Page 1

Flexcap FLC Coping

Tapered, Flat and Existing Slope with Nailer Versions

Warranty:

Testing:

Available Materials:

Watertight:

Competitively Priced:

Efficient Design:

Colors:

The entire roof system is covered under one warranty and inspected after the project is complete to

assure proper installation. The system is inspected after the project is complete to assure proper

installation. This ensures protection for the most vulnerable area of the roof against failure due to

extreme wind up lift pressures.

• Tested per ANSI/SPRI ES-1 Standard to comply with the International Building Code.

“ Factory Mutual 1-90 approved for wind up lift protection.

• Miami-Dade Approved (No. 08-0604.02 12/11/13) to comply with the “High Velocity Hurricane

Zone of the Florida Building Code”.

Its unique design allows for covers to be manufactured in 24 ga. steel, .040", .050" and .063"

aluminum.

Its 8" wide concealed splice plates with dual non-curling isocryl butyl sealant strips allow for thermal

movement of materials and provides a watertight seal at all joints.

The installed cost rivals even light gauge roof edge systems fabricated locally or in a roofer’s shop.

A fuU, snap-on design in 12'-0" lengths and no crimping make for quick installation and low labor

costs. Pre-punched fastening holes ensure proper attachment to the building substrate. Corrosion

resistant, stainless steel springs are factory attached to the anchor clips and provide long-term,

positive spring loading. No adhesives are required.

Choose among a wide range of standard colors and finishes that meet your job requirements. A 20

year Kynar 500® finish warranty is included on standard colors. Custom post-coated Kynar 500

colors are available with an included 10 year Kynar 500 finish warranty or a 20 year Kynar 500 finish

warranty is available upon request. Anodized finishes are also available, but are not warranted.

Custom Capabilities:

Accessories:

Also Included:

p: 800-969-0108

f: 610-916-9501

Radius and specially fabricated products are available to meet the unique needs of each project.

Factory fabricated miters provide a cleaner, more aesthetically pleasing appearance. This eliminates

the need for field fabrication, providing time and labor savings.

All fasteners are included and will arrive to the job site with the product.

features & benefits

71

Page 2

APPROVE)

FLEXCAP FLC COPING

TAPERED VERSION

ANSI/SPRI ES-1 TESTED

Coping cover 12'-0'

(3.65 m) lengths

8" (203 mm) wide

concealed splice plate at

each joint

'A'

Inside Face

Min. 2 1/4" (57 mm)

Max. 6" (152 mm)

3/8" (10 mm)

space provided for

wall variations

Coping is to be installed per Specifications and Flex's Installation Instruction Dwg. # 28111-3454

- Concealed splice plates are provided with factory applied dual

non- curing sealant strips.

“ Unless otherwise noted, fabrication of miters and accessories

are furnished standard utilizing a non-penetrating quicklock Joint,

then factory sealed watertight.

Actual wall width

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by: _____________________________

Date:

_____________________

12" (305 mm) wide

20 ga. (1 mm) galvanized

anchor clips 4'-0" (1.22 m) o.c.

NOANa-M^ll \Vm)

Cwsty,

'C

Outside Face

Min. 3" (76 mm)

Max. 6" (152 mm)

■ Welded Miters and Accessories

Check one □ Required (surcharge) □ Not applicable

MATERIAL:

24 Ga. (0.65 mm) Galv.

. .040" (1.01 mm) Alum.

.050" (1.27 mm) Alum.

. .063" (1.60 mm) Alum. Finish:

OTHER________________

Color:

QUANTITIES:

__ Lineal Feet (12'-0" (3.65 m) Lengths)

Outside Miters @ (

Inside Miters @ (

Right End Caps

Left End Caps

_______

______

°)

°)

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

print approval

72

Customer Service: Phone: 800^969-0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28011-3169

p: 800-969-0108

f: 610-916-9501

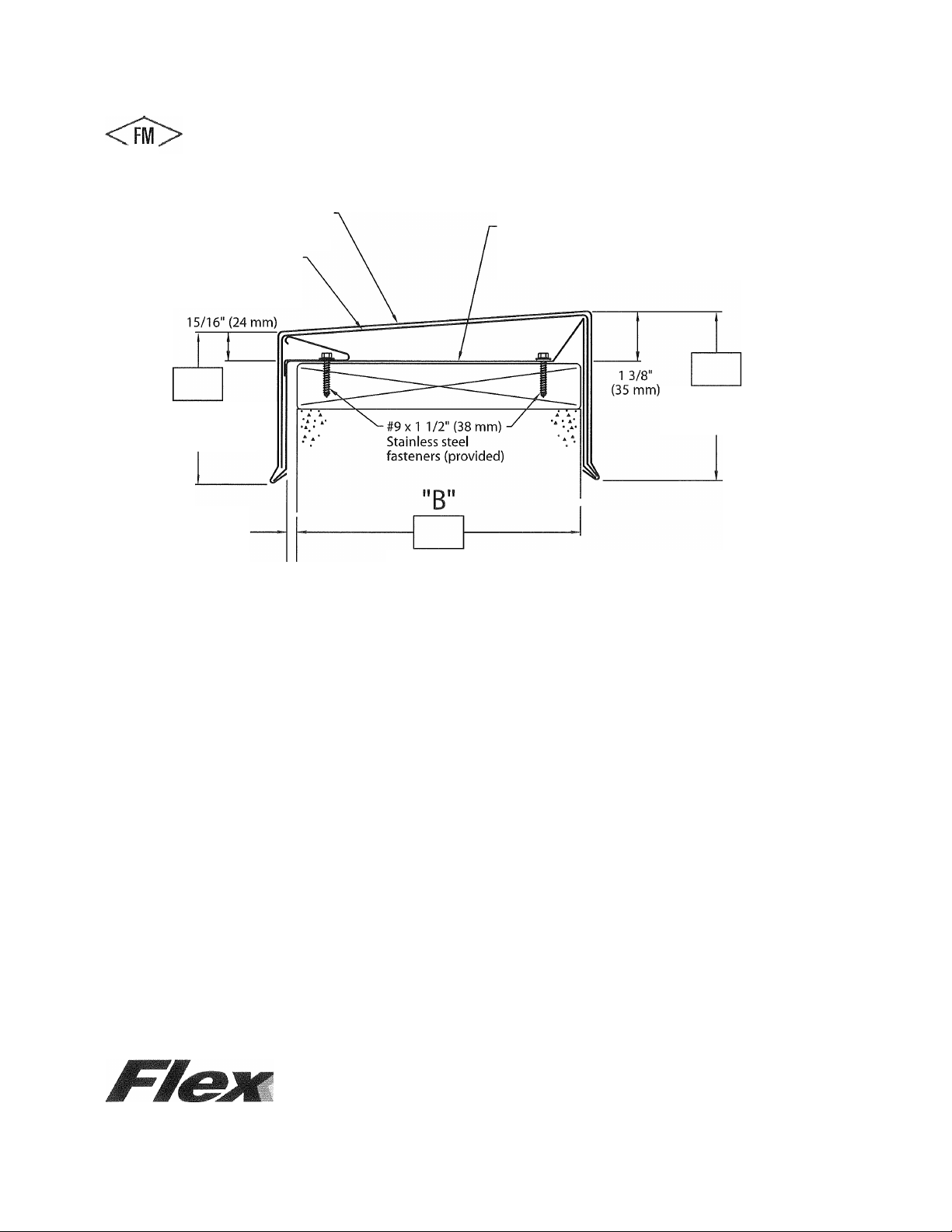

Page 3

s

APPROVED

Coping cover 12'-0"

