Page 1

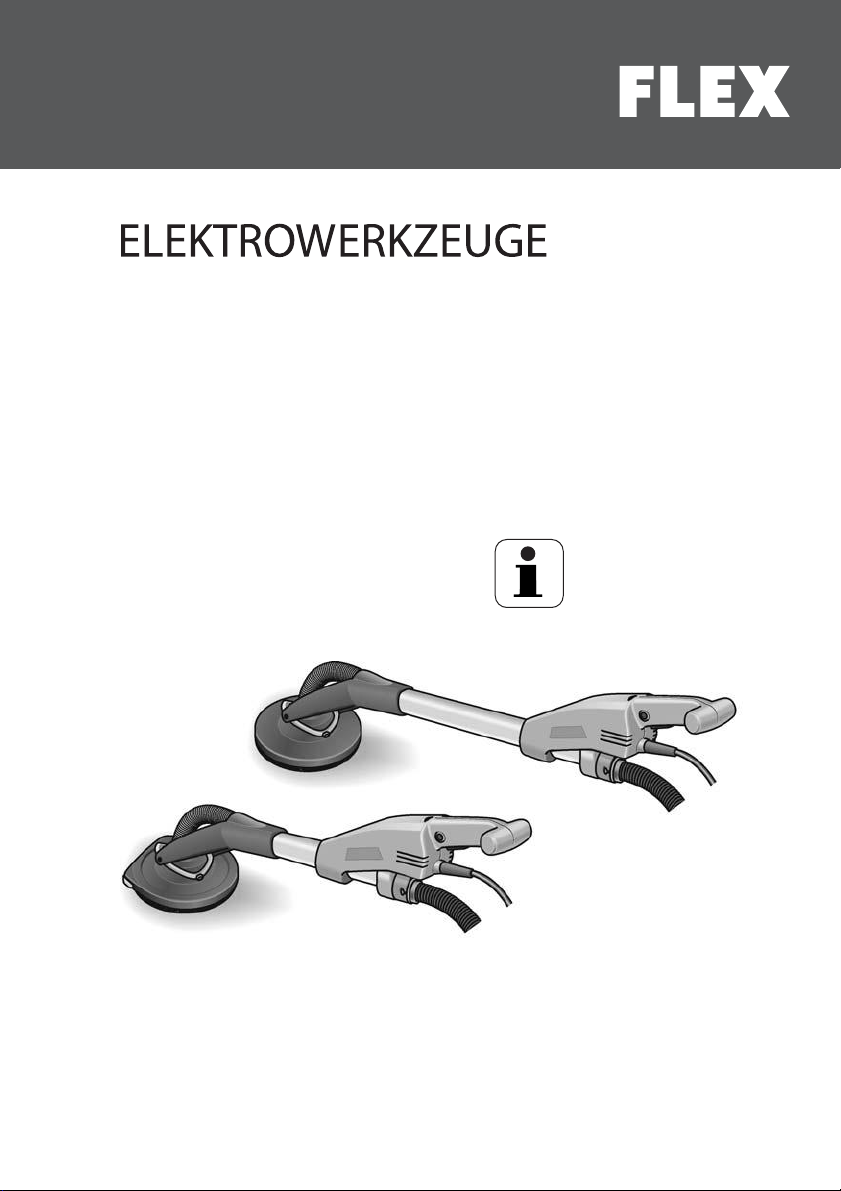

GE 5

GE 5 R

GSE 5

GSE 5 R

Page 2

Originalbetriebsanleitung . . . . . . . . . . . . . . . . . . . . . . . 3

Original operating instructions . . . . . . . . . . . . . . . . . . . 15

Notice d’instructions d’origine . . . . . . . . . . . . . . . . . . . 26

Istruzioni per l’uso originali . . . . . . . . . . . . . . . . . . . . . . 38

Instrucciones de funcionamiento originales . . . . . . . . . 50

Instruções de serviço originais . . . . . . . . . . . . . . . . . . . 62

Originele gebruiksaanwijzing . . . . . . . . . . . . . . . . . . . . 74

Originale driftsvejledning . . . . . . . . . . . . . . . . . . . . . . . 86

Originale driftsanvisningen . . . . . . . . . . . . . . . . . . . . . . 98

Originalbruksanvisning . . . . . . . . . . . . . . . . . . . . . . . . . 109

Alkuperäinen käyttöohjekirja . . . . . . . . . . . . . . . . . . . . 120

Αυθεντικές οδηγίες χειρισμού . . . . . . . . . . . . . . . . . . . . . 131

Orijinal işletme kılavuzu . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Instrukcja oryginalna . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Eredeti üzemeltetési útmutató . . . . . . . . . . . . . . . . . . . 166

