flexbar 15947, 15949 Operation Manual

ULTRASONIC THICKNESS GAGE

MODEL NO. 15947 & 15949

OPERATION MANUAL

250 Gibbs Road • Islandia, NY 11749

Tel: (631) 582-8440 • Fax: (631) 582-8487

E-Mail: sales@flexbar.com

www.flexbar.com

INDEX

1) GENERAL

1.1) APPLICATIONS 3

1.2) BASIC WORKING PRINCIPLE 3

2) SPECIFICATIONS 3

3) DIAGRAM

4) MAIN FUNCTIONS 5

4.1) PREPARING FOR MEASUREMENT 5

5) SETTING PARAMETERS 5

5.1) Velocity 6

a) Velocity Setting 6

b) Velocity Measuring

5.2) Probe selection 6

5.3) Resolution 7

6) TESTING PROCEDURE 7

7) CALIBRATION 7

8) MEASURING THICKNESS 7

9) MAINTENANCE 8

9.1) Battery replacement 8

9.2) Storage 8

Appendix A: Decimal and Fractions to Millimeters 9

Appendix B: Millimeters to Inches 10

Appendix C: Sound Velocity in Materials 11

Model#15947 & 15949 4

6

2

1. GENERAL

1.1) APPLICATIONS

The Flexbar Ultrasonic Thickness Gage, Model No. 15947 & 15949 are

designed for measuring the thickness of metals, plastics, ceramics, glass and other

ultrasonic wave conducting materials with two parallel surfaces (top & bottom).

The 15947/15949 can be used in industrial applications to perform precise

measurements on various kinds of materials, parts and components. Additionally, it can

be used to monitor various kinds of pipes and pressure vessels for decreasing thickness

due to corrosion and/or erosion.

1.2) BASIC WORKING PRINCIPLE

The basic principle of the ultrasonic wave in a thickness measurement is similar to that

of an optical wave. The ultrasonic wave pulses are transmitted by the probe face and

are coupled to the object to be measured using a viscous fluid called “couplant”. These

ultrasonic pulses propagate through the measured object and reflect back to the

transducer when they encounter the back surface. The thickness of the object is

determined by precisely measuring the time the ultrasonic wave travels in the object.

2) SPECIFICATIONS

DISPLAY:

RESOLUTION:

WORKING FREQUENCY:

MEASURING RANGE:

LOWER MEASURING LIMIT FOR PIPES:

MEASURING ERROR:

ADJUSTING RANGE OF SOUND VELOCITY

MEASUREMENT OF SOUND VELOCITY WITH

KNOWN THICKNESS VALUE:

MEASUREMENT RANGE:

IF THICKNESS IS LESS THAN 0.8” (20mm):

IF THICKNESS IS GREATER THAN 0.8” (20mm)

RANGE OF OPERATING TEMPERATURE:

POWER SUPPLY:

POWER CONSUMPTION:

Auto Power Off

DIMENSIONS:

WEIGHT:

FOUR DIGIT LCD DISPLAY

0.01in / 0.1mm & 0.001” / 0.01MM

5 MHz

.047in – 8.0in (1.2 - 200.0 MM) (STEEL)

0.8 X 0.1” or 20 X 3mm (STEEL)

+/- (1%H+0.004”) or ±(1%H+0.1)MM

0.039 to 0.3937in/us or (1000-9999 M/S)

37-373 MILES/MIN (1000-9999 M/S)

+/- 0.004”H x 100% or ± 1mm/H X 100%

± 5%

32-104 DEGREES F (0-40 DEGREES C)

