FLENDER BNN, BIPEX-S, BGG, BHH, BCS Operating Instructions Manual

...

FLENDER COUPLINGS

BIPEX-S

Operating Instructions 3410en

Edition 10/2017

BNN, BGG, BCC, BHH, BKK, BCS, BHH-W

21.09.2017 12:18

V6.00

FLENDER COUPLINGS

BIPEX-S

3410en

BNN, BGG, BCC, BHH, BKK, BCS, BHH-W

Introduction

1

Operating Instructions

Safety instructions

Description

Application planning

Assembly

Commissioning

Operation

Servicing

2

3

4

5

6

7

8

Service and support

Disposal

Spare parts

Technical data

9

10

11

A

Edition 10/2017

Legal information

Warning notice system

This manual contains notices you have to observe in order to ensure your personal safety, as well as to prevent

damage to property. The notices referring to your personal safety are highlighted in the manual by a safety alert

symbol, notices referring only to property damage have no safety alert symbol. These notices shown below are

graded according to the degree of danger.

DANGER

indicates that death or severe personal injury will result if proper precautions are not taken.

WARNING

indicates that death or severe personal injury may result if proper precautions are not taken.

CAUTION

indicates that minor personal injury can result if proper precautions are not taken.

NOTICE

indicates that property damage can result if proper precautions are not taken.

If more than one degree of danger is present, the warning notice representing the highest degree of danger will be

used. A notice warning of injury to persons with a safety alert symbol may also include a warning relating to property

damage.

Qualified Personnel

The product/system described in this documentation may be operated only by personnel qualified for the specific

task in accordance with the relevant documentation, in particular its warning notices and safety instructions. Qualified

personnel are those who, based on their training and experience, are capable of identifying risks and avoiding

potential hazards when working with these products/systems.

Proper use of Flender products

Note the following:

WARNING

Flender products may only be used for the applications described in the catalog and in the relevant technical

documentation. If products and components from other manufacturers are used, these must be recommended or

approved by Flender. Proper transport, storage, installation, assembly, commissioning, operation and maintenance

are required to ensure that the products operate safely and without any problems. The permissible ambient

conditions must be complied with. The information in the relevant documentation must be observed.

Trademarks

All names identified by ® are registered trademarks of Flender GmbH. The remaining trademarks in this publication

may be trademarks whose use by third parties for their own purposes could violate the rights of the owner.

Disclaimer of Liability

We have reviewed the contents of this publication to ensure consistency with the hardware and software described.

Since variance cannot be precluded entirely, we cannot guarantee full consistency. However, the information in

this publication is reviewed regularly and any necessary corrections are included in subsequent editions.

Flender GmbH

Alfred-Flender-Straße 77

46395 BOCHOLT

GERMANY

Document order number: 3410en

Ⓟ 09/2017 Subject to change

Copyright © Flender GmbH 2016, -,

2017.

All rights reserved

Table of contents

1 Introduction...................................................................................................................................................9

1.1 About these instructions...........................................................................................................9

1.2 Text attributes..........................................................................................................................9

1.3 Copyright..................................................................................................................................9

2 Safety instructions......................................................................................................................................11

2.1 General information................................................................................................................11

2.2 Intended use..........................................................................................................................12

2.3 General warning notices........................................................................................................13

3 Description..................................................................................................................................................15

4 Application planning...................................................................................................................................23

4.1 Transport of the coupling.......................................................................................................23

4.2 Storage of the coupling..........................................................................................................23

5 Assembly....................................................................................................................................................25

5.1 Preparatory work....................................................................................................................25

5.2 Assembling the coupling........................................................................................................26

5.2.1 Assembling the coupling parts...............................................................................................26

5.2.1.1 Attach the coupling part N (1) with parallel key to the shaft...................................................26

5.2.1.2 Attaching coupling part G (2), C (3), H (4) or K (5) to the shaft with a clamping connection......27

5.2.1.3 Attach coupling part S (6) to the hollow shaft with a clamping connection............................27

5.2.2 Plug-in assembly of the coupling halves................................................................................28

5.2.2.1 Plug-in assembly of types BNN, BGG, BCC, BHH, BKK and BCS........................................28

5.2.2.2 Plug-in assembly of type BHH-W...........................................................................................28