Originální návod k obsluze . . . . . . . . . . . . . . . . . . . . . . 178

Originálny návod na obsluhu . . . . . . . . . . . . . . . . . . . . 189

Originalna uputa za rad . . . . . . . . . . . . . . . . . . . . . . . . 200

Izvirno navodilo za obratovanje . . . . . . . . . . . . . . . . . . 211

Instrucţiuni de funcţionare originale . . . . . . . . . . . . . . . 222

Оригинално упътване за експлоатация . . . . . . . . . . 234

Оригинальная инструкция по эксплуатации

. . . . . .

246

Originaalkasutusjuhend . . . . . . . . . . . . . . . . . . . . . . . . 259

Originali naudojimo instrukcija . . . . . . . . . . . . . . . . . . . 270

Lietošanas pamācības oriģināls . . . . . . . . . . . . . . . . . . 281

ﺔﻴﻠــــﺻﻷا ﻞﻴﻐــــﺸﺘﻟا تادﺎــــﺷرﻹ ﺔــــﻤﺟﺮﺗ . . . . . . . . . . . . . . . . . . . . 301

Page 3

GE 5/GE 5 R/GSE 5/GSE 5 R

Contents

Symbols used in this manual . . . . . . . . 15

Symbols on the power tool. . . . . . . . . . . 15

For your safety . . . . . . . . . . . . . . . . . . . 15

Noise and vibration . . . . . . . . . . . . . . . . 18

Disposal information . . . . . . . . . . . . . . . 18

-Declaration of Conformity . . . . . . . . 18

Overview . . . . . . . . . . . . . . . . . . . . . . . . 19

Technical specifications . . . . . . . . . . . . 20

Instructions for use . . . . . . . . . . . . . . . . 21

Instructions for use . . . . . . . . . . . . . . . . 23

Operating instructions . . . . . . . . . . . . . . 23

Maintenance and care . . . . . . . . . . . . . . 24

Exemption from liability . . . . . . . . . . . . . 25

Symbols used in this manual

WARNING!

Denotes impending danger.

Non-observance of this warning may result

in death or extremely severe injuries.

CAUTION!

Denotes a possibly dangerous situation.

Non-observance of this warning may result

in slight injury or damage to property.

NOTE

Denotes application tips and important

information.

Symbols on the power tool

Before switching on the power

tool, read the operating manual!

Wear goggles!

Disposal information for the old

machine (see page 18)!

For your safety

WARNING!

Before using the power tool, please read and

follow:

–

these operating instructions,

–

the ”General safety instructions” on the

handling of power tools in the enclosed

booklet (leaflet-no.: 315.915),

–

the currently valid site rules and the regu-

lations for the prevention of accidents.

This power tool is state of the art and has been

constructed in accordance with the acknowledged safety regulations. Nevertheless, when

in use, the power tool may be a danger to life

and limb of the user or a third party, or the

power tool or other property may be damaged.

The power tool may be operated only if it is

–

as intended,

–

in perfect working order.

Faults which impair safety must be repaired

immediately.

Intended use

The wall sander

GSE 5 R

– for commercial use in industry and trade,

– for sanding walls and ceilings inside and

– for sanding smoothed drywalls,

– for use with tools which FLEX offer

It is not permitted to use cutting-off wheels,

roughing wheels, fan-like grinding wheels

or wire brushes.

When using the wall sander

GSE 5/GSE 5 R

extractor.

is designed

outside,

for these power tools and which are

authorised to run at a speed of at least

1750 r.p.m.

GE 5/GE 5 R/GSE 5/

GE 5/GE 5 R/

, connect a Class M dust

15

Page 4

GE 5/GE 5 R/GSE 5/GSE 5 R

Safety instructions

WARNING!

