Page 1

Submittal Sheet

Securock® Gypsum-Fiber

Roof Board

High-performance gypsum-fiber roof board for use in low-slope commercial roofing systems

– Exceptional bond and low absorption in adhered systems

– Moisture and mold resistant

– Excellent wind-uplift performance

– Manufactured from 95% recycled material

Description Securock® Gypsum-Fiber roof board is a high-performance roof board for use in low-slope roofing systems. Its unique,

fiber-reinforced, homogenous composition gives the panel strength and water resistance through to the core.

S

ecurock Gypsum-Fiber roof board provides exceptional bond and low absorption in adhered systems and with its

homogenous composition achieves high wind-uplift ratings with no risk of facer delamination. Made from 95%

recycled material, S

types of roofing systems including single-ply, fluid-applied, built-up, spray foam, metal and modified bitumen roofing.

ecurock Gypsum-Fiber roof board combines superior performance with sustainable design for all

Advantages

Limitations –

– Consult roofing manufacturers for specific instructions on the application of their products to

– Weather conditions, dew, application temperature, installation techniques and moisture drive can have adverse

– Keep

– For re-roof or re-cover applications, existing roofing system must be dry throughout prior to application of

– Plastic or poly packaging applied at the plant to protect board during rail or other transit should be removed

–

– When applying solvent-based adhesives or primers, allow sufficient time for the solvent to evaporate to

– USG allows the bonding of cold mastic modified bitumen and torching directly to the surface. Consult with

– USG recommends maximum asphalt application temperature for Type III asphalt of 455 °F when using

Installation

– Use fasteners specified in accordance with above requirements. Install approved fasteners with plates into

the

with the roof system manufacturer’s installation recommendations and FMG Loss Prevention Data Sheet 1-29.

Proper fastener spacing is essential to achieve wind-uplift performance.

– Refer to roof system manufacturer's written instructions, local code requirements and Factory Mutual Global (FMG)

Exceptional Strength Engineered to provide superior wind-uplift performance for a wide variety of roof assemblies.

Securock Gypsum-Fiber roof board has uniform composition providing enhanced bond strength of membrane

systems with no risk of facer delamination.

Fire Performance Provides excellent fire performance and demonstrates exceptional surface burning

characteristics (ASTM E84 (CAN/ULC-S102) Flame Spread 5, Smoke Developed 0).

Moisture and Mold Uniform water-resistant core ensures excellent moisture and mold resistance.

Scored a maximum "10" for mold resistance on ASTM D3273.

Versatile Can be used as a component in single-ply, fluid-applied, built-up, spray foam, metal and modified

bitumen roofing.

Sustainability Made from 95% recycled materials and has earned independent certification from Scientific

Certification Systems for this achievement.

Securock Gypsum-Fiber roof board is engineered to perform within a properly designed roof system. The use

of

Securock Gypsum-Fiber roof board as a roofing component is the responsibility of the design professional.

Securock

Gypsum-Fiber roof board

effects on the performance of the roof system and are beyond the control of USG.

Securock Gypsum-Fiber roof board panels dry before, during and after installation. Securock Gypsum-Fiber

roof board should not be installed during rains, heavy fogs and any other conditions that deposit moisture

on the surface of the board. Apply only as much

roof membrane system in the same day. Avoid exposure to moisture from leaks or condensation.

Securock Gypsum-Fiber roof board.

upon receipt to prevent condensation or trapping of moisture, which may cause application problems.

Securock Gypsum-Fiber roof board should be stored flat and off the ground with protection from the weather.

If stored outdoors, a breathable waterproof covering should be used.

avoid damage to roofing components.

the system manufacturer for recommendations on this application.

Securock Gypsum-Fiber roof board. Application temperatures above these recommended temperatures may

adversely affect roof system performance.

and/or Underwriters Laboratories (UL) requirements for proper installation techniques.

Securock Gypsum-Fiber roof board, flush with the surface. Fasteners should be installed in strict compliance

Securock Gypsum-Fiber roof board that can be covered by final

Page 2

– Locate edge joints on, and parallel to, deck ribs. Stagger end joints of adjacent lengths of Securock Gypsum-Fiber

roof board. Butt board edges and ends loosely in typical installations. Long, uninterrupted runs (greater than 200

feet) of

Securock Gypsum-Fiber roof board will require slight gapping due to thermal expansion.