(3.65 m) lengths

8" (203 mm) wide

concealed splice plate at

each joint

FLEXCAP FLC COPING

FLAT VERSION

ANSI/SPRI ES-1 TESTED

12" (305 mm) wide

20 ga. (1 mm) galvanized

anchor clips 4'-0" (1.22 m) o.c.

NOAK0.WWM Il'IDti

15/16"

(24 mm)

'A'

Inside Face

Min. 2 1/4" (57 mm)

Max. 6" (152 mm)

,1/

3/8" (10 mm)

space provided for

wall variations

Coping is to be installed per Specifications and Flex's Installation Instruction Dwg, # 28111-3454

- Concealed splice plates are provided with factory applied dual

non- curing sealant strips.

- Unless otherwise noted, fabrication of miters and accessories

are furnished standard utilizing a non-penetrating quicklock joint,

then factory sealed watertight.

■#9x 1 1/2" (38 mm)

Stainless steel

fasteners (provided)

B'

Actual wall width

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by:

Date:

______

15/16"

(24 mm)

"C"

Outside Face

Min. 3" (76 mm)

Max. 6" (152 mm)

_______t

- Welded Miters and Accessories

Check one □ Required (surcharge) □ Not applicable

MATERIAL:

__

24 Ga. (0.65 mm) Galv.

__

.040" (1.01 mm) Alum.

_ .050" (1.27 mm) Alum.

__

.063" (1.60 mm) Alum.

OTHER

Color:

Finish:

QUANTITIES:

__________

_

______

_______

_______

_______

Lineal Feet 12'-0" (3.65 m) Lengths

Outside Miters @ (

Inside Miters @ (

Right End Caps

Left End Caps

______

__

°)

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

p: 800-969-0108

f: 610-916-9501

Customer Service: Phone: 800--969-0108 Fax: 610-916-^9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28011-3458

print approval

c

73

Page 4

APPROVH

FLEXCAP FLC COPING

EXISTING SLOPE WITH NAILER VERSION

ANSI/SPRI ES-1 TESTED

L

Coping is to be installed per Specifications and Flex's Installation Instruction Dwg. # 28111-3460

- Concealed splice plates are provided with factory applied dual

non- curing sealant strips.

- Unless otherwise noted, fabrication of miters and accessories

are furnished standard utilizing a non-penetrating quicklock joint,

then factory sealed watertight.

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by:

Date:

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

_____

■ Welded Miters and Accessories

Check one □ Required (surcharge) □ Not applicable

MATERIAL:

__

24 Ga. (0.65 mm) Galv.

_ .040" (1.01 mm) Alum. Color:.

_ .050" (1.27 mm) Alum.

__

.063" (1.60 mm) Alum. Finish:

OTHER________________

QUANTITIES:

___

Lineal Feet 12'-0" (3.65 m) Lengths

Outside Miters @ (

Inside Miters @ (

Right End Caps

Left End Caps

_______

______

Customer Service: Phone: 800-969-0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

DWG# 28011-3459

°)

°)