Read all safety warnings and all

instructions. Failure to follow the warnings

and instructions may result in electric shock,

fire and/or serious injuries. Save all

warnings and instructions for future

reference.

This power tool is intended to function

as a sander. Read all safety warnings,

instructions, illustrations and specifications provided with this power tool.

Failure to follow all instructions listed

below may result in electric shock,

fire and/or serious injury.

Operations such as grinding, wire

brushing, or for polishing and cut-off

are not recommended to be performed

with this power tool.

Operations for which the power tool

was not designed may create a hazard

and cause personal injury.

Do not use accessories which are not

specifically designed and recommended

by the tool manufacturer.

Just because the accessory can

be attached to your power tool,

it does not assure safe operation.

The rated speed of the accessory must

be at least equal to the maximum speed

marked on the power tool.

Accessories running faster than their

rated speed can break and fly apart.

The outside diameter and the thickness

of your accessory must be within the

capacity rating of your power tool.

Incorrectly sized accessories cannot be

adequately guarded or controlled.

Threaded mounting of accessories must

match the grinder spindle thread. For

accessories mounted by flanges, the

arbour hole of the accessory must fit the

locating diameter of the flange.

Accessories that do not match the

mounting hardware of the power tool will

run out of balance, vibrate excessively and

may cause loss of control.

Do not use a damaged accessory. Before

each use inspect the accessory such as

abrasive wheels for chips and cracks,

backing pad for cracks, tear or excess

wear, wire brush for loose or cracked

wires. If power tool or accessory is

dropped, inspect for damage or install an

undamaged accessory. After inspecting

and installing an accessory, position

yourself and bystanders away from the

plane of the rotating accessory and run the

power tool at maximum no-load speed for

one minute.

Damaged accessories will

normally break apart during this test time.

Wear personal protective equipment.

Depending on application, use face shield,

safety goggles or safety glasses. As

appropriate, wear dust mask, hearing

protectors, gloves and shop apron

capable of stopping small abrasive or

workpiece fragments.

The eye protection

must be capable of stopping flying debris

generated by various operations. The dust

mask or respirator must be capable of

filtrating particles generated by your

operation. Prolonged exposure to high

intensity noise may cause hearing loss.

Keep bystanders a safe distance away

from work area. Anyone entering the

work area must wear personal protective

equipment.

Fragments of workpiece or of a broken

accessory may fly away and cause injury

beyond immediate area of operation.

Hold power tool by insulated gripping

surfaces only, when performing an operation where the cutting accessory may

contact hidden wiring or its own cord.

Cutting accessory contacting a “live” wire

may make exposed metal parts of the

power tool “live” and shock the operator.

Position the cord clear of the spinning

accessory.

If you lose control, the cord may be cut

or snagged and your hand or arm may

be pulled into the spinning accessory.

Never lay the power tool down until the

accessory has come to a complete stop.

The spinning accessory may grab the

surface and pull the power tool out

of your control.

Do not run the power tool while carrying

it at y our sid e. Accidental contact with the

spinning accessory could snag your

clothing, pulling the accessory into your

body.

16

Page 5

GE 5/GE 5 R/GSE 5/GSE 5 R

Regularly clean the power tool's air

vents.

The motor's fan will draw the dust inside

the housing and excessive accumulation

of powdered metal may cause electrical

hazards.

Do not operate the power tool near flam-

mable materials.

Sparks could ignite these materials.

Do not use accessories that require liquid

coolants.

Using water or other liquid coolants may

result reesult in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched

or snagged rotating wheel, backing pad,

brush or any other accessory. Pinching or

snagging causes rapid stalling of the

rotating accessory which in turn causes the

uncontrolled power tool to be forced in the

direction opposite of the accessory’s

rotation at the point of the binding.

For example, if an abrasive wheel is

snagged or pinched by the workpiece, the

edge of the wheel that is entering into the

pinch point can dig into the surface of the

material causing the wheel to climb out or

kick out. The wheel may either jump toward

or away from the operator, depending on

direction of the wheel’s movement at the

point of pinching. Abrasive wheels may also

break under these conditions.

Kickback is the result of power tool misuse

and/or incorrect operating procedures or

conditions and can be avoided by taking

proper precautions as given below.

