nylon 3.6, steel 3.6

RS187 200 35 3/16-1/4 4.8-6.4 4 102 nylon .203, steel .187 nylon 5.2, steel 4.7

Tension

Range

P.I.W. kN/m in. mm in. mm in. (nylon-steel) mm (nylon-steel)

Belt

Thickness

Range

Min.

Pulley

Diameter

Approx.

Hinge Pin Diameter

Maintenance Tips

• Clean tool with brush only.

• DO NOT use air pressure.

• Add lubricant as required.

—7—

Alligator® Staple Gold Class™ Plus

Spare Parts

1. Cam Lever

2. Guide Block

3. Anvil Replacement Kit

1

2

3

Spare Parts List

Description

Cam Lever ST8-Cam 55592

Guide Block ST7-5 55554

Anvil Replacement Kit ST8-A-SN200 55589

Ordering

Number

Item Code

2525 Wisconsin Avenue • Downers Grove, IL 60515-4200 • USA

Tel: (630) 971-0150 • Fax: (630) 971-1180 • E-mail: info@flexco.com

Visit www.flexco.com for other Flexco locations and products.

©2014 Flexible Steel Lacing Company. 08-01-18. For reorder: X2415

—8—

Loading...

Loading...