SHT.# OF

c

print approvai

74

p: 800-969-0108

f: 610-916-9501

Page 5

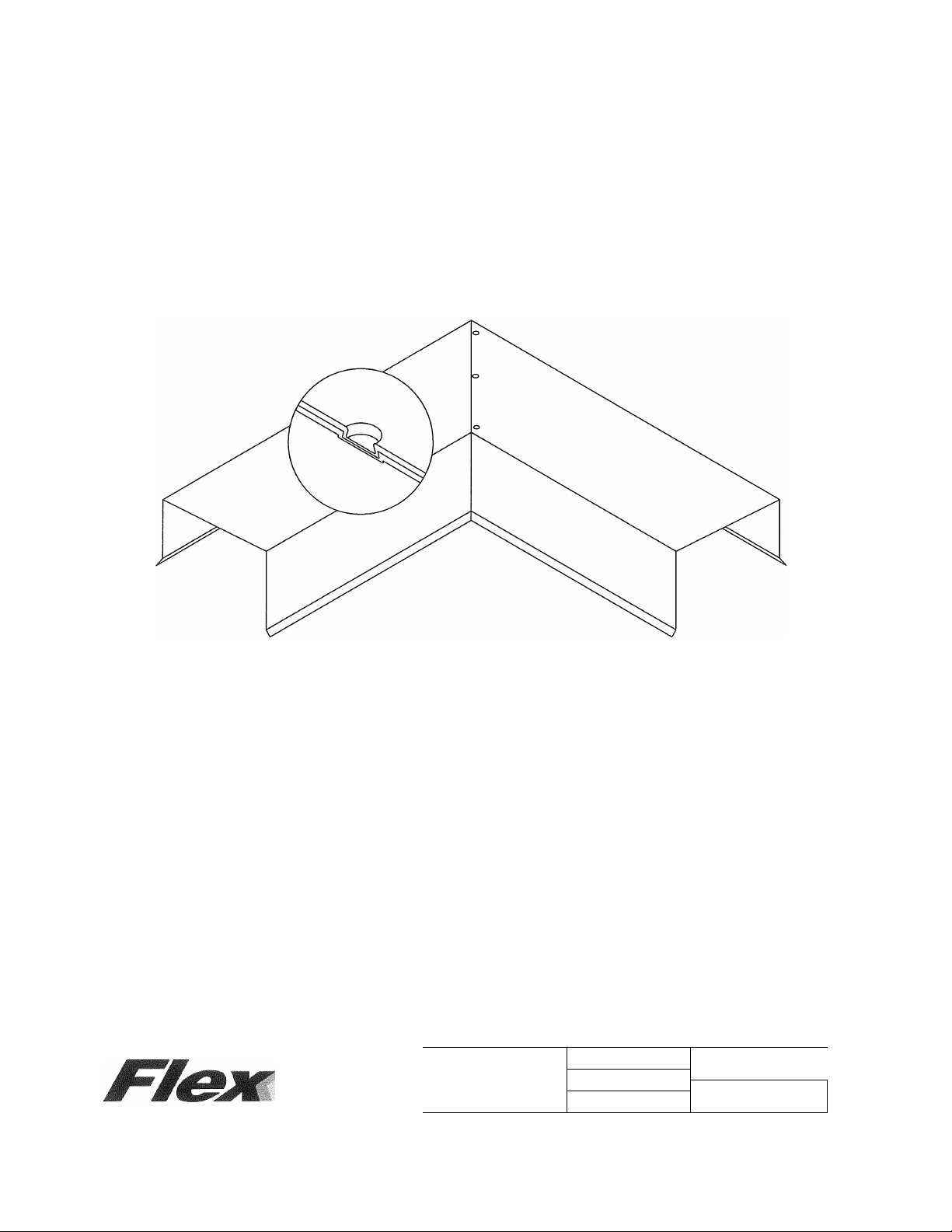

QUICKLOCK MITERS / ACCESSORIES

p: 800-969-0108

f: 610-916-9501

Non-penetrating lock without welding

Smooth, neat finished appearance

No leak lock

20 year Kynar finish warranty

Customer Service

Phone: 800-969-0108

Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28511-3462

detail

75

Page 6

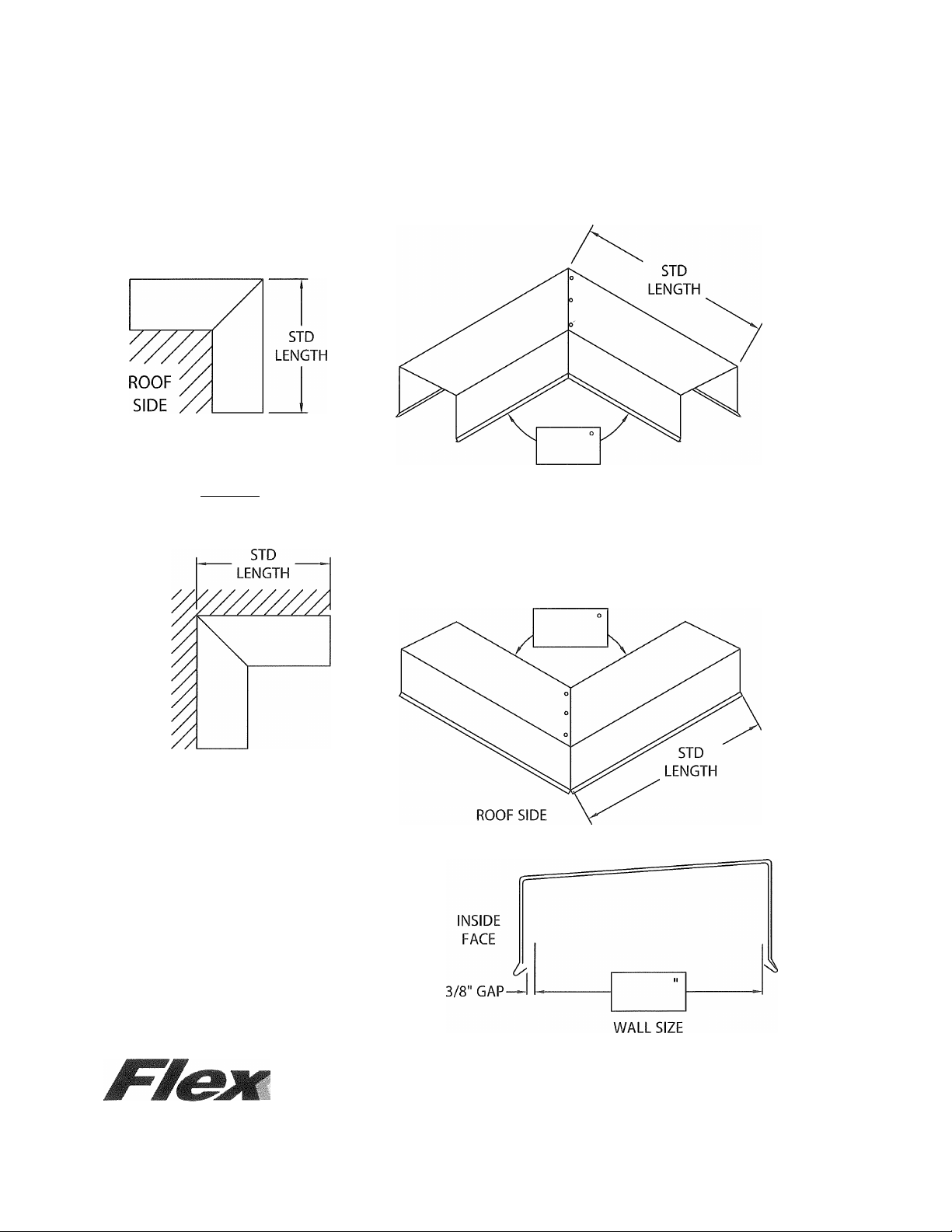

MITERS - QUICKLOCK CONSTRUCTION WITH SEALANT

OUTSIDE MITER

FLEXCAP FLC COPING

FLAT OR TAPERED

STANDARD OUTSIDE LEG LENGTH:

WALL SIZE + 9 5/8" = LENGTH

INSIDE MITER

ROOF

SIDE

STANDARD INSIDE LEG LENGTH:

WALL SIZE + 9 5/8" = LENGTH

* TREATED WOOD NAILERS RECOMMENDED

^ CUSTOM ANGLES & SIZES AVAILABLE

ROOF SIDE

OUTSIDE

FACE

detail

76

Customer Service

Phone: 800-969-0108

Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28511-3461

p: 800-969-0108

f: 610-916-9501

Page 7

"T" MITER

(TAPERED SHOWN)

ROOF SIDE

STRAIGHT TRANSITIONAL MITER

(TAPERED SHOWN)

FLEXCAP FLC COPING

FLAT OR TAPERED

MITERS - QUICKLOCK CONSTRUCTION WITH SEALANT

TRANSITIONAL MITER

(FOR 2 DIFFERENT WALL WIDTHS)

(TAPERED SHOWN)

NOTE: TREATED WOOD

NAILERS RECOMMENDED.