5.3 Aligning the coupling..............................................................................................................29

5.3.1 Purpose of alignment.............................................................................................................29

5.3.2 Possible misalignment...........................................................................................................29

5.3.2.1 Axial misalignment.................................................................................................................30

5.3.2.2 Angular misalignment.............................................................................................................30

5.3.2.3 Radial misalignment...............................................................................................................30

6 Commissioning...........................................................................................................................................31

7 Operation....................................................................................................................................................33

7.1 Normal operation of the coupling...........................................................................................33

7.2 Faults - causes and rectification.............................................................................................33

7.2.1 Procedure in the event of malfunctions..................................................................................33

7.2.2 Identifying the fault cause......................................................................................................33

7.2.2.1 Possible faults........................................................................................................................34

7.2.2.2 Possible causes.....................................................................................................................35

7.2.3 Correcting faults.....................................................................................................................36

BIPEX-S 3410en

Operating Instructions 10/2017 5

Table of contents

7.2.3.1 Replacing wearing parts.........................................................................................................36

7.2.3.2 Correcting the changed alignment.........................................................................................37

8 Servicing.....................................................................................................................................................39

8.1 Maintenance intervals............................................................................................................39

8.2 Maximum permissible torsional backlash...............................................................................40

8.3 Replacing wearing parts.........................................................................................................40

8.4 Removing coupling part N (1)................................................................................................41

8.5 Removing coupling part G (2), C (3), H (4) or K (5)...............................................................42

8.6 Removing coupling part S (6).................................................................................................42

9 Service and support....................................................................................................................................43

9.1 Contact...................................................................................................................................43

10 Disposal......................................................................................................................................................45

11 Spare parts.................................................................................................................................................47

11.1 Ordering spare parts..............................................................................................................47

11.2 Spare parts drawing and spare parts list................................................................................48

11.2.1 Type BNN...............................................................................................................................48

11.2.2 Type BGG..............................................................................................................................49

11.2.3 Type BCC...............................................................................................................................50

11.2.4 Type BHH...............................................................................................................................51

11.2.5 Type BKK...............................................................................................................................52

11.2.6 Type BCS...............................................................................................................................53

11.2.7 Type BHH-W..........................................................................................................................54

A Technical data............................................................................................................................................55

A.1 Speeds, geometry data and weights......................................................................................55

A.1.1 Type BNN...............................................................................................................................55

A.1.2 Type BGG..............................................................................................................................56

A.1.3 Type BCC...............................................................................................................................57

A.1.4 Type BHH...............................................................................................................................58

A.1.5 Type BKK...............................................................................................................................59

A.1.6 Type BCS...............................................................................................................................60

A.1.7 Type BHH-W..........................................................................................................................61

A.2 Shaft misalignment values during operation..........................................................................62

A.3 Tightening torques and widths A/F.........................................................................................63

A.4 Tightening procedure.............................................................................................................63

A.5 Cam rings...............................................................................................................................64

A.5.1 Use and storage of the cam rings..........................................................................................64

A.5.2 BIPEX-S cam ring (20)...........................................................................................................64

Tables

Table 4-1 Types of preservative agents for long-term storage....................................................................24

BIPEX-S 3410en

6 Operating Instructions 10/2017

Table of contents

Table 7-1 Table of faults..............................................................................................................................34

Table 8-1 Maintenance intervals.................................................................................................................39

Table 8-2 Maximum permissible torsional backlash for the BIPEX-S coupling...........................................40

Table 11-1 Spare parts list for type BNN.......................................................................................................48

Table 11-2 Spare parts list for type BGG......................................................................................................49

Table 11-3 Spare parts list for type BCC.......................................................................................................50

Table 11-4 Spare parts list for type BHH.......................................................................................................51

Table 11-5 Spare parts list for type BKK.......................................................................................................52

Table 11-6 Spare parts list for type BCS.......................................................................................................53

Table 11-7 Spare parts list for type BHH-W..................................................................................................54

Table A-1 Geometry data and weights of type BNN....................................................................................56

Table A-2 Geometry data and weights of type BGG....................................................................................57

