Page 1

Alligator® Light-Duty Belt Splicing

Training Manual

LIGHT-DUTY BELT FASTENER SYSTEMS

Page 2

LIGHT-DUTY BELT FASTENER SYSTEMS

Table of Contents

Proper Belt End Preparation .............................................................. 3

Alligator® Ready Set™ Staple Belt Fasteners

Overview............................................................................................................. 4

Installation Tools ................................................................................................. 5

Installation Accessories ...................................................................................... 6

Identifying a Properly Installed Alligator Ready Set Splice ................................. 7

Troubleshooting ............................................................................................... 8-9

Tips ..................................................................................................................... 9

Alligator® Lacing

Overview........................................................................................................... 10

Identifying a Properly Installed Alligator Lacing Splice ......................................11

Troubleshooting .................................................................................................11

Alligator® Rivet Baler Fasteners

Overview........................................................................................................... 12

Identifying a Properly Installed Alligator Rivet Splice........................................ 13

Troubleshooting ................................................................................................ 13

Tips ................................................................................................................... 13

Alligator® Non-Metallic Splicing

Overview........................................................................................................... 14

Identifying a Properly Installed Alligator Plastic Rivet Splice ............................ 14

Troubleshooting ................................................................................................ 15

Tips ................................................................................................................... 15

