Page 1

COMPOSITION

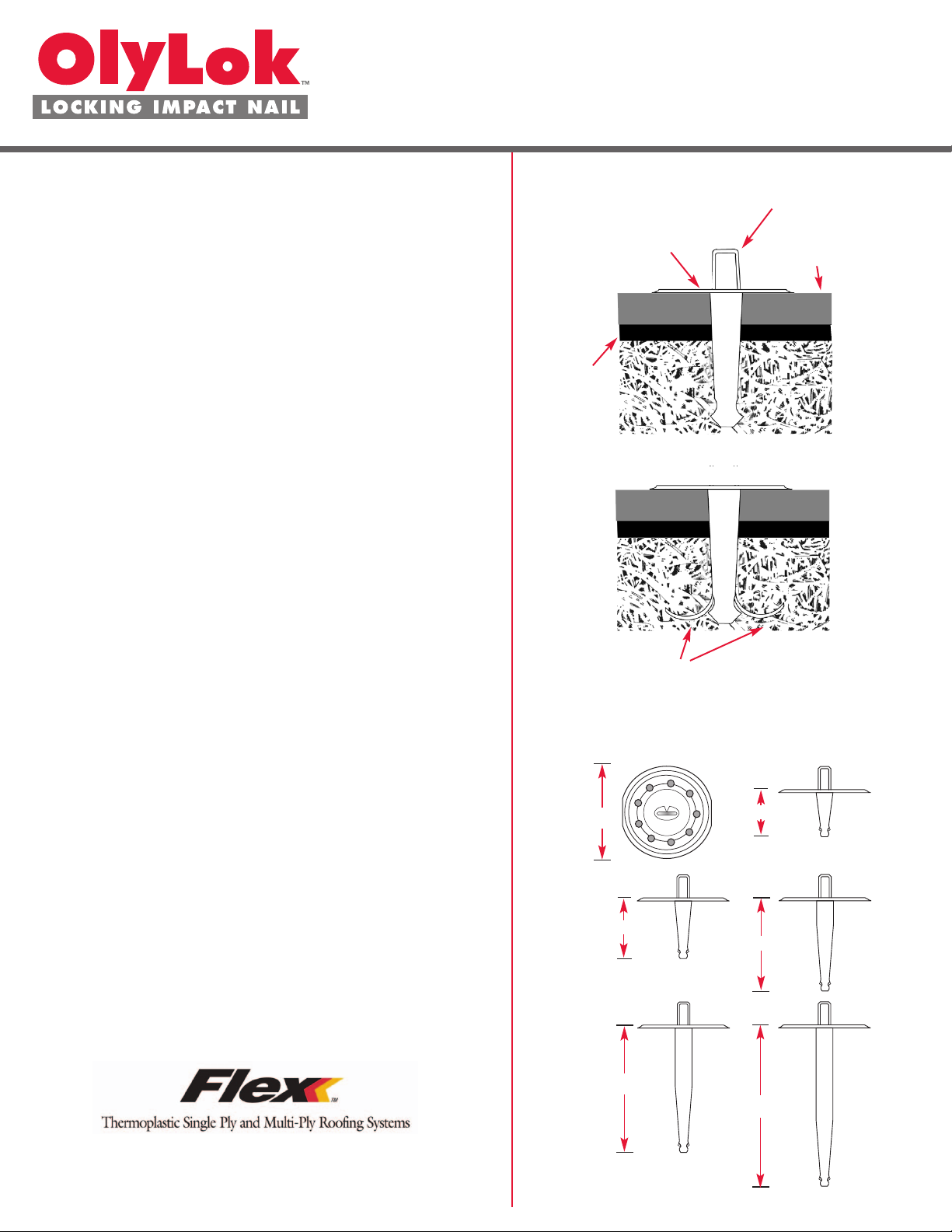

Factory preassembled components consisting of:

Tube:

Precision formed from Galvanized (G-90) coated steel to prevent corrosion.

The tube is shaped to easily penetrate decking and existing membranes.

Disk: Precision formed from Galvalume (AZ-55) coated steel to prevent corrosion.

Securely clamped to the tube, 2.7" diameter, rib reinforced to resist cupping.

Locking Staple: Precision formed from high tensile steel wire.