TWO AAA BATTERIES

3 Volts at less than 20MA

2 Minutes

4.3 X 2.4 X 0.9IN

4.7oz

H = actual thickness of the object to be

measured

3

7

1

3

5

UTG-

6

2

4

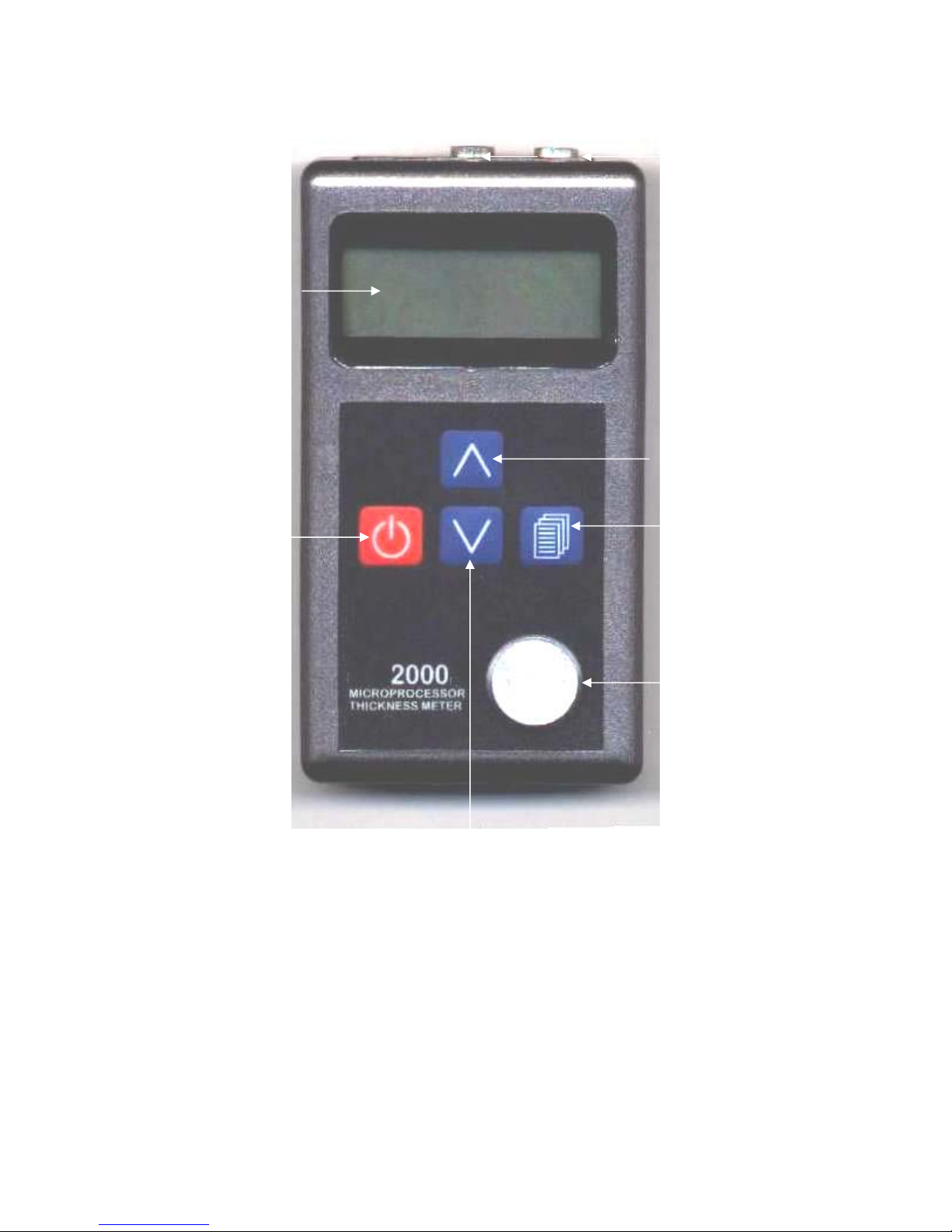

Model 15947/15949

1. LCD Screen 2. Calibration Block

3. Increase/Change Setting/Backlight 4. Decrease/Change Setting/AutoCalibrat

5. Power On/Off 6. Menu Program/Save