2

Page 3

Proper Belt End Preparation

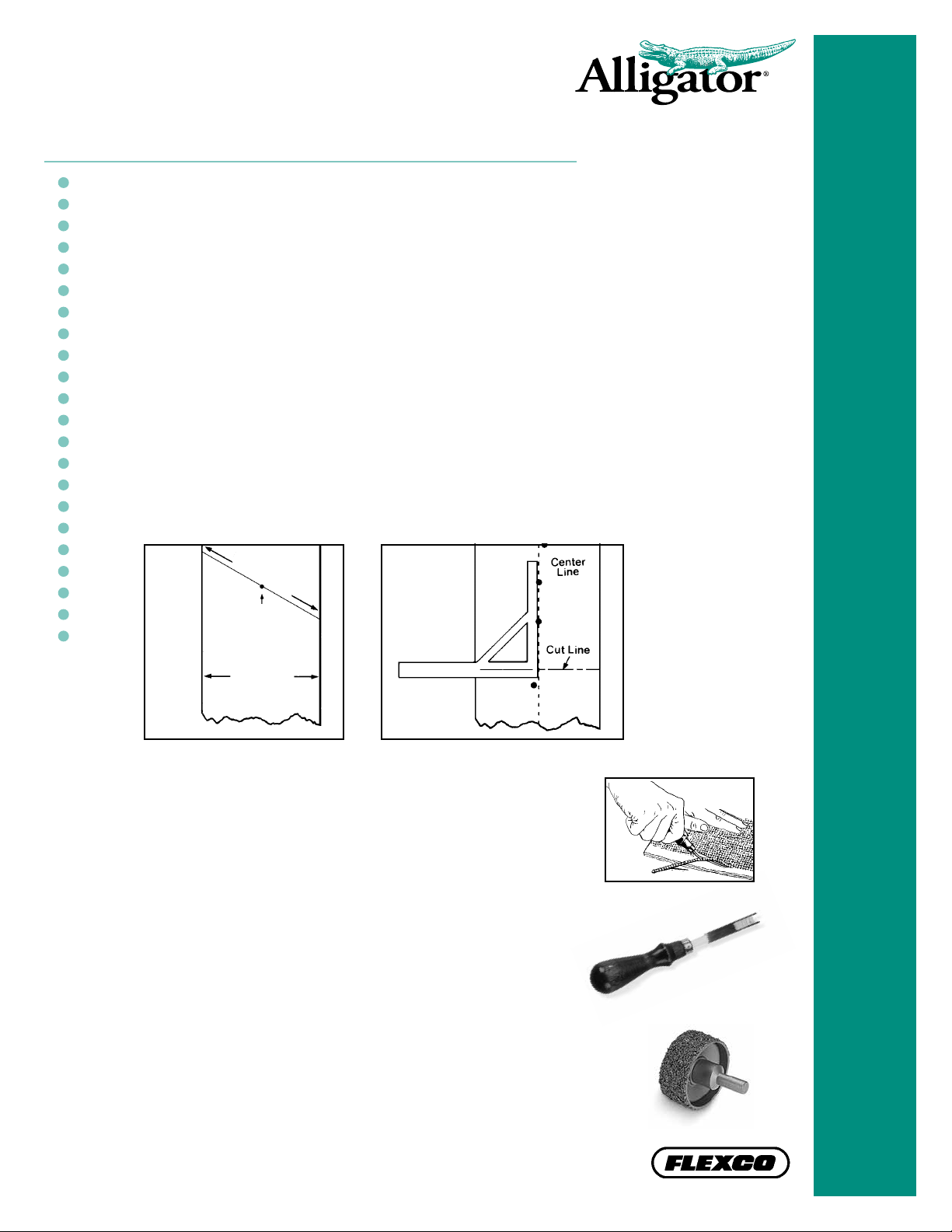

Importance of a Square Cut

To prevent mistracking and extend splice life, it is critical to obtain a square cut

off from the centerline of the belt. To achieve this, follow these simple steps:

1. Prior to any work on your conveyors, make certain that the power has been

turned off and the belt is “locked out”.

2. Using a diagonal measurement that is approximately 6" (150 mm) wider than

the belt width, mark the center point of the measurement every 3 to 5 feet down

the length of the belt, for a distance of 15 to 20 feet. Tip: Use a number that is

easily divisible by two for your diagonal measurement. Any even number that is

approximately 6" (150 mm) or wider than the belt width can be used (Fig. A).

3 Using either a steel rule or a chalk line, mark the average centerline across the

belt width (Fig. B).

4. Using a square, draw a line perpendicular to the average centerline across the

belt width (Fig. B).

5. Cut the belt using the Clipper

the cutter.

48" (1200 mm)

Diagonal Measure

®

845LD Belt Cutter, following the instructions for

LIGHT-DUTY BELT FASTENER SYSTEMS

Midpoint

24" (600 mm)

42" Belt

(1060 mm)

Skive Impression Cover Before Fastener Installation

It is important to skive off the impression cover of a belt in the area

where fasteners will be applied. This allows the proper size fastener

to be selected and for proper penetration/clinch. Two tools are

available to assist in this process:

Rough Top Belt Skiver

This simple-to-use, hand-held tool skives off the

impression cover when pushed along the belt cover.

RB-1 Belt Grinder

This air-drill attachable tool is made with carbide to cut the

impression cover off the belt. Most standard grinders burn

the impression cover off, which heats and damages the

belt carcass, resulting in shorter splice life.

3

Page 4

ALLIGATOR

Alligator® Staple Overview

Advantages of Alligator® Ready Set™ Staple Fastening System:

• High strength splice

• Inexpensive, portable installation tool

• Easy to mesh lacing and insert pin

®

STAPLE

Two Styles of Alligator Staple Fasteners:

Ready Set™: Available in Steel, 430 Stainless Steel and 316 Stainless Steel. Ready Set

Staple Fasteners feature a one-piece fastener strip with pre-inserted staples, reducing

installation time by eliminating the need to handle and load individual staples. The result

is a strong splice that resists impact damage, as well as a smooth, unrippled joint

to simplify hinge pin insertion.

• Abrasion resistant splice

• Easy installation procedures

Conventional Staple Fasteners: Available in abrasion resistant MegAlloy®, providing

several times the service life of steel. Staples are separate from the fastener plates.

Green guide blocks (ST4-5) must be installed on the installation tool and users can insert

staples using the C150 staple dispenser.

