USER MANUAL

Streamer

STR-4000

®

System

05-12-17

Rev 6.0

Flexcell International Corporation 2730 Tucker Street, Suite 200 Burlington, NC 27215

800-728-3714 (919) 732-1591 FAX: (919) 732-5196 www.flexcellint.com

Culturing Cells in a Mechanically Active Environment™

COPYRIGHT © 2003 FLEXCELL

INTERNATIONAL CORPORATION

FLEXCELL

®

INTERNATIONAL CORPORATION

TABLE OF CONTENTS

1. Getting Started .............................................................................................................. 1

Introduction ........................................................................................................................................ 1

Streamer® Components ...................................................................................................................... 1

Streamer® Setup and Assembly ......................................................................................................... 1

Sterilizing the Streamer® ................................................................................................................... 2

Streamer® Placement in the Incubator .............................................................................................. 3

Using the Pump .................................................................................................................................. 3

Quickstart Instructions ....................................................................................................................... 3

2. StreamSoft™ V4.2 Software ......................................................................................... 5

Installation Instructions ...................................................................................................................... 5

Setting up Parameters in StreamSoft

Main Panel .......................................................................................................................................... 6

General Information Tab ............................................................................................................. 6

System Tab ................................................................................................................................... 7

Pre-Test Configuration ................................................................................................................ 8

Pull-down Menus ......................................................................................................................... 9

Operate Menu ................................................................................................................................... 10

Manual Mode ............................................................................................................................. 10

View Data .................................................................................................................................. 11

Configure Users ......................................................................................................................... 12

Configure Regimes: Setup Parameters ..................................................................................... 13

Configure Testing Apparatus .................................................................................................... 15

How to enter the proper values for your device ....................................................................... 16

Configure System Variables ..................................................................................................... 17

Reinitialize Hardware ................................................................................................................ 18

StreamSoft

™

V4.2 Notes .................................................................................................................. 18

™

V4.2 ..................................................................................... 5

3. Doing an Experiment ................................................................................................. 19

Overview .......................................................................................................................................... 19

Creating a Regime ............................................................................................................................ 19

Setting up an Experiment ................................................................................................................. 20

Filling the System to Eliminate Air Bubbles .................................................................................. 21

Post-Experimental Analysis ............................................................................................................. 21

Application Notes ........................................................................................................... 22

Culturing Cells on Culture Slips® .................................................................................................... 22

Appendix: Parallel Streamer® Shear Stress Numbers ................................................... 23

Warranty Information ..................................................................................................... 24

Contacting Flexcell ......................................................................................................... 25

i

FLEXCELL

®

INTERNATIONAL CORPORATION

1. GETTING STARTED

I

NTRODUCTION

Fluid-induced shear stress occurs in every tissue

in the body as a result of interstitial fluid

movement. Tissue deformation by

compression, tension or shear forces results in

the movement of interstitial fluid around cells.

Fluid movement acts as a transport vehicle for

ions, proteins, carbohydrates and other

molecules capable of movement within the

matrix. As the fluid moves past cell membranes,

a shear stress () is generated. If one assumes

that laminar flow occurs through a parallel-plate

flow chamber, fluid-induced shear stress values

can be determined with the following formula:

where is the shear stress in dyne/cm2, is the

viscosity of the fluid in dynes/cm2, Q is the flow

rate in ml/s, b is the width of the flow channel

in cm, and h is the height of the flow channel in

cm. Shear stress in the vascular system may

vary from less than 1 to more than 35 dyne/cm2.

Fluid shear stress in canaliculi of bone may vary

from 1 to 20 dyne/cm2, while in cartilage it may

be in the range of 1 to 5 dyne/cm2.

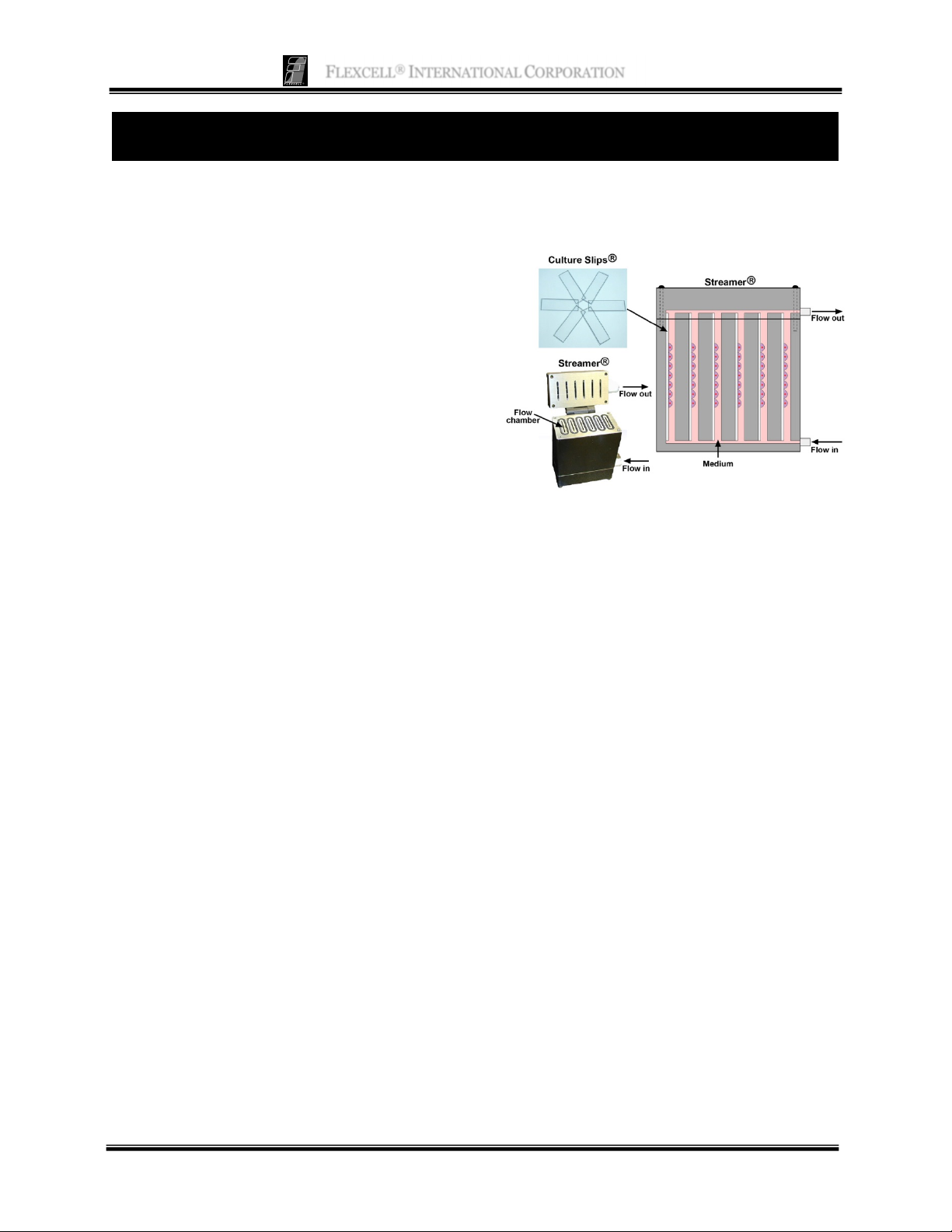

The Streamer

that is used to apply fluid-induced shear stress

to cells grown in a monolayer. The system

includes a six-chamber laminar flow device

designed to hold 75 x 25 x 1 mm Culture Slips®

(Fig. 1). Cells are cultured on these matrixcoated glass slides. StreamSoft software

controls a peristaltic pump, thereby regulating

the flow rate into the chamber and the

magnitude of shear stress applied to the cells.

Shear stress values from 0 to 35 dyne/cm

be achieved depending on the tubing size used.

This six place flow chamber can be used to

assess RNA and protein expression by cells in

response to fluid-induced shear stress, and

= 6Q/bh2

®

is a parallel-plate flow system

2

can

production of secreted molecules into the

perfusate.

Figure 1. Image and schematic of Streamer®

device with cells cultured in monolayer on Culture

Slips

®

.

