Page 1

Page 2

TABLE OF CONTENTS

Introduction ......................................................................................1

Box Contents ....................................................................................1

Replacement Parts Listing............................................................2

Completion Items ..........................................................................2

Specications.................................................................................... 2

Battery Charging Guidelines.......................................................2

Special Language Denitions.....................................................3

Important Information Regarding Warranty......................... 3

Safety Warnings and Precautions..............................................3

Low Voltage....................................................................................... 3

Main Landing Gear Installation..................................................4

Tailwheel Installation.....................................................................4

Horizontal Stabilizer Installation................................................5

Main Wing Installation................................................................... 6

Aura 8 ACFS.......................................................................................7

Receiver Installation/Servo Connections................................7

Transmitter Setup............................................................................8

Connecting Battery/Arming ESC ...............................................8

Flight Control Direction Sensing Test.......................................9

Control Direction Test..................................................................10

Linkage Setup.................................................................................10

SFG Installation ..............................................................................11

Propeller/Spinner Installation...................................................11

Battery Installation........................................................................12

Center of Gravity............................................................................12

Flying your QQ Extra 300............................................................13

Learning to Fly 3D with the QQ Extra 300............................13

Airframe Repairs ............................................................................14

Replacing Servos ...........................................................................14

Servicing the Power System......................................................15

Optional Wheelpant Removal ..................................................15

Aircraft Troubleshooting Guide................................................16

Limited Warranty...........................................................................17

AMA Safety Code...........................................................................18

1

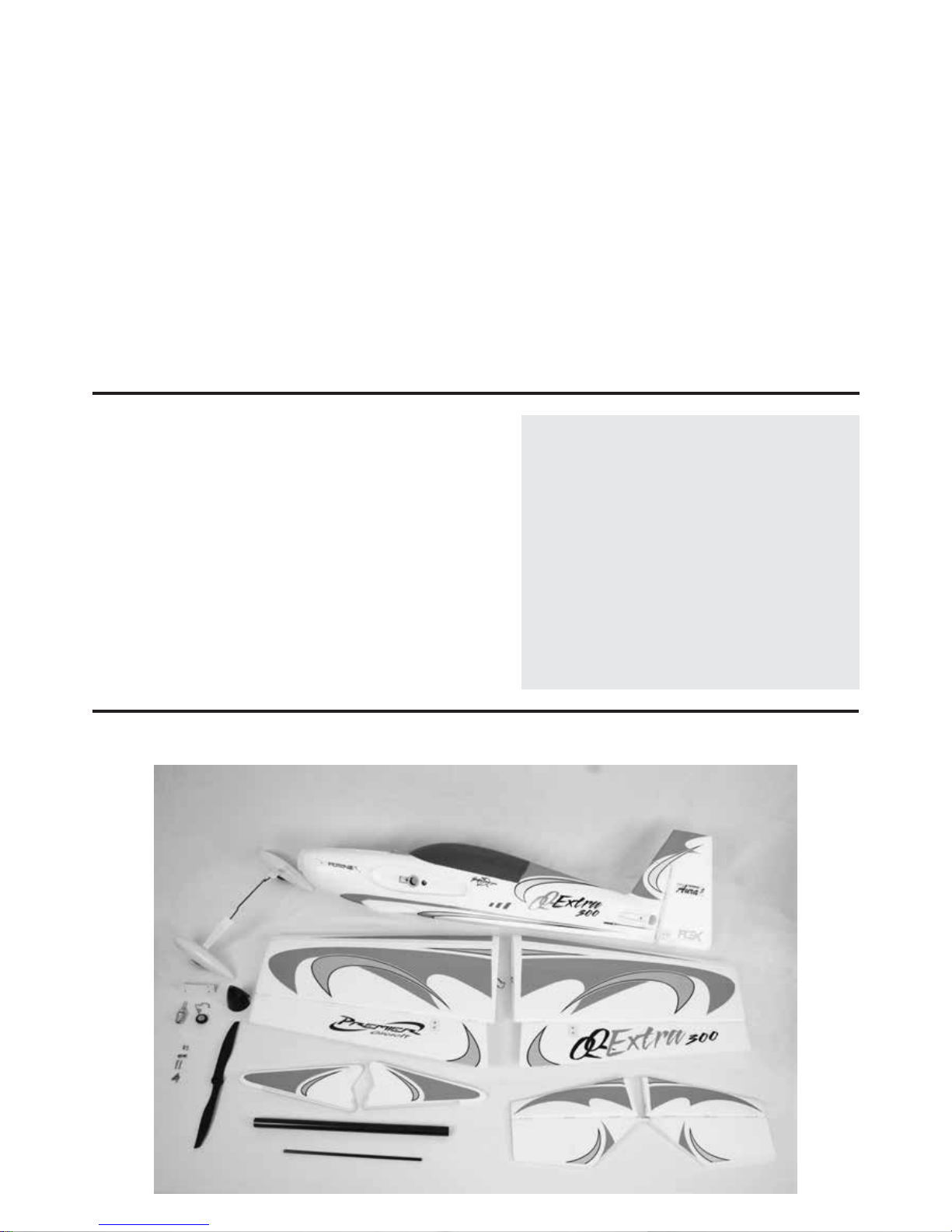

BOX CONTENTS

INTRODUCTION

QQ Extra 300 and Aura 8: the perfect combination!

The QQ Extra 300 - it is the evolution and accumulation of many years of

experience in the aerodynamic and electronic control stabilization world.

A perfectly balanced airframe design combined with today’s most

advanced control system gives an unmatched ying experience.

Pilots will feel smooth, precise aircraft control without any interference to

pilot inputs. The aircraft will y as if it were much larger, turbulent air will

be less noticeable, rotations will stop more precisely and landing will be

easier to execute. Flex Innovations has tuned and matched both to their

best potential, however, the Aura 8 programming capability allows total

freedom to the pilot to adjust (including setting ight modes that can

switch it o). USB rmware update capability allows you to enjoy and

benet from the latest features and advancements.