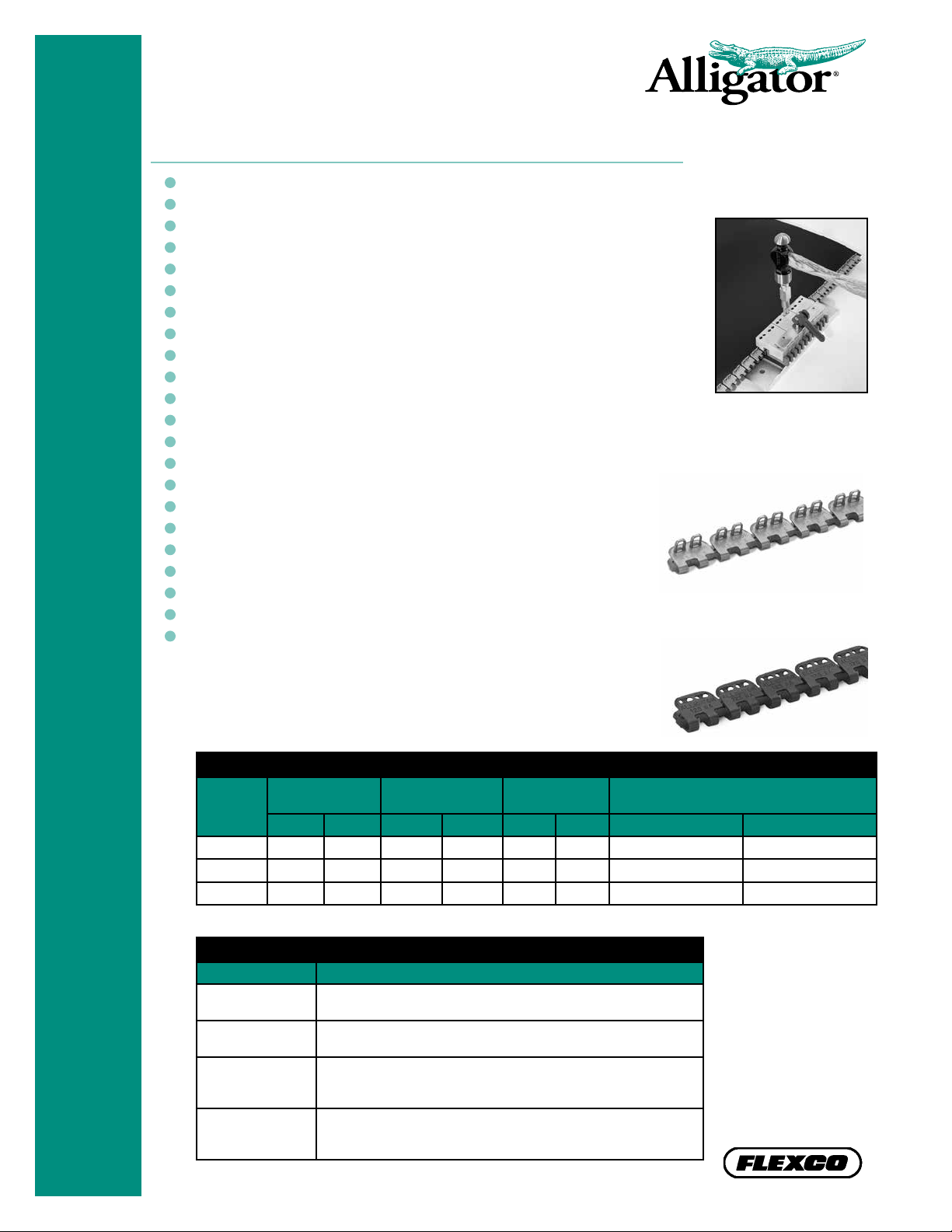

ALLIGATOR® READY SET™ STAPLE

Fastener

Size

RS62 100 17 1/16-1/8 1.5-3.2 2 50 nylon .080, steel .080 nylon 2.0, steel 2.0

RS125 160 28 1/8-3/16 3.2-4.8 3 75 nylon .141, steel .141 nylon 3.6, steel 3.6

RS187 200 35 3/16-1/4 4.8-6.4 4 100 nylon .203, steel .187 nylon 5.2, steel 4.7

Operating

Tension Range

P.I.W. kN/m in. mm in. mm in. (nylon-steel) mm (nylon-steel)

Belt Thickness

Range

Minimum

Pulley Diameter

Approximate Hinge Pin Diameter

METAL SELECTION CHART

Metal Type Application

Steel Standard fastener material suitable for most applications. Plated for

316 Stainless Steel Extra resistance to abrasion, magnetic attraction, and corrosion

430 Magnetic

Stainless Steel

MegAlloy

®

rust and corrosion resistance.

from acids and chemicals. Excellent for high sanitary requirements.

For use with magnetic separators. Provides resistance to wear and

abrasion. Plate, staples, and hinge pins are all constructed from

magnetic stainless steel.