p: 800-969-0108

f: 610-916-9501

ROOF SIDE

Customer Service

Phone:800-969-0108

Fax:610-916-9501

NOTE: OUTSIDE MITER SHOWN

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

DWG# 28511-3463

SHTJ OF

detail

77

Page 8

FLEXCAP FLC COPING MITERS

QUICKLOCK MITER ASSEMBLY

detail

78

Customer Service

Phone: 800-969-0108

Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28511-3464

p: 800-969-0108

f: 610-916-9501

c

Page 9

FLEXCAP FLC COPING MITERS

WELDED PRE-FINISHED MITER ASSEMBLY

p: 800-969-0108

f: 610-916-9501

Customer Service

Phone: 800-969-0108

Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHTJ OF

DWG# 28511-3466

c

detail

79

Page 10

FLEXCAP FLC COPING MITERS

WELDED POST-FINISHED MITER ASSEMBLY

detail

80

Customer Service

Phone: 800-969-0108

Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHTJ OF

DWG# 28511-3468

p: 800-969-0108

f: 610-916-9501

c

Page 11

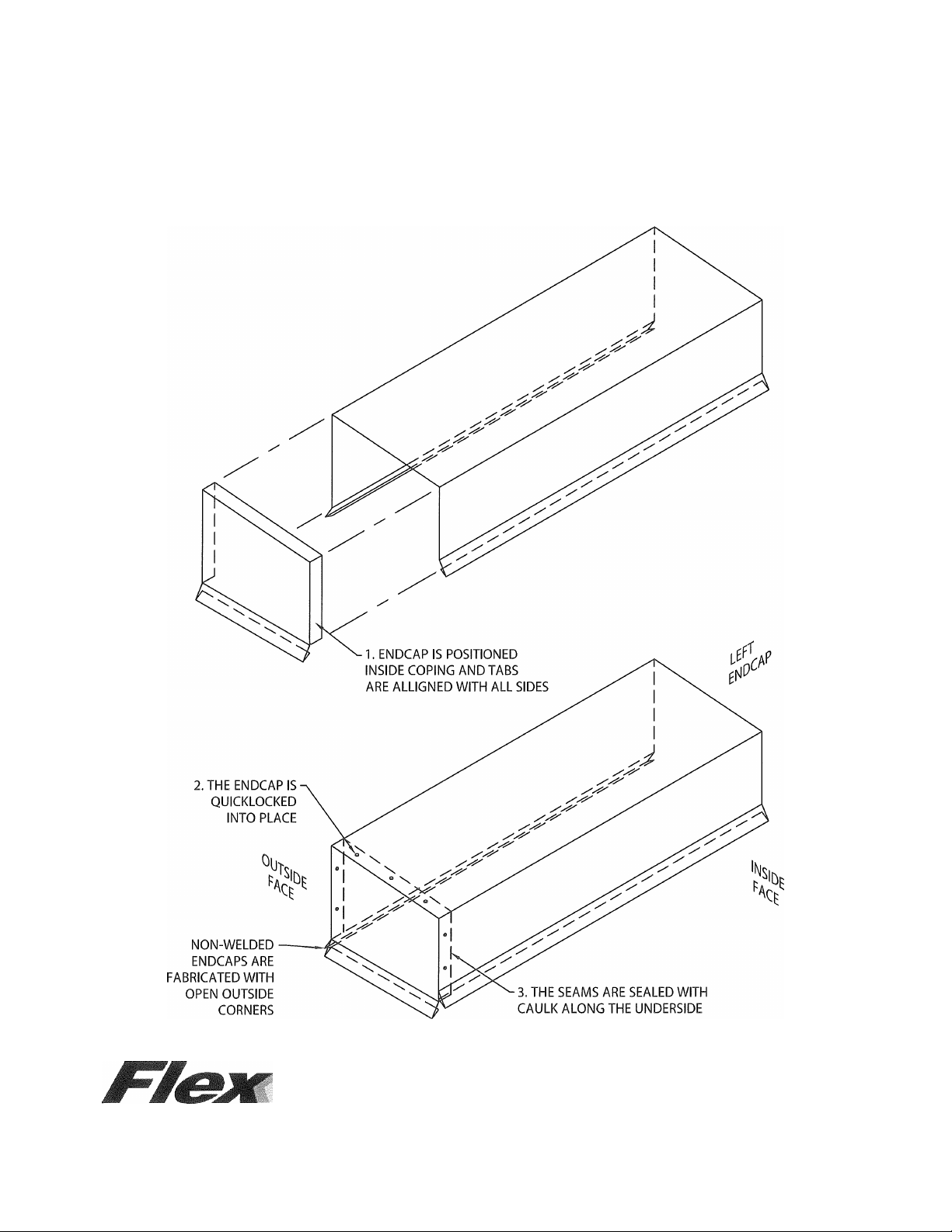

FLEXCAP FLC COPING ENDCAPS

STANDARD ENDCAP LENGTH IS 18’