7. Probe Ports

4

1

7

3

9

5

UTG-

8

6

2

4

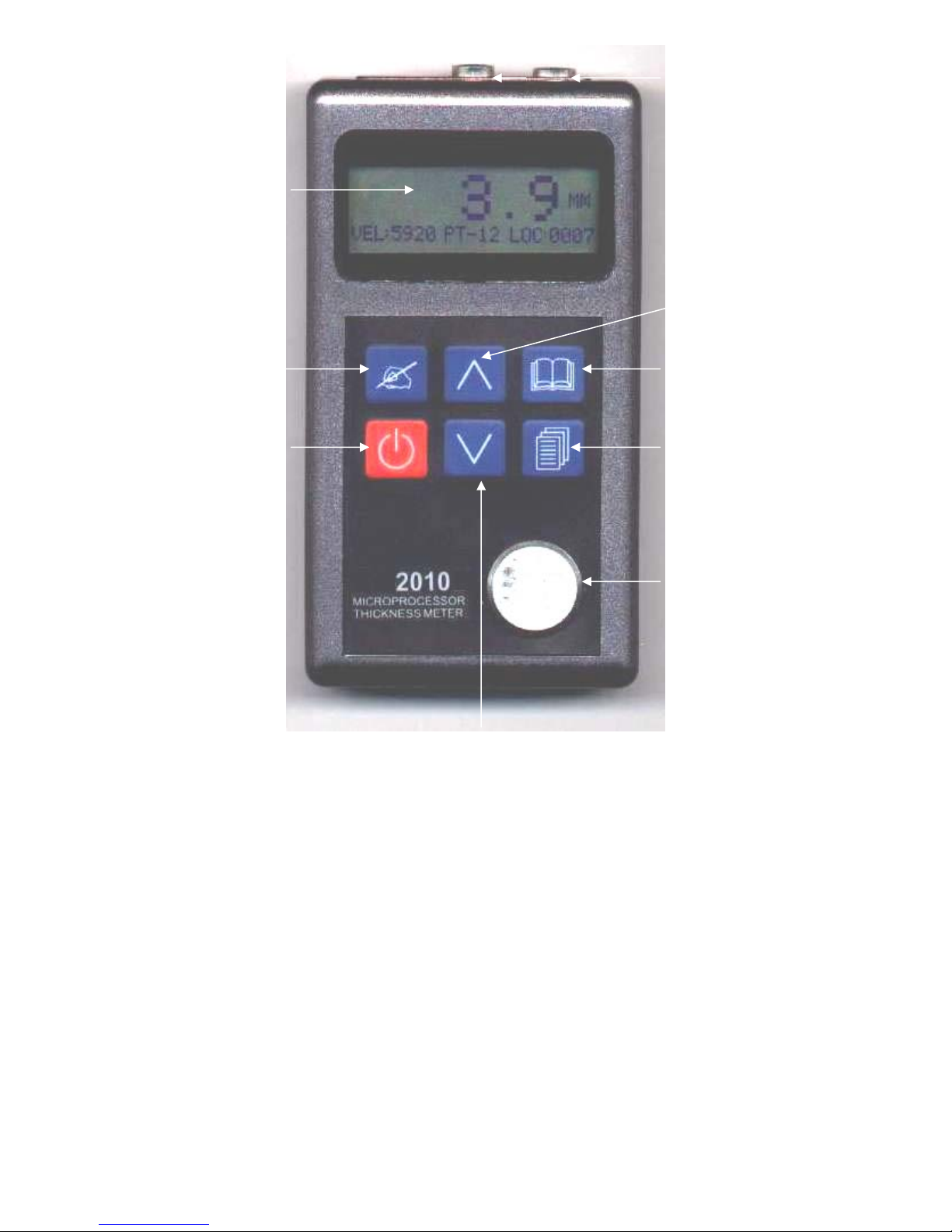

Model 15947/15949

1. LCD Screen 2. Test Shim

3. Increase/Change Setting/Backlight 4. Decrease/Change Setting/Auto

Calibration

5. Power On/Off 6. Menu Program/Save

7. Probe Ports 8. Memory Recall (15947/15949 Only)

9. Store Data (15947/15949 Only)

5

Loading...

Loading...