Superior resistance to wear and abrasion, providing several times

the service life of steel. Not recommended where subject to impact

or corrosion. Not available in the Ready Set conguration.

4

Page 5

Alligator® Staple

Installation Tools

Alligator® RSC187 Installation Tool

The RSC187 Installation Tool securely holds

fasteners in proper alignment and guides

staples as they are driven. Installs two staples

simultaneously for fast and simple splicing.

Also provides a solid anvil surface for initial

staple clinching.

The RSC187 comes complete with a driver

and guide blocks for all three fastener sizes.

Also available in sizes to match a variety of belt

widths; wider tools are available for production

lacing and fabrication shop requirements.

ALLIGATOR

®

STAPLE

Alligator® Staple Tool Kit

Everything needed to install Alligator® Ready

Set™ Fastener Systems, in a lightweight, easyto-carry toolbox. Includes a RSC187 Installation

Tool, ST3-9 Staple Driver, SR-28 Staple Set

Plate, RTBS Rough Top Belt Skiver, BN-1 belt

nippers, and 1-lb. hammer.

Alligator® Staple

Gold Class™ Power Driver*

The air-operated Power Driver* allows

belt fabricators to install Alligator

Set™ Staple plates with quick and effortless

trigger pulls. This simple installation

process allows for splices to be installed

quickly and consistently, regardless of

operator skill and experience.

By eliminating the need to hammerinstall the fasteners, the Alligator

Staple Gold Class tool reduces the

risk of repetitive motion injuries.

It also reduces operator fatigue

associated with hammer-installing

numerous splices throughout the day.

®

Ready

*Patent pending

5

Page 6

ALLIGATOR

Alligator® Staple

Installation Accessories

Staple Setting Plate (ST-28)

Final set of the staples and proper compression of the

fastener plate are necessary for long splice life. The heattreated steel setting plate provides the required hardened

surface to achieve a properly installed splice. The ST-28

also features countersunk bolt holes for mounting onto a

work surface.

®

STAPLE

Alligator® Hinge Pin Cutter (APC-1)

Cuts bulk hinge pin cable quickly and easily. Provides a

clean cut with no frayed ends.

Hinge Pin Retaining Washers

Retaining washers prevent migration of nylon-covered cable

hinge pins. Check hinge pins frequently during the rst few

hours of operation to determine whether migration is a problem

in your application; use retaining washers if necessary.

Hinge Pin Bender (PB1)

For use with steel spring wire pin. Bends hinge pin end to

prevent pin migration.

Rough-Top Belt Skiver (RTBS)

Durable, hand-operated tool for quick and clean removal of

rough top from light- and medium-duty conveyor belting.

Belt Nippers (BN-1)

A simple, hand-held tool used to notch/chamfer belt edges

and to remove individual fastener plates from belt.

6

Page 7

Identifying a Properly

Installed Alligator® Ready Set™ Splice

1. Staples should be completely driven through and properly

set into pockets on bottom side of fastener plates.

Incorrect Correct

2. There should be a slight puckering of the belt at the front

edge of the top plate. On belts with very hard top covers,

or no top cover, this may not always be possible.

3. Fastener plates should be rmly compressed onto belt

and you should not be able to catch your ngernail under

front edge of fastener plate.

ALLIGATOR

®

STAPLE

4. Loops have not been crushed. Hinge pin insertion is easy.

5. Belt is ush against fastener belt stops across width of belt;

fasteners are parallel with belt edge.

6. Corners on trailing end of belt have been notched/chamfered.

7. Pin Retaining Washers, if used, are properly crimped.

Direction of

Travel

Chamfer

trailing edge

7

Page 8

ALLIGATOR

Troubleshooting

®

STAPLE

The Fastener Plates Are Loose:

Fasteners were not fully set.

• Fasteners should be rmly set, creating a slight puckering

of belt around front edge of top plate. This may not be

possible on hard belts or belts with little top cover.

• You should not be able to catch a ngernail under plates.

• Belt is either too thin or too thick for size of Alligator® Staple fastener selected.

Conrm proper size has been selected.

• Rough top belt was either not skived or the belt was skived too thin for the size

of Alligator Staple fastener being used.

‘Final Set’ procedure was performed on a surface other than a hardened steel plate.