QUICKLOCK ENDCAP ASSEMBLY

p: 800-969-0108

f: 610-916-9501

Customer Service

Phone: 800-969-0108

Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28511-3465

c

detail

81

Page 12

FLEXCAP FLC COPING ENDCAPS

WELDED PRE-FINISHED ENDCAP ASSEMBLY

detail

82

p: 800-969-0108

f: 610-916-9501

Page 13

FLEXCAP FLC COPING ENDCAPS

WELDED POST-FINISHED ENDCAP ASSEMBLY

p: 800-969-0108

f: 610-916-9501

detail

83

Page 14

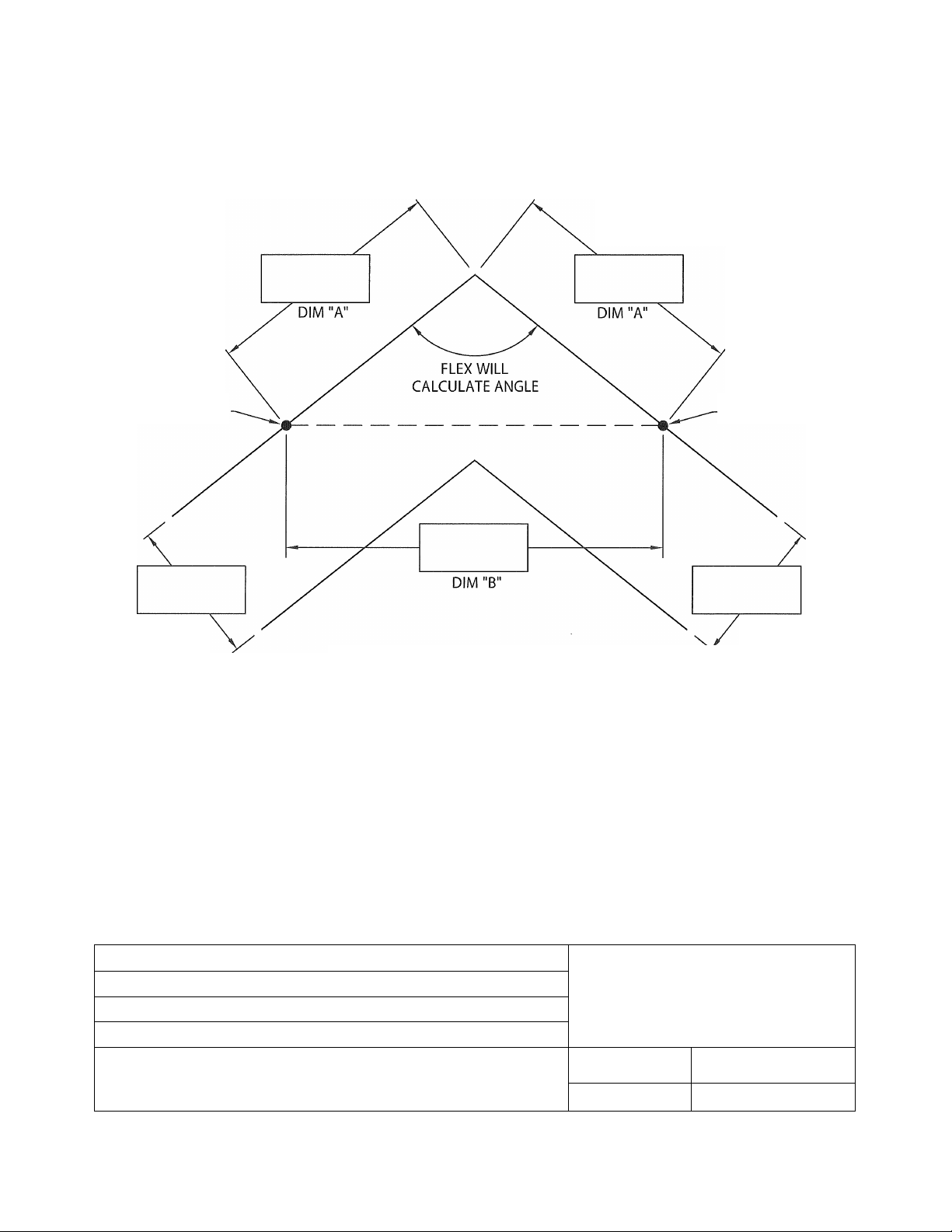

NON 90° ANGLE FOR COPING

MEASUREMENT WORKSHEET FOR USE WITHOUT A PROTRACTOR

ROOF

SIDE

PLACE MARK HERE

WALL

SIZE

1. CIRCLE APPROPRIATE "ROOF SIDE" TO INDICATE OUTSIDE MITER OR INSIDE MITER.

2. STARTING AT EITHER SIDE OF THE CORNER, MEASURE ALONG THE WALL EDGE A CONVENIENT

DIMENSION, SUCH AS 24" OR 36", DEPENDING ON JOB SITE CONDITIONS. PLACE A MARK ON

THE WALL AND RECORD MEASURED DIMENSION AS "DIM A" IN THE DRAWING ABOVE, REPEAT

PROCEDURE FOR THE OPPOSITE WALL, AS SHOWN ABOVE.

3. MEASURE STRAIGHT ACROSS FROM MARK TO MARK, AS SHOWN, AND RECORD THE MEASURED

DIMENSION AS "DIM B".

ROOF

SIDE

PLACE MARK HERE

WALL

SIZE

4. IF ORDERING COPING, PLEASE RECORD THE WALL SIZES WHERE INDICATED. FAX THIS SHEET

TO 610-916-9501 WITH ORDER.

PROJECT:

ARCHITECT:

Customer Service:

Phone: 800-969-0108

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

detail

84

Fax:610-916-9501

DATE: 12/13/10

DRN BY- JJC

CKD BY: SAK

SHT.# OF

DWG# 28811-3470 C

p: 800-969-0108

f: 610-916-9501

Page 15

NON 90° COPING MITERS

OUTSIDE MITER-OBTUSE

INSIDE MITER-OBTUSE

□ Standard Leg Lengths

□ Custom Leg Lengths _

Qty.

NOTES: -- Concealed splice plates are provided with factory

applied dual non-curing sealant strips.

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

□ Standard Leg Lengths

□ Custom Leg Lengths

OUTSIDE MITER

ACUTE

Qty.

- Unless otherwise noted, fabrication of miters and

accessories are furnished standard utilizing a non

penetrating quicklock joint, then factory sealed watertight.

— Welded Miters and Accessories

Check one □ Required (surcharge) □ Not applicable

MATERIALS:

__

24 Ga. (.65 mm) Steel

__

.040" (1.01 mm) Alum.

__

.050" (1.27 mm) Alum.

__

.063" (1.60 mm) Alum.

Other

Color:

Finish:

Approved by:

Date:

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

_____

REPRESENTATIVE/DISTRIBUTOR:

p: 800-969-0108

f: 610-916-9501

□ Tapered □ Flat

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

Customer Service:

Phone:800-969-0108

Fax:610-916-9501

SHT.# OF

DWG# 28011-3471

print approval

c

85

Page 16

COPING TRANSITION MITERS

□ Standard Leg Lengths

□ Custom Leg Lengths _

NOTES: -- Concealed splice plates are provided with factory

applied dual non-curing sealant strips.

- Unless otherwise noted, fabrication of miters and accessories are

furnished standard utilizing a non-penetrating quicklock joint,

then factory sealed watertight.

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by:

Date:

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

_____

□ Standard Leg Lengths

□ Custom Leg Lengths _

■ Welded Miters and Accessories

Check one □ Required (surcharge) □ Not applicable

MATERIAL:

__

24 Ga. (.65 mm) Steel

040" (1.01 mm) Alum.

__

.050" (1.27 mm) Alum.

__

.063" (1.60 mm) Alum.

Other

Color:

Finish:

QUANTITIES:

Outside Miter(s) @

Inside Miter(s) @ L

Customer Service: Phone: 800-969-0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT# OF

DWG# 28011-3474

c

print approval

86

p: 800-969-0108

f: 610-916-9501

Page 17

STRAIGHT COPING TRANSITIONS

NOTE: Indicate slope by circling appropriate outside face.

RIGHT TRANSITION

OUTSIDE

FACE

SPECIFY

WALL

SIZE

OUTSIDE

FACE

□ Standard Leg Lengths

□ Custom Leg Lengths _

NOTES: - Concealed splice plates are provided with factory

applied dual non-curing sealant strips.

- Unless otherwise noted, fabrication of miters and accessories are

furnished standard utilizing a non-penetrating quicklock joint,

then factory sealed watertight.

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

LEFT TRANSITION

OUTSIDE

FACE

□ Standard Leg Lengths

□ Custom Leg Lengths _

Welded Miters and Accessories

Check one □ Required (surcharge) □ Not applicable

MATERIAL:

__

24 Ga. (.65 mm) Steel

__

.040" (1.01 mm) Alum.

__

.050" (1.27 mm) Alum.

__

.063" (1.60 mm) Alum.