§ Available in blue/yellow and red/silver schemes

§ Low wing loading oers superb stability at slow speed

§ Custom-tuned Aura 8 gyro stabilization

system provides the ultimate in stability and control

§ Powerful 10-sized motor provides the punch for

demanding aerobatics

§ High-precision digital servos with full metal gears

§ Light weight EPO foam is sti and tough

§ Hollow carbon and plywood-reinforced wing is

sti and lightweight

§ CA hinges for high throw and low resistance

§ Custom-designed control horns to maximize control

surface throw and precision

§ Wheel pants to enhance the scale looks

Page 3

FPM3070A QQ Extra 300 Super PNP Blue Scheme

FPM3070B QQ Extra 300 Super PNP Red Scheme

FPM307001 QQ Extra 300: Fuselage

FPM307002 QQ Extra 300: Wing set SFG Included

FPM307003 QQ Extra 300: Tail set

FPM307004 QQ Extra 300: Hatch set / Cowling

FPM307005 QQ Extra 300: Landing gear set

FPM307006 QQ Extra 300: Tube Joiner set

FPM307007 QQ Extra 300: Pushrod set

FPM307008 QQ Extra 300: Red/Silver Decal Set

FPM307009 QQ Extra 300: Blue/Yellow Decal set

FPM307010 2 Blade black spinner 55mm

FPZM1010A1 5mm Collet Prop Adapter

FPZM1010A2 Potenza 10 Aluminum X-Mount

w/Screws

FPZM1010A3 Potenza 10 5mm Motor Shaft W/Collar

2

REPLACEMENT PARTS LISTING

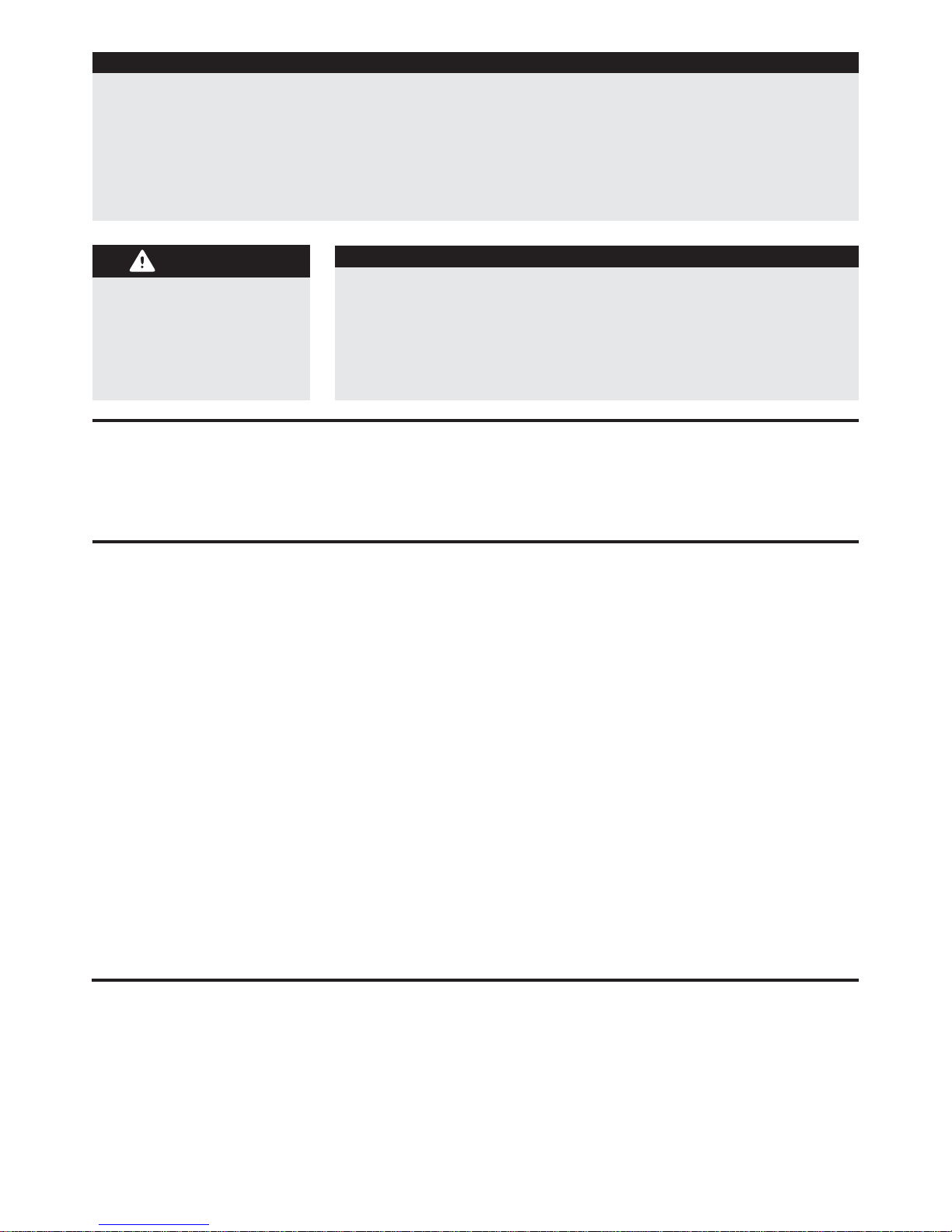

BATTERY CHARGING GUIDELINES

The assembly of the QQ Extra 300 can be accomplished in

less than twenty minutes, even for a novice. Prior to

assembling the airplane, it is advisable to charge your

battery so that you are ready to y upon completion of the

assembly of your model.

We recommend the use of an advanced LiPo balancing

charger, such as our Potenza C80 Multi Chemistry Touch

Screen AC/DC balancing charger for your batteries to get

the maximum performance and lifespan from them.

Our airplanes are designed around our Potenza LiPo

batteries and we recommend the Potenza 3S 2200mAh 40C

LiPo in the QQ Extra 300 based on our extensive testing and

development. This battery features an EC3 connector, so no

soldering is required for use in your Extra.

Both are available at your Flex Innovations retailer.

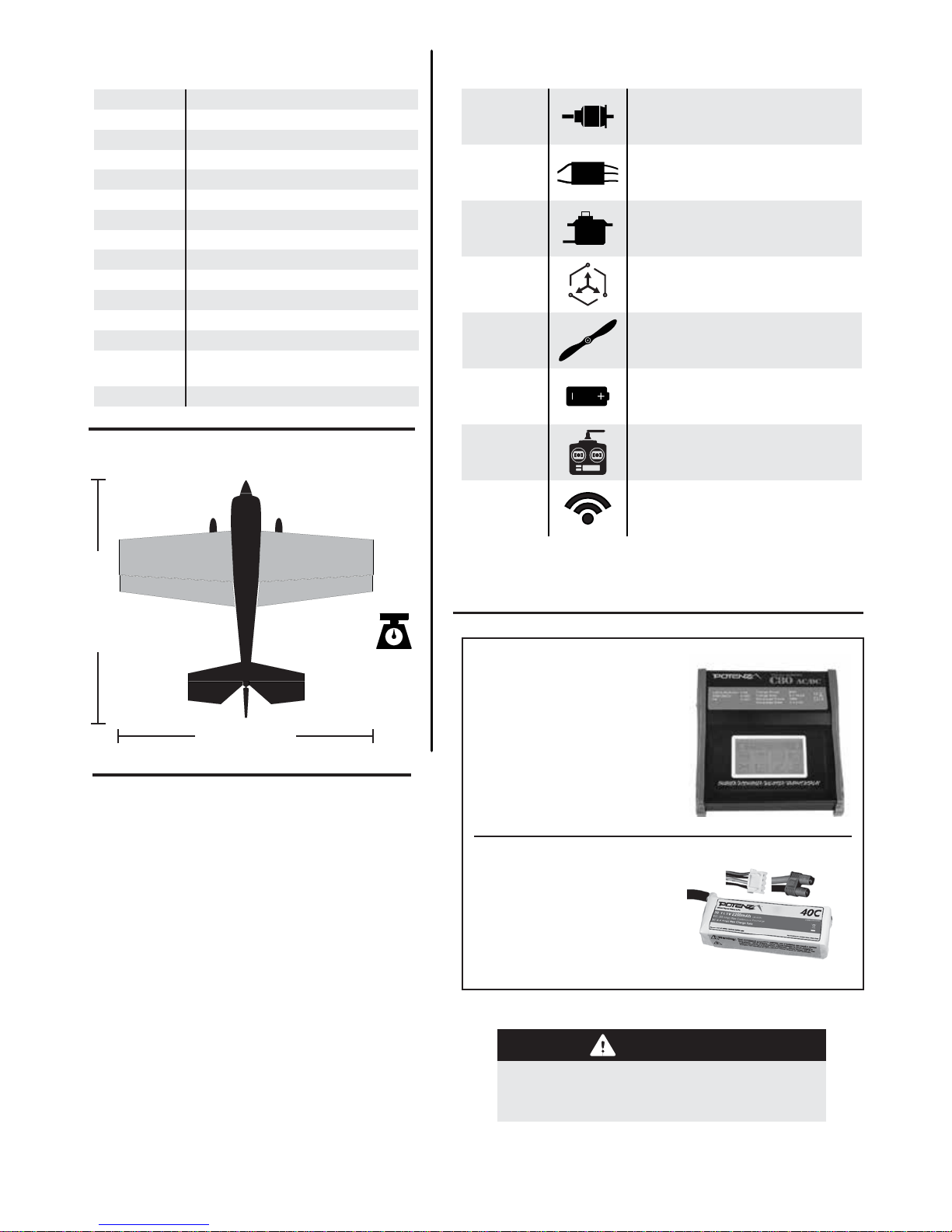

SPECIFICATIONS

47.8 in (1215mm)

47.8 in (1215mm)

572.5 sq. in

(39.95 dm2)

48.0 oz (1360g)

RTF with battery installed

INSTALLED!