Maintain a firm grip on the power tool

and position your body and arm to allow

you to resist kickback forces.

Always use auxiliary handle, if provided,

for maximum control over kickback

or torque reaction during start-up.

The operator can control torque reactions or kickback forces, if proper precautions are taken.

Never place your hand near the rotating

accessory.

Accessory may kickback over your hand.

Do not position your body in the area

where power tool will move if kickback

occurs.

Kickback will propel the tool in direction

opposite to the wheel‘s movement at the

point of snagging.

Use special care when working corners,

sharp edges etc. Avoid bouncing and

snagging the accessory.

Corners, sharp edges or bouncing have

a tendency to snag the rotating accessory and cause loss of control or kickback.

Do not attach a saw chain woodcarving

blade or toothed saw blade.

Such blades create frequent kickback

and loss of control.

Special safety instructions for sanding

Do not use excessively oversized

sanding disc paper. Follow manufacturers recommendations, when selecting

sanding paper.

Larger sanding paper extending beyond

the sanding pad presents a laceration

hazard and may cause snagging, tearing

of the disc or kickback.

Additional safety instructions

Use only extension cables permitted

for outdoor use.

It is not recommended to sand lead paint.

Lead paint should be removed

by a specialist only.

If plaster board or plaster is sanded,

this may cause static electricity to build

up on the tool. To ensure your safety,

the wall sander is earthed.

Remove dust with an earthed dust

extractor only.

Do not work on materials which release

hazardous substances (e.g. asbestos).

Take precautions if hazardous, combustible or explosive dust is likely to occur.

Wear protective dust mask.

Use dust extraction system.

Damage to property!

The mains voltage and the voltage speci-

fications on the rating plate must correspond.

17

Page 6

GE 5/GE 5 R/GSE 5/GSE 5 R

Noise and vibration

NOTE

Values for the A-weighted sound pressure

level and for the total vibration values can be

found in the “Technical specifications” table.

The noise and vibration values have been

determined in accordance with EN 60745.

CAUTION!

The indicated measurements refer to new

power tools. Daily use causes the noise and

vibration values to change.

NOTE

The vibration emission level given in this

information sheet has been measured

in accordance with a standardised test

given in EN 60745 and may be used

to compare one tool with another.

It may be used for a preliminary assessment

of exposure. The declared vibration emission level represents the main applications

of the tool. However if the tool is used

for different applications, with different

accessories or poorly maintained,

the vibration emission may differ.

This may significantly increase the exposure level over the total working period.

However if the tool is used for different

applications, with different accessories

or poorly maintained, the vibration emission

may differ. This may significantly decrease

the exposure level over the total working

period. Identify additional safety measures

to protect the operator from the effects

of vibration such as: maintain the tool and

the accessories, keep the hands warm,

organisation of work patterns.

CAUTION!

Wear ear protection at a sound pressure

above 85 dB(A).

Disposal information

WARNING!

Render redundant power tools unusable by

removing the power cord.

EU countries only

Do not throw electric power tools into

the household waste!

In accordance with the European Directive

2012/19/EU on Waste Electrical and

Electronic Equipment and transposition into

national law used electric power tools must

be collected separately and recycled in an

environmentally friendly manner.

NOTE

Please ask your dealer about disposal

options!

-Declaration of Conformity

We declare under our sole responsibility that

the product described under “Technical

specifications“ conforms to the following

standards or normative documents:

EN 60745 in accordance with the

regulations of the directives

2014/30/EU, 2006/42/EC, 2011/65/EU.

Responsible for technical documents:

FLEX-Elektrowerkzeuge GmbH, R & D

Bahnhofstrasse 15, D-71711 Steinheim/Murr

Manager Research &

Development (R & D)

26.09.2018

FLEX-Elektrowerkzeuge GmbH

Bahnhofstrasse 15, D-71711 Steinheim/Murr

Klaus Peter WeinperEckhard Rühle

Head of Quality

Department (QD)