– See product data table below for maximum flute span when panels are applied directly over metal decking.

– For vertical parapet applications, only 1/2" or 5/8" panels should be used. Maximum framing spacing is 24" o.c.

Fire Performance – UL Classified as to Surface Burning Characteristics and Non-Combustability in accordance with ASTM E84 (CAN/ULC-S102)

– Flame Spread 5 and Smoke Developed 0

– 1/4", 3/8", 1/2" and 5/8" Thickness — Class A in accordance with UL790 (CAN/ULC-S107). See the UL

Building Materials Directory for more information.

– 5/8" Thickness — Meets requirements of Type X per ASTM C1278 and may be used in P series designs as a

thermal barrier.

System Performance – FM Approved

– Complies with requirements of FM 4450 and FM 4470

– Meets FM Class 1

Standards Compliance

Securock Gypsum-Fiber roof board is manufactured to conform to ASTM C1278, “Standard Specification for

Fiber-Reinforced Gypsum Panel.”

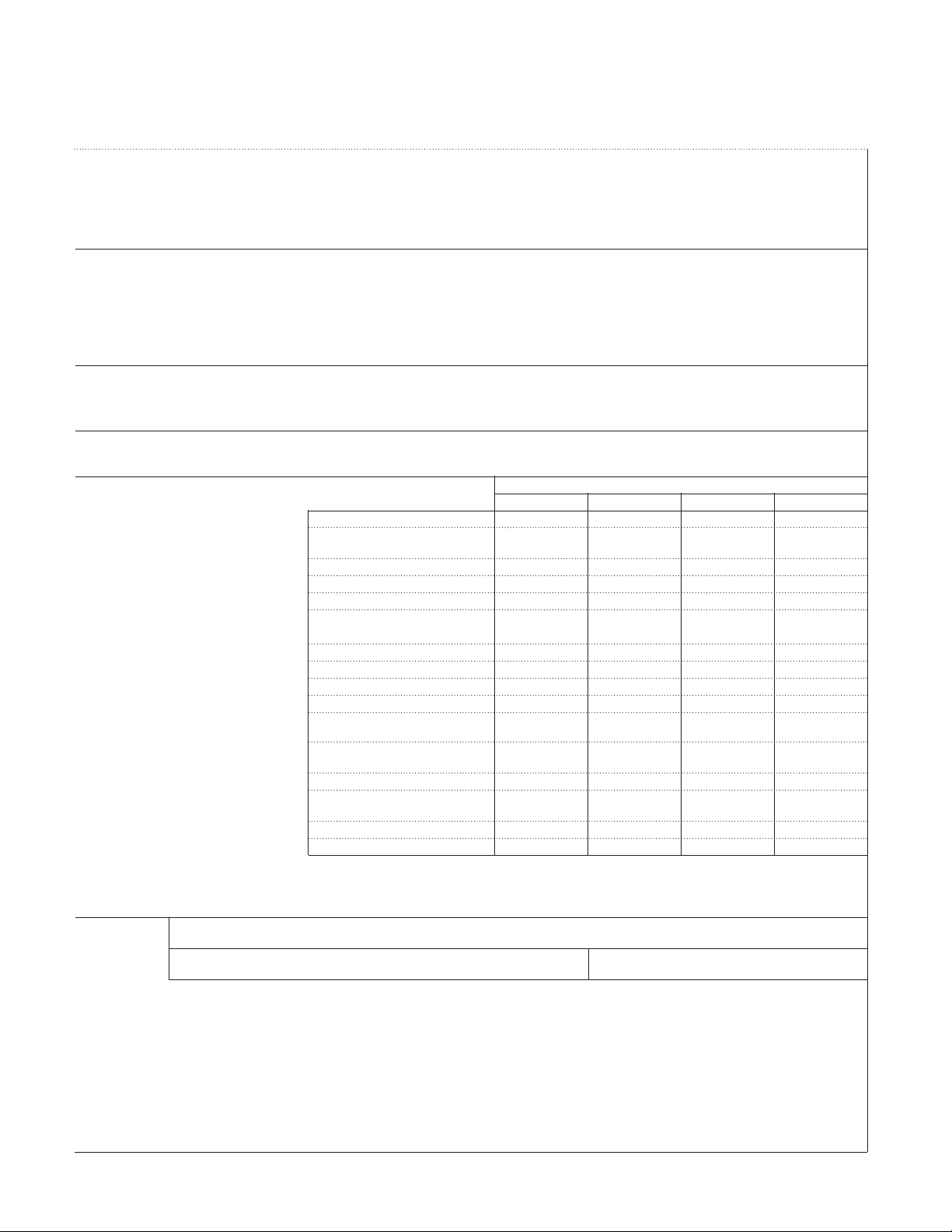

Physical Properties

1/4" (6.6 mm) 3/8" (9.5 mm) 1/2" (12.7 mm) 5/8" (15.9 mm)

Width, standard

Length, standard 4' (1220 mm) and 4' (1220 mm) and 4' (1220 mm) and 4' (1220 mm) and

8' (2440 mm) 8' (2440 mm) 8' (2440 mm) 8' (2440 mm)

Pieces per unit for 4' x 8' sheets 50 40 30 24

Weight, nominal lbs./unit, 4' x 8' sheet 2,575 2,575 2,725 2,525

Weight, nominal lbs./sq. ft. 1.57 1.96 2.76 3.20

Flexural strength, parallel, lbs. min., 40 70 110 161

per ASTM C 473

Compressive strength, psi nominal 1800 1800 1800 1800

Flute spannability per ASTM E 661 2-5/8" 5" 8" 10"

Permeance, perms, per ASTM E 96 30 26 26 24

R Value per ASTM C 518 0.2 0.3 0.5 0.6

Coefficient of thermal expansion, 8.0 x 10

inches/inch °F, per ASTM E 831

Linear variation with change in moisture, 8.0 x 10

inches/inch %RH, per ASTM D 1037

Water absorption, % max, per ASTM C 473 10 10 10 10

Surface water absorption, nominal grams, 1.6 1.6 1.6 1.6

per ASTM C 473

Mold resistance per ASTM D 3273* 10 10 10 10

Bending Radius 25' 25' 25' 30'

*ASTMD3273 Mold Resistance Testing - In independent lab tests conducted on Securock Gypsum-Fiber roof board and Securock Glass-Mat roof board at the time of manufacture per ASTM D3273 Standard Test Method for Resistance

