Flexboat Miniflex-S, TD-10, Miniflex, TD-8, SR-9.5 Owner's Manual

...

O

O

OO

O

O

OO

w

w

ww

w

w

ww

SSSS

m

m

mm

SSSS

m

m

mm

n

n

nn

n

n

nn

aaaa

aaaa

e

e

ee

e

e

ee

llll

llll

llll

llll

bbbb

bbbb

r

r

rr

r

r

rr

oooo

oooo

''''

s

s

ss

''''

s

s

ss

aaaa

aaaa

tttt

tttt

m

m

mm

m

m

mm

ssss

ssss

uuuu

uuuu

pppp

pppp

a

a

aa

a

a

aa

tttt

tttt

oooo

oooo

n

n

nn

n

n

nn

1111

1111

u

u

uu

u

u

uu

0000

0000

ffff

ffff

a

a

aa

a

a

aa

tttt

tttt

llll

llll

Index

1 - Introduction

2 - Flexboat history

3 - Builders Certificates

4 - Vessel Registration

5 - Owner responsibilities

6 - Features of the small boats up to 10 ft

6.1 - Miniflex, MiniflexS and TD 8 line of foldable boats

6.1.1 - Assembly, disassembly and transportation of boats with folding bottom

6.2 - TD 10 boat that can be disassembled

6.1.2 - Assembly, disassembly and transportation of boats that can be disassembled

6.3 - Mini SR, SR 9.5, SR 10 and SR 10 S line of rigid bottom boats

7 - Dimensions

8 - Knowing the Miniflex

9 - Knowing the Miniflex S

10 - Knowing the TD 8

11 - Knowing the TD 10

12 - Knowing the Mini SR

13 - Knowing the SR 9.5

14 - Knowing the SR 10

15 - Knowing the SR 10 S

16 - Basic items for all models

17 - How to inflate your Flexboat

18 - Maximum capacity

19 - Engine ratings

20 - Maintenance and cleaning

20.1 - Hull and cockpit cleaning

20.2 - Tube cleaning

20.2.1 - Using the Hypalon cleaning Blue Kit

20.3 - Stainless steel cleaning

20.4 - Windshield cleaning

20.5 - Upholstery cleaning

20.6 - Cleaning products NOT TO BE USED on board

21 - Before navigation

21.1 - Complete checklist, still in land

21.2 - In-water checklist

21.3 - Engine starting checklist

22- Onboard safety

23 - Anchoring your Flexboat

23.1 - Launching the anchor

23.2 - Retrieving the anchor

24 - Navigation tips

25 - Returning from your trip

26 - Fuel

26.1 - Fueling the boat

26.2 - Using the right fuels

27 - Engine care

28- Small repairs on the tubes

29 - Air valve replacement

30 - Final considerations

31 - Warranty

32 - Warranty card

2

Congratulations! You have just purchased a FLEXBOAT.

versatile and dynamic vessel. Stability, safety and high capacity a

the highest quality materials and components to build our boats. The tubes are built with the best

material imported from France, a fabric made of Hypalon, Neoprene and Polyester which is highly hermetic and

emely resistant to abrasion, chemicals, sun rays, and wear & tear. The use of those materials guarantees

superior durability.

good moments in the water

ead this manual. Here you will learn how to h

how to take care of your boat, do some basic troubleshooting,

rranty. Our goal is helping you getting the most of your Flexboat so you can enjoy it

are under constant development and improvement. All images, drawings, descriptions and

specifications in this manual reflect the most current models

Flexboat reserves the right to do changes to this Manual at any time as needed.

Late 1988 Jaime Jose Alves Silva, an entrepreneur from Rio de Janeiro, decided to settle in Sao Paulo after

arching for technology and for the most advanced materials in order to start

building the best inflatable boats in Brazil.

FLEXBOAT CONSTRUCOES NAUTICAS LTDA was born in 1990 in its facility located in the city of Atibaia, 40

ulo, on a 270,000 s

Atibaia was chosen due to its prime location as a transportation hub and also because it is close to the main

marine markets in Brazil's south / southeast regions.

8 years have demanded lots of work and dedication. During this period FLEXBOAT has created a

brand name which is a reference of quality. It has turned into a synonym of inflatable boats.