Table A-3 Geometry data and weights of type BCC....................................................................................58

Table A-4 Geometry data and weights of type BHH....................................................................................58

Table A-5 Geometry data and weights of type BKK....................................................................................59

Table A-6 Geometry data and weights of type BCS....................................................................................60

Table A-7 Geometry data and weights of type BHH-W...............................................................................61

Table A-8 Maximum permissible shaft misalignment values during operation............................................62

Table A-9 Tightening torques TAand widths A/F SW for parts 11, 12 and 13..............................................63

Table A-10 Tightening procedure..................................................................................................................63

Table A-11 BIPEX-S cam ring.......................................................................................................................64

Figures

Figure 3-1 Type BNN....................................................................................................................................16

Figure 3-2 Type BGG...................................................................................................................................17

Figure 3-3 Type BCC....................................................................................................................................17

Figure 3-4 Type BHH....................................................................................................................................18

Figure 3-5 Type BKK....................................................................................................................................19

Figure 3-6 Type BCS....................................................................................................................................20

Figure 3-7 Type BHH-W...............................................................................................................................21

Figure 4-1 Transport symbols.......................................................................................................................23

Figure 5-1 Possible misalignment.................................................................................................................29

Figure 8-1 Markings for calculating the torsional backlash...........................................................................40

Figure 11-1 Spare parts drawing for type BNN...............................................................................................48

Figure 11-2 Spare parts drawing for type BGG..............................................................................................49

Figure 11-3 Spare parts drawing for type BCC...............................................................................................50

Figure 11-4 Spare parts drawing for type BHH...............................................................................................51

Figure 11-5 Spare parts drawing for type BKK...............................................................................................52

BIPEX-S 3410en

Operating Instructions 10/2017 7

Table of contents

Figure 11-6 Spare parts drawing for type BCS...............................................................................................53

Figure 11-7 Spare parts drawing for type BHH-W..........................................................................................54

Figure A-1 Type BNN....................................................................................................................................55

Figure A-2 Type BGG...................................................................................................................................56

Figure A-3 Type BCC....................................................................................................................................57

Figure A-4 Type BHH....................................................................................................................................58

Figure A-5 Type BKK....................................................................................................................................59

Figure A-6 Type BCS....................................................................................................................................60

Figure A-7 Type BHH-W...............................................................................................................................61

BIPEX-S 3410en

8 Operating Instructions 10/2017

Introduction

1.1 About these instructions

These instructions describe the coupling and provide information about its handling - from

assembly to maintenance. Please keep these instructions for later use.

Please read these instructions prior to handling the coupling and follow the information in them.

1.2 Text attributes

The warning notice system is explained on the back of the inner cover. Always follow the safety

information and notices in these instructions.

In addition to the warning notices, which have to be observed without fail, you will find the

following text attributes in these instructions:

1. Procedural instructions are shown as a numbered list. Always perform the steps in the order

given.

● Lists are formatted as bulleted lists.

– The dash is used for lists at the second level.

1

(1) Numbers in brackets are part numbers.

Note

A note is an important item of information about the product, the handling of the product or the

relevant section of the instructions. The note provides you with help or further suggestions/

ideas.

1.3 Copyright

The copyright for these instructions is held by Flender.

These instructions must not be used wholly or in parts without our authorisation or be given to

third parties.

If you have any technical queries, please contact our factory or one of our service outlets (refer

to Service and support (Page 43)).

BIPEX-S 3410en

Operating Instructions 10/2017 9

Introduction

1.3 Copyright

BIPEX-S 3410en

10 Operating Instructions 10/2017

Safety instructions

2.1 General information

Instructions

These instructions are part of the delivery. Always keep these instructions close to the coupling.

Please make sure that every person who is commissioned to work on the coupling has read

and understood these instructions prior to handling the coupling and observes all of the points.

Only the knowledge of these instructions can avoid faults on the coupling and ensure fault-free

and safe operation. Non-adherence to the instructions can cause product or property damage

or personal injury. Flender does not accept any liability for damage or operating failures that

are due to non-adherence to these instructions.

State of the art

The coupling described here has been designed in consideration of the latest findings for

demanding technical requirements. This coupling is state-of-the-art at the time of printing these

instructions.