18

Page 7

GE 5/GE 5 R/GSE 5/GSE 5 R

Overview

1 Sanding head (GE 5/GSE 5)

with closed brush ring

2 Sanding head (GE 5 R/GSE 5 R)

with open brush ring for sanding edges

3 Gimbal bearings

4 Tubular handle

5 Housing

6 Dial for preselecting the speed

7 Handle

8 5.0 m power cord with plug

9Switch

10 Locking button

11 32 mm connection

12 Retaining washer

13 Screw

14 Velcro pad

15 Backing pad

16 Replaceable protective corners

(GE 5 R/GSE 5 R)

17 Brush ring

18 Suction hose

19 Adapter for extraction hose (optional)

for connection of electric power tools

using conventional connection piece

20 Extension tube (optional)

21 Bail handle (optional)

19

Page 8

GE 5/GE 5 R/GSE 5/GSE 5 R

Technical specifications

Machine type Wall sander

GE 5 GE 5 R GSE 5 GSE 5 R

Mains voltage V/Hz 230/50

Protection class I

Power input W 500

Speed r.p.m. 1100–1650

Max. disc diameter mm 225

Length mm 1520 1160

Suction hose/length x diameter mm 4000 x 32

Weight (without power cord and

backing pad)

A-weighted sound pressure level according to EN 60745 (see “Noise and vibration”):

Sound pressure level L

Sound power level L

pA

WA

Uncertainty K dB 3

Total vibration value according to EN 60745 (see “Noise and vibration”):

Emmission value a

when

h

sanding smoothed plasterboard

walls

Uncertainty K

kg 3.9 3.6

dB(A) 79

dB(A) 90

m/s

m/s

2

2

< 2.5

1.5

20

Page 9

GE 5/GE 5 R/GSE 5/GSE 5 R

Instructions for use

Before switching on the power tool

Unpack power tool and accessories

and check that no parts are missing

or damaged.

Connecting the extractor

Connect extraction hose to the 32 mm

connector.

NOTE

The connection piece of the GE 5/GE 5 R/

GSE 5/GSE 5 R is a new development.If

electric power tools are used with

conventional connection pieces together

with the extraction hose of the GE 5/GE 5 R/

GSE 5/GSE 5 R, an adapter from the FLEX

accessories programme can be used.

Using a dust extraction system

CAUTION!

–

When using the wall sander, connect

a Class M dust extractor.

–

If a dust bag is used which is not authorised for use with dry construction dust,

the amount of dust particles in the air

may increase at the work place.

Over a prolonged period high concentrations of dust in the air may damage

the human respiratory system.

Insert the special dust bag for dry con-

struction dust into your dust extractor

according to the instructions supplied

with the dust extractor.

Connect extraction hose to the dust

extraction system. Follow the operating

instructions for the dust extraction system! Check the attachment!

If required, use an appropriate adapter.

NOTE

If your dust extractor requires a special

connector, the clip-on connection can

be removed and a matching adapter selected from the FLEX accessories range.

Attaching and changing the sanding

tools

CAUTION!

Before performing any work on the electric

power tool, pull out the mains plug.

Remove worn sanding tool from

the Velcro pad.

Place the sanding sheet in the centre

of the Velcro pad and press on.

Conduct a test run to check that the san-

ding tool is clamped in the centre.

CAUTION!

Never use the Velcro pad as a sanding tool.

Never use the wall sander without the sanding sheet, otherwise the work surface will

be seriously damaged!

21

Page 10

GE 5/GE 5 R/GSE 5/GSE 5 R

Switching the electric power

tool on and off

Switch on the machine:

Press the switch (1.).

To engage, press the locking button

and release switch (2.).

Switch off the machine:

Press the switch briefly

Using extension (optional)

An extension tube is available for the wall

sander

GE 5/GE 5 R/GSE 5/GSE 5 R

The extension tube can be used to increase

the range when working with the wall sander.

Attach extension tube from below

to the housing of the wall sander (1.)

and push it forwards until it engages (2.).

.

Preselecting the speed

To set the operating speed, move the dial

to the required value.

22

To remove, press in both catches (1.)

and remove extension tube (2.).

Working with the power tool

CAUTION!

Hold the electric power tool with both hands!

When working, always have one hand

on the handle – even when working with

attached extension. Keep your hands away

from the sanding head.

Otherwise, your hand could become caught,

as the sanding head swivels in different

directions.

