Page 1

Flex Retrofit Drain

PVC Coated Flange Model

PRODUCT DATA SPECIFICATIONS

PRODUCT DESCRIPTION

Constructed of aluminum and stainless

steel components with a large, plastisol

coated flange for hot air welding of Flex

Membrane PVC roof membranes. The drain

flange has a depressed sump area and

an oversized, low profile strainer dome to

facilitate the easy drainage of all water

from the roof surface. The Flex Retrofit

Drain PVC Coated Flange Model incorporates the technology of the RAC Backflow

Compression Seal providing a mechanical

watertight connection.

FEATURES & BENEFITS

• Pre-punched, .080-in. thick, extra large

18-in. x 18-in. aluminum drain flange

with plastisol coating. The coated

flange, provides ample area for hot

air welding of Flex Membrane PVC

membranes, giving a homogeneous

water tight connection.

• 14-in. diameter .080-in. thick aluminum

drain strainer dome.

• 9-in. long drain stem.

• Incorporates the RAC Backflow

Compression Seal.

• Simple and easy to install.

APPlICATION

Flex Retrofit Drains are designed to replace

existing drains in reroofing applications.

Installed from the roof surface, Flex Retrofit

Drains are engineered to be installed without removing the existing plumbing or fixture

while providing a watertight connection to

the roof system and the existing plumbing.

APPROvAlS

& STANDARDS

ANSI/SPRI RD-1 is a national performance

standard for retrofit roof drains. While most

retrofit drains are not tested to this standard,

the Flex Retrofit Drain PVC Coated Flange

Model with RAC Backflow Compression Seal

exceeds the standard, which requires that

the seal hold a 10-ft. column of water for 24

hours without leaking.

IAPMO PS 97-96 – a standard plumbing

industry test designed to check for leakage

at connections under a 10 foot head of

water for a 24 hour period. This test was

performed by the Smith-Emery Company,

a nationally recognized independent test

laboratory providing physical testing of

construction related materials. The Flex

Retrofit Drain produced no leakage.

PHYSICAl DATA

The data below is constant for all Flex Retrofit Drain

PVC Coated Flange Models.

DRAIN BODY SEAL

.080" thick

aluminum

FLANGE STRAINER DOME

18" x 18"

plastisol coated

with sump area

STEM

9" length

Watertight RAC Backflow

Compression Seal requires

7

/16" wrench

14" width, 4" high, made

of .080" thick aluminum;

vandal-resistant

model available

ORDERING INFORMATION

CAT. NO. SIzE DOME TYPE PKG

8020 3" Aluminum Each 32 lbs.

8021 4" Aluminum Each 32 lbs.

8022 5" Aluminum Each 32 lbs.

DIMENSIONAL

WEIGHT

800-969-0108•610-916-9501(Fax)

2670Leiscz’sBridgeRoad,Suite400,Leesport,PA19533

e-mail:flexroof@cs.com•www.flexroofingsystems.com

As with all building materials, it is the responsibility of the installer to review its usage with a design professional to

confirm safety, compatibility and acceptance with the Flex Membrane roof system as well as local building codes.

8041 6" Aluminum Each 32 lbs.

MADE IN USA

RP12104 Rev. 0512

Page 2

Flex Retrofit Drain

PVC Coated Flange Model

INSTAllATION PROCEDURE

FOR USE WITH

Flex PVC membrane roof systems.

JOB PREPARATION

The existing leader pipe shall be cleaned

of excess bitumen build-up, dirt and debris.

Remove the clamping ring assembly and bolts

from the existing drain and discard. If required,

comply with roof manufacturer’s directions for

additional cleaning or detailing.

STEP 1

Important – The aluminum activation cone

may have settled into the backflow seal during

shipping which may partially activate the seal.

To deactivate the seal, simply push down on the

top of the two backflow bolts. Note: The top

of the tapered metal cone should remain inside

the bottom of the urethane seal. Do not fully

disengage cone from urethane seal.