In the interest of further development, Flender reserves the right to make such changes to the

individual components and accessories that increase performance and safety whilst

maintaining the essential features.

2

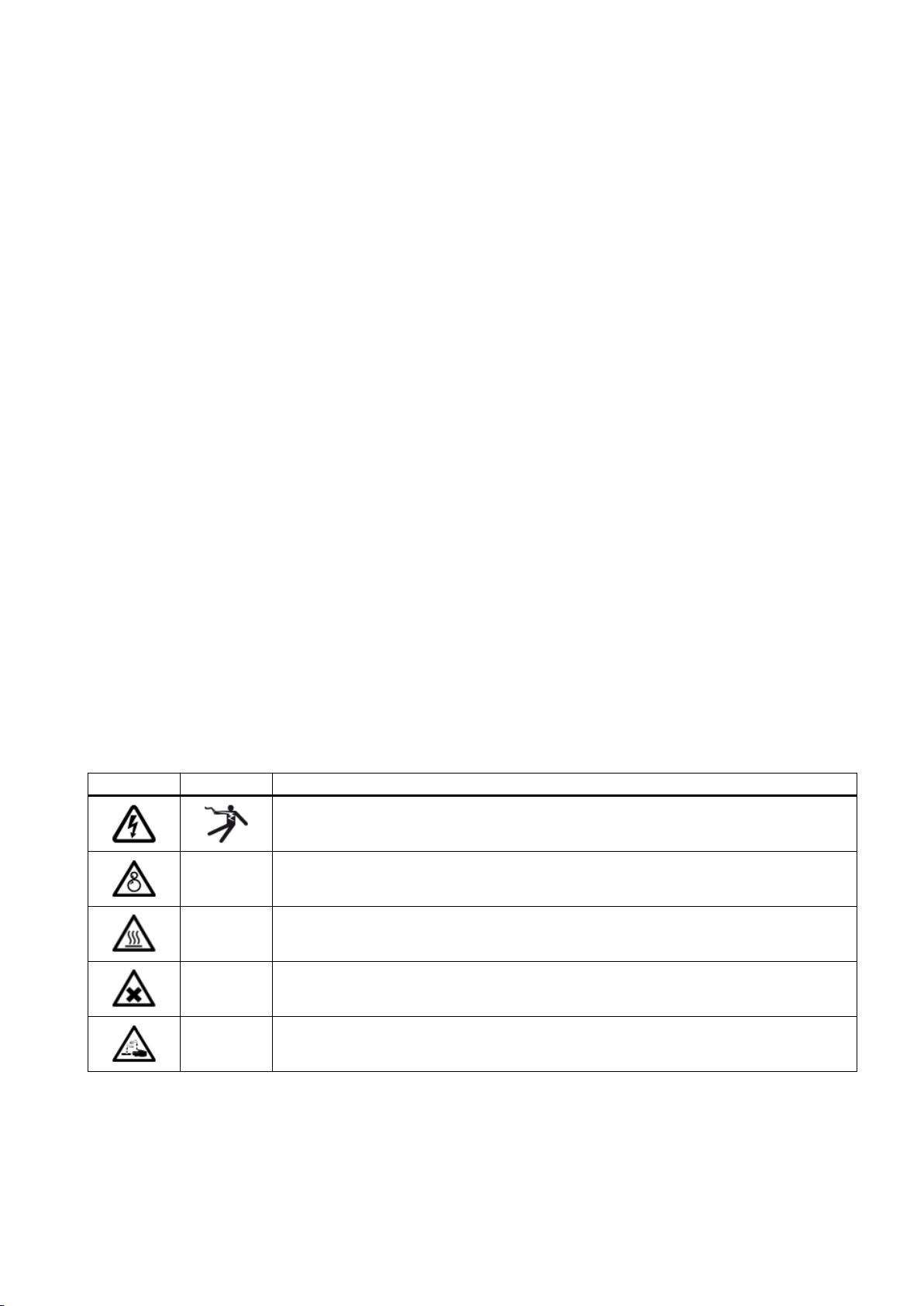

Symbols

ISO ANSI Warning

Warning - hazardous electrical voltage

--- Warning - entanglement hazard

--- Warning - hot surfaces

--- Warning - substances that are harmful to health or are irritants

--- Warning - corrosive substances

BIPEX-S 3410en

Operating Instructions 10/2017 11

Safety instructions

2.2 Intended use

ISO ANSI Warning

--- Warning - suspended load

--- Warning - hand injuries

Explanation regarding Machinery Directive 2006/42/EC

The couplings described here are “components” in accordance with the Machinery Directive

and do not require a declaration of incorporation.