• A hardened steel plate, such as the Flexco ST-28 setting plate, should be used.

Surfaces such as soft steel or wood will not allow staples to be fully set and/or

can cause staple leg to deect out of the pocket.

‘Final Set’ procedure was performed from bottom side of the

fastener, causing staples to back out or to buckle inside of

the belt.

• Final setting of staples should always be performed

from top side of fastener on a hardened steel plate.

The Staples Misre During Installation:

Either too heavy a hammer or the wrong type of hammer was used.

• A 1-lb. hammer is recommended with the standard Staple Driver.

• A 2-lb. hammer is recommended with the Quad Staple Driver™.

• A dead blow, soft steel or rubber hammer should not be used.

Initial hit with the hammer was too hard.

• Starting with a moderate blow, hit driver with three to ve consecutive

blows, each blow harder than the previous one.

®

Anvils in the Alligator

• Inspect for deep/worn pockets and chipped/worn

walls in angled areas of the anvils.

• Check alignment of guide block posts.

RSC187 Tool are worn or broken.

A mild steel plate was used for ‘Final Set’ procedure.

• Use only a hardened steel plate, such as the Flexco

ST-28, when performing the ‘Final Set’ procedure of

the Ready Set fasteners.

8

Page 9

Troubleshooting (cont.)

The Fasteners Are Not Flush and Parallel With Belt Edge:

Belt was not installed ush against the Ready Set fastener belt stops.

ALLIGATOR

Fasteners were installed from ‘left to right’ or ‘right to left’.

• First install the center two fasteners and then install

fasteners on outside edges. Finish by installing the

remaining fasteners.

Cam levers were not properly engaged or are worn.

• Tighten cam lever by turning it clockwise until a snug lock is achieved.

• Replace cam levers.

Spring-loaded belt nails located in top block of the Alligator RSC187 are stuck or

are missing. Replace top block as needed.

Tips

• Procedure for removing an Alligator

In the event of a misred staple there may be the need to remove a single

Staple fastener plate from the laced belt end. To do so:

1. Using the Flexco Belt Nippers, cut the back side of both loops on the

fastener to be removed.

2. Use the Belt Nippers pull the top plate off. This will take some effort

because the staples will need to be pulled straight.

3. Break the bottom plate free from the adjoining fasteners by exing the

belt back and forth at one of the two scores on the bottom plate.

4. With one score broken, use the Belt Nippers to ex the loose plate at

the remaining score to break the bottom plate free.

5. Remove a single Staple fastener plate from a new fastener strip by

exing an end fastener at the score until it breaks off.

6. Install the single fastener plate using the RSC187 installation tool and

a standard two-pronged driver.

®

Staple fastener from a laced belt end

Correct

®

STAPLE

• Alligator RSC187 Installation Tools that are 12" (300 mm)

or wider are designed with a Belt Release Bar. Use a

light hammer blow on the ends of the Belt Release Bar to

disengage the Ready Set fasteners from the tool.

• If you are not sure of the direction of belt travel,

notch/chamfer all four corners.

9

Page 10

ALLIGATOR

Alligator® Lacing Overview

Advantages of the Alligator® Lacing System:

• Low prole

• Hammer applied; Does not require special installation tools

• Can be installed in the Clipper

with appropriate combs, if so desired.

®

Roller Lacer® and Pro Lacers

®

LACING

Two Styles of Alligator Lacing:

Conveyor Belt Lacing: Features a “radius check” reference point

to aid in trimming strips for narrower belt widths.

Transmission Lacing: For at power transmission belts up to

12" (300 mm) wide. Lacing is scored, so it can break away to

custom-t belts narrower than the packaged fastener length.