®

S

TREAMER

C

OMPONENTS

Streamer® Device

Streamer® Tubing (includes quick

disconnect fittings)

Masterflex L/S Peristaltic Pump

RS232 to USB Connector Cable

Pulse Dampeners (2)

®

12 Culture Slips

StreamSoft

Software V4.2

500 ml Culture Medium Collection

Reservoir (includes quick disconnects and

filter)

Dell Inspiron Notebook Computer

(optional)

S

TREAMER® SETUP AND ASSEMBLY

The following instructions are for the full

®

Streamer

system. Once fully assembled in the

incubator, the system should resemble the one

pictured in Figure 2. Always check the tubing

for cracks or leaks prior to use.

1

FLEXCELL

®

INTERNATIONAL CORPORATION

A

B

Figure 2. A) Streamer® system setup on the shelf

in a standard incubator. B) Schematic of Streamer

system setup.

®

1. Connect the medium collection reservoir to

the first pulse dampener with the 3’ (0.9 m)

long piece of beige Phar-Med® tubing. On

the medium reservoir, the quick disconnect

connected to the long tubing extending to

the bottom of the bottle should be used. Do

not use the quick disconnect leading to

the bent tubing in the bottle for this

connection.

2. Move the clamp mounted onto the Phar-

®

tubing to the end closest to the pulse

Med

dampener. Place the middle of this tubing

segment into the pump head. Rotate the

lever to the left to open the pump head for

tubing placement, then rotate the lever to

the right to secure the tubing into the pump

head. When not doing an experiment, the

pump head lever should be rotated to the

left to eliminate pressure on the tubing.

3. Connect the first pulse dampener to the

second pulse dampener with the 3” (7.6 cm)

long segment of silicone tubing.

4. Connect the second pulse dampener to the

inlet port (bottom) of the Streamer

®

with

one of the 2’ (0.6 m) pieces of silicone

tubing.

5. Connect the outlet port (top) of the

Streamer® to the quick disconnect on the

medium bottle that is connected to the short,

bent tubing in the bottle, using the other 2’

(0.6 m ) long piece of silicone tubing.

6. Before the first use, run deionized water

through the entire system to make sure there

are no leaks.

Note: Any of the tubing lengths above can be shorted

or extended according to your setup needs.

S

TERILIZING THE STREAMER

®

All components of the flow system (except the

pump and computer) can be effectively and

safely sterilized in an autoclave at standard

autoclave temperature, pressure and time period

(120 °C, 15 psi, 15-20 minutes). When

autoclaving, leave all system components

connected together. Release the clamp on the

Phar-Med® tubing used between the medium

collection reservoir and the first pulse

dampener. Open the top of the Streamer®

slightly so that steam can reach the inside of the

device. Also, do not place any system

component on top of the pulse dampeners, as

the pulse dampeners may deform under load at

high temperatures. The pulse dampeners should

be placed on top of all system components in

the autoclave.

Note: After autoclaving, check the threaded quick

disconnect fittings on the Streamer® inlet and outlet

and on the pulse dampeners for tightness. If any of

the fittings have become loose, turn them until they

are ¼ turn past finger tight.

If you do not have access to an autoclave you

can use ethylene oxide gas treatment with

subsequent vacuum treatment. 70% ethyl

2

FLEXCELL

®

INTERNATIONAL CORPORATION

alcohol can also be pumped through the system

for cleaning, however, this will not completely

sterilize the system.

S

TREAMER®

I

NCUBATOR

P

LACEMENT IN THE

®

The Streamer

temperature-controlled, CO

system should be placed into a

incubator for

2

experiments. We recommend that the

Streamer® be kept in the incubator for at least

20 minutes before starting an experiment to

assure that the device is at a stable temperature

for cell culture. The pump is placed into the

incubator with the rest of the system. A

containment tray is placed underneath the

system to provide a means to transport the

system to the cell culture hood, and to catch any

fluid should a leak occur. The computer must

not be placed into the incubator.

U

SING THE PUMP

1. Plug the pump into a power outlet (110 V

for North America, 220 V for Europe and

Japan).

2. If using the flow system manually (i.e.

without computer control), ensure that the

correct tubing size is selected on the pump

and the clockwise flow direction. The

standard tubing included with the

®

Streamer

system is MasterFlex L/S 17.

Therefore, you will want to press the “size”

button on the bottom right of the pump face

until the green light is beside the number

“17”.

NOTE: Once you reach the tubing size “25”, the

green light will remain on the same level for two

depressions and the second one will cause the “HP”

LED (near the bottom of the indicator light column)

to light up. The “HP” button specifies the tubing

numbers on the right column of the size listings.

Therefore, when the green light is beside the number

“17” you will want the “HP” light to be off.

Once this is set, the display on the pump

will read the flow rate for that particular

tubing as the pump is running. Consult the

appendix or the data following this manual

to find which flow rate corresponds to the

desired level of shear stress. Use the arrow

keys on the top left of the pump face to

select the required flow rate. Press the blue

start/stop button to initiate and stop flow.

3. If using the system with computer

control, connect the male end of the RS232 cable into the back of the pump and the

USB end into a USB port of the computer.

Turn on the power and start the software.

When the software controller is functional,

“PO1” will appear on the pump display.

Use the software to create a regime with

your desired flowrate(s). See pages 5-18 for

further instructions on using the

StreamSoft™ software.

Q

UICKSTART INSTRUCTIONS

1. Set up the entire system in an incubator. See

page 1 for the system setup.

2. Sterilize the Streamer® and system

components. See page 2 for sterilization

instructions.

3. Connect the cable from the pump to the

serial port of the computer. Turn on the

computer and pump and open up the

™

StreamSoft

software program.

4. Select the Operate menu, then select Users.

Add your name as a user by clicking Add

User, then click the Return button.

5. Select the Operate menu again, then select

Configure Regimes. Type a new name in

the Regime Name field and click on Insert

Step to insert a step into the regime. Create

a regime by entering values in one or more

steps. Once complete, click on Save

Regime. Click Return to exit.

6. On the main screen, click on Configure; this

will open the Pre-Test Configuration

window. Select the appropriate User,

3

FLEXCELL

®

INTERNATIONAL CORPORATION

Regime and Hardware, then click Update.

The regimen is now ready to start.

7. Culture cells on six Culture Slips®. Be sure

that you culture on the side with the Teflon®

rim printed around the borders. Be careful

to plate cells only within this rim. We

recommend allowing cells at least 48 hours

to attach to slides before beginning your

flow experiment.

After cells have attached to slides:

8. Be sure that the Streamer® is closed (the top

lid should be flush with the body of the

device).

9. Place 500 ml of PBS into the medium

container and pump through the system to

flush out impurities. This can be done by

starting your regime or using the manual

mode under the Operate menu in the

software. If you are not using the software,

set the pump to the appropriate tubing size,

set the flowrate at 300 ml/min and press the

start button.

10. After pumping for several minutes, remove

the PBS from the medium container and

replace with 500 ml of sterile tissue culture

medium.

11. Pump the culture medium through the

system to flush out remaining PBS.

Remove the medium and replace with 500

ml of fresh sterile tissue culture medium.

12. Pump the tissue culture medium through

the entire system. Once the system is full,

tilt the pulse dampeners, one at a time, at an

angle of approximately 20 degrees, such

that the direction of the flow is going from

the vertex of the angle to the open end of the

angle. Leave the pulse dampener in this

position until the fluid comes through the

outlet fitting again, then lay the pulse

dampener down horizontally. This process

will allow the pulse dampener to fill to a

level slightly higher than the fittings,

thereby creating a bubble trap for any air

bubbles that may accidentally enter the

system. Do the same with the second pulse

dampener. Once this process is complete,

allow flow to continue and go to the next

step.

13. As the flow continues, check for any air

bubbles visibly trapped within the tubing.

Also check the walls of the medium

container to be sure that no air bubbles have

formed on the sides. If so, swirl the medium

around to release air bubbles from the side

walls.

14. Once the tubing and flow device are filled

with medium and all air bubbles are

eliminated, reverse the flow direction on the

pump to draw the medium level back to the

flow chamber and down past the head of the

chamber, then stop the pump. The fluid

level will have to be estimated once the

fluid can no longer be seen in the tubing

coming from the head of the Streamer®.