INSTALLED!

INSTALLED!

NEEDED TO

COMPLETE

NEEDED TO

COMPLETE

2200mAh 3S 11.1v 40C LiPo

(FPZB22003S40 )

3S 11.1v 2100-3300mAh minimum 30C LiPo

6-Channel Computer Transmitter*

Potenza 10 1350 Kv Brushless

Outrunner Motor (FPZM1010A)

HobbyWing SkyWalker 40A ESC

w/ 3A BEC (FTVHWBQ8004B)

INSTALLED!

Aura 8 Advanced Flight Control System

(FPZAURA08)

Potenza DS19 Digital Full Metal

Gear 19g Servo (FPZDS19)

DSM2/DSMX satellite

S.Bus Futaba/Graupner HOTT/ JR XBus Rx

5+ Channel RX (any brand)

NEEDED TO

COMPLETE

COMPLETION ITEMS

WARNING

FOLLOW ALL INSTRUCTIONS PROVIDED BY YOUR

BATTERY AND CHARGER MANUFACTURER. FAILURE

TO COMPLY CAN RESULT IN FIRE.

Large touch screen and intuitive software for

ease of use

Convenient AC/DC operation

Multi-chemistry operation charges LiPo (1-6S),

LiFe (1-6S), Li-Ion (1-6S), NiMH (1-16 cells),

NiCd (1-16 cells), Pb (1-10 cells) batteries

Automatic lithium chemistry balance charge

cell detection

10 pre-programmed memory programs and 8

user-programmable memories

Potenza C80 AC/DC Charger

(FPZC80)

Potenza 3S 2200mAh 40C LiPo

(FPZB22003S40)

§

§

§

§

§

Capable of up to 40C (88.0A) maxmium

continuous discharge

JST-XH balance connector and EC3 power

lead connector are compatible with a wide

range of aircraft and chargers

Maximum 3C (6.6A) charge rate

§

§

§

INCLUDED!

SR 11.5x4.5 Thin Electric Propeller

(FPMP11545E)

*DX4/5e class transmitter supported with special model program download

Page 4

3

NOTICE: Procedures, which if not properly followed, create a possibility of physical property

damage AND a little or no possibility of injury.

CAUTION: Procedures, which if not properly followed, create the probability of physical

property damage AND a possibility of serious injury.

WARNING: Procedures, which if not properly followed, create the probability of property damage,

collateral damage, and serious injury OR create a high probability of serious injury.

ATTENTION

Read the ENTIRE instruction manual to become familiar with the features of the product before

operating. Failure to assemble or operate the product correctly can result in damage to the

product, personal property, and cause serious or fatal injury.

All instructions, warranties and other collateral documents are subject to change at the sole

discretion of Flex Innovations, Inc. For up-to-date product literature, please visit our website at

www.exinnovations.com and click on the QQ Extra 300 and Aura 8 product pages.

SPECIAL LANGUAGE DEFINITIONS

The following terms are used throughout the product literature to indicate various levels of potential harm when operating this product:

WARNING

This product is not intended for use by

children under 14 years without direct

adult supervision.

AGES 14+

IMPORTANT INFORMATION REGARDING WARRANTY

Please read our Warranty and Liability Limitations section before building this product. If you as the Purchaser or user are not prepared to

accept the liability associated with the use of this Product, you are advised to return this Product immediately in new and unused condition

to the place of purchase.

SAFETY WARNINGS AND PRECAUTIONS

Protect yourself and others by following these basic safety guidelines.

1. This manual contains instructions for safety, operation and maintenance. It is essential to read and follow all the instructions and warnings

in the manual, prior to assembly, setup or use, in order to operate correctly and avoid damage or serious injury.

2. This model is not a toy, rather it is a sophisticated hobby product and must be operated with caution and common sense. This product

requires some basic mechanical ability. Failure to operate this product in a safe and responsible manner could result in injury or damage

to the product or other property.

3. This model must be assembled according to these instructions. Do not alter or modify the model outside of these instructions provided by

Flex Innovations, Inc, as doing so may render it unsafe and/or unyable. It is your responsibility to ensure the airworthiness of the model.

4. Inspect and check operation of the model and all its components before every ight.

5. If you are not an experienced pilot or have not own a high-performance model before, it is recommended that you seek assistance from

an experienced pilot in your R/C club for your rst ights. If you’re not a member of a club, the Academy of Model Aeronautics (AMA) has

information about clubs in your area whose membership includes experienced pilots.

6. Keep the propeller area clear from such items such as loose clothing, jewelry, long hair, or tools as they can become entangled. Keep your

hands and body parts away from the propeller as injury can occur.

7. Never y in visible moisture or submerge the airplane or any of its electronic components in water. Permanent damage to electronic

components may occur, or corrosion of components may lead to intermittent failures.

LOW VOLTAGE CUTOFF

LiPo batteries have a nominal (rated) voltage of 3.7v per cell, and fully charged, reach 4.2v per cell. Batteries are designed to be discharged

below the nominal voltage, however, if they are discharged below 3.0v per cell, damage will occur and the pack will lose capacity. For best

long term battery life, set a timer and land after a time that leaves approximately 15% of the battery’s capacity remaining.

Low voltage cuto is a feature that is built into the Hobby Wing SkyWalker 40A ESC that is designed to protect the connected battery from

being discharged too far and causing permanent damage to the cells. Circuitry within the ESC will automatically detect when the input

voltage from the battery pack reaches below 3.15v per cell (average) and will remove power to the motor, but still deliver power to the

servos so that a safe landing may be made. If the motor begins to lose power rapidly during ight, the LVC has sensed that the total voltage

of the pack has dropped below 3.15v per cell average, and the airplane should be landed immediately.

Page 5

4

MAIN LANDING GEAR INSTALLATION

Required Tools and Fasteners: #1 Phillips Screwdriver, (4) M1.5x5 self-tapping screws

1. Insert the landing gear assembly into the slot in the bottom of the fuselage. The gear will sweep forward.

2. Install the cover plate over the landing gear slot and attach with (4) M1.5x5mm self-tapping screws.

TAILWHEEL INSTALLATION

Required Tools and Fasteners: #1 Phillips Screwdriver, (3) M1.5x5 self-tapping screws