Coated to prevent corrosion.

TECHNICAL DATA

Fastening Pattern: Consult Flex for requirements for recommended patterns

in normal, exposed, and hurricane areas.

Field Testing: On-site withdrawal testing should always be performed to

evaluate the ability of the roofing substrate to satisfactorily accept and retain

fasteners. Such testing may alter fastener selection and modify applicable

fastening patterns.

The OlyLok should always be embedded into the structural roof deck to a

depth of at least 1".

INSTALLATION

Installation Tools: There are two tools that must be used to install the OlyLok

Locking Impact Nail. The OlyLok Driver is for installing base sheet and recovery

board to the substrate. For securing ISO or EPS to the substrate use the OlyLok

Insulation Tool, which has a larger impact area. Consult Flex for the specific

driver for your application.

Method: Drive fastener perpendicular to roof deck seating cap flush with roofing

surface. Once tube is set, drive the locking staple thru the tube/disk unit into the

deck until the top of the staple is flush with the cap (see illustration).

Operation: When locking staple is driven, its dual wire legs diverge anchoring

the fastener in place (see illustration). Uplift resistance may vary depending on

the density and integrity of the substrate.

Packaging: 1.4", 1.8", 2.8", and 3.8" OlyLoks packaged 500 per carton.

4.8" OlyLoks packaged 250 per carton.

SPECIFICATIONS

For Attaching Base Ply, Recovery Board and

Insulation to Wood Fiber/Poured Gypsum Decks

1.8"

2.7"

2.8"

5 LENGTHS

Roofing disk is

securely clamped

to the tube.

Recovery

Board

Existing

membrane

As locking staple is driven, its dual wire legs

diverge anchoring the fastener in place.

FIRST IMPACT SETS TUBE.

SECOND IMPACT ACTUATES STAPLE.

Factory

preinserted

staple.

MADE IN THE U.S.A.

1.4"

3.8"

4.8

"

800-969-0108 • 610-916-9501 (Fax)

2670 Leiscz’s Bridge Road, Suite 400, Leesport, PA 19533

e-mail: flexroof@cs.com • www.flexroofingsystems.com

Page 2

For Attaching Base Ply, Recovery Board and

Insulation to Wood Fiber/Poured Gypsum Decks

Fastener density and spacing vary depending on applicable uplift require-

ments. Local codes, governing approval bodies, membrane manufactur-

ers, and individual roofdeck manufacturers all may have specific require-

ments that need to be addressed prior to beginning any roofing project.

The OlyLok should always be embedded into the structural roof

deck to a depth of at least 1". The following illustrates typical Factory

Mutual recommended fastening patterns widely accepted by membrane

and roofdeck manufacturers.

USING THE OLYLOK

Fastening Guide 2

Recovery board and insulation attachment under fully adhered

single ply membranes.

Class I-90 Windstorm Classification.

An FMRC Approved Recovery Board/Insulation suitable for use

with fully adhered single ply membranes is attached with 12 OlyLok

fasteners per 4'x 4' board in 4 rows of 3 fasteners per row.

(1 fastener per 1.33 ft.

2

)

Consult Flex for a complete listing of approved recovery

boards/insulations.

Fastening Guide 1

Recovery board and Insulation attachment under built-up and

modified bitumen roof covers.

Class I-90 Windstorm Classification.

An FMRC Approved Recovery Board/Insulation suitable for use

with minimum 3 ply built-up or modified membranes is attached with

8 OlyLok fasteners per 4'x 4' board in a diamond in a box pattern.

(1 fastener per 2 ft.

2

)

Consult Flex for a complete listing of approved recovery

boards/insulations.

6"

6"

+

+

+

+++

+

+

+

+++

12"

12"

12"

12 Fasteners

¨

¨

¨

¨

¨

¨¨ ¨

¨

¨

¨

¨

¨

¨

6"

6"

¨

¨

¨

¨

¨

¨

¨

¨

++

+

+

+

+

+

+

6"

6"

12"

24"

8 Fasteners

800-969-0108 • 610-916-9501 (Fax)

2670 Leiscz’s Bridge Road, Suite 400, Leesport, PA 19533

e-mail: flexroof@cs.com • www.flexroofingsystems.com

Loading...

Loading...