Since its inception FLEXBOAT has been using Hypalon (special fabric

from France) to build its tubes. This material and its incomparable features guarantees the boats will have the

highest safety standard. It makes sure the boats will last longer. When used in conjunction with other hi

raw materials and components and when handled by a team of highly trained and qualified workers the final

result is FLEXBOAT, the best inflatable boat made in Brazil.

After starting building small inflatables up to 12 feet long Flexboat kept on

release of the SR 1000, the largest (33 ft) and most advanced inflatable build in Brazil. Until now more than

15,000 boats were built and sold in Brazil, USA, Caribbean and Europe.

pment of boats focused on military use and since then we have become

the main vendor for Brazil armed forces. Federal Police, Navy, Firemen, First Responders, IBAMA and Ambient

Police are among FLEXBOAT customers.

FLEXBOAT is looking to the future and wor

offering larger boats with a cabin, and other innovations, both for the Brazilian and International markets. In the

military and professional sectors, FLEXBOAT is developing a new line of p

Small boats up to 10ft

re just some of its strengths.

To make sure you achieve this we strongly suggest you

it in a safe way. You will also learn

how to properly maintain it. And you will also

o Dias Highway. The city of

based on rubber and neoprene, imported

expanding its product line until the

king onto increasing its product offering in the leisure market by

roducts that will be second to none.

1 - Introduction

A lightweight,

We only use

extr

Flexboat inflatables’ a

Boating means spending

r

find information about its wa

safely.

Our products

Owner’s Manual –

.

andle your boat and how to use

and

available.

2 – Flexboat history

travelling to Italy and France se

miles from the city of Sao Pa

Since then 2

In 2005 FLEXBOAT started the develo

q ft area right across the Fernã

gh quality

This is FLEXBOAT!

Best regards,

THE FLEXBOAT TEAM

3

All our boats are subjected to quality tests before delivery to the customer, guaranteeing a superior level of

You should register your boat according to the local laws and regulations. Please contact your nearest marine

authorities or your closest FLEXBOAT dealer if needed

The owner or user is responsible for acknowledging

Correct usage and maintenance of the boat and its systems

Passengers safety preparation and train

Knowledge of the boats systems

Knowledge of the sea conditions

Owner’s Manual –

Small boats up to 10ft

and following the requirements and procedures below:

3 – Quality you can trust

quality.

4 - Vessel registration

5 – Owner responsibilities

• Coast Guard registration

• Insurance

• Warranty registration

• Warranty terms and conditions

•

• Safety equipment

•

•

•

• Safe practices

• No use of drugs and alcohol

• Environmental regulations

• Accident reports

• Operators license if needed

ing

4

Features of the small boats up to 10 ft

ts was developed to work as support boats for larger vessels and t

Depending on its bottom style, the small boats are divided into three groups as follows:

Boats that can be disassembled

TD

fits into a small carrying bag;

assures excellent p

om plate and the bottom planks are made of fiberglass thus increasing its durability even

when exposed to bad weather.

disassembly

The foldable boats are very light and fit into a carrying bag which was specially developed for

its transportation. Assembling and disassembling the Miniflex is a simple process that can de

Se

ee detailed inflating instructions

Small boats up to 10ft

Flat bottom with

fiberglass planks and Hypalon fabric.

som plate and bottom

consist of marine ply

encapsulated with reinforced fiberglass

with orthophthalic polyester resin,

450 g/m² of fabric and

Coremat. Finishing in isopht

coat with NPG and anti

and transportation of boats with fold

Se

6 -

Flexboat line of small boa

friendly boat.

a)

Folding boats

b)

c)

Boats with rigid bottom

6.1 - Miniflex, Miniflex-S and

Ideal to support larger vessels;

When folded, it

Very light;

Easy to be transported;

Its hydrodynamics

The trans

Owner’s Manual –

-8 line of foldable boats

erformance and maneuverability;

Bottom type:

Materials: Tran

planks

o be a family

wood

reinforced with

halic gel

UV.

6.1.1 Assembly,

ing bottom

performed by anyone.

e a step by step explanation below:

S

in item 17 of this manual.

5

TD 10 boat that can be disassembled

The TD 10 has a removable bottom. When disassembled it is fitted in two separate carrying bags that can

cle. Transverse and longitudi

rigidity to the bottom during navigation.