Other

QUANTITIES:

Right Transition(s)

OUTSIDE

FACE

SPECIFY

WALL

SIZE

Color:

Finish:

Approved by:

Date:

______________

____________________________

______

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

p; 800-969-0108

f: 610-916-9501

Left Transition(s)

Customer Service: Phone: 800-969-0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28011-3472

print approval

87

Page 18

OUTSIDE "T" COPING MITERS

RIGHT OUTSIDE "T" MITER

SPECIFY

WALL SIZE

WALL SIZE

SPECIFY inside

WALL SIZE face

OUTSIDE

OUTSIDE FACE

INSIDE

FACE

FACE

SPECIFY

WALL SIZE

NOTES: -- Concealed splice plates are provided with factory

applied dual non-curing sealant strips.

- Unless otherwise noted, fabrication of miters and accessories are

furnished standard utilizing a non-penetrating quicklock joint,

then factory sealed watertight.

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by: _____________________________

LEFT OUTSIDE "T" MITER

OUTSIDE FACE

SPECIFY

- Welded Miters and Accessories

INSIDE

FACE

SPECIFY

WALL SIZE

Check one □ Required (surcharge) □ Not applicable

MATERIAL:

_ 24 Ga. (.65 mm) Steel

__

.040" (1.01 mm) Alum.

_.050" (1.27 mm) Alum.

__

.063" (1.60 mm) Alum.

Other

Color:

Finish:

QUANTITIES:

Right Outside "T" Miter(s)

Left Outside "T" Miter(s)

SPECIFY

WALL SIZE

INSIDE

FACE

OUTSIDE

FACE

Date:

_____________________

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

print approval

88

Customer Service: Phone: 800-969-0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT# OF

DWG# 28011-3473

p: 800-969-0108

f: 610-916-9501

c

Page 19

INSIDE "T" COPING MITERS

RIGHT INSIDE "T" MITER

INSIDE FACE

SPECIFY

WALL SIZE OUTSIDE

FACE

INSIDE

FACE

SPECIFY

WALL SIZE

SPECIFY

WALL SIZE

OUTSIDE

FACE

WALL SIZE face

NOTES; - Concealed splice plates are provided with factory

applied dual non-curing sealant strips.

- Unless otherwise noted, fabrication of miters and accessories are

furnished standard utilizing a non-penetrating quicklock joint,

then factory sealed watertight.

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

LEFT INSIDE "T" MITER

SPECIFY OUTSIDE

INSIDE

FACE

- Welded Miters and Accessories

Check one □ Required (surcharge) □ Not applicable

MATERIAL:

__

24 Ga. (.65 mm) Steel

_.040" (1.01 mm) Alum.

_.050"(1.27mm) Alum.

__

.063" (1.60 mm) Alum. Finish;

Other

QUANTITIES:

Right Inside "T" Miter(s)

INSIDE FACE

SPECIFY

WALL SIZE

SPECIFY

WALL SIZE

OUTSIDE

FACE

Color:

Approved by:

Date: ______

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

p: 800-969-0108

f: 610-916-9501

Left Inside "T" Miter(s)

Customer Service: Phone: 800^969-0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28011-3475

print approval

89

Page 20

*7" COPING MITERS

OUTSIDE

FACE

R.H. QUANTITY,

□ STANDARD LEG LENGTHS

□ CUSTOM LEG LENGTHS _

OUTSIDE FACE HEIGHT

NOTES: - Concealed splice plates are provided with factory

“ Unless otherwise noted, fabrication of miters and accessories are

furnished standard utilizing a non-penetrating quicklock joint, then

factory sealed watertight.

Fabrication will proceed only after receipt of

signed print approval.

applied dual non-curing sealant strips.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

OUTSIDE

OUTSIDE FACE HEIGHT FACE

LH. QUANTITY.____________

□ STANDARD LEG LENGTHS

□ CUSTOM LEG LENGTHS _

- Welded Miters and Accessories

Check one □ Required (surcharge) □ Not applicable

MATERIAL:

__

24 Ga. (.65 mm) Steel

__

.040" (1.01 mm) Alum.

__

.050" (1.27 mm) Alum.

__

.063" (1.60 mm) Alum.

Other

Color:

Finish:

QUANTITIES:

Right Hand Miter(s) @ (_

Approved by:

Date:

_____

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR;

REPRESENTATIVE/DISTRIBUTOR:

print approval

90

Left Hand Miter(s) @

Customer Service: Phone: 800-^969-0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHTJ OF

DWG# 28011-3476

p: 800-969-0108

f: 610-916-9501

Page 21

STEP-UP COPING MITERS

LEFT HAND STEP-UP MITER

SPECIFY RISE

DIMENSION

DIRECTION IS DETERMINED AS SEEN FROM ROOF

NOTES:

^ Concealed splice plates are provided with factory

applied dual non-curing sealant strips.

^ Unless otherwise noted, fabrication of miters and

accessories are furnished standard utilizing a

non-penetrating quicklock joint, then factory sealed

watertight.

Fabrication will proceed only after receipt of

signed print approval.

OUTSIDE

FACE

RIGHT HAND STEP-UP MITER

SPECIFY RISE

DIMENSION

\ROOFO

- Welded Miters and Accessories

Check one □ Required (surcharge) □ Not applicable

MATERIALS:

__

24 GA. (.65 mm) Steel

__

.040" (1.01 mm) Aluminum

__

.050" (1.27 mm) Aluminum

__

.063" (1.60 mm) Aluminum

__

Other___________________

Color;______________________

Finish:

___________________

QUANTITIES:

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by:

Date:

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

p: 800-969-0108

f: 610-916-9501

_____

Inside

Face

Right Hand Step-Up Miter(s)

Left Hand Step-Up Miter(s)

Outside

Actual Wall Size

□ Tapered

Face

Inside

Face

Actual Wall Size

□ Flat

Customer Service: Phone: 800^969^0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28011-11382

Outside

Face

B

print approval

91

Page 22

ENDWALL FLASHING

SPLICE PLATE VERSION

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by:

Date:

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

print approval

92

_____

MATERIALS:

.040" (1.01 mm) Aluminum

Color:

______________________

Finish:______________________

QUANTITIES:

_____

Right End Flashing

_____

Left End Flashing

□ Tapered □ Flat

Customer Service: Phone: 800-969^0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28011-3477

p: 800-969-0108

f: 610-916-9501

c

Page 23

ENDWALL FLASHING

COPING VERSION

3"

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by;

Date:

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

p: 800-969-0108

f: 610-916-9501

______

MATERIALS:

__

24 GA. (0.65 mm) Steel

_.040" (1.01 mm) Alum.

__

.050" (1.27 mm) Alum.

__

.063" (1.60 mm) Alum.

Other

_________________

QUANTITIES:

_______

Right End Flashing .

□ Tapered □ Flat

Customer Service: Phone: 800-969^0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

Color;.

Finish:

Left End Flashing

SHT# OF

DWG# 28011-11384

print approval

В

93

Page 24

FLEXCAP FLC

QUICKLOCK RADIUS COPING

>

>

>

TYP.

Premanufactured radius coping utilizing a non-penetrating lock system.

The non-penetrating quicklock joint is then factory sealed watertight.