1. Insert the tailwheel assembly in the slot in the bottom of the rudder.

2. Install the cover plate over the tailwheel slot and attach with (3) M1.5x5mm self-tapping screws.

Page 6

5

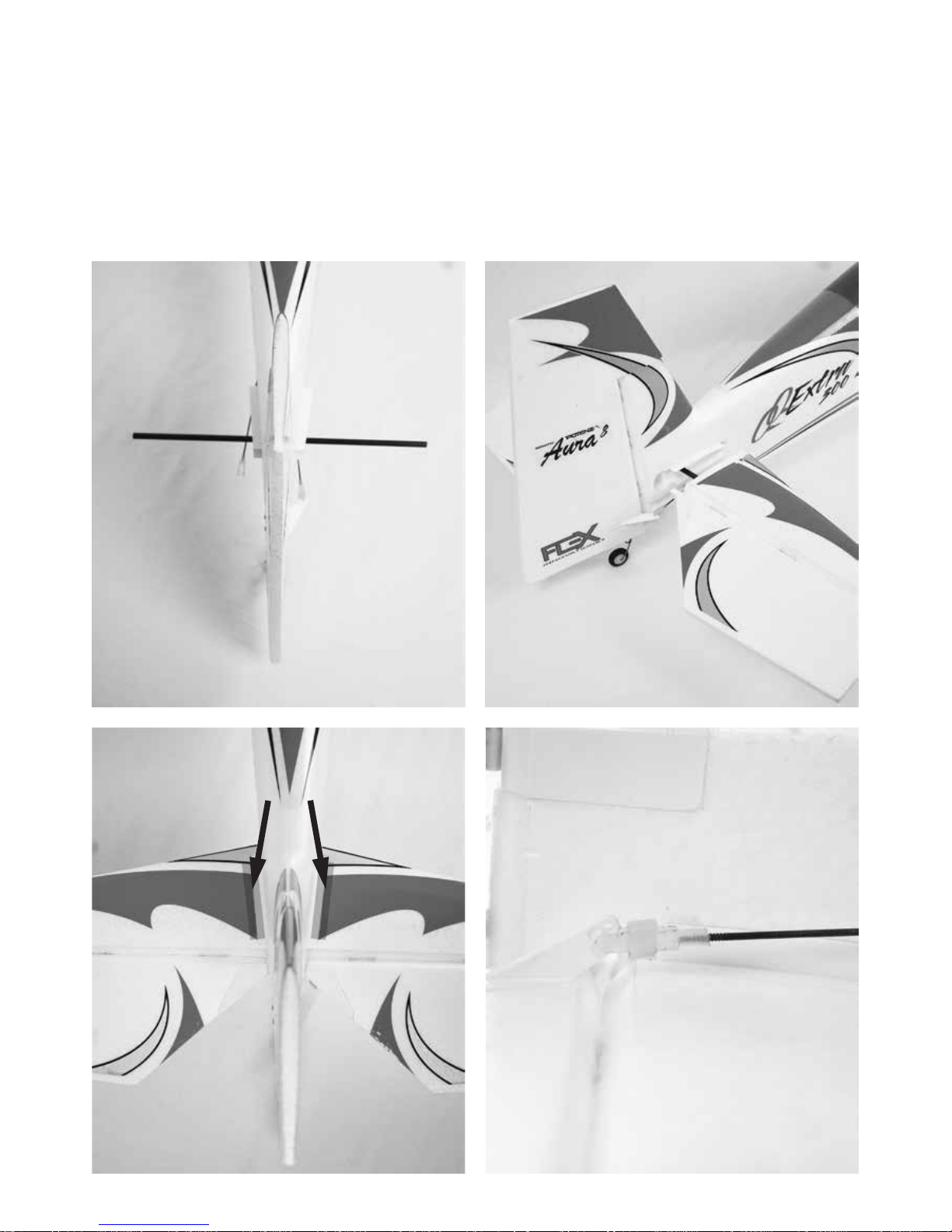

HORIZONTAL STABILIZER INSTALLATION

Required Tools and Fasteners: Clear Tape (4 strips)

1. Insert the horizontal stabilizer tube into the fuselage and roughly center.

2. Slide the left and right stabilizer halves onto the tube. Ensure that the control horn orients towards the belly of the airplane and that the

elevator joiner tabs are properly indexed. Do not force the stabilizer into place.

3. Apply 4 pieces of clear tape to the joint between the stabilizer and the plastic mounts. Be sure to apply tape to both the top and bottom.

4. Attach the clevis to the elevator control horn in the innermost hole. Slide the clear tubing over the forks.

TOP AND BOTTOM

Page 7

6

MAIN WING INSTALLATION

Required Tools and Fasteners: #1 Phillips Screwdriver, (2) M2.5x10mm self-tapping screws

1. Remove the belly hatch by peeling back the tape at the rear of the hatch.

2. Install the wing tube into the fuselage.

3. Slide the left or right wing panel on the wing tube and guide the servo wire into the fuselage.

4. Invert the airplane so that the belly is facing up. Secure the wing to the fuselage with (1) M2.5x10mm self-tapping screw.

5. Slide the wing tube into the installed wing panel until it bottoms out. DO NOT FORCE THE TUBE INTO THE WING.

6. Slide the other wing panel guiding the servo wire into the fuselage.

7. Secure the wing to the fuselage with (1) M2.5x10mm self-tapping screw.

8. Use a small piece of music wire with tip hook shape to sh the aileron servo lead thought the hole as shown in picture below.

NOTE- Take special caution to prevent the aileron servo extension from being pinched when installing the wing panels.

Page 8

7

RECEIVER INSTALLATION/SERVO CONNECTIONS

For the latest Aura Features, programs, transmitter downloads, and instructions, please visit www.exinnovations.com/aura.

To connect

modern data-linked receivers, follow these instructions. For traditional PWM receivers, refer to the connection diagram at the bottom.

1. Plug the left aileron servo into the S2 port on the Aura 8 and the right aileron servo into the S3 port.

2. Install the receiver in the fuselage using either Velcro tape or double-sided foam tape (not included)

3. Connect the receiver to the Aura 8 using the appropriate connection illustrations below.

DSM2/DSMX REMOTE RECEIVER

Connect one remote DSM2/DSMX receiver to antenna port ‘A’ on

the side of the unit. Attach the remote receiver securely to the

fuselage using hook-and-loop tape or double sided foam tape.

PWM (TRADITIONAL) RECEIVER PORT CONNECTIONS

Refer to the chart below for channel mapping for traditional

receiver connections for receivers not specically supported.

Male to male extensions* are used for the following connections.

Lead to ESC/BEC

Leads to ight

control servos

ESC WILL CONNECT DIRECTLY TO

THE RECEIVER. NO CONNECTION

FROM THE AURA TO RECEIVER

WILL BE MADE FOR THE ESC.

CONTROL SURFACE

AURA 8

RECEIVER

AURA 8

CH 5 (Gear) S4

Aileron

S1

Rudder

S3

Left Aileron

S5

Right Aileron

S6

Rudder

S8

Elevator

S7

Elevator S2

CONNECTIONS IN CONNECTIONS OUT

§ Works conveniently with all major radio systems

§ Accepts signals from DSM Satellite(s), Futaba S.Bus ,

Graupner Hott, JR XBus, PPM stream, or any brand of

Rx via male to male servo connectors

§ Expertly tuned and ready to use

§ USB port allows loading model congurations, user

programming, and rmware updates (cable included)

§ Flexible and extensive programming through PC or

mobile device (iPhone®/Android™)

§ 3+ ight modes allow precise or aggressive settings to

be selected in ight

§ 3-axis gyro utilized in QQ Extra 300 programming

§ Powerful 32-bit processor and 6 axis sensor for future

updates and re-use

The Aura 8 advanced ight control system installed in your QQ Extra 300

is a giant leap forward in aircraft ight control system technology.

Compatible with virtually every receiver on the market today via PWM

connections, the Aura features special conguration for DSM systems

via remote receiver connection, and serial data connection for Futaba

S.Bus, Graupner HOTT, and JR XBus systems.

The Aura 8 advanced ight control system in your QQ Extra has been

pre-tuned for ease of use, eliminating many hours of setting gains.

For

the latest Aura Features, programs, transmitter downloads, and

instructions, please visit www.exinnovations.com/aura.

The Aura is programmable through either PC or mobile device and

every axis has independent gain adjustment and by each ight mode.

All dual rate, expo, travel, and mode programs are adjusted inside the

Aura through the PC/mobile application. An assignable master gain

that is OFF by default can be enabled by the Aura application. If

desired, assign it to CH 8/AUX 3 on a proportional dial or slider.

By default CH5/Gear is used to select the 3 ight modes by 3 position

transmitter switch.

AURA 8 ACFS

*(FPZAU01 3pc Male to Male Servo Cable/S.Bus) not included | ‡ non-PWM connections

FUTABA S.BUS/GRAUPNER HOTT/JR XBUS CONNECTION

Connect the included male to male extension to the receiver’s data

port and connect to port ‘B’ on the face of the unit. Refer to your

radio manufacturer’s instructions for specic information on

appropriate serial port connections and system settings.

DEFAULT CONNECTIONS ‡

S1 Throttle (ESC/BEC)

S2 Left Aileron

S3 Right Aileron

S4 Elevator

S5 Rudder

Page 9

8

CAUTION

Always connect the battery when the throttle and

throttle trim are in the cut-o position.

Observe the following procedures to safely power up your

model after it has been bound. Ensure propeller is removed

unless sequence is followed to power up before ight.