to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber, both panels scored a 10. The ASTM lab test may not accurately represent the mold performance of building materials in actual use. Given unsuitable

project conditions during storage, installation or after completion, any building material can be overwhelmed by mold. To manage the growth of mold, the best and most cost-effective strategy is to protect building products from water

exposure during storage and installation and after completion of the building. This can be accomplished by using good design and construction practices.

4' (1220 mm) 4' (1220 mm) 4' (1220 mm) 4' (1220 mm)

Securock Gypsum-Fiber Roof Board

-6

8.0 x 10-6 8.0 x 10-6 8.0 x 10

-6

8.0 x 10-6 8.0 x 10-6 8.0 x 10

-6

-6

Submittal Job Name

Approvals:

Contractor Date

Product Information

See usg.com for the most

up-to-date product information.

Trademarks

The following trademarks used

herein are owned by United

States Gypsum Company or

a related company:

USG, USG in stylized letters.

Note

Products described here

may not be available in all

Manufactured by

United States Gypsum Company

550 West Adams Street

Chicago, IL 60661

Securock,

geographic markets. Consult

your U.S. Gypsum Company

sales office or representative

for information.

Notice

We shall not be liable for

incidental or consequential

damages, directly or indirectly

sustained, nor for any loss

caused by application of these

goods not in accordance with

current printed instructions or

(800) USG.4YOU (874.4968)

usg.com

for other than their intended

use. Our liability is expressly

limited to replacement of

defective goods. Any claim

shall be deemed waived unless

made in writing to us within

thirty (30) days from the date it

was or reasonably should have

been discovered.

Safety First!

Follow good safety and

industrial hygiene practices

during handling and installation

of all products and systems.

Take necessary precautions

and wear the appropriate

personal protective equipment

as needed. Read material

safety data sheets and related

literature on products before

specification and/or installation.

RF5/rev. 10-11

© 2011, United States Gypsum Company

Printed in U.S.A.

Loading...

Loading...