15. Tighten the small clamp on the Phar-Med®

tubing just to the right of the pump head so

that the flow path in the tubing is

completely closed off.

16. Turn the lever arm on the MasterFlex

pump all the way to the left to release the

tubing and remove the tubing from the

pump head. Carefully move the tray

containing the Streamer® device, tubing,

pulse dampeners, and fluid collection

reservoir to the tissue culture hood.

®

17. Remove the Streamer

screws and open the

hinged top.

18. Transfer your cells from the incubator to the

tissue culture hood.

19. Using forceps and/or your fingers with

sterile gloves, pick up each Culture Slip®

and place it into each one of the slots in the

flow device. Be sure that the side of the

slide with cells attached is facing the flow

area adjacent to the slot, not the closed

wall of the slot. Gently slide each Culture

Slip® downward until it reaches the bottom

of its chamber. Be careful that the Culture

®

Slip

glass is not chipped against the

stainless steel surface during this process.

4

FLEXCELL

®

INTERNATIONAL CORPORATION

All six slots must be filled to ensure proper

flow rate readings. If you do not wish to

®

use all six Culture Slips

blank Culture Slips

with cells, use

®

for the remaining

slots.

20. Close the top of the device, turn the bolts by

hand, then tighten them with the hex

wrench provided with the system.

21. Move the tray with the system components

back to the incubator. Put the Phar-Med®

tubing back into the MasterFlex® pump

head and clamp the head down.

22. Unscrew the small clamp on the Phar-Med®

tubing to open the flow path to full capacity.

23. Click the Start button in the software (or set

the pump to the desired flowrate and

depress the start button). Your regimen will

start and a green light will go on at the top

right corner of the screen.

24. The expected shear stress and actual value

will be displayed on the graph in real time.

Periodically monitor the flow system for

leaks during the protocol.

25. When the flow regimen is over and the

pump has stopped, remove the Streamer®

system from the incubator as before. Open

the top and remove the slides for

processing.

26. Clean the Streamer® and system with

deionized water. Never leave culture media

in the Streamer® device after an

experiment, as this will corrode the

stainless steel finish over time.

See the instructional video, Streamer®

Assembly, on Flexcell®’s website

(http://www.flexcellint.com/videosinstruct.htm) for a demonstration of how to

assemble the Flexcell® Streamer® and

associated tubing to run with a MasterFlex

Peristaltic Pump.

2. STREAMSOFT™ V4.2 SOFTWARE

I

NSTALLATION INSTRUCTIONS

1. Insert the StreamSoft™ V4.2 DVD into the

DVD-ROM drive on the computer.

2. Double click My Computer (Windows

XP) or Computer (Windows

Vista/Windows 7).

3. Double click the DVD-ROM drive.

4. Double click the Setup installer.

5. The installer will now open and run.

6. On the Product Notification screen, click

Next.

7. On the Destination Directory screen, click

Next.

8. On the License Agreement screen, click I

accept the License Agreement and then

click Next.

9. On the next License Agreement screen,

click I accept the above 2 License

Agreement(s) and then click Next.

10. On the Start Installation screen, click Next.

11. Installation of the required National

Instruments and StreamSoft™ software

will now begin.

12. Once the installation is complete click

Finish and restart the computer.

™

13. Installation of StreamSoft

V4.2 is now

complete.

NOTE: When the Select Pump to Use window

appears when opening the StreamSoft™ V4.2

software, select the pump named MasterFlex

Peristaltic Pump to ensure correct function of the

equipment.

S

ETTING UP PARAMETERS IN

S

TREAMSOFT™

V4.2

Specific parameters will need to be set up in

™

StreamSoft

V4.2 to customize it for your

particular device and system. Setting up

these parameters is extremely important to

5

FLEXCELL

®

INTERNATIONAL CORPORATION

ensure accurate flow results for your

system. For instructions on setting up these

parameters, see Configure Testing Apparatus

MAIN PANEL

G

ENERAL INFORMATION TAB

and Configure System Variables, pages 15-

17. Complete this setup before proceeding

with any experiments.

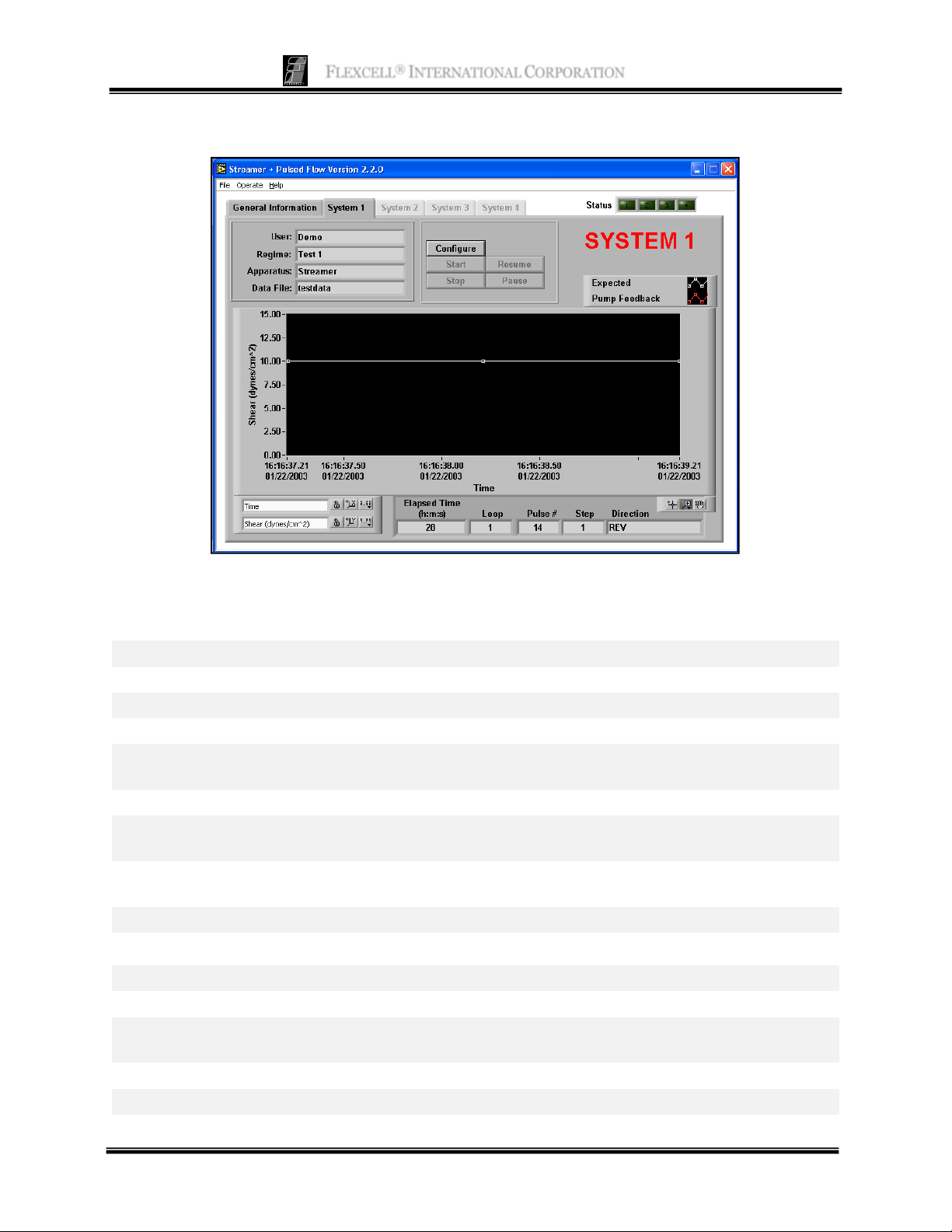

Function: The default main panel allows the user to verify that the system is running and to stop the

tests at any time.

Buttons and Fields

Status

System 1,2,3,4

General Information

Number is bright green when an experiment is running

These tabs will automatically become highlighted according to the

number of pumps connected to the computer (1 - 4).