1. Lower the throttle stick and trim to their lowest setting

and turn on the transmitter. Wait for your transmitter to

indicate the RF signal is being broadcast before proceeding.

If a battery is connected to the ESC with the throttle fully

open on the active transmitter, the ESC will enter into

programming mode. If this occurs, simply disconnect the

battery, lower the throttle, and reconnect the battery.

2. Ensure the rudder, elevator, and aileron gimbals are

centered.

3. With the airplane on a solid surface; connect the battery

tothe ESC and wait. The ESC will emit a series of audible

tones during its initialization process.

4. The ESC will emit a short, nal tone sequence indicating

that the ESC is now armed.

CONNECTING BATTERY/ARMING ESC

WARNING

When making adjustments to linkages, transmitter

settings, or the Aura 8 ight control system, remove the

propeller to guard against accidental spool up.

WARNING

Hold aircraft securely when connecting the battery before

ight. Always ensure that the propeller is clear of any and all

objects as they may become entangled.

TRANSMITTER SETUP

The Aura 8 on QQ Extra 300 defaults to 3 ight modes that are

changed via transmitter CH5/Gear which is assigned to a 3-position

switch of your choice.

TRANSMITTER CONFIGURATION GUIDE

ATV Setup

Sub Trim

125%

Aileron/Elevator/Rudder

Throttle

100%

Trim Levers

Veried neutral, sub trim not allowed

Veried neutral

CH 5 (Gear) Assigned to a 3-position switch

All channels normal

Reversing

Aileron

Elevator

Rudder

Mode 3Mode 1

‡Aura 8

Rate Setup

‡Aura 8

Expo Setup

Aileron

Elevator

Rudder

40%

25%

100%

Mode 2

38%

25%

100%

100%

100%

100%

Mode 3Mode 1

30%

25%

25%

Mode 2

15%

10%

20%

30%

25%

5%

AURA CONFIGURATION REFERENCE

WARNING

DO NOT ATTEMPT RADIO SETUP WITH PROPELLER INSTALLED. INADVERTENT POWER UP COULD CAUSE PERSONAL INJURY.

Set to 4:30 for initial ights*Timer

*The QQ Extra 300 can y anywhere between 4:00 to 6:30 depending on ying style

‡ The shown Aura 8 settings are pre-congured and the unit is ready to use. The chart shown is for

information purposes only. No additional action is required to y the airplane.

For large (>5%) changes in expo, either (1) make a change in the

Aura programming, or (2) zero expo values in the Aura and rely on

transmitter programming for expo values.

After intial setup is complete, power up the model and bind the

receiver to the transmitter using the instructions provided by the

radio manufacturer.

To bind a DSM connection utilizing a remote receiver, insert a bind

plug in Aura port S8. Power the model and follow the instructions

from the transmitter manufacturer. Remove and store bind plug to

complete the process.

Description of Pre-Loaded Aura Flight Modes

Mode 1: Flight Control system is o. Rates are set for general

ight (same as FM 2). Exponential is tuned for comfortable ight.

Mode 2: Flight Control system is on. Gains are moderate and

tuned for comfortable feel/best performance for precision

aerobatics. Expo is tuned for comfortable ight.

Mode 3: Flight Control system is on. Gains are highest and tuned

for 3D aerobatics. Rate are set to highest. Exponential is tuned for

comfortable ight.

Each of the modes has been tuned by our team to oer a solid

start. Because tastes in control feel are unique, if changes in rate

and expo are needed adjustments may be made through either

the transmitter or Aura 8. Changes on gain value may only be

made through the Aura.

Page 10

9

Aircraft

Movement

Proper Control

Surface Deection

AILERON

RUDDER ELEVATOR

FLIGHT CONTROL SENSING DIRECTION TEST

Perform a test of the gyro system to verify the corrections made for a given movement are correct. If any of the tests do not result in the

correct reaction from the airplane’s gyro system, do not y the airplane, and refer to the Aura 8 manual for more information.

The ight control system activates with RF broadcast. Perform these tests in Mode 3 (higher gain) for better visibility and then in Mode 2,

and any other modes that have gyro gains assigned. (By default, Mode 1 has no gain assigned.). Control surface deections are exagerated in

the drawings below for clarity.

Page 11

10

CONTROL DIRECTION TEST

Refer to the chart at right to determine the proper control

surface direction. Reversed controls may be corrected in

either the transmitter’s servo reverse menu or through the

Aura 8 app in the outputs section.

After any adjustments, repeat the ight control sensing

direction test, and the control direction test to conrm

that all control surfaces respond according to the correct

corresponding stick movement.

AILERONRUDDER ELEVATOR

Transmitter

Command

Proper Control

Surface Deection

Stick Left

Stick Right

Stick Forward

Stick Aft

Stick Left

Stick Right

LINKAGE SETUP

Adjust the control linkages so that the surfaces are neutral with zero trim and zero subtrim. Adjustments may be required during ight

trimming − for more information, please refer to the trimming section located on page 13 of this manual.

At the servo, the stock linkage attachment is a Z-bend located in the outermost hole in the servo arm for the rudder, the second hole in

from the outside for the elevator, and the third hole in from the outside for the ailerons.

At the control horn, the stock attachment is a nylon clevis located in the outermost hole for aileron, and innermost hole for rudder/elevator.

SERVO ARMS

AILERONSELEVATOR

RUDDER

CONTROL HORNS

AILERONSRUDDER/ELEVATOR

Page 12

11

PROPELLER/SPINNER INSTALLATION

Required Tools and Fasteners: #1 Phillips Screwdriver, 13mm Box Wrench, M3x6mm machine screw

1. Insert the prop collet onto the motor shaft. Ensure that it is fully seated.

2. Temporarily remove the prop nut and washer and install the propeller with the convex surface facing forward. The propeller size numbers

are printed on the front face of the prop and should orient forward.

3. Slide the prop washer on the collet with the widest face aft, and tighten the prop nut.

NOTICE

Because the spinner does not have a backplate, spin the motor over by hand to ensure that the spinner is true after installation.

SFG INSTALLATION

1. Liberally apply medium CA (cyanoacrylate adhesive) to the airfoil-shaped mounting plate on the inside of the SFG.

2. Insert the SFG into the molded cavity in the wingtip and press tightly. NOTE- the plastic skid is on the BOTTOM of the SFG.

Page 13

12

CENTER OF GRAVITY

The location of the center of gravity for the QQ Extra

300 is aligned with the FRONT EDGE of the RADIO

HATCH. This measurement was determined from

many test ights by designer and many time world

aerobatic champion, Quique Somenzini. Lift the

airplane from the underside of the wing to check the

CG.

Setting the center of gravity is one of the most

important steps for success, particulary with a new

airplane. The Extra is a high-performance airplane

with large control surface throws, and a high thrust to

weight ratio. These two factors combined make it a

very enjoyable aircraft to y, but if the center of

gravity is not within an acceptable range, it will make

the airplane dicult, if not impossible, to control.

NOTICE

The CG measurement should be made with

the completed airframe with all components

(

batteries, servos, receiver, linkages, screws,

bolts, hardware, etc.) installed. Failure to do

so will result in inaccurate measurement.

BATTERY INSTALLATION

1. Push the spring-loaded battery latch tab back to release the battery hatch.

2. OPTIONAL- Apply a strip of adhesive-backed hook-and-loop fastener (not included) to the bottom of your battery and battery tray.

3. Press the battery to the center of the battery tray and secure with the provided hook-and-loop strap.

4. Reinstall the hatch, and conrm that the latch has positively engaged.

CAUTION

Always keep limbs clear from the propeller when the

battery is connected. After the ESC arms, the propeller

will rotate when the throttle is moved. Unlike an internal

combustion engine, electric motors apply more voltage

to counteract resistance, therefore any object that is

entangled in the propeller will be severely damaged

before the motor will stop

WARNING

When making adjustments to linkages, transmitter

settings, or the Aura 8 ight control system, remove

the propeller to guard against accidental spool up.