Protective clothing

In addition to the generally prescribed personal protective equipment (safety shoes, overalls,

helmet, etc.), also wear suitable safety gloves and safety goggles when handling the coupling.

Using the coupling

The relevant work safety and environmental protection regulations must be complied with at

all times during transport, assembly, installation, dismantling, operation and maintenance of

the coupling.

Only qualified personnel may operate, assemble, maintain and repair the coupling. Information

about qualified personnel can be found in the legal notes at the beginning of these instructions.

If lifting gear or load suspension devices are used for transporting, these have to be suitable

for the weight of the coupling.

If the coupling has visible damage, it may not be assembled or put into operation.

The coupling may only be operated in a suitable housing or with touch protection according to

applicable standards. This also applies to test runs and rotational direction checks.

Work on the coupling

Only carry out work on the coupling when it is not in operation and is not under load.

Secure the drive unit against being switched on accidentally. Attach a notice to the switch

stating clearly that work is being carried out on the coupling. Ensure that the entire unit is not

under load.

2.2 Intended use

Only use the coupling according to the conditions specified in the service and delivery contract

and the technical data in the annex. Deviating operating conditions are considered improper

use. The user or owner of the machine or plant is solely liable for any resulting damage.

BIPEX-S 3410en

12 Operating Instructions 10/2017

When using the coupling please specifically observe the following:

● Do not make any modifications to the coupling that go beyond the permissible machining

described in these instructions. This also applies to touch protection facilities.

● Only use original spare parts from Flender. Flender only accepts liability for original spare

parts from Flender.

Other spare parts are not tested and approved by Flender. Non-approved spare parts may

possibly change the design characteristics of the coupling and thus impact active and/or

passive safety.

Flender will accept no liability or warranty whatsoever for damage occurring as a result of

the use of non-approved spare parts. The same applies to any accessories that were not

supplied by Flender.

If you have any queries, please contact our customer service (see Service and support

(Page 43)).

2.3 General warning notices

Safety instructions

2.3 General warning notices

WARNING

Danger due to bursting of the coupling

The coupling may burst if it is not used properly. There is a risk of fatal injury from flying

fragments.

● Use the coupling for the purpose for which it is intended.

WARNING

Danger from hot coupling parts

Risk of injury due to hot surfaces.

● Wear suitable protective equipment (gloves, safety goggles).

WARNING

Risk of chemical burns due to chemical substances

There is a risk of chemical burns when handling aggressive cleaning agents.

● Please observe the manufacturer's information on how to handle cleaning agents and

solvents.

● Wear suitable protective equipment (gloves, safety goggles).

CAUTION

Physical injury

Risk of injury due to falling coupling parts.

● Secure the coupling parts to prevent them from falling.

BIPEX-S 3410en

Operating Instructions 10/2017 13

Safety instructions

2.3 General warning notices

BIPEX-S 3410en

14 Operating Instructions 10/2017

Description

Application

Design

3

The BIPEX-S couplings described here are torsionally flexible claw couplings that are free of

torsional backlash and are available in various types and sizes. They are characterised by a

very compact design.

BIPEX-S couplings are fail-safe.

These instructions describe the assembly and operation of a BIPEX-S coupling arranged

horizontally with a shaft-hub connection made by a cylindrical or conical bore with a parallel

key or by various clamping connections. Please consult Flender if you want to use a different

type of installation.

BIPEX-S couplings are designed for use in all kinds of machines. They are primarily used in

drive units with torque transmission without any backlash and only low misalignment.

A BIPEX-S coupling consists of two hub parts that are connected to one another by a cam ring

made of an elastomer material. In the BHH-W type the hub parts are connected to one another

by two cam rings and a spacer.