Current date and time

6

FLEXCELL

®

INTERNATIONAL CORPORATION

S

YSTEM TAB

Function: This panel is used to run the experiments. Each System tab is identical.

Buttons and Fields

User

Regime

Apparatus

Data File

Configure

Start

Stop

Pause

Resume

Graph

Elapsed Time (h:m:s)

Loop

Pulse #

Step

Direction

Current user in currently configured regime

Regime currently configured

Device being used with the software (Streamer® or FlexFlow™)

Name of file to which data is being saved (if appropriate)

Configure (load) the experiment. The Pre-Test Configuration window will

appear.

Start the experiment.

Terminate the experiment. This button is only active when an experiment is

running.

Suspend the experiment. The pump will stop, but the test regimen is kept in

memory.

Resume a paused experiment.

This graph shows the expected and actual shear stresses during the experiment.

Elapsed time in the current experiment

Current loop in the current step or series of steps

Total number of pulsations (square wave) or oscillations (FWD/REV)

produced by the valves in this regime

Current (active) step in regime

Current flow direction (FWD/REV)

7

FLEXCELL

®

INTERNATIONAL CORPORATION

PRE-T

EST CONFIGURATION

Function: This panel allows the user to configure the parameters of an experiment. It appears when the

user presses the Configure button on the System panel. The information selected here is transferred to

the User, Regime and Apparatus fields on the System panel.

Buttons and Fields

Users

Regimes

List of all users. Select users with the mouse.

List of regimes created by the previously selected user. Select from list by using

the mouse to highlight the desired regime.

List of configured flow devices. Select the device that will be used for the

Apparatus

experiment. Important: Be sure that all parameters have been properly set for

your device in the Configure Testing Apparatus window (see page 15).

Print

Update

Cancel

Help

Print the current panel to a printer or HTML file.

Use the current selections to run the experiment.

Cancel any new selections and use the previously configured setup for the

experiment.

Online help (not currently available)

8

FLEXCELL

®

INTERNATIONAL CORPORATION

P

ULL-DOWN MENUS

This section summarizes the function of each item in the three pull-down menus.

File

Print

Allows user to print a copy of the current panel. This system is configured such that printing

sends a copy of the panel being viewed to a printer or to an html file. If there is no printer

connected to the computer, an error message from the Windows default printer queue will

appear when the user tries to print.

File Operate Help

-Print -Manual Mode -Help

-Exit -View Data -About LabVIEW

-Users

-Configure Regime

-Configure Apparatus

-Configure System

-Reinitialize Hardware

Exit

Allows user to close the program. If the pump is operating at the time of exit, it will continue

running. The keyboard short-cut is Ctrl-Q.

Operate

Manual Mode

View Data

Users

Configure Regime

Configure Apparatus

Configure System

Reinitialize Hardware

Help

Help

Manually control the pump without setting up an experimental regimen.

View shear stress data from a previous experiment.

Add and remove user names.

Create an experimental protocol.

Configure parameters of the flow device so that the software can assign the

flow rates corresponding to the desired shear stress. These parameters

must be set correctly to ensure that the proper shear stress values are

shown. See the manual of your device for the appropriate values.

Configure the system parameters such as data saving, the Com port used and

®

the presence or absence of valves in the system (Osci-Flow

).

This will reinitialize the software to connect the pump and Osci-Flow® (if

present) in the event that a cable is disconnected or the pump is turned off.

Online help (not currently available)

About LabVIEW

Software version information

9

FLEXCELL

®

INTERNATIONAL CORPORATION

OPERATE MENU

M

ANUAL MODE

Function: This panel allows the user to manually control the pump. The actual flow rate and speed of

the pump (RPM) are shown on the graph when the pump is working. Manual mode may be used to

troubleshoot the pump operation. The shear stress value is not shown on this panel since it will depend

on the tubing size and flow chamber used.

Instructions

1. Enter the flow set point (pump speed) either by entering a number in the box or using the mouse to

drag the dial to the desired level.

2. Adjust the seconds between readings to a number between 0 and 5. This is the time between each

update of the pump data on the graph.

3. Click on Press to Start.

4. Click on Press to Stop when ready to stop.

5. Click on Return when done.

10

FLEXCELL

®

INTERNATIONAL CORPORATION

V

IEW DATA

Function: This panel allows the user to view previously collected experimental data in a table format.

Buttons and Fields

File

Table

Export File

Print

Open

Return

Help

The complete file path to the data file being viewed

Contents of the experimental data log file

Export data to a spreadsheet-compatible format

Print a copy of this panel to the Windows default printer or write a copy

to an HTML file.

Open a data file.

Close this panel and return to the Main panel.

Online help (not currently available)

11

FLEXCELL

®

INTERNATIONAL CORPORATION

C

ONFIGURE USERS

Function: This panel allows the user to create or delete users.

Buttons and Fields

Existing Users

User Name

Add User

Delete User

Help

Return

Lists all current users of the system

Field used to enter new users

Add new users to the system.

Delete users from the system.

Online help (not currently available)

Exit this panel and return to the Main panel.

Instructions

To add a user:

1) Type the name into the User Name field.

2) Press the Add User button.

To delete a user:

1) Using the mouse, select the user from the list of Existing Users.

2) Press the Delete User button. If the user has any stored regimes and data sets, the operator will

be prompted to confirm the deletion.

12

FLEXCELL

®

INTERNATIONAL CORPORATION

C

ONFIGURE REGIMES: SETUP PARAMETERS

Function: This panel allows the user to configure (create) a regime.

Buttons and Fields

Existing Users

Regimes for

Selected Users

Regime Name

Time Between

Pump Updates

List of all users; select a user from the list using the mouse.

List of regimens created by the current user. Selecting from this list will

load that regimen and allow the user to view and/or modify that regime.

Name of the current regimen; if creating a new regimen, enter a name in

this field.

Time elapsed between computer updates of the pump parameters; default

is 1 second.

Time interval between each computer sampling of the experimental flow

Time Between

Data Log to File

data. Default value is 10 seconds. For an extremely long test, increase

this interval to reduce the size of the data file.

NOTE: this function only applies when the data saving option is selected in the

Configure System Variables window (see page 17).

This is an estimate of how large the data file would be given the total test

Estimated file

length and the time between data.

size

NOTE: this function only applies when the data saving option is selected in the

Configure System Variables window (see page 17).

Step

Step Name

Current step number selected or being modified

Name of the currently selected step

13

FLEXCELL

®

INTERNATIONAL CORPORATION

Flow Type

ON/HI (s)

OFF/LO (s)

Shear

(dyne/cm^2)

Duration

(h:m:s.ss)

GoTo

Loop

Summary Table

Specifies the direction or type of flow for this step (forward, reverse,

pulsed (square wave), oscillation)

When using pulsed (square wave) or oscillatory flow, specifies how long

the valves remain in a position to allow the fluid flow to continue

unhindered or flow in the forward direction, respectively. For normal

forward or reverse (unidirectional) flow, this value remains at 1.00.

When using pulsed (square wave) or oscillatory flow, specifies how long

the valves remain in a position to stop the fluid flow to the device or

cause it to flow in the reverse direction, respectively. For normal forward

or reverse (unidirectional) flow, this value remains at 1.00.

The value of shear stress to be applied to the cells in this step.

Time to spend in this step (hours:minutes:seconds.milliseconds)

To create a loop, indicate which step to go back to. The GoTo step must

always be a step number before the current step.

Indicates how many times to loop between the GoTo step and the current

step.

This table is a listing of the current steps in the regimen. Selecting a row

from this table will allow the parameters of the step to be viewed and

modified.

Insert Step

Delete Step

New Regime

Delete Regime

Save Regime

Return

Check Shear

Print

Help

Insert a step into the regimen before or after the current step.

Delete the currently selected step.

Clear all parameters and start a new regime. Type in a new name under

Regime Name and select Insert Step.

Delete the currently selected regime.

Save a new or modified regime.

Exit this panel and return to the Main Panel

Check the shear stresses entered in your regime to see if they are

achievable with the apparatus, pump and tubing size that you are using.

Print the current panel to a printer or an HTML file.

