Page 1

How to Run a Flex RhinoBond

®

Job

THINK OUTSIDE THE SEAMS

With the Flex RhinoBond system, you

have to think differently when it comes to

scheduling and running your job, par-

ticularly when compared to a traditional

mechanically attached installation.

These Best Practice recommendations

are based on several years of Flex

RhinoBond project observation and

Best Practices

evaluation.

It should also be noted that for

improved productivity, a minimum of

two Flex RhinoBond tools should be

used.

FASTENER INSTALLATION

Fasteners MUST be in a straight row in at least

one direction. The more even the spacing, the easier

they are to find under the membrane, and the faster

the installation.

Straight – good

Random – harder to find

Snap chalk lies to layout grid pattern for corners,

perimeter and field. Build an 8' template bar with grid

measurements marked on it to speed up marking for

chalk lines.

REVISED AUGUST 2012 How to Run a Flex RhinoBond Job • Page 1

Page 2

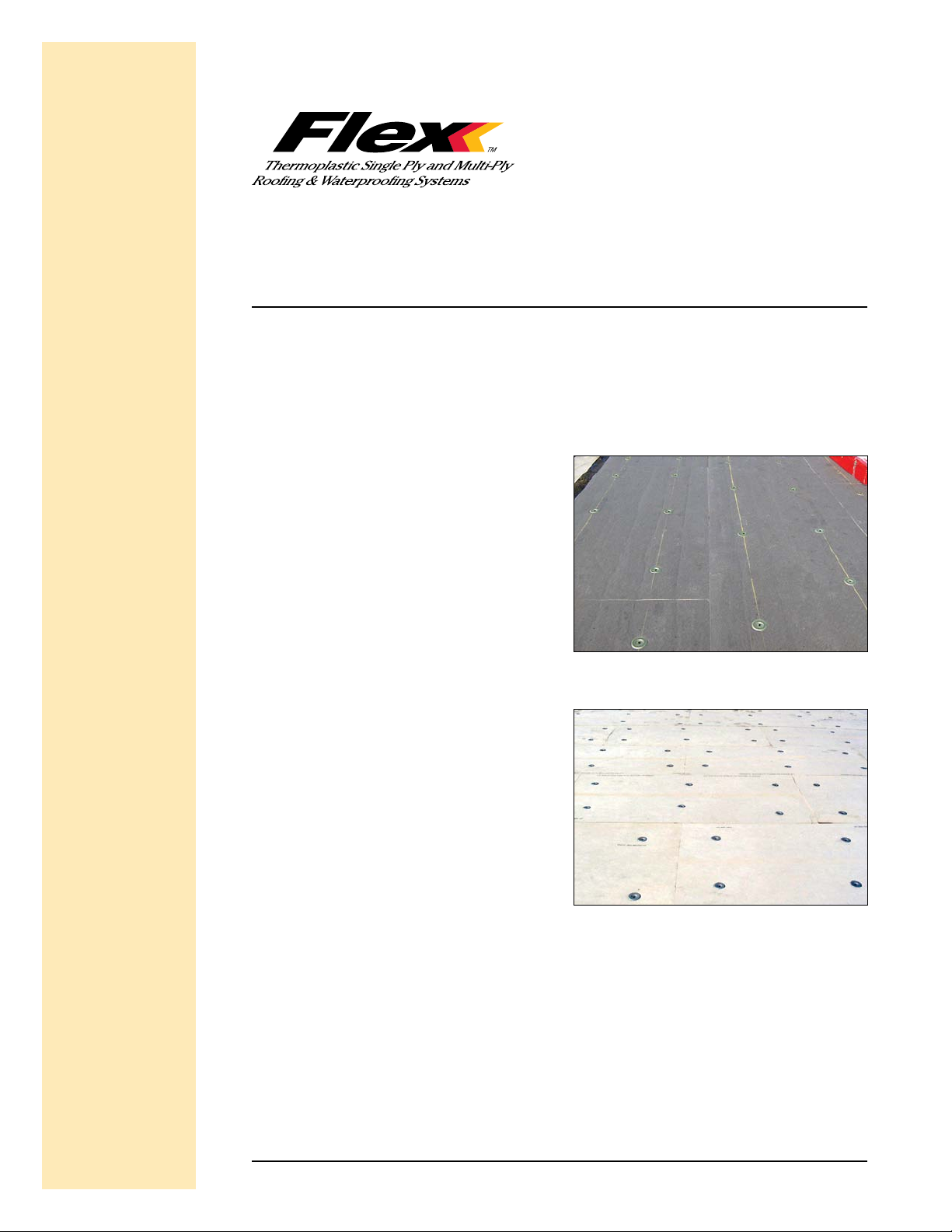

Fasteners must not be overdriven. They should be

tight enough that you can not turn the plates with your

hand. Overdriven fasteners are harder to find, and may

result in a poor or partial bond.