ALLIGATOR® LACING SELECTION CHART

Lacing

Size

00 25 4.3 up thru 1/16 up thru 1.6 1 25 3/64 1.2

1 45 7.8 1/16–3/32 1.6–2.4 1-1/2 38 1/16 1.6

7 50 8.7 3/32–9/64 2.4–3.6 2 51 1/16 1.6

15 65 11.4 1/8–5/32 3.2–4.0 2-1/2 64 3/32 2.4

20 95 16.6 5/32–3/16 4.0–4.8 3 76 7/64 2.8

25 100 17.5 3/16–7/32 4.8–5.6 4 102 1/8 3.2

27 100 17.5 7/32–9/32 5.6–7.1 5 127 1/8 3.2

35 150 26 9/32–5/16 7.1–7.9 7 178 9/64 3.6

45 165 28 5/16–3/8 7.9–9.5 9 229 3/16 4.8

55 175 30 3/8–7/16 9.5–11.1 12 305 13/64 5.2

65 200 35 7/16–1/2 11.1–12.7 14 356 13/64 5.2

Radius Check

Score

For Belts with

Mechanical Fastener

Ratings Up To:

P.I.W. kN/m in. mm in. mm in. mm

Belt Thickness Range

Minimum Pulley

Diameter

Corrugated

Hinge Pin Diameter

METAL SELECTION CHART

Metal Type Application

Steel Suitable for most applications.

316 Stainless

Steel

Sizes 00, 1, and 7 are plated for

rust and corrosion resistance.

Provides extra resistance to

abrasion, magnetic attraction,

and corrosion from acids and

chemicals. Also excellent for

high sanitary requirements.

10

PIN SELECTION CHART

Metal Type Application

Corrugated Steel

or Stainless Steel

Nylon Covered

Steel or Stainless

Cable

Steel or Stainless

Steel Rocker Pins

Rigid pin with corrugation to prevent pin from

migrating out of the splice.

Available in coil lengths. Ideal for applications

with crowned pulleys or with troughing idlers.

Used with Transmission Lacing. Two-piece

design creates a rocking action to reduce

wear and friction on the fastener loops.

Furnished with Transmission Belt Lacing sizes

15 - 65. Corrugated pins are furnished with

Transmission Belt Lacing sizes 00, 1 and 7.

Page 11

Identifying a Properly

®

Installed Alligator

Lacing should be ush with belt surface.

1.

2. Points should slightly penetrate opposite side of belt.

3. Loops of lacing should not be crushed and will easily

accept the hinge pin.

Lacing Splice

3

Troubleshooting

Lacing Teeth Do Not Fully Penetrate Belt and Clinch Over

ALLIGATOR

1

2

®

LACING

Be sure to use a soft piece of wood under the fastener when rst applying lacing. This

allows the teeth to fully penetrate the belt.

Ensure the following installation procedures have been followed. NOTE: Steps 1-4 are

performed using the soft piece of wood as a backing plate.

1. From top side of belt, install end two teeth on both belt edges halfway in.

2. Flip belt over and install fastener teeth on bottom side of belt halfway in

across entire splice width.

3. Flip belt back over and nish installing remaining teeth on top side of belt.

4. Repeat on bottom side of belt.

5. Use a hardened steel plate and nal set the lacing.

Hinge Pin is Difcult to Insert

Be sure to use gauge pin and clips when applying Alligator Lacing. This will ensure a

uniform loop across the entire width.

Loops may have been crushed with direct hammer blows. Use caution when installing

fasteners and do not hit the loops.

Failure to follow proper lacing installation sequence as described above in Steps 1-5 can

cause points on non-bar side of lacing to wander and not penetrate correctly. This can

cause a distortion in the loop area, making pin insertion very difcult.

11

Page 12

ALLIGATOR

Alligator® Rivet

Baler Fastener Overview

Advantages of Alligator® Rivet Fastener System:

• High strength splice

• Superior abrasion resistance

• Portable tool allows for on-site installation

• Easy installation

• Fasteners are available in pre-cut common baler belt widths

®

RIVET

ALLIGATOR® RIVET SPECIFICATION CHART

Operating Tension

P.I.W. kN/m in. mm in. mm in. mm

300 52 1/8 – 7/32 3.2 – 5.6 3-1/2 88 .140 3.6

Application Tools and Accessories:

Hand Applicator Tool: Available in 7" and 14" widths.

Portable for on-site installation. Tool has built-in belt stops

to prevent belt from entering fastener loop area. Belt clamp

secures belt during installation process.

Multiple Rivet Installation Tool: Available in 7" and 14"

widths. This tool is comprised of a Hand Applicator Tool

plus the Multiple Rivet Installation block. Users can install

rivets with either a hammer and hand-punch, or with an

air hammer and pneumatic punch. Simplies installation

procedure and reduces fatigue.