Online help (not currently available)

Instructions on how to set all the parameters for an experiment are included in the Doing an Experiment

section of this manual.

14

FLEXCELL

®

INTERNATIONAL CORPORATION

C

ONFIGURE TESTING APPARATUS

Function: This panel allows the user to create, modify or delete a testing apparatus (Streamer® or

FlexFlow flow chamber).

As each Streamer® and FlexFlow device is manufactured to strict dimensional specifications,

the values for the height and width of the chambers must be entered into the software for each

individual device.

These values are measured for your specific device and must be correct for accurate shear stress

measurement. The values can be found in the appendix of the manual for your device.

Buttons and Fields

Testing Apparatus

Name

Flow Factor

List of all flow devices available

When a testing apparatus is selected, this field (and the parameters)

will be updated.

A factor that accounts for any parallel paths in the flow stream. This

number is 6 for the Streamer® and 1 for the FlexFlow.

Hose size determines how fast the pump must move to achieve the

Hose Size

desired flow rate and shear stress level. The sizes listed are standard

for Masterflex

tubing. Select the hose size that you are using with

your system.

Width of the flow area (cm) in a single chamber of the Streamer® or

b

FlexFlow device. This number is found in the back of the manual

for your device listed as Flow Area Width (cm).

15

FLEXCELL

®

INTERNATIONAL CORPORATION

Height of the flow area (cm) in a single chamber of the Streamer® or

h

FlexFlow

device. This number is found in the back of the manual

for your device listed as Flow Area Height (cm).

Viscosity

Print

Save Apparatus

Delete Apparatus

Help

Return

Viscosity of the perfusate/media used in the experiment. The

standard value is 0.01.

Print the current panel to a printer or an HTML file.

Save changes to the apparatus listed in Name.

Deletes apparatus listed in Name.

Online help (not yet available)

Exit this panel and return to the Main panel. Any changes that have

not been saved will be discarded.

H

OW TO ENTER THE PROPER VALUES FOR YOUR DEVICE

Please check the Appendix of the manual for your device for the proper b and h values.

1. Select the Testing Apparatus being used for the experiment or enter a name for a new apparatus in

the Name box.

2. Enter the correct flow factor for your device. This specifies the number of parallel flow chambers

in your device.

3. Select the correct Hose Size for the type of Masterflex tubing being used in the experiment.

4. Enter the proper b and h values for your device.

5. Enter the Viscosity of the perfusate fluid used in the experiment. The default value is 0.01

dynes*s/cm2.

6. Click Save Apparatus button, then click Return to exit this screen.

16

FLEXCELL

®

INTERNATIONAL CORPORATION

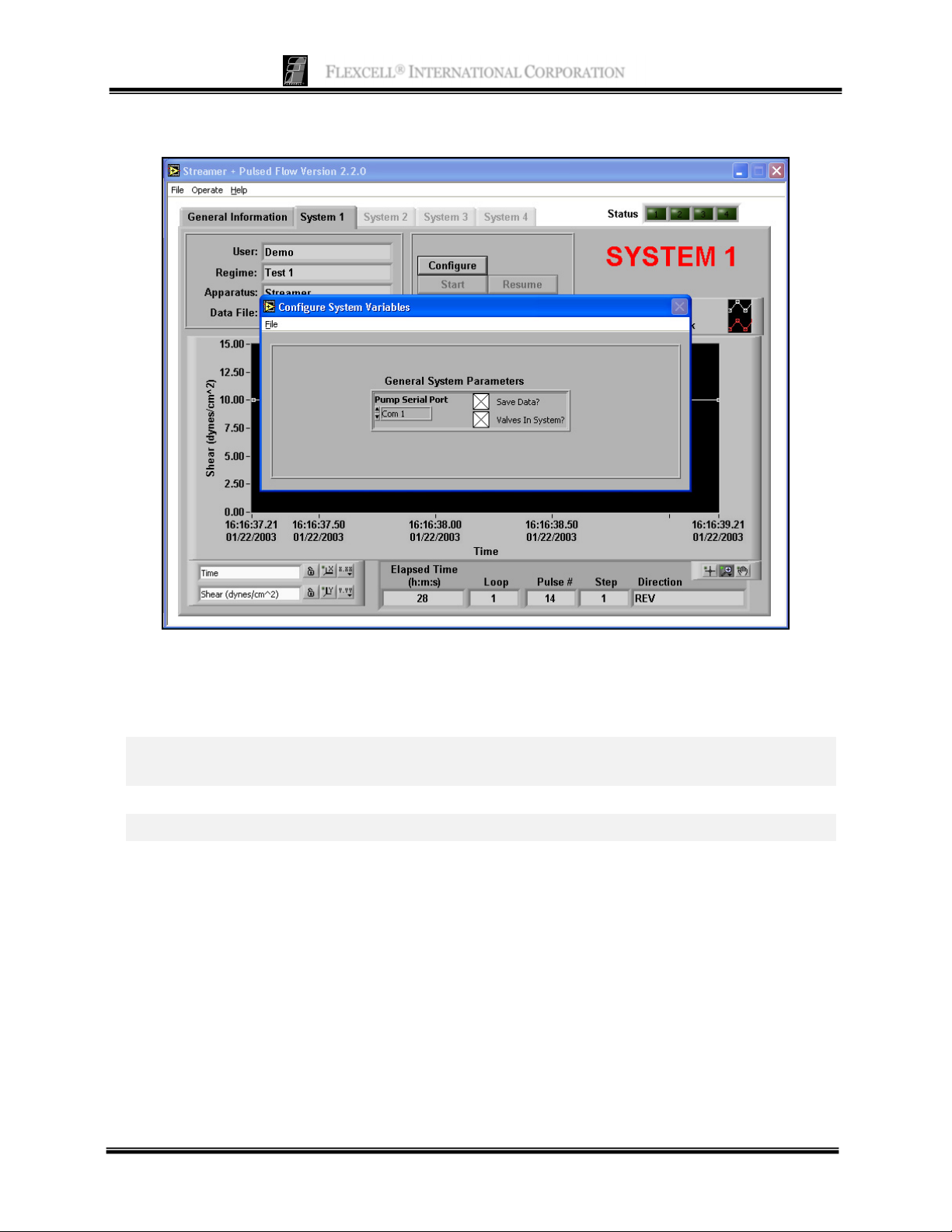

C

ONFIGURE SYSTEM VARIABLES

Function: This panel is used to select three system parameters – Communications port, data saving,

and the presence of valves in the flow system.

Buttons and Fields

Pump Serial Port

Save Data?

Valves in System?

Com 1 is the default port. This should be changed only if there is a

conflict with this port on your computer.

Select this option if you want to save regime data files.

Select this option if you are using the Osci-Flow® Flow Controller.