Page 14

13

The QQ Extra 300 was designed from the ground up to be a

superior 3D aircraft. Pilot workload has been greatly reduced

thanks to its nely tuned aerodynamic design to the incredible

performance and pre-set conguration of the Aura 8 advanced

ight control system, intermediate pilots will nd that they are

now able to do what they previously only dreamed of.

Sharpening Your Skills

Obviously before attempting any of these maneuvers, you should

be procient at ying an airplane. Practice orientation maneuversbe able to y the airplane anywhere you want upright, inverted,

knife edge, ying towards yourself, ying away from yourself. Part

of learning 3D is being able to bail out of a maneuver gone wrong

consistently and safely.

A good 3D pilot will be smooth, but assertive in manipulations of

all ight controls. Throttle and rudder are just as important to

ying 3D as aileron and elevator. Competency with these controls

is a must before progressing into 3D maneuver training.

After becoming procient in basic aerobatics and being able to

comfortable control the airplane in any ight attitude, you may

progress on to some 3D maneuvers. At right, there is a list of some

of the more common 3D maneuvers in practice today. These

maneuvers are in order of increasing diculty, so be sure to work

into them in a logical progression. Once you master some of the

more basic maneuvers, try your hand at more complex maneuvers

and then practice variations of maneuvers and putting them into

a sequence. There is no limit to the QQ Extra 300’s performance

envelope.

LEARNING TO FLY 3D WITH THE QQ EXTRA 300

Harrier- The harrier is one of the most basic 3D maneuveres and is

a good maneuver to start your training. A harrier is own at a

nose-high attitude (around 45°) while maintaining constant

altitude and can be own upright or inverted. Transition into a

hover or into forward ight for recovery.

Hover- In a hover, the airplane is in a vertical attitude and is held

in place by manipulating the throttle and ight controls to

prevent the airplane from climbing or descending, and remain

stationary. Transition into a harrier or exit into a vertical upline to

recover.

Torque Roll- A torque roll is a slight modication to the hover.

Instead of keeping the airplane in a stationary hover, the the

aileron is neutralized to allow the torque of the motor to rotate

the airplane.

Waterfall- Waterfalls are accomplished by pivoting 360° in pitch

with little or no altitude change or forward movement. Transition

into a harrier or exit into a vertical upline to recover.

Blender- The blender is not a particularly dicult maneuver, but it

is very dynamic and very impressive. From high altitude, the

airplane enters a vertical downline at low throttle and rolls to the

left. At a predetermined altitude (not too low!) an outside snap is

intiated while simultaneously advancing the throttle to enter a at

spin. Ensure adequate altitude for recovery.

Harrier Roll- Harrier rolls are by far the most dicult 3D maneuver

to perfect, but without a doubt are the most impressive to the idle

bystander and R/C pilot alike. A harrier roll is as it sounds- a

continous aileron roll while performing a harrier. Many hours of

practice are required to master this maneuver, and there are many

variations to it as well.

Selecting a Flying Site

Selecting a ying site is critical to a successful ight. Airplanes

require a lot more room than other R/C products, therefore, a

neighborhood or parking lot is less than ideal. A large open eld

with short grass and generous overy area are the best candidates

if no AMA eld is available in your area. Know your overy areaensure that there are no houses, playgrounds, or other buildings

that may be damaged if the airplane were to crash.

Takeo

Taxi or place the aircraft on the runway centerline, with the nose

into the wind. Select Mode 2, then smoothly advance the throttle

to full while maintaining directional control with the rudder and

slight back pressure on the elevator. The airplane should lift o

smoothly before the throttle is fully open. Fly in Mode 2 until the

aircraft is fully trimmed (see special trimming instructions), and

you are comfortable with it's handling, then explore the other

modes as desired.

Flying

Altitude is your friend on the rst ight. Briskly climb to a safe

altitude and trim the airplane out. The airplane should y straight

and level a 1/2 to 3/4 power with no hands on the transmitter. Try

some basic maneuvers, and slowly progress into the airplane’s

ight envelope as you become more comfortable with the

airplane’s ight qualities and perfect your setup. Note: If at any

time, such as after gain adjustments, you experience

unexpected control system inputs or oscillations, switch to

Mode 1, and land and troubleshoot the issue. (Mode 1 turns

the sensor inputs o with default programming)

FLYING YOUR QQ EXTRA 300

USE CAUTION WHEN FLYING YOUR QQ EXTRA IN MODE 3

AT HIGH AIRSPEEDS. DOING SO CAN INDUCE CONTROL

SURFACE OSCILLATIONS AND MAY CAUSE A CRASH.

Trimming

The rst several ights on your QQ Extra should be dedicated

to trimming and setup. Fly the airplane at full power in Mode

2 and trim for level ight. Land, adjust linkages and return

the trim and/or subtrim to zero and y again. Repeat

until the airplane ies hands o, straight and level.

Landing

Be mindful of your ight time and allow adequate battery reserve

for a couple of go-arounds, if necessary, on the rst few ights.

Select Mode 2 and slow the airplane and align with the runway,

into the wind. The airplane should descend smoothly in this

conguration with proper airspeed. Once you are close to the

ground, gradually close the throttle fully and begin to smoothly

apply up elevator as required to arrest descent and the airplane

should gently touch down with a short roll out.

Page 15

14

AIRFRAME REPAIRS

The QQ Extra 300 is molded from durable EPO foam and is repairable with most adhesives. Similar to building and repairing wood or

composite airplanes, the correct glue for a given application is critical to the repair holding and not breaking again. For major repairs, such

as a broken fuselage, epoxy is preferred because it allows time to correct any misalignment. For smaller repairs, such as a cracked control

surface or small chunk of material missing from the airframe, regular CA is very eective. The use of odorless (foam safe) CA is not recommended on EPO foam aircraft because it is weaker than regular CA and takes a longer period of time to cure and the bond tends to be

weaker.

If a part is damaged too badly to be repaired, please refer to the front of the manual for a complete listing of spare airframe parts.

NOTE: Avoid the use of CA accelerant in repairs. It can damage paint and will weaken the bond of the glue. If CA accelerant is

used, be mindful of the locations of CA to prevent premature bonding of parts, or bonding a hand or clamp to the airframe.

REPLACING SERVOS

Required Tools and Fasteners: #1 Phillips Screwdriver

1. Unplug the servo from the receiver.

2. Unscrew the servo arm from the servo and remove the servo arm.

3. Unscrew the two mounting screws located at each end of the servo and remove.

NOTICE: If a crash is imminent, fully reduce the throttle to prevent further damage to the power system and reduce energy

to lessen impact damage. Never allow the propeller to contact the ground under power, even idle.

BE ADVISED THAT CRASH DAMAGE IS NOT COVERED UNDER ANY PRODUCT WARRANTY.

Avoid keeping the airplane in direct sunlight when not ying. Excessive heat can damage the airplane’s structure and UV

damage can permanently discolor decals.

TIP: Plug a spare extension lead into the servo when removing to make it easier to install the lead of the

servo when replaced.

Page 16

15

SERVICING THE POWER SYSTEM

Required Tools and Fasteners: #1 Phillips Screwdriver, 13mm box wrench

1. Remove the propeller and spinner assembly from the motor.

2. Remove the cowling by unscrewing the (2) M1.5x4mm self-tapping screws from the plastic mounts on the side of the cowling.

3. Gently pry the rear of the plastic mount upward to remove it from its base and then free the cowling from the fuselage.

4. Remove the (4) bolts holding the motor to the rewall using a #1 Phillips screwdriver. Disconnect the motor from the ESC.

5. To remove the ESC, simply unplug its lead from the receiver and the output leads from the motor.

OPTIONAL WHEEL PANT REMOVAL

For yers that want the lightest possible setup, or that y o of rough/unimproved elds, the wheelpants on the Extra are designed to

be removable. Two wheel collars have been provided in the hardware bag to retain the wheels after the wheelpants are removed.