.1 Assembly, disas

Owner’s Manual –

Small boats up to 10ft

nal aluminum profiles guarantee

pe: V bottom with

and inflatable keel with

Hypalon fabric

Materials: Hypalon f

aluminum profiles.

ly and transportation of boats that can be

6.2 -

be transported in any vehi

bottom panels and assure

6.2

disassembled

semb

a perfect fit for the

Bottom ty

fiberglass

.

fiberglass

with anodyzed

abric, and

6

The TD 10 comes in two separate carrying bags. One bag stores the tubes and the other bag stores

arranging

the bottom in the boat

Install the bottom parts following their numbers. Start at the bow

Part # 4 should be the last one to be put in place.

the final fitting by applying some down pressure in

adjust the side fabric from the tube to the sides of the floor.

4 pieces of side aluminum profiles by fitting them to the sides of the floor. Check the final

pump a little air on each tube to help the bottom to

e inflation of the tubes. Only after the

inflate the keel of the boat. Inflate the keel until the bottom it straight and has a V shape.

Small boats up to 10ft

and move your way to the

fit part # 4 into part # 5 and slightly raise part #3 to do

the whole floor

accommodate

inflated to their correct pressure it is t

Step 1– Preparing the parts.

Laying the bottom out and

Step 2 – Installing

stern until you get to part # 5.

Owner’s Manual –

the

disassembled bottom.

the rubber parts.

with part # 1

Install the

adjustment of the floor.

First

order to accommodate

in place. Then

Step 3– Inflating the boat

Inflate the tubes. First

complete th

tubers are

correctly. Then

ime to

7

Fit the seat onto the screw installed on the tube. Tighten the bolts. Repeat on the o

nflated keel

Mini SR, SR 9.5, SR 10 and SR 10 S line of rigid bottom boats

They all have a rigid fiberglass bottom which makes them suited for a

Reinforced fiberglass hull laminated with orthophtalic polyester resin, reinforced with

alic gel coat with NPG and anti

fiberglass hull laminated with orthophtalic polyester resin, reinforced with

, and injected polyurethane foam between the hull and liner

Small boats up to 10ft

ny kind of use and activity.

450 g/m² of fabric and

. Finishing in isopht

Step 4 – Installing the seat

Owner’s Manual –

ther side.

6.3-

MINI-SR, SR 9.5 and SR 10

I

Lifeline

Coremat finishing in isophth

SR 10-S

Reinforced

Coremat

NPG and anti UV.

-UV.