17

FLEXCELL

®

INTERNATIONAL CORPORATION

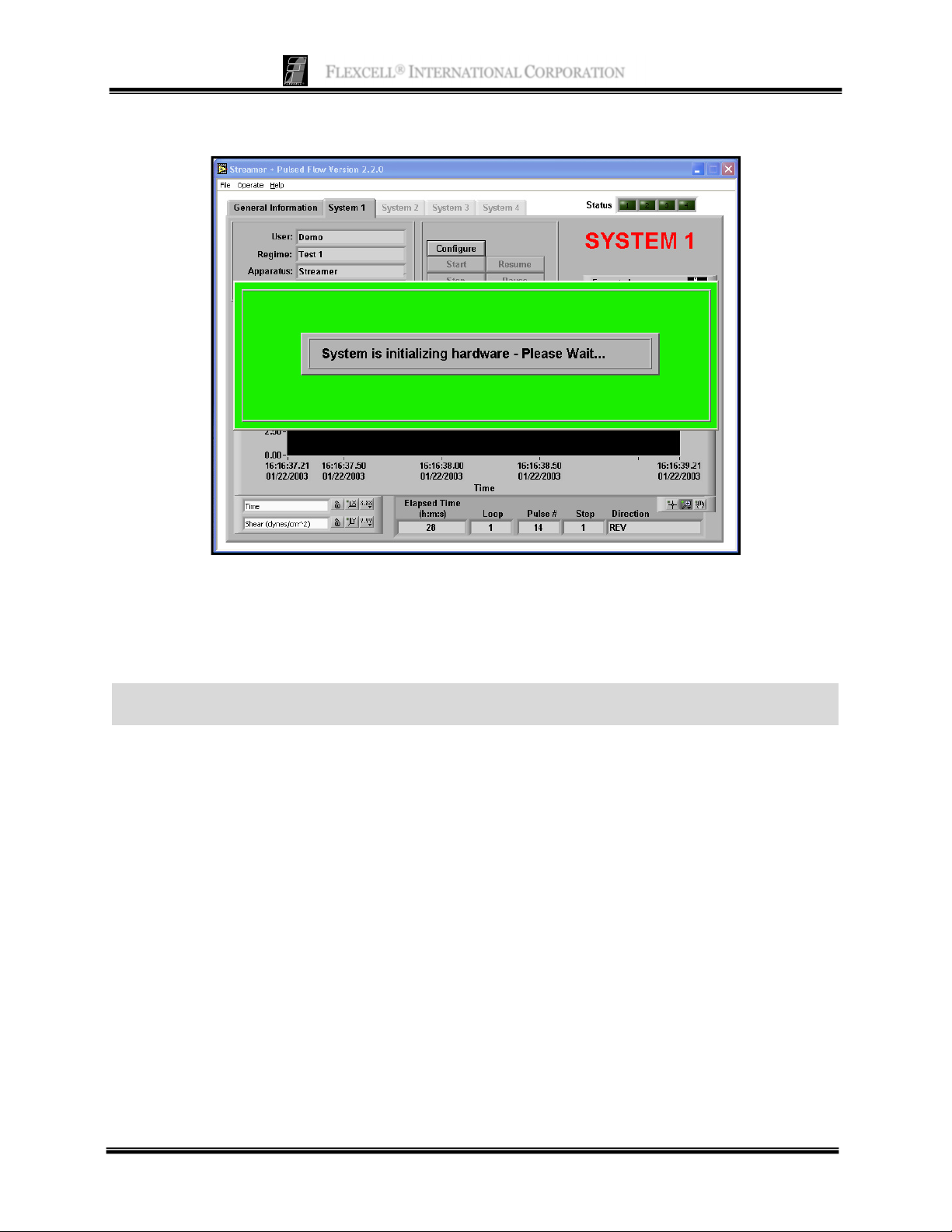

R

EINITIALIZE HARDWARE

Function: This panel will appear when the computer program is first started. It will also appear when

the Reinitialize Hardware item is selected in the Operate menu. When the system is properly initiated,

the pump will display PO1. If power to the pump is cycled during experimentation, or communication

is lost, the user should reinitialize the hardware before turning off the program and starting it again.

STREAMSOFT™ V4.2 NOTES

™

When running a regime in StreamSoft

The communication timing to the pump and Osci-Flow® requires full CPU availability. If another

program or operation is running that requires CPU power, it is possible that the pump or valve

timing could be interrupted. This effect may be noticeable when using the Osci-Flow® at a higher

frequency than 2 seconds on, 2 seconds off, or when oscillating the pump speed to create pulsatile

flow.

When the Select Pump to Use window appears when opening the StreamSoft

select the pump named MasterFlex Peristaltic Pump to ensure correct function of the

equipment.

V4.2, do not run other applications on the same computer.

™

V4.2 software,

18

FLEXCELL

®

INTERNATIONAL CORPORATION

3. DOING AN EXPERIMENT

O

VERVIEW

There are two major components to running an

experiment with the Streamer® system:

configuration of the pump software and

preparation of the flow chamber with Culture

®

and cells.

Slips

We suggest that the following steps be done:

1. Culture cells on Culture Slips

the Streamer® system components.

2. Configure a regimen in the StreamSoft

program.

3. Prepare the Streamer® system with media,

then place the Culture Slips® into the

chambers of the Streamer® device in a

sterile environment such as a laminar flow

hood. Move the system to the incubator. Be

sure that you have placed six Culture

Slips® into the device, as any less will

invalidate the shear stress values. Use

blank Culture Slips® if necessary.

4. Assign the user, regime and apparatus for

the experiment.

5. Start the experiment.

6. When the experiment is finished, remove

the Culture Slips® from the Streamer® flow

device and proceed to analyze the cells.

The processes of creating a regimen and placing

the slides into the flow device are described in

further detail in this section.

C

REATING A REGIME

1. From the main panel, select the Configure

Regimes item in the Operate menu.

2. Click on an existing user name.

3. To create a new regimen, click on New

Regime. Enter a name in the Regime Name

field.

4. Click Insert Step; give this step a name in

the Step Name field.

®

and sterilize

5. Click on Save Regime. The regime name

should appear in the Regimes for Selected

Users field at the top.

6. Specify the Flow Type (FWD, REV,

PULSED, OSCILLATION), ON/HI &

OFF/LO times (only when using the pulsed

or oscillation functions; see pages 13-14 for

more details), Shear, and Duration for this

step. Click on Save Regime to save all

information entered up to this point.

NOTE: The Flow Type can only be specified when

using the Osci-Flow® device-- without the ‘Valves in

System’ selection used with the Osci-Flow®, the

Flow Type will remain on FWD. See page 17 for

more details.

If you wish to add additional steps:

1. Click Insert Step. You will be queried as to

whether this step should be inserted before

or after the current step. Click on before or

after according to your preference. Enter

the preferred parameters as in #6. If this step

was inserted after the step entered in #6, you

can also use the GoTo and Loop options to

loop through steps 1 and 2. Under GoTo in

step 2, enter “1”. Under Loop, enter the

number of times that you would like to loop

through steps 1 and 2.

2. Add additional steps as desired. Once the

regime is complete, click on Save Regime.

3. Optional: Check the shear stress(es) in

your regime to be sure that they are

achievable with your apparatus, tubing size

and pump. Click on Check Shear at the

bottom of the Configure Regimes window

while your regime is selected (see page 13).

The Pre-Test Configuration window will

appear (see page 8). Select a user, regime,

and apparatus. Click on Update. The

software will tell you if your shear stresses

are achievable with this apparatus and the

19

FLEXCELL

®

INTERNATIONAL CORPORATION

tubing size and pump assigned to it. Modify

shear stresses if necessary.

4. The regime is now ready to run.

S

ETTING UP AN EXPERIMENT

1. Set up the system in an incubator according

to instructions on page 2.

2. Sterilize the Streamer

®

unit according to

instructions on page 2. Close the lid and

tighten screws until the lid is flush with the

body of the device.

3. Place the Streamer® in the incubator with

the remainder of the system. This will keep

the temperature of the unit at 37°C.

4. Culture cells on 6 Culture Slips®. Be sure

that you culture on the side with the brown

Teflon® rim printed around the borders.

Be careful to plate cells only within this rim.

Allow cells at least 48 hours for full

attachment to slides.

5. Create your regime in the StreamSoft

software.

After cells have attached to slides:

1. Put one bottle of PBS into the system

medium container.

2. Pump the PBS through the system to flush

the tubing and Streamer® device, then

discard the perfusate; this is done to remove

any cytotoxic substances that may have

accumulated during sterilization.

3. Put 500 ml of medium into the medium

container (this may be adjusted later as you

determine your system volume

requirements).

4. Flow the medium through the system to

flush out remaining PBS. Remove medium

and replace with 500 ml of fresh sterile

tissue culture medium.

5. Pump medium through the entire system to

fill the flow device and tubing. Once the

system is full, tilt the pulse dampeners, one

at a time, at an angle of approximately 20

degrees, such that the direction of the flow

is going from the vertex of the angle to the

open end of the angle. Leave the pulse

dampener in this position until the fluid

comes through the outlet fitting again, then

lay the pulse dampener down horizontally.

This process will allow the pulse dampener

to fill to a level slightly higher than the

fittings, thereby creating a bubble trap for

any air bubbles that may accidentally enter

the system. Do the same with the second

pulse dampener. Once this process is

complete, allow flow to continue.

6. As the flow continues, check to be sure that

no air bubbles are visibly trapped within the

tubing. Also check the walls of the medium

container to be sure that no air bubbles have

formed on the sides. If so, swirl the medium

around to release air bubbles from the side

walls.