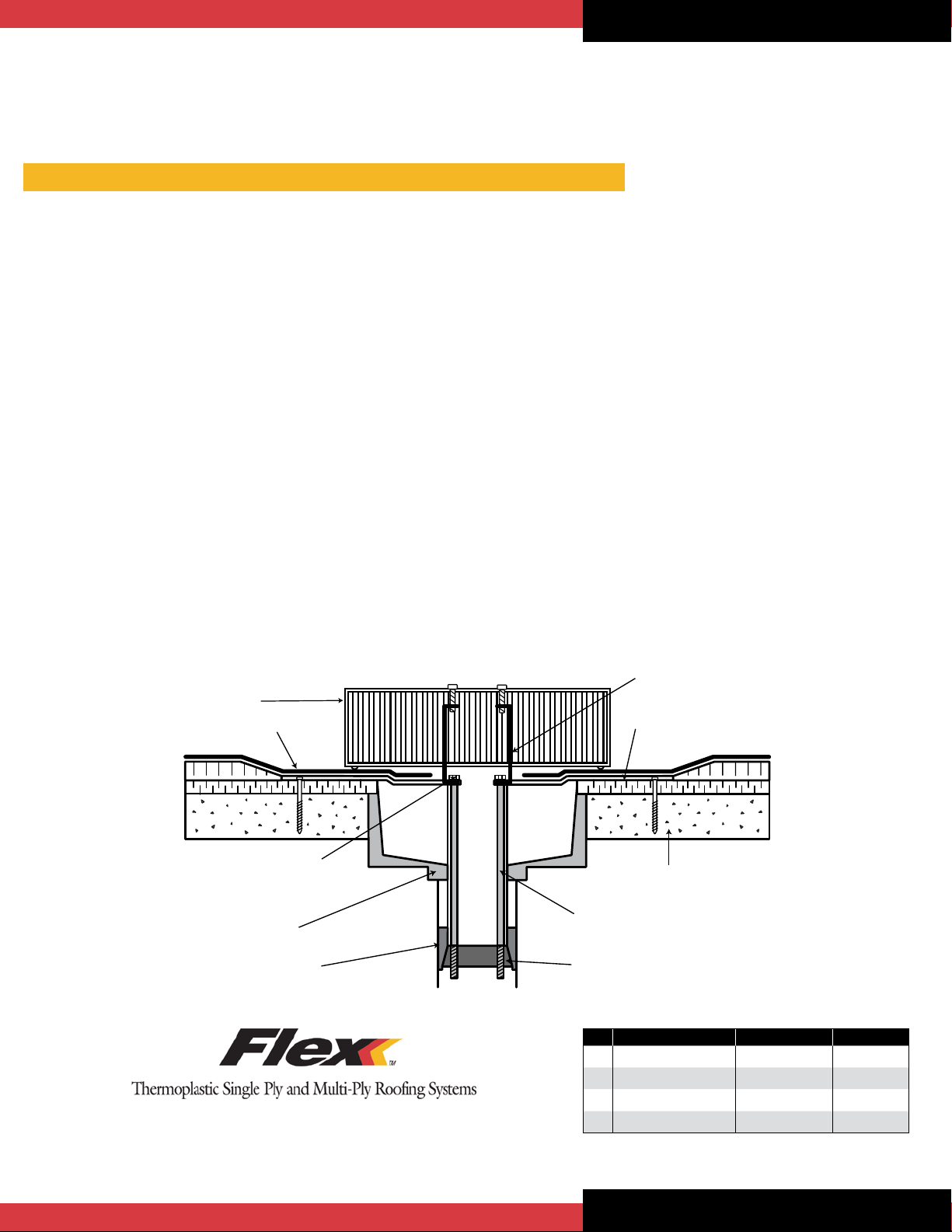

Drain Strainer

Roofing System

STEP 2

Install the Flex PVC membrane over the existing

drain location. Cut a hole in the membrane the

same diameter as existing leader pipe. The

hole should be centered over the existing pipe

opening and accommodate the O.D. of RAC

drain pipe to be installed.

STEP 3

Lower the RAC PVC Drain Assembly into the

existing drain leader pipe until the underside

of the drain flange sits flat on the roof. Using

the pre-punched holes in the perimeter of the

flange, secure the drain flange to the substrate

with appropriate fasteners.

STEP 4

Hand tighten the 7/16-in. bolts on the backflow

rods to activate the seal. Alternate tightening

between the bolts for an even seal. Rods should

be snug when fully activated. Do not over tighten.

STEP 5

Clean membrane and drain flange surfaces. Hot

air weld the flashing membrane to the coated

drain flange and to the surrounding field sheet.

Flashing membrane should extend onto field

sheet a minimum of 4 inches.

STEP 6

Place the drain strainer over the two strainer

securement brackets, lining the brackets up

with the two 5-in. long slots in the top of the

strainer. Install stainless steel bolts and washers

(provided) into the securement brackets with a

7

/16-in. wrench. Tighten nuts snugly into position.

For technical assistance contact

Flex at 800.969.0108 or fax 610.916.9501.

Strainer Securement Brackets

PVC Coated Pre-Punched

Drain Flange

7

/16" Stainless Steel Bolt

Heads for Activation of

the Backflow Seal

Existing Drain Bowl

Compressible Urethane

Backflow Seal

800-969-0108•610-916-9501(Fax)

2670Leiscz’sBridgeRoad,Suite400,Leesport,PA19533

e-mail:flexroof@cs.com•www.flexroofingsystems.com

As with all building materials, it is the responsibility of the installer to review its usage with a design professional to

confirm safety, compatibility and acceptance with the Flex Membrane roof system as well as local building codes.

Roof Decking

Stainless Steel Rods for

Backflow Seal Activation

Cast Aluminum Activation Cone

SEAl EXPANSION CAPACITY

SIzE O.D. OF PRE-EXPANDED SEAL FIT INTO MIN. PIPE I.D. FULLY EXPANDED

3" 2.75" 2.77" 3.12"

4" 3.85" 3.87" 4.20"

5" 4.81" 4.83" 5.12"

6" 5.85" 5.87" 6.30"

O.D. = Outside Diameter I.D. = Inside Diameter

Due to manufacturing variances and job site inconsistencies, these figures

are guidelines and are not guaranteed.

Loading...

Loading...