2 to 3 week lead time instead of the standard 5 to 6 week lead time for

welded post coated radius coping.

No welding required.

^ K-

QUICKLOCK

INSIDE EDGE

SEALANT

INSIDE

QUICKLOCK-

JOINT

SEALANT-

OUTSIDE

1 1/4 U—

TYP.

SEALANT

QUICKLOCK

OUTSIDE EDGE

QUICKLOCK

CROSS SECTION

W/ (2) DUAL ROWS

OF SEALANT 4'-0" SECTIONS

ANCHOR CLIP

^ Full snap-on desgn allows for fast easy installation. No crimping required.

^ Competitively priced when compared to locally fabricated roofer shop designs.

^ Custom fabricated to fit exact job requirements

> Corrosion resistant, stainless steel springs provided factory attached to anchor clips.

^ Concealed splice plates with sealant strips factory applied. No unsightly cover plates.

Customer Service

■ /-C;,, • ; \ Phone: 800-969-0108

M ru hax: 610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28511-3480

L

detail

94

p: 800-969-0108

f: 610-916-9501

Page 25

FLEXCAP FLC QUICKLOCK RADIUS COPING

TAPERED VERSION

IMPORTANT!!!

MUST INDICATE PROPER RADIUS CONDITION BY

CIRCLING APPROPRIATE OUTSIDE FACE

PROVIDING A RADIUS

THE RADIUS MAY BE PROVIDED

IN ONE OF TWO METHODS:

1.) THE ACTUAL KNOWN RADIUS IS

OR

2.) FIELD CONDITION MEASUREMENTS

NOTE: REFER TO ATTACHED WORKSHEET

MIN. 2 1/4" (57 mm)

MIDPOINT OF

STRAIGHT EDGE

(914 mm)

LENGTH OF

STRAIGHT EDGE

NOTE: CHECK MEASUREMENTS ALONG ENTIRE RADIUS.

DETAIL A

INSIDE

FACE

MAX. 6" (152 mm)

%"(10mm) SPACE

PROVIDED FOR

VUALL VARIATION

MIN. 3" (76 mm)

MAX. 6" (152 mm)

MOTF^" -- Concealed splice plates are provided with factory

- Fabrication of radius is furnished utilizing a non-penetrating

quicklock joint, then factory sealed watertight.

‘ applied dual non-curing sealant strips.

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by: _____________________________

Date;

_________________________

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

p: 800-969-0108

f: 610-916-9501

MATERIAL:

. 24 Ga. (.65 mm) Steel

. .040" (1.01 mm) Aluminum

. .050" (1.27 mm) Aluminum

. .063" (1.60 mm) Aluminum

Other

_________________

Color:

Finish:

QUANTITIES:

.Lineal Feet 4'-0" (1.22 m) Lengths

Customer Service: Phone: 800^969-0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28011-3481

print approval

95

Page 26

FLEXCAP FLC WELDED RADIUS COPING

TAPERED VERSION

IMPORTANT!!!

PROVIDING A RADIUS

THE RADIUS MAY BE PROVIDED

IN ONE OF TWO METHODS:

1.) THE ACTUAL KNOWN RADIUS IS

OR

2.) FIELD CONDITION MEASUREMENTS

NOTE: REFER TO ATTACHED WORKSHEET

MIDPOINT OF

STRAIGHT EDGE

(914 mm)

LENGTH OF

STRAIGHT EDGE

NOTE: CHECK MEASUREMENTS ALONG ENTIRE RADIUS.

DETAIL A

MUST INDICATE PROPER RADIUS CONDITION BY

CIRCLING APPROPRIATE OUTSIDE FACE

MIN. 2 1/4" (57 mm)

INSIDE

FACE

MAX. 6" (152 mm)

J^"(10mm) SPACE-

PROVIDED FOR

WALL VARIATION

OUTSIDE

FACE

ROOF LINE

TOP

VIEW

WELDED -

#9 X 1 1/2" (38 mm)

STAINLESS STEEL

FASTENERS (PROVIDED)

WALL

SIZE

_ -- Concealed splice plates are provided with factory

“ applied dual non-curing sealant strips.

RADIUS

(PROVIDED BY APPROVER

PER DETAIL A)

1 3/8"

(35 mm)

MIN. 3" (76 mm)

MAX. 6" (152 mm)

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by:

Date:

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

print approval

96

_____

MATERIALS:

Top - .080" (2.03 mm) Alum.

Sides - .063" (1.60 mm) Alum.

Color:_________________________

Finish:

________________________

QUANTITIES:

Lineal Feet 4-0" (1.22 m) Lengths

Customer Service: Phone: 800-969^0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHTJ OF

DWG# 28011-3478

p: 800-969-0108

f: 610-916-9501

c

Page 27

FLEXCAP FLC QUICKLOCK RADIUS COPING

FLAT VERSION

IMPORTANT!!!

PROVIDING A RADIUS

THE RADIUS MAY BE PROVIDED

IN ONE OF TWO METHODS:

1.) THE ACTUAL KNOWN RADIUS IS

OR

2.) FIELD CONDITION MEASUREMENTS

NOTE: REFER TO ATTACHED WORKSHEET

MIDPOINT OF

STRAIGHT EDGE

(914 mm)

LENGTH OF

STRAIGHT EDGE

NOTE: CHECK MEASUREMENTS ALONG ENTIRE RADIUS.

DETAIL A

MUST INDICATE PROPER RADIUS CONDITION BY

CIRCLING APPROPRIATE OUTSIDE FACE

MIN. 2 1/4" (57 mm)

INSIDE

FACE

MAX. 6" (152 mm)

%''(10mm) SPACE

PROVIDED FOR

WALL VARIATION

OUTSIDE

FACE

ROOF LINE

TOP

VIEW

MOTF^* ” splice plates are provided with factory

“ Fabrication of radius is furnished utilizing a non-penetrating

quicklock joint, then factory sealed watertight.

■ applied dual non-curing sealant strips.