450 g/m² of fabric and

halic gel coat with

8

Small boats up to 10ft

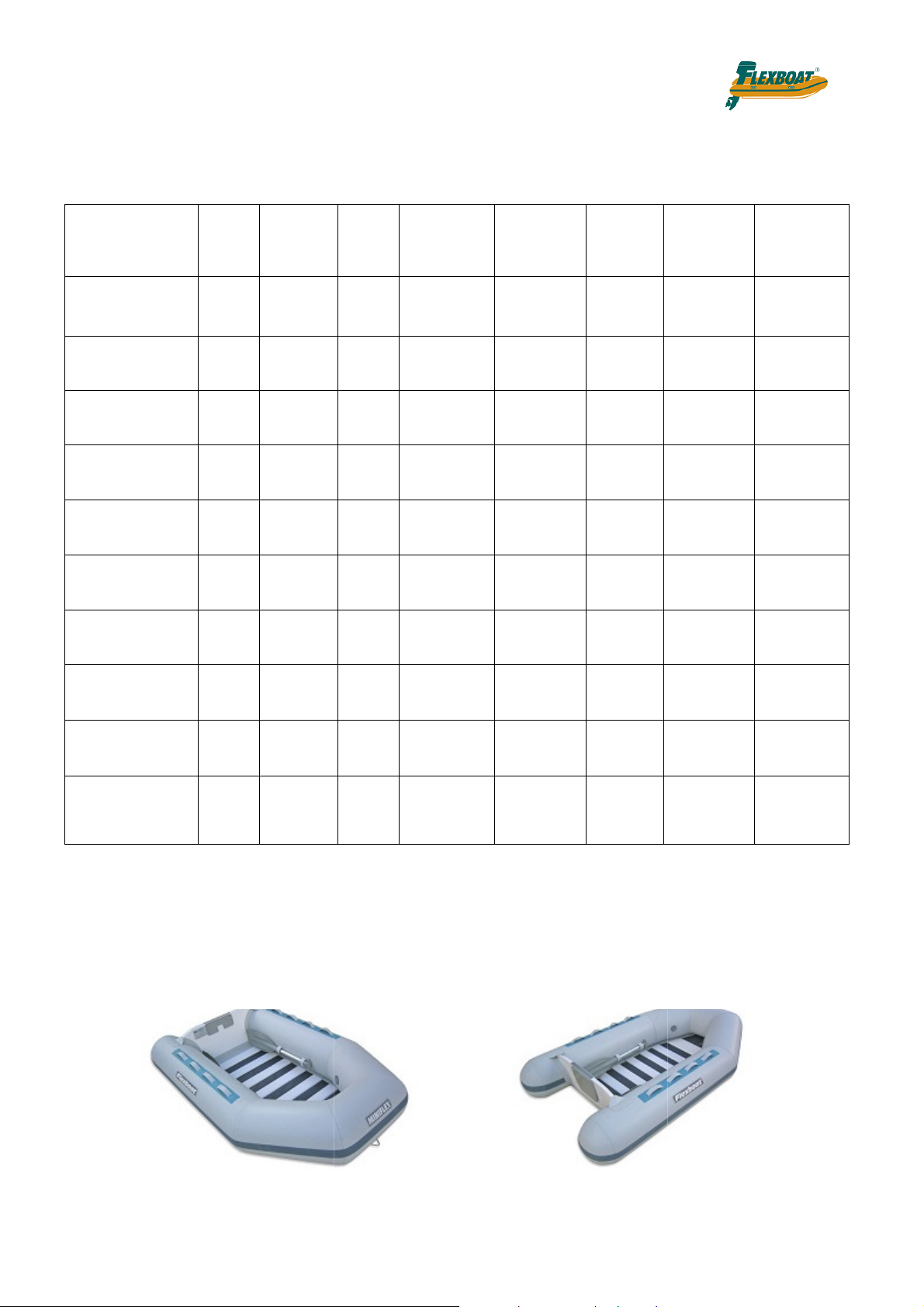

7

– Dimensions

Owner’s Manual –

Length overall

(outside)

Length overall

(inside)

Beam

(outside)

Beam (inside)

Tube diameter

Quantity of

chambers

Max person

capacity

Max HP

recommended

Miniflex Miniflex S

6 ft 7 in 7 ft 5 in

4 ft 4 in

4 ft 4 ft 4 in

1 ft 10 in 2 ft 2 in

1 ft 1 in 1 ft 1 in

2

2

3.3hp 4hp

5 ft 2 in

2

3

TD-8 TD-10 Mini SR SR-9.5

8 ft 2 in

5 ft 10 in 7 ft 5 in 5 ft 2 in 6 ft 5 in

5 ft 5 ft 4 in 4 ft 4 in 5 ft 5 in

2 ft 5 in

1 ft 1 in

2

4

5hp 15hp 4hp 8hp

10 ft 7 ft 5 in 9 ft 5 in

2 ft 6 in 2 ft 2 in 2 ft 4 in

1 ft 4 in /

1 ft 2 in

3

5

1 ft 1 in 1 ft 5 in

2

3

2

5

SR-10 SR-10 S

10 ft 3 in 10 ft

7 ft 3 in 7 ft 6 in

5 ft 8 in 5 ft 4 in

2 ft 9 in 2 ft 6 in

1 ft 5 in

3

5

15hp 15hp

1 ft 4 in /

1 ft 2 in

2

5

Product line

Weight (w/o

engine)