Page 11

GE 5/GE 5 R/GSE 5/GSE 5 R

1. Attach sanding tool.

2. Connect dust extraction system.

3. Insert mains plug.

4. Set required speed.

5. Switch on dust extraction system.

6. Hold the wall sander with both hands.

This provides the best possible

combination of range and leverage

for the application.

7. Switch on the device.

8. Press the wall sander gently against

the work surface (the pressure should

be just enough to ensure that the sanding head is flush with the work surface).

9. Increase the pressure to bring the sanding sheet into contact with the work

surface. In doing so, swing the sander

in overlapping movements to smooth

the surface to the required fineness.

CAUTION!

The rotating parts of the sanding head must

not come into contact with sharp projecting

objects (e.g. nails, screws, junction boxes).

The Velcro pad may be damaged if it comes

into contact with projecting objects.

The Velcro pad can be replaced if it

is damaged or severely abraded (see

section entitled “Maintenance and care”).

Operating instructions

Brush ring

A brush-type ring surrounds the sanding

head. This ring has two functions:

– As the ring projects above the surface

of the sanding plate, it is the ring which

comes into contact with the work surface

first. As a result, the sanding head

is brought parallel to the work surface

before the sanding tool comes into

contact with the work surface.

This avoids a sickle-shaped depression

caused by the edge of the sanding disc.

– The ring also retains the dust until

it is extracted by the dust extractor.

If the brush ring is damaged or shows

excessive wear, it should be replaced

(see section entitled “Maintenance and

care”). Replacement brush rings are available from any FLEX customer service centre.

Sanding in dry construction

The wall sander features a unique swivel

head. As this head can swivel in different

directions, the sanding head can

be adjusted to the work surface.

As a result, the user can sand the upper,

middle and lower wall areas or ceiling profiles without having to change his position.

When working, apply only as much pressure

as is required to keep the sanding plate

in contact with the work surface. Excessive

pressure may result in a disagreeable spiral

pattern of scratches and an uneven work

surface.

Move the sander constantly while the sanding plate is in contact with the work surface. In doing so, ensure that you move

the sander evenly and over a wide area.

23

Page 12

If you stop the sander on the work surface

or move the sander unevenly, this may

result in a disagreeable spiral pattern

of scratches and an uneven work surface.

NOTE

The wall sander features an overload cutout for protecting the device.

If the load is too great, the device switches

off and immediately restarts.

Maintenance and care

WARNING!

Before performing any work, pull out

the mains plug.

Cleaning

WARNING!

Do not use water or liquid detergents.

Regularly blow out the housing interior

and motor with dry compressed air.

Blow out the sanding head and gimbal

bearing with dry compressed air.

Replacing Velcro or backing pad

Take hold of the sanding plate together

with the sanding head to prevent

the sanding plate from turning.

GE 5/GE 5 R/GSE 5/GSE 5 R

Replace parts.

Assemble sanding head in reverse

sequence.

Replacing the brush ring

Remove the sanding head (see section

“Replacing Velcro or backing pad”).

Turn the screw in an anti-clockwise

direction and remove.

Disassemble the sanding head.

24

Loosen the retaining screws.

Take the ring out of the housing.

Insert a new brush ring into the housing

and screw in the retaining screws.

Assemble sanding head in reverse

sequence.

Page 13

GE 5/GE 5 R/GSE 5/GSE 5 R

Replacing the protective corners

(GE 5 R/GSE 5 R)

Remove protective corners

to be replaced.

Attach new protective corners.

Repairs

Repairs may be carried out by an authorised

customer service centre only.

NOTE

During the warranty period do not loosen

the screws on the housing.

Non-compliance will deem the guarantee

obligations of the manufacturer null and

void.

Exemption from liability

The manufacturer and his representative

are not liable for any damage and lost profit

due to interruption in business caused

by the product or by an unusable product.

The manufacturer and his representative are

not liable for any damage which was caused

by improper use of the product or by use

of the product with products from other

manufacturers.

Spare parts and accessories

Other accessories, in particular insertion

tools, can be found in the manufacturer’s

catalogues.

Exploded drawings and spare-part lists

can be found on our homepage:

www.flex-tools.com

25

Page 14

406.937 / 09–2018 / Für Druckfehler keine Gewähr. Technische Änderungen vorbehalten.

Loading...

Loading...