RADIUS

(PROVIDED BY APPROVER

PER DETAIL A)

SEALANT

MIN. 3" (76 mm)

MAX. 6" (152 mm)

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by: ____________

Date:

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

p: 800-969-0108

f; 610-916-9501

_________________

MATERIAL:

___

24 Ga. (.65 mm) Steel

___

.040" (1.01 mm) Aluminum

___

.050" (1.27 mm) Aluminum

___

.063" (1.60 mm) Aiuminum

___

Other__________________

Color:

__________________________

Finish:

QUANTITIES:

Customer Service: Phone: 800^969-0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

.Lineal Feet 4'-0" (1.22 m) Lengths

SHT# OF

DWG# 28011-11386

print approval

B

97

Page 28

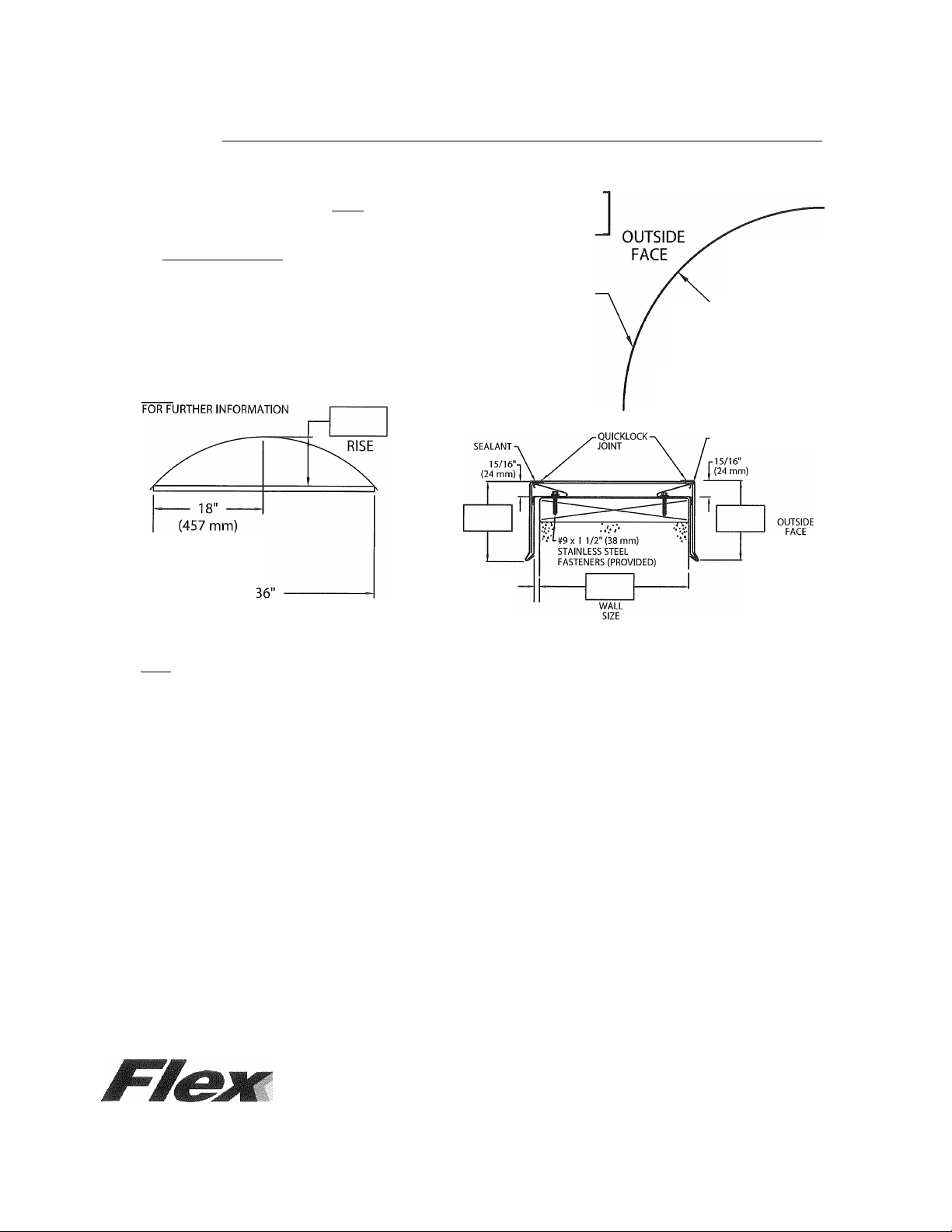

FLEXCAP FLC WELDED RADIUS COPING

FLAT VERSION

IMPORTANT!!!

PROVIDING A RADIUS

THE RADIUS MAY BE PROVIDED

IN ONE OF TWO METHODS:

1.) THE ACTUAL KNOWN RADIUS IS

OR

2.) FIELD CONDITION MEASUREMENTS

NOTE: REFER TO ATTACHED WORKSHEET

(457 mm)

MIDPOINT OF

STRAIGHT EDGE

(914 mm)

LENGTH OF

STRAIGHT EDGE

NOTE: CHECK MEASUREMENTS ALONG ENTIRE RADIUS.

DETAIL A

MUST INDICATE PROPER RADIUS CONDITION BY

CIRCLING APPROPRIATE OUTSIDE FACE

MIN. 2 1/4" (57 mm)

INSIDE

FACE

MAX. 6" (152 mm)

3/^"(10mm) SPACE

PROVIDED FOR

WALL VARIATION

15/16“

(24 mm) I

OUTSIDE

FACE

ROOF LINE

TOP

VIEW

MOTF^* “ Concealed splice plates are provided with factory

” applied dual non-curing sealant strips.

RADIUS

(PROVIDED BY APPROVER

PER DETAIL A)

15/16“

(24 mm)

OUTSIDE

MIN. 3“ (76 mm)

MAX. 6“ (152 mm)

FACE

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by:

Date:

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

print approval

98

_____

MATERiALS:

Top - .080" (2.03 mm) Alum.

Sides - .063" (1.60 mm) Alum.

Color:_________________________

Finish:

________________________

QUANTITiES:

Lineal Feet 4'-0" (1.22 m) Lengths

Customer Service: Phone: 800-969-0108 Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28011-11385

p: 800-969-0108

f: 610-916-9501

B

Page 29

2 PC COUNTERFLASHING

REGLET AND SURFACE VERSION

NOTE: PRE-NOTCHED LAP JOINT 3" (76 mm)

Fabrication will proceed only after receipt of

signed print approval.

Print Approval:

Architect and/or contractor shall verify all

dimensions, sizes and quantities. All

products to be installed in strict accordance

with Flex's printed instructions.

Approved by:

Date:

PROJECT:

ARCHITECT:

ROOFING CONTRACTOR:

REPRESENTATIVE/DISTRIBUTOR:

______

MATERIAL:

__

24 Ga. (.65 mm) Galv.

__

.040" (1.01 mm) Alum,

__

.050" (1.27 mm) Alum.

OTHER

_______________

QUANTITIES:

Lineal Feet (12'-0" (3.65 m) Lengths)

Customer Service:

Phone:800-969-0108

Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

Color:_

Finish:

SHT.# OF

DWG# 28015-11392

B

p: 800-969-0108

f: 610-916-9501

print approval

99

Page 30

m

Q.

t*

-- O

o o

'lO

—* m

Oik %o

ma

o

tn —“

o o

—^ as

TYPICAL COPING COMPONENTS

Customer Service

Phone: 800-969-0108

Fax:610-916-9501

DATE: 12/13/10

DRN BY: JJC

CKD BY: SAK

SHT.# OF

DWG# 28511-3455

Loading...

Loading...