Range

Belt Thickness Range Pulley Diameter Hinge Pin Diameter

Identifying a Properly

Installed Alligator® Rivet Splice

1. Fasteners should be fully clinched and you

should not be able to catch your ngernail

under the front edge of the fastener plates.

NOTE: Using the Alligator Rivet Application

Gauge can help to insure fasteners are

properly set. Finished splice should t into

the “Maximum Finished Rivet Height” slot

in the gauge.

2. There should be a slight puckering of the

belt at the front edge of the top plates.

12

Page 13

Identifying a Properly

Installed Alligator® Rivet Splice

(continued)

3. Rivets should be fully set and curled on bottom side of splice.

4. Loop area of fastener is oval in shape and easily accepts

the hinge pin.

ALLIGATOR

5. Fasteners are inset 1/4" (6.4 mm) from each belt edge.

6. Corners of trailing end of belt have been notched/chamfered.

Troubleshooting

Direction of Travel

Fasteners Are Loose

Fasteners were not fully set when applied.

• You may be able to reinsert splice into the ART tool and reset with a hammer.

If you attempt to reinsert splice into the ART tool, make sure you have left

Pilot Nails in tool so rivets properly curl.

Belt was not skived to remove rough top or diamond top impression cover.

Belt was skived too thin for Alligator Rivet fasteners.

• Use Alligator Rivet Application Gauge to double-check acceptable

skived belt thickness.

®

RIVET

Belt Edges Do Not Line Up

Align belt edges with appropriate scribe marks on ART tool

based on your belt width.

Tips

• You may nd it easier to join splices together by laying

one laced belt end over the other belt and pressing them

together versus trying to mesh them end to end.

• Hitting center of belt directly behind ART tool helps to

release Pilot Nails, making it easier to remove laced belt

from the tool.

13

Page 14

ALLIGATOR

Alligator® Non-Metallic

Splicing Overview

Advantages of Alligator® Non-Metallic Splices:

• Non-metallic

• Non-magnetic

• Non-sparking

• Quiet

• Hinged splice; quicker installation on conveyor system.

• Compatible with X ray machines, metal detectors, and

®

food applications

NON-METALLIC SPLICING

Two styles of Alligator Non-Metallic Fasteners:

Alligator® Spiral Lace: Low-prole, non-metallic splice that

is compatible with pulleys as small as 1/2” (13 mm) and for

applications up to 50 PIW (8.7 kN/m). Splice is fabricated

into belt through a ply separation, ply step, or nger splice

vulcanization processes. Available in black or white polyester,

or in PEEK for high heat applications.

Alligator® Plastic Rivet: One-piece, cover-mounted fastener

features an integrated design with rivets molded into the

fastener top plate. Fastener edge is beveled to ensure

smooth transition and easy cleaning. Fasteners are installed

with the Alligator Spin Set Tool™. This portable tool allows for

simple installation anywhere in your facility.

APF FASTENER

Identifying a Properly Installed

Alligator® Plastic Rivet Splice

1. Fastener plates are ush against belt and you cannot catch

a ngernail under the front edge of the fastener plate.

2. Rivets have been fully compressed and melted into a nice

dome shape.

3. Corners have been notched/chamfered on trailing end of belt.

MDT-1

14

Page 15

Troubleshooting

Fasteners Are Loose

Plastic rivets may not have been fully compressed during installation.

Alligator Plastic Rivet Lube was not used during

installation of the fasteners.

• Using lube allows plastic rivets to melt at the

proper speed and helps to control heat generated

during the installation/melting process.

The Rivets Loosen or Break When In Service

Rivets may have been overheated during installation process.

• Be sure to use Alligator Plastic Rivet Lube when compressing/melting plastic

rivets to avoid overheating plastic and making it brittle.

ALLIGATOR

®

NON-METALLIC SPLICING

Conveyor tension exceeds recommended tension for this fastener.

15

Page 16

2525 Wisconsin Avenue • Downers Grove, IL 60515-4200 • USA

Tel: (630) 971-0150 • Fax: (630) 971-1180 • E-mail: info@exco.com

Visit www.flexco.com for other Flexco locations and products.

©2009 Alligator®, Clipper® and Roller Lacer® are registered trademarks. 02-14. For Reorder: X1385

Loading...

Loading...