Required Tools and Fasteners: #1 Phillips Screwdriver, 1.5mm hex driver, (2) wheel collars

1. Invert the airplane and locate the two wheelpant retaining screws and remove them. Slide the wheelpants and tires o of the axles.

2. Remove the wheel from the wheelpant and reinstall on the axle.

3. Slide the wheel collar onto the axle with the shoulder (oset) side towards the wheel. Tighten the set screw on the wheel collar.

TIP: reinstall the wheelpant retaining collar and screws to prevent losing parts in case you wish to reinstall them.

TIP: use blue threadlocker on the wheel collar set screw for added security.

Page 17

Ensure battery packs are adequately warm (70°F/21°C) before ight

Install propeller so that the convex side faces forward (tractor conguration)

16

DISCREPANCY PROBABLE CAUSE RECOMMENDED SOLUTION

Motor nonresponsive (ESC

intialization tones audible)

Throttle not at idle and/or throttle trim too high

Lower throttle stick and trim completely. If problem persists, ensure that the subtrim and travel adjust are properly set in the radio’s programming.

Throttle channel is reversed Reverse throttle channel in radio programming

Motor nonresponsive (no ESC

initialization tones audible)

Motor disconnected from ESC

Ensure plugs are fully seated. Check battery and/or plugs for damage and replace

any damaged components found - DO NOT ATTEMPT REPAIR

Motor turns in the wrong

direction

The three motor wires are connected incorrectly

to the ESC

Swap any TWO motor wires.

aircraft underpowered

Flight battery not fully charged Ensure battery is fully charged prior to installing in aircraft

Propeller installed backwards

Flight battery damaged

Ambient temperature is too cold

Battery capacity too small for intended use Replace battery with one of proper capacity and discharge capacity (C rating)

Battery is too weak or damaged Check battery’s physical condition, check battery voltages after charge

Battery’s discharge rating may be too small Replace battery with one with higher ‘C’ rating

Excessive propeller noise

and/or vibration

Damaged spinner and/or propeller, collet, or motor Replace damaged components - DO NOT ATTEMPT REPAIR

Propeller is not balanced Balance or replace the propeller

Prop nut is loose Tighten prop nut with appropriate-sized wrench

Spinner is not fully in place or tightened Loosen the spinner bolt, adjust as required, retighten spinner bolt

Control surfaces

nonresponsive

Airframe or control linkage system damage

Examine airframe for damage, repair as required; inspect control linkage system

(servo, pushrod, control horn) for damaged components and replace as required

Wire damaged or connector loose Examine wires and conntections, replace as neccesary

Transmitter bound incorrectly, incorrect active

model memory, incorrect Aura data input

conguration, incorrect Aura transmitter settings

Consult radio manual for proper binding and model selection instructions

AIRCRAFT TROUBLESHOOTING GUIDE

Should you encounter any abnormal situations with your QQ Extra 300, refer to the matrix below to determine probable cause and a

recommended solution for the action.

If the required solution does not rectify the problem, please contact product support for further assistance.

Refer to the product web page and www.exinnovations.com/aura for the latest information and downloads.

NOTICE

Unless specically required, ALWAYS troubleshoot the airplane with the propeller removed.

Battery voltage too low Use volt meter to check battery; recharge or replace as necessary

Battery disconnected from ESC Check that the EC3 plugs are fully seated

BEC (battery elimination circuit) damaged Replace ESC- DO NOT ATTEMPT REPAIR

Failed control direction test Incorrect Aura 8 setting- DO NOT FLY! Refer to Aura 8 manual/website to correct the direction of gain correction

Controls reversed Aura 8 or transmitter settings incorrect Refer to control surface direction chart and adjust appropriate settings as required

Control surface oscillation

Reduce airspeed

Propeller/spinner not balanced Balance or replace propeller and/or spinner

Motor vibration Inspect motor mounting bolts and re-tighten as necessary

Loose Aura 8 mounting Re-align and secure the Aura 8 to the aircraft

Control linkage slop Examine control system and repair or replace work components

Improper transmitter setup

Trim changes between

Trims are not properly zeroed Readjust control linkage and re-center trims in radio

Sub-trim is not properly zeroed Remove sub-trim; adjust the servo arm or clevis to achieve proper geometry

Damaged propeller or spinner Replace damaged component- DO NOT ATTEMPT REPAIR

Refer to Aura 8 manual to decrease desired control surface gain

Page 18

17

COMPLIANCE INFORMATION FOR THE

EUROPEAN UNION

Declaration of Conformity (In accordance with ISO/IEC

17050-1)

Product(s): QQ Extra 300 Super PNP

Item Number(s): FPR3070A/FPR3070B

The object of declaration described above is in conformity with

the requirements of the specications listed below, following the

provisions of the EMC Directive 2004/108/EC.

EN 55022: 2010+AC: 2011

EN 55024: 2010

EN 61000-3-2: 2006+A2:2009

EN 61000-3-3: 2013

EN 61000-6-3: 2007/A1:2011

EN 61000-6-1: 2007

LIMITED WARRANTY

Warranty Coverage

Flex Innovations, Inc. and its authorized resellers (“Flex”) warrant to

the original purchaser that the product purchased (the “Product”) it

will be free from defects in materials and workmanship at the date

of purchase.

Outside of Coverage

This warranty is not transferable and does not cover:

(a) Products with more than 45 days after purchased date.

(b) Damage due to acts of God, accident, misuse, abuse,

negligence, commercial use, or due to improper use,

installation, operation or maintenance

(c) Modication of or to any part of the Product.

(d) Product not compliant with applicable technical regulations.

(e) Shipping damage.

(f) Cosmetic damage

OTHER THAN THE EXPRESS WARRANTY ABOVE, FLEX MAKES NO

OTHER WARRANTY OR REPRESENTATION, AND HEREBY DISCLAIMS

ANY AND ALL IMPLIED WARRANTIES, INCLUDING, WITHOUT

LIMITATION, THE IMPLIED WARRANTIES OF NONINFRINGEMENT,

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE

PURCHASER ACKNOWLEDGES THAT THEY ALONE HAVE DETERMINED THAT THE PRODUCT WILL SUITABLY MEET THE REQUIREMENTS OF THE PURCHASER’S INTENDED USE.

Purchaser’s Solution

Flex’s sole obligation and purchaser’s sole and exclusive remedy

shall be that Flex will, at its option, either (i) service, or (ii) replace,

any Product determined by Flex to be defective. Flex reserves the

right to inspect any and all Product(s) involved in a warranty claim.

Service or replacement decisions are at the sole discretion of Flex.

Proof of purchase is required for all warranty claims. SERVICE OR

REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE

PURCHASER’S SOLE AND EXCLUSIVE REMEDY.

Limitation of Liability

FLEX SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR

COMMERCIAL LOSS IN ANY WAY, REGARDLESS OF WHETHER SUCH

CLAIM IS BASED IN CONTRACT, WARRANTY, TORT, NEGLIGENCE,

STRICT LIABILITY OR ANY OTHER THEORY OF LIABILITY, EVEN IF FLEX

HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Further, in no event shall the liability of Flex exceed the individual

price of the Product on which liability is asserted. As Flex has no

control over use, setup, assembly, modication or misuse, no

liability shall be assumed nor accepted for any resulting damage or

injury. By the act of use, setup or assembly, the user accepts all

resulting liability. If you as the purchaser or user are not prepared to

accept the liability associated with the use of the Product, purchaser is advised to return the Product immediately in new and unused

condition to the place of purchase.

Law

These terms are governed by Florida law (without regard to

conict of law principals). This warranty gives you specic legal

rights, and you may also have other rights which vary from state to

state. FLEX RESERVES THE RIGHT TO MODIFY THIS WARRANTY AT

ANY TIME WITHOUT PRIOR NOTICE.

Questions & Assistance

Visit http://www.exinnovations.com/ex-authorized-reseller

for customer support in your region.