8

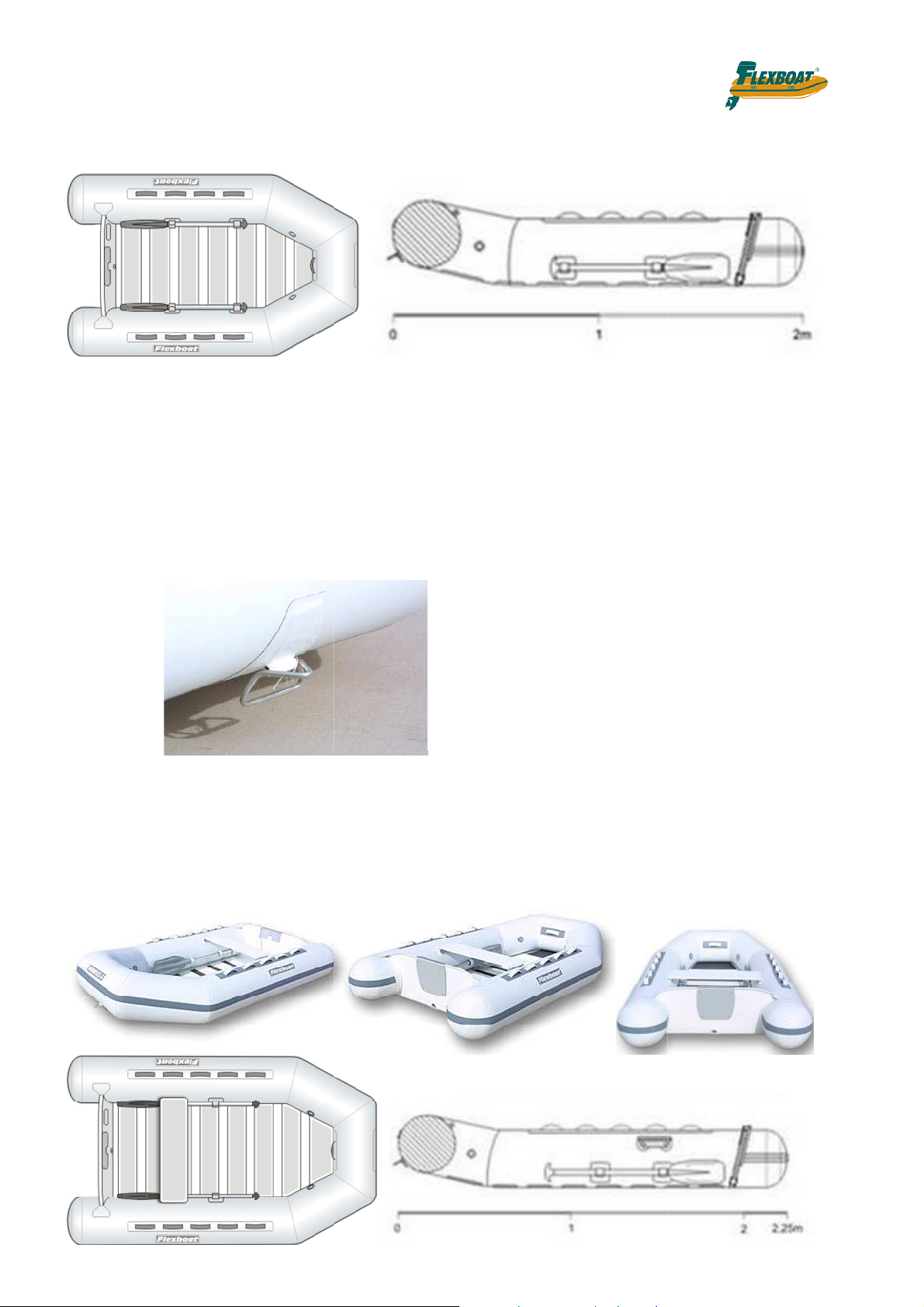

– Knowing the Miniflex

Foldable Foldable

46 lb 62 lb

Foldable Disassembled

82 lb 106 lb 73 lb 128 lb

Rigid

bottom

Rigid

bottom

Rigid

bottom

150 lb 132 lb

Rigid

bottom

9

rubber handle in the bow

Small boats up to 10ft

Triangular shaped stainless steel

fixture in the bow, for towing, anchoring

Items located at the transom plate:

Nylon plate

Boat ID label

Drainplug with valve

There is an internal

Owner’s Manual –

, vulcanized to the tube.