7. Once the tubing and flow device are filled

with medium and all air bubbles are

eliminated, stop flow, then reverse flow so

that the medium is drawn down to about

80% of the Streamer® body. The fluid level

will have to be estimated once the fluid

flows past the Streamer® outlet fitting.

When the fluid reaches this level, stop the

flow again.

8. Tighten the clamp on the Phar-Med® tubing

just to the right of the pump head so that the

flow path in the tubing is completely closed

off.

9. Turn the lever arm on the MasterFlex

pump all the way to the left to release the

tubing and remove the tubing from the

pump head. Carefully move the tray

containing the Streamer® device, tubing,

pulse dampeners, and fluid collection

reservoir to the tissue culture hood.

10. Remove the Streamer

®

screws and open the

hinged top.

11. Transfer your cells from the incubator to the

tissue culture hood.

12. Using forceps and/or your fingers with

sterile gloves, grasp a Culture Slip® at one

20

FLEXCELL

®

INTERNATIONAL CORPORATION

end. Be careful not to stimulate or crush any

cells on the slide.

13. Place the Culture Slip® into one of the slots

in the Streamer® device. Be sure that the

side with cells attached is facing the flow

area (the shorter slot parallel and adjacent

to the slide slot). Be careful not to chip the

glass against the stainless steel surface.

14. Repeat this for the other Culture Slips®,

making sure the surface with the cells all

face the proper direction in the flow device.

NOTE: All six slots must be filled to ensure proper

flow rate readings. If you do not wish to use all six

Culture Slips® with cells, use blank Culture Slips®

for the remaining slots.

15. Once all Culture Slips® are in the Streamer®

unit, close the lid and tighten the screws

using the hex head tool provided with the

system.

NOTE: As you are moving the Streamer® from this

point on, always position the device vertically such

that the inlet connector is at the bottom and the

outlet connector is at the top.

If you wish to run the Streamer

the remainder of the system with fluid so that all air

is completely out of the Streamer® chamber.

Be aware that any air that accidentally enters the

system may eventually form a dry area at the

topmost slide so that these cells will no longer see

fluid media and shear stress.

Be sure that your system does not regularly see

additional air bubbles (after initial filling and air

bubble elimination) before using the Streamer® on

its side.

®

on its side, first fill

16. Move the tray with the system components

back to the incubator. Put the Phar-Med®

tubing back into the MasterFlex® pump

head and clamp the head down.

17. Unscrew the clamp on the Phar-Med

®

tubing to open the flow path to full capacity.

18. If you are running the experiment manually,

set the pump to the desired flow rate and

press the start button. If running the

experiment under software control, go to

the System tab, click on the Configure

button, assign the User, Regime and

Apparatus. Click Update, then Start.

19. Once the experiment is over, move the

Streamer® back to the tissue culture hood

and remove the slides.

20. Once the slides are removed, place the

Streamer® back into the incubator and run

deionized water through the system to

remove all remaining media. Refresh the

deionized water and run a second or third

time if necessary. Be sure to never leave the

Streamer® with culture media inside as

this will corrode the stainless steel finish

over time.

F

ILLING THE SYSTEM TO ELIMINATE AIR

B

UBBLES

Before using the Streamer® system with cells,

all of the tubing must be filled with media and

all air bubbles removed. To fill the system,

create a regime with two steps, the first in FWD

mode and the second in REV mode. Each step

should be 2 minutes at a shear stress level ½ that

of which your device is capable. This will give

sufficient time for fluid to fill all of the tubing.

As you notice air bubbles in the silicone tubing

at different locations, shake the tubing to release

the air bubbles.

P

OST-EXPERIMENT ANALYSIS

Upon removal of the slides from the flow

device, many post-flow evaluations can be

done.

®

Cells on the Culture Slips

can be fixed

with formalin then permeabilized and

stained with rhodamine Phalloidin and

DAPI to visualize cell alignment.

21

FLEXCELL

®

INTERNATIONAL CORPORATION

Cells can be lysed with appropriate buffer

to collect total RNA or intracellular

proteins.

®

The Culture Slips

can be returned to their

original culture vessel for further incubation

and subsequent collection of cell

supernatant. The medium can then be

assayed for released effector molecules.

The cells can be trypsinized for replating or

counting.

APPLICATION NOTES

C

ULTURING CELLS ON CULTURE SLIPS

®

Culture Slips

are Teflon®-bordered 75 x 25 x 1 mm glass culture surfaces that are either untreated or

bonded with peptides of collagen, elastin, fibronectin (RGD repeat as Pronectin F), laminin (as the

YIGSR peptide). The Teflon

®

border provides a means to culture cells only in the flow area. Bonded

peptides increase cell attachment.

Cells are plated on the growth surface at 10-25,000 cells/cm2 in 3 to 5 ml of medium. Be sure to plate

cells on the side where the Teflon® border is printed. Once the cells are attached, additional medium

is added and the culture vessel placed into a CO2 incubator at 37°C. Once the cells have grown to

confluence (normally 48 hours), the Culture Slips® are removed and inserted into the Streamer® flow

device for the experiment. Once the flow experiment is over, the Culture Slips® can be returned to their

original culture vessel to allow the measurement of secreted molecules post-flow.

If you experience cell detachment problems during flow regimes, try the following protocol for better

cell attachment to the Culture Slips®.

1. Plate ½ of the normal amount of cells on the Culture Slips®.

2. Reduce the media serum concentration (5% preferably) to slow the cell growth rate. This will

give the cells time to make their own protein matrix which will improve attachment.