Inspection or Services

If this Product needs to be inspected or serviced and is compliant in

the region you live and use the Product in, please contact your

regional Flex authorized reseller. Pack the Product securely using a

shipping carton. Please note that original boxes needs to be

included, but are not designed to withstand the rigors of shipping

without additional protection. Ship via a carrier that provides

tracking and insurance for lost or damaged parcels, as Flex is not

responsible for merchandise until it arrives and is accepted at our

facility.

Warranty Requirements

For Warranty consideration, you must include your original sales

receipt verifying the proof of purchase date. Provided warranty

conditions have been met, your Product will be replaced free of

charge. Shipping charges are as follow: to Flex by customer, Flex out

it is by Flex. Service or replacement decisions are at the sole

discretion of Flex.

Instructions for disposal of WEEE by users in the

European Union

This product must not be disposed of with other waste.

Instead, it is the user’s responsibility to dispose of their

waste equipment by handing it over to a designated

collections point for the recycling of waste and electronic

equipment. The sepearate collection and recycling of

your waste equipment at the time of disposal will help to

conserve natural resources and ensure that it is recycled

in a manner that protects human health and the

environment. For more information about where to drop

o your waste equipment for recycling, please contact

your local city oce, your household waste disposal

service or where you purchased the product.

Page 19

Academy of Model Aeronautics National Model Aircraft Safety Code

Eective January 1, 2014

A. GENERAL: A model aircraft is a non-human-carrying aircraft capable

of sustained ight in the atmosphere. It may not exceed limitations of this

code and is intended exclusively for sport, recreation, education and/or

competition. All model ights must be conducted in accordance with this

safety code and any additional rules specic to the ying site.

1. Model aircraft will not be own:

(a) In a careless or reckless manner.

(b) At a location where model aircraft activities are prohibited.

2. Model aircraft pilots will:

(a) Yield the right of way to all human-carrying aircraft.

(b) See and avoid all aircraft and a spotter must be used when

appropriate. (AMA Document #540-D.)

(c) Not y higher than approximately 400 feet above ground level

within three (3) miles of an airport without notifying the airport

operator.

(d) Not interfere with operations and trac patterns at any airport,

heliport or seaplane base except where there is a mixed use

agreement.

(e) Not exceed a takeo weight, including fuel, of 55 pounds unless

in compliance with the AMA Large Model Airplane program.

(AMA Document 520-A.)

(f ) Ensure the aircraft is identied with the name and address or

AMA number of the owner on the inside or axed to the outside

of the model aircraft. (This does not apply to model aircraft

own indoors.)

(g) Not operate aircraft with metal-blade propellers or with gaseous

boosts except for helicopters operated under the provisions of

AMA Document #555.

(h) Not operate model aircraft while under the inuence of alcohol

or while using any drug that could adversely aect the pilot’s

ability to safely control the model.

(i) Not operate model aircraft carrying pyrotechnic devices that

explode or burn, or any device which propels a projectile or

drops any object that creates hazard to persons or property.

Exceptions:

§ Free Flight fuses or devices that burn producing smoke and are

securely attached to the model aircraft during ight.

§ Rocket motors (using solid propellant) up to a G-series size may be

used provided they remain attached to the model during ight.

Model rockets may be own in accordance with the National

Model Rocketry Safety Code but may not be launched from model

aircraft.

§ Ocially designated AMA Air Show Teams (AST) are authorized to

use devices and practices as dened within the Team AMA

Program Document. (AMA Document #718.)

(j) Not operate a turbine-powered aircraft, unless in compliance

with the AMA turbine regulations. (AMA Document #510-A.)

3. Model aircraft will not be own in AMA sanctioned events, air shows

or model demonstrations unless:

(a) The aircraft, control system and pilot skills have successfully

demonstrated all maneuvers intended or anticipated prior to the

specic event.

(b) An inexperienced pilot is assisted by an experienced pilot.

4. When and where required by rule, helmets must be properly worn

and fastened. They must be OSHA, DOT, ANSI, SNELL or NOCSAE

approved or comply with comparable standards.

B. RADIO CONTROL (RC)

1. All pilots shall avoid ying directly over unprotected people, vessels,

vehicles or structures and shall avoid endangerment of life and

property of others.

2. A successful radio equipment ground-range check in accordance

with manufacturer’s recommendations will be completed before the

rst ight of a new or repaired model aircraft.

3. At all ying sites a safety line(s) must be established in front of which

all ying takes place. (AMA Document #706.)

(a) Only personnel associated with ying the model aircraft are

allowed at or in front of the safety line.

(b) At air shows or demonstrations, a straight safety line must be

established.

(c) An area away from the safety line must be maintained for

spectators.

(d) Intentional ying behind the safety line is prohibited.

4. RC model aircraft must use the radio-control frequencies currently

allowed by the Federal Communications Commission (FCC). Only

individuals properly licensed by the FCC are authorized to operate

equipment on Amateur Band frequencies.

5. RC model aircraft will not knowingly operate within three (3) miles of

any pre-existing ying site without a frequency-management

agreement. (AMA Documents #922 and #923.)

6. With the exception of events own under ocial AMA Competition

Regulations, excluding takeo and landing, no powered model may be

own outdoors closer than 25 feet to any individual, except for the

pilot and the pilot's helper(s) located at the ightline.

7. Under no circumstances may a pilot or other person touch an outdoor

model aircraft in ight while it is still under power, except to divert it

from striking an individual.

8. RC night ying requires a lighting system providing the pilot with a

clear view of the model’s attitude and orientation at all times. Hand held illumination systems are inadequate for night ying operations.

9. The pilot of an RC model aircraft shall:

(a) Maintain control during the entire ight, maintaining visual contact

without enhancement other than by corrective lenses prescribed

for the pilot.

(b) Fly using the assistance of a camera or First-Person View (FPV) only

in accordance with the procedures outlined in AMA Document

#550.

(c) Fly using the assistance of autopilot or stabilization system only in

accordance with the procedures outlined in AMA Document #560.

C. FREE FLIGHT

1. Must be at least 100 feet downwind of spectators and automobile

parking when the model aircraft is launched.

2. Launch area must be clear of all individuals except mechanics, ocials,

and other iers.

3. An eective device will be used to extinguish any fuse on the model

aircraft after the fuse has completed its function.

D. CONTROL LINE

1. The complete control system (including the safety thong where

applicable) must have an inspection and pull test prior to ying.

2. The pull test will be in accordance with the current Competition

Regulations for the applicable model aircraft category.

3. Model aircraft not tting a specic category shall use those pull-test

requirements as indicated for Control Line Precision Aerobatics.

4. The ying area must be clear of all utility wires or poles and a model

aircraft will not be own closer than 50 feet to any above-ground

electric utility lines.

5. The ying area must be clear of all nonessential participants and

spectators before the engine is started.

If you are not an AMA member, please consider joining. Founded

in 1936 and open to anyone interested in model aviation, the AMA

is the governing body for model aviation in the United States and

sanctions over 2,000 competitions annually. Membership in the

AMA provides liability insurance coverage, protects modelers’

rights and interests, and is required to y at most of the 2,700+ R/C

sites nationwide.

Academy of Model Aeronautics

5161 East Memorial Drive

Muncie, IN 47302-9252

Toll Free (800) 435-9262

Fax (765) 741-0057

www.modelaircraft.org

18

Page 20

© 2015 Flex Innovations, Inc.

Premier Aircraft™, Potenza™, and Top Value RC™ are trademarks or registered trademarks of Flex Innovations, Inc.

Android is a trademark of Google Inc. iPhone® is a trademark of Apple Inc registered in the US and other countries.

DSM®, DSM2™, and DSMX™ are trademarks of Horizon Hobby, Inc.

Futaba is a registered trademark of Futaba Denshi Kogyo Kabushiki Kaisha Corporation of Japan.

HoTT is a registered trademark of SJ, Inc.

Created 04/2015

Loading...

Loading...