Proper installation

Best Practices

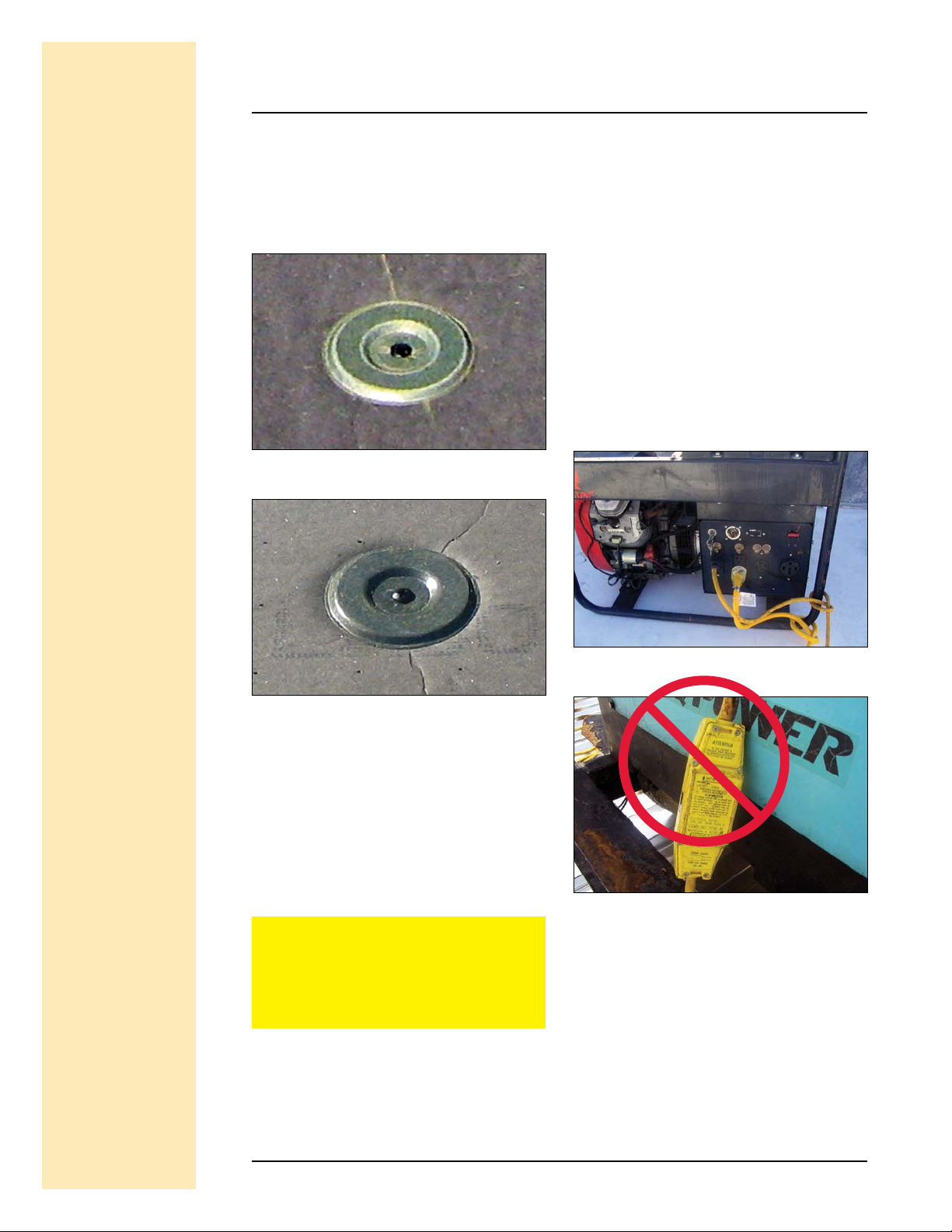

Each Flex RhinoBond tool should run on a dedicated

20A circuit, with no more than 100 feet of good quality

(12 ga. min.) extension cord per tool. Do not plug the

tools into a pigtail, and do not plug them into a 15A

GFCI adapter. Generator power usually works better

than house power because house power often requires

longer extension cords. The tools are designed to run on

105-130V. If the cycle time lasts more than 8 seconds,

check the power source.

Generators should be 5,000 watt (min.) with one 20A

GFCI circuit per tool. Two tools (max.) per 5,000 watt

generator. NO OTHER TOOLS SHOULD BE PLUGGED

INTO DEDICATED FLEX RHINOBOND TOOL

GENERATOR DURING OPERATION.