3. Allow the cells to grow to near confluency (4-5 days).

®

22

FLEXCELL

®

INTERNATIONAL CORPORATION

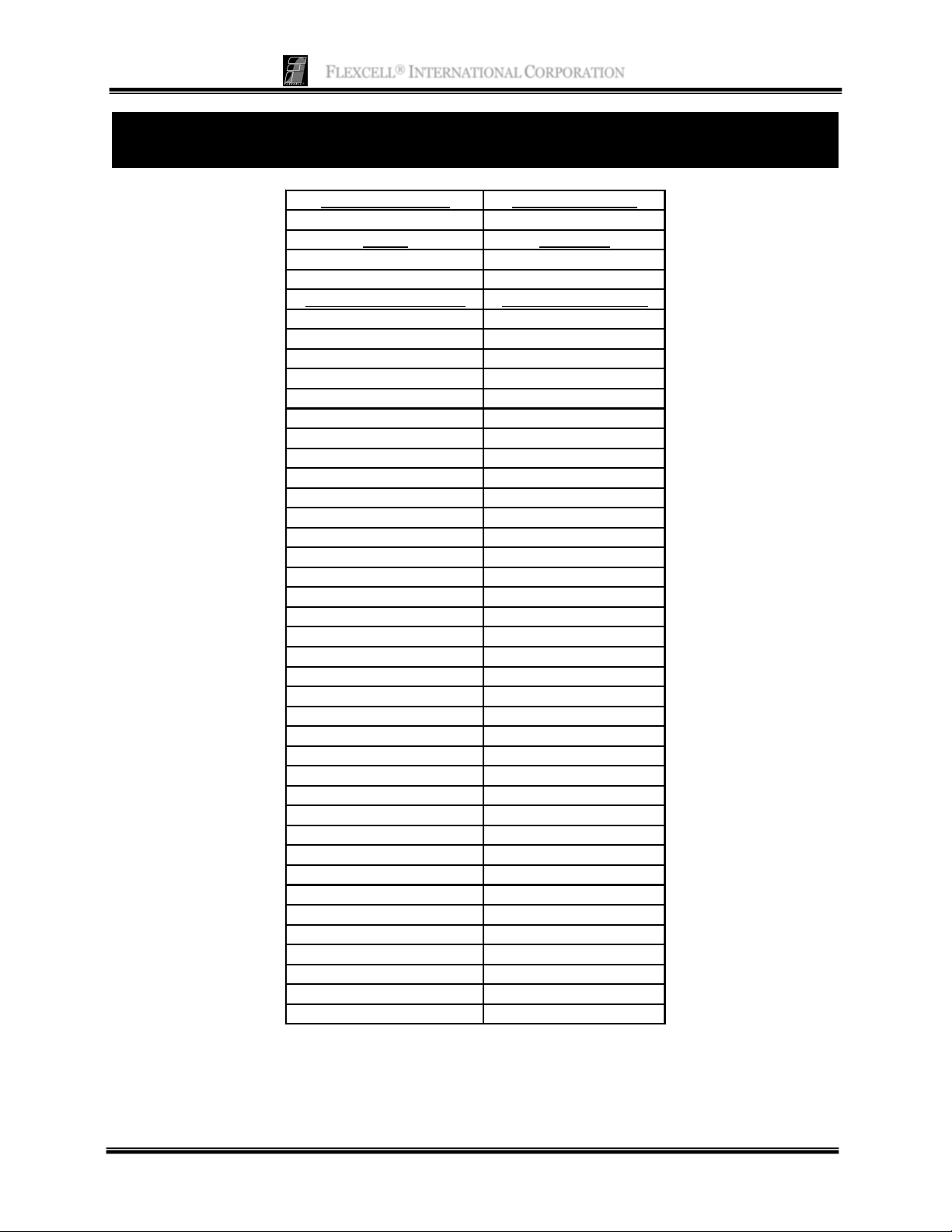

APPENDIX: PARALLEL STREAMER® SHEAR STRESS

NUMBERS

Flow Area Height(cm) Flow Area Width(cm)

0.0513 2.3396

Serial # Flow Factor

SGS-1109 6

System Flow Rate (ml/min) Shear Stress (dyn/cm^2)

00.0

37 1.0

74 2.0

111 3.0

148 4.0

185 5.0

222 6.0

259 7.0

296 8.0

332 9.0

369 10.0

406 11.0

443 12.0

480 13.0

517 14.0

554 15.0

591 16.0

628 17.0

665 18.0

702 19.0

739 20.0

776 21.0

813 22.0

850 23.0

887 24.0

924 25.0

961 26.0

997 27.0

1034 28.0

1071 29.0

1108 30.0

1145 31.0

1182 32.0

1219 33.0

1256 34.0

1293 35.0

23

FLEXCELL

®

INTERNATIONAL CORPORATION

WARRANTY INFORMATION

1. FLEXCELL INTERNATIONAL CORPORATION warrants to the original purchaser/customer all hardware components of the

Streamer

defects in workmanship or materials with the following exceptions, terms and conditions:

a. ITEMS EXCLUDED FROM THE WARRANTY ARE: software, disks, manuals and external peripherals such as printers,

mouse or track ball units, imaging devices, vacuum pumps, air tanks, electric voltage converters, compressors, surge suppressers and all

other accessory equipment.

b. DURING THE WARRANTY PERIOD, the purchaser/customer must notify Flexcell of any warranty claim in writing, by

telephone, fax transmission or email identifying each defective part or specifically describe the exact problem no later than the last day the

warranty is in effect.

c. FLEXCELL AGREES to correct any defect in workmanship or material and supply new or rebuilt parts in exchange for

defective parts upon completion and submission by purchaser/customer of a printed “Parts Return Authorization” form furnished by Flexcell.

Parts must be properly packed in original container and shipped to our factory service center or distributor with all shipping costs prepaid if

the unit is out of warranty coverage. If the original shipping box is not available, Flexcell will send the required protective shipping container.

(Flexcell will recommend the insurance value for parts or equipment to be shipped.) Return carrier shipping costs will be paid by Flexcell

from the service center. The purchaser/customer is solely responsible for payment of custom fees, taxes, holding fees or value added taxes.

d. THIS LIMITED WARRANTY only covers failures due to defects in materials or workmanship which occur during normal

use. It does not cover damage which occurs in shipment or failures of original equipment due to products identified as add-ons not

manufactured by Flexcell International Corporation or its distributors nor does this limited warranty cover damages or failures which result

from accident or disaster such as fire, explosion, flood, wind, lightning, or earthquake or misuse, abuse, neglect, mishandling, misapplication,

alteration, faulty installation, modification or service by anyone other than our factory or distributor. This warranty is extended only to the

original purchaser/customer unless a transfer of ownership is approved by Flexcell in writing.

e. LIMITED LIABILITY. Flexcell or its distributor’s only liability shall be to remedy any defect to comply with its warranty

and return the repaired equipment to function as designed. Under no circumstances shall Flexcell or its distributors be liable for any special

incidental or consequential damages based upon breach of warranty or contract or negligence. Such damages include, but are not limited to:

loss of profits, revenue, loss of data, down time, customer’s material or time.

f. DISCLAIMER OF WARRANTIES: The Limited Warranty expressed in the foregoing language is the only warranty

applicable to this product. Any other warranty, expressed or implied warranty or of merchantability or fitness for a particular purpose are

hereby disclaimed. No oral or written information or advice provided by Flexcell, through its agents or employees, in the use and functioning

of the equipment shall in any way create a warranty or in anyway increase the scope of this limited warranty.

g. DISCLAIMER: LANGUAGE. This warranty document, accompanying instruction manual and supplemental applicable

laws appear in the English language. In the event of any inconsistency in the meaning of the words and terminology and any foreign language

translation, the English language shall prevail.

2. GOVERNING LAW. The performance of the duties and liabilities of the parties under the terms and conditions of this Limited

Warranty shall be governed in all respects by the laws of the Commonwealth of Pennsylvania, the United States of America.

APPLICATION OF STATE LAWS: Some states do not allow the exclusion or limitation of consequential damages nor do some states

allow limitations on how long an implied warranty lasts, so the above limitations may not apply to you. This warranty gives you specific

legal rights and you may also have other rights which vary from state to state.

3. INTERNATIONAL CUSTOMERS. The full text of the foregoing limited warranty and all disclaimers is applicable to international

customers/purchasers except when the purchase was made from an international distributor or reseller, the warranty will be covered through

your distributor or reseller.

If technical advisory support service is not available through your distributor or reseller, for service contact warranty headquarters by phone

or fax.

®

Shear Stress System for a period of one year from the date of delivery to the purchaser/customer to be free from manufacturing

Within the United States only - Toll Free 1-800-728-3714 - Fax: 1-919-732-5196

Email : info@flexcellint.com

Issued April 2011

24

North America

Flexcell International Corporation

2730 Tucker Street, Suite 200

Burlington

NC 27215

USA

Phone: 919-732-1591

800-728-3714 (USA only)

Fax: 919-732-5196

Email: info@flexcellint.com

Web: www.flexcellint.com

Europe

Dunn Labortechnik GmbH

Thelenberg 6

56567 Asbach

Germany

Phone: +49-2683-43094

Fax: +49-2683-42776

Email: info@dunnlab.de

Web: www.dunnlab.de

Japan

LMS CO. LTD.

3-6-7, Hongo,

Bunkyo-ku, Tokyo 113-0033

Japan

Phone: +81-3-5842-4171

Fax: +81-3-5842-4180

Email: intldpt@lms.co.jp

FLEXCELL

®

INTERNATIONAL CORPORATION

CONTACTING FLEXCELL

Taiwan

Nature Opera Biotechnology, Inc.

9F-2, No.70 Sec.4, Cheng Kung Rd.

Nei-Hu Dist.

Taipei

Taiwan

Phone: +886-2-27905097

Fax: +886-2-27931322

Email: nobio@seed.net.tw

Brazil

Sellex, Inc.

5225 Wisconsin Ave, NW

Suite 306

Washington, DC 20015

Phone: 5506-4646

Fax: 5505-7433

Web: www.sellex.com

China, Hong Kong, Malaysia

Bio Excellence International Tech Co., Ltd

Email: slby800@yahoo.com

Web: www.bio-goods.com

South Korea

Lee Baeg Scientific Co., Ltd.

Web: www.lbscience.com

NOTICE

The information in this document is subject to change without notice. Flexcell International

Corporation assumes no responsibility for any errors that may appear in this guide. This manual is

believed to be complete and accurate at the time of publication. In no event shall Flexcell International

Corporation be liable for incidental or consequential damages in connection with or arising from the

use of this manual.

25

Loading...

Loading...