The cam ring is fitted between the hub cams with a small amount of interference. The coupling

characteristic of zero backlash is based on this.

The hub parts are joined to the shaft by finished bores with a parallel key or various clamping

connections.

The diagrams show the various types with their constituent parts and their part numbers.

BIPEX-S 3410en

Operating Instructions 10/2017 15

Description

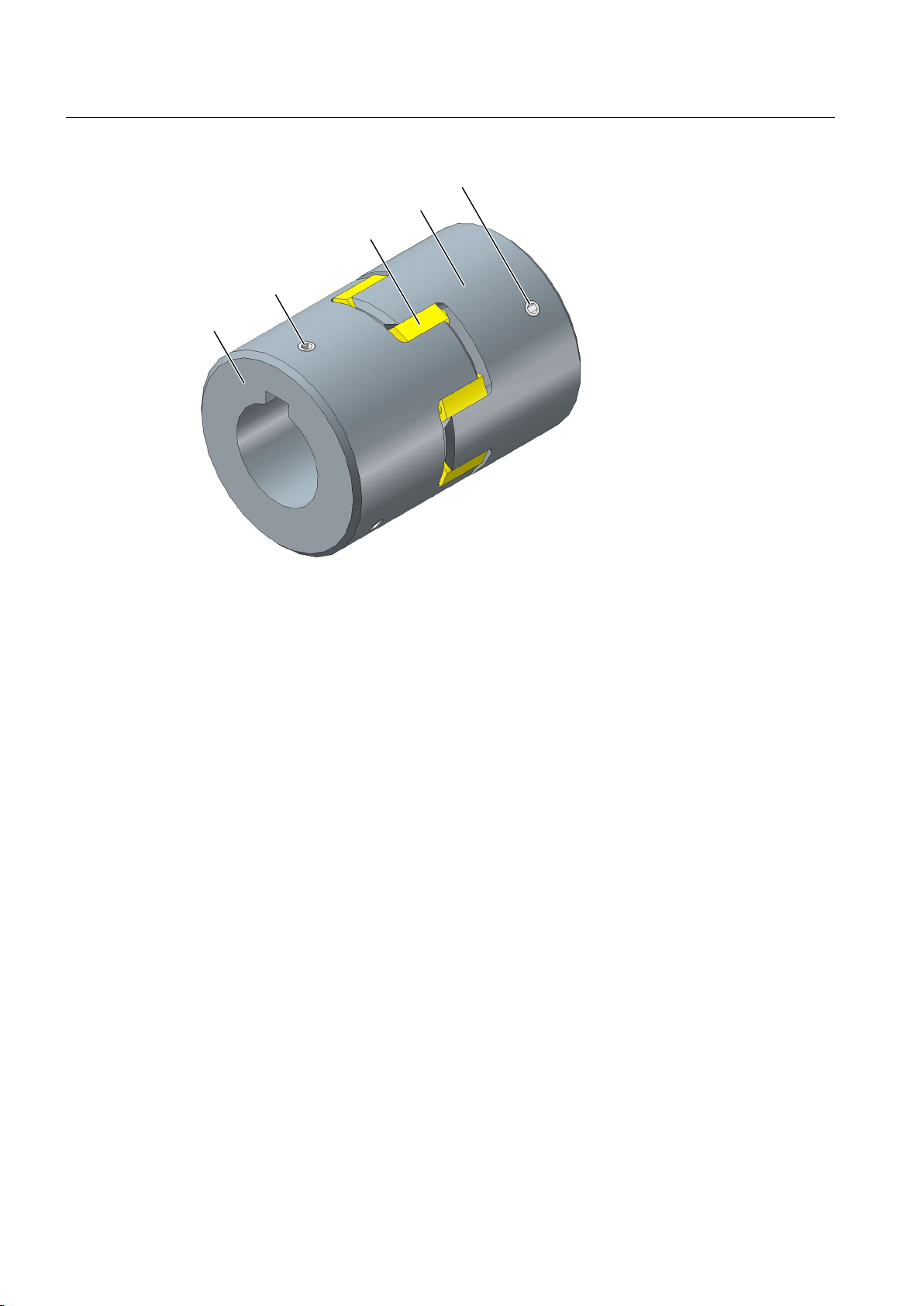

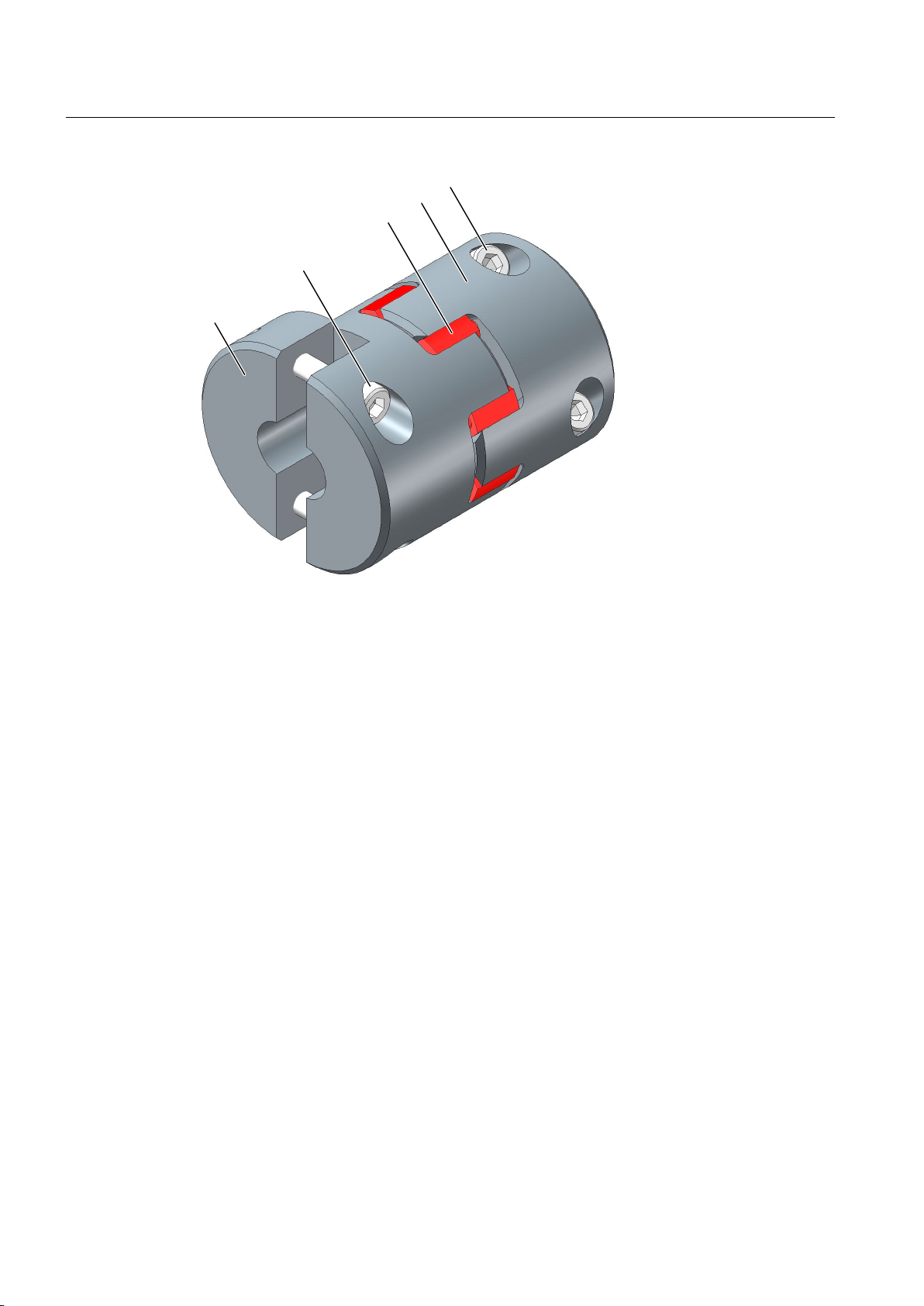

1 Coupling part N

11 Set screw

20 Cam ring

Figure 3-1 Type BNN

BIPEX-S 3410en

16 Operating Instructions 10/2017

Description