Overdriven

Position membrane so seams do not pass

directly over Flex RhinoBond plates. It is best to

install the membrane so that the seams are between

the rows of Flex RhinoBond plates. If a seam does

pass directly over a plate, weld the seam and then

bond the membrane to the Flex RhinoBond plate.

POWER REQUIREMENTS

WARNING: Do not plug Flex RhinoBond tool

into generator until the generator is running

at full speed and delivering stable power.

Unstable power during start-up increases the risk

of damage to the Flex RhinoBond tool.

One cord per circuit and per tool

Do not use pigtails

Static interference. If there is a radio on the job

site, you may hear interference (i.e. static) when the

tool is operating. Don’t worry, this is normal. The tool

meets FCC transmission requirements for industrial

tools, but can cause static interference under certain

How to Run a Flex RhinoBond Job • Page 2

Page 3

circumstances, especially if the radio is plugged into

the same circuit as the tool.

TOOL ALIGNMENT

For optimum weld quality, the Flex RhinoBond plate

must be centered under the red dot on the foot of the

tool within 1 inch. This is not hard to do if the operator

pays attention. Best practice is for each new operator

to have a grease pencil, and to outline the base of the

tool on every 10th plate or so, to check the alignment.

After checking the alignment several times, the operator will get the hang of it.

Best Practices

MAGNET ISSUES

Magnet alignment is important. Operators should

make sure the magnet completely covers the plate.

Misalignment will result in less than perfect welds.

Keep the membrane clean. Any debris on the top of

the membrane can be pushed into the surface by the

magnet during the bonding process. Use a leaf blower

to eliminate all debris from the membrane surface

prior to welding.

Keep the magnets clean. If a metal shard or other

debris from the roof sticks to the magnet, it can make

a mark in the membrane on every weld. Therefore,

it’s a good idea to periodically wipe the bottom of

the magnet. As long as the operator and foreman are

paying attention, this should not be an issue.

ALWAYS CALIBRATE THE TOOLS

Calibrate each tool at least once in the morning, and

once after lunch, or whenever the temperature changes

more than +/– 15°F. Use a grease pencil to check alignment when calibrating. Use the up and down arrows on

the Flex RhinoBond tool to change the power level, and

set the tool to the level that provides a 100% bond. Be

sure to allow test assemblies to cool completely before

evaluating bond strength.

The tool must be centered properly over the plate

Train operators to develop the hand-eye coordination

to align the tool consistently.

Evaluate bond strength through calibration

Accurately test weld. When making test welds, be

sure to test the plates in the same assembly used in

the actual installation. As an example, don’t test the

plate on a concrete deck if they are being installed

on polyiso.

How to Run a Flex RhinoBond Job • Page 3

Page 4

WELD IN STRAIGHT LINES

Operator #1 lines all of the magnets up on the first

row. Operator #2 begins work on the adjacent row

after the first operator completes the first five welds.

This procedure helps make sure that the magnets

remain on the plates for at least one minute. This

method also minimizes motion and increases

productivity.

Magnets from the first row are used by the second

operator in the adjacent row. This procedure continues

across the roof.

Best Practices

Work one row after another for maximum productivity

FLEX RHINOBOND STANDING

SEAM RETROFIT PROJECTS

Night before:

Meet with foreman to discuss tool operation and

project coordination. This is KEY!

Day of:

• Load roof

• Fill flutes

• Apply cover board

• Snap lines over purlins

• Apply fasteners and Flex RhinoBond plates

• Blow any debris off cover boards and plates

with a leaf blower

• Roll out membrane (position sheets so seams

do not fall on rows of plates)

• Let sheets “relax”

• Set seam welders for conditions and weld

membrane seams

• Make sure generator is up to full speed and

delivering stable power before plugging in Flex

RhinoBond tool

• Calibrate Flex RhinoBond tools and start bonding

plates

• Ballast any sections that don’t get welded

RP12222 Rev. 0812

Subsequent days:

• 2 guys with Flex RhinoBond tools finish welding

membrane from the previous day

• All other guys in crew repeat the process above.

RESOURCES

Review Flex RhinoBond Owner’s Manual for additional

information.

CONTACT

If you have any questions or need more information, contact the Flex Technical or Sales Department at

1-800-969-0108.

How to Run a Flex RhinoBond Job • Page 4

Flex Membrane International Corp.

2670 Leiscz’s Bridge Road, Suite 400

Leesport, PA 19533 800-969-0108

www.flexroofingsystems.com

RhinoBond® is a trademark of OMG, Inc. Copyright © 2012 OMG, Inc. Used with permission.

Loading...

Loading...