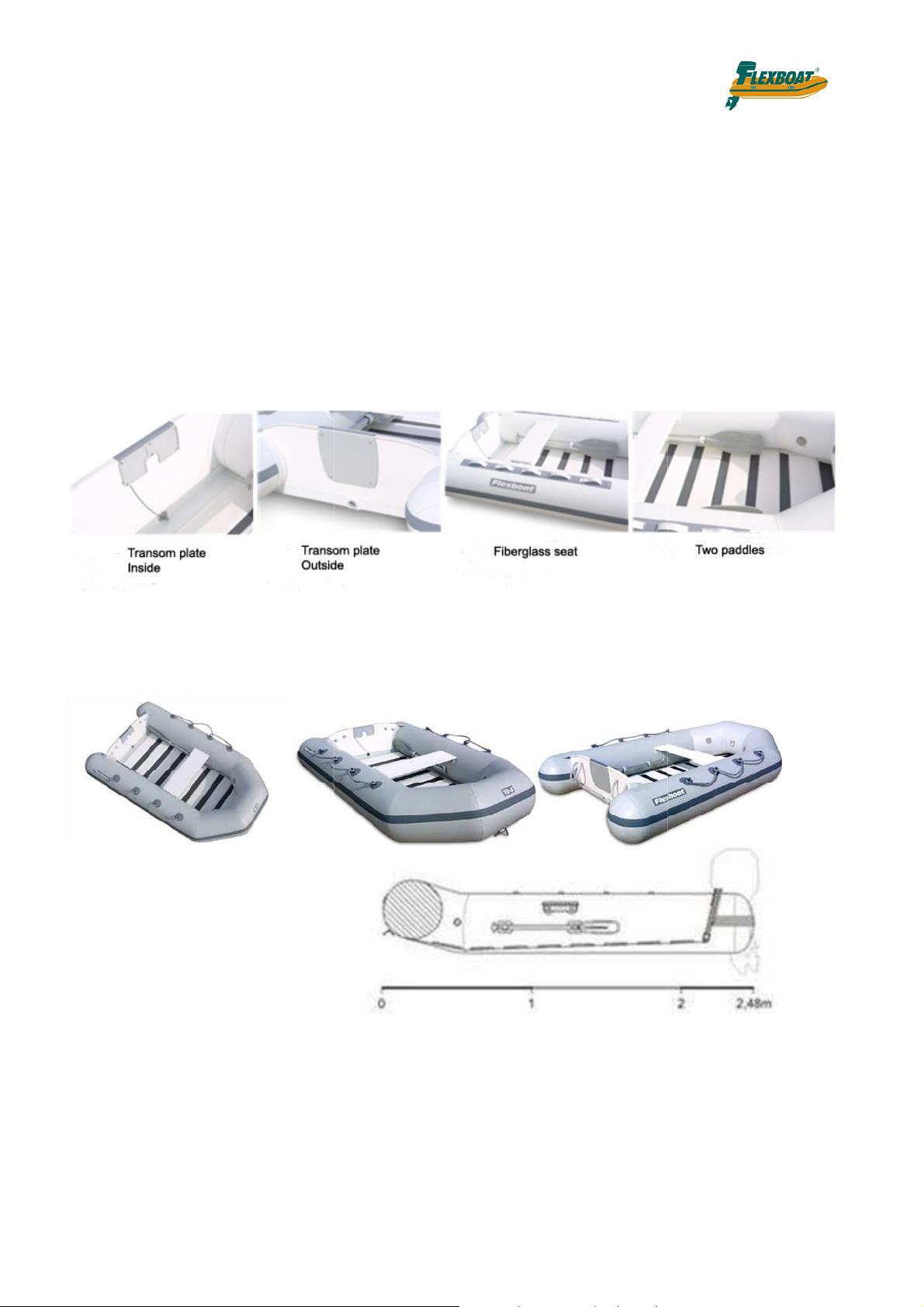

9

– Knowing the Miniflex-S

and tying to the dock.

10

steel D ring in the bow

EVA padded fiberglass captain seat.

Triangular shaped stainless steel fixture in the bow, for towing, anchoring and tying to the dock.

There is a internal rubber handle in the boat, vulcanized to the tube, and a triangular shaped

fixture in the bow, for towing, anchoring and tying to the dock.

Two polyamide straps for transpo

Stainless steel D ring in the bow

n seat.

Triangular shaped stainless steel fixture in the bow, for towing, anchoring and tying to the dock.

Small boats up to 10ft

Items located at the transom plate:

Nylon plate

Boat ID label

Drainplug with valve

Stainless

Owner’s Manual –

stainless steel

10

– Knowing theTD-8

Items located at the transom plate:

Nylon plate

Boat ID label

Drainplug with valve

EVA padded fiberglass captai

rtation

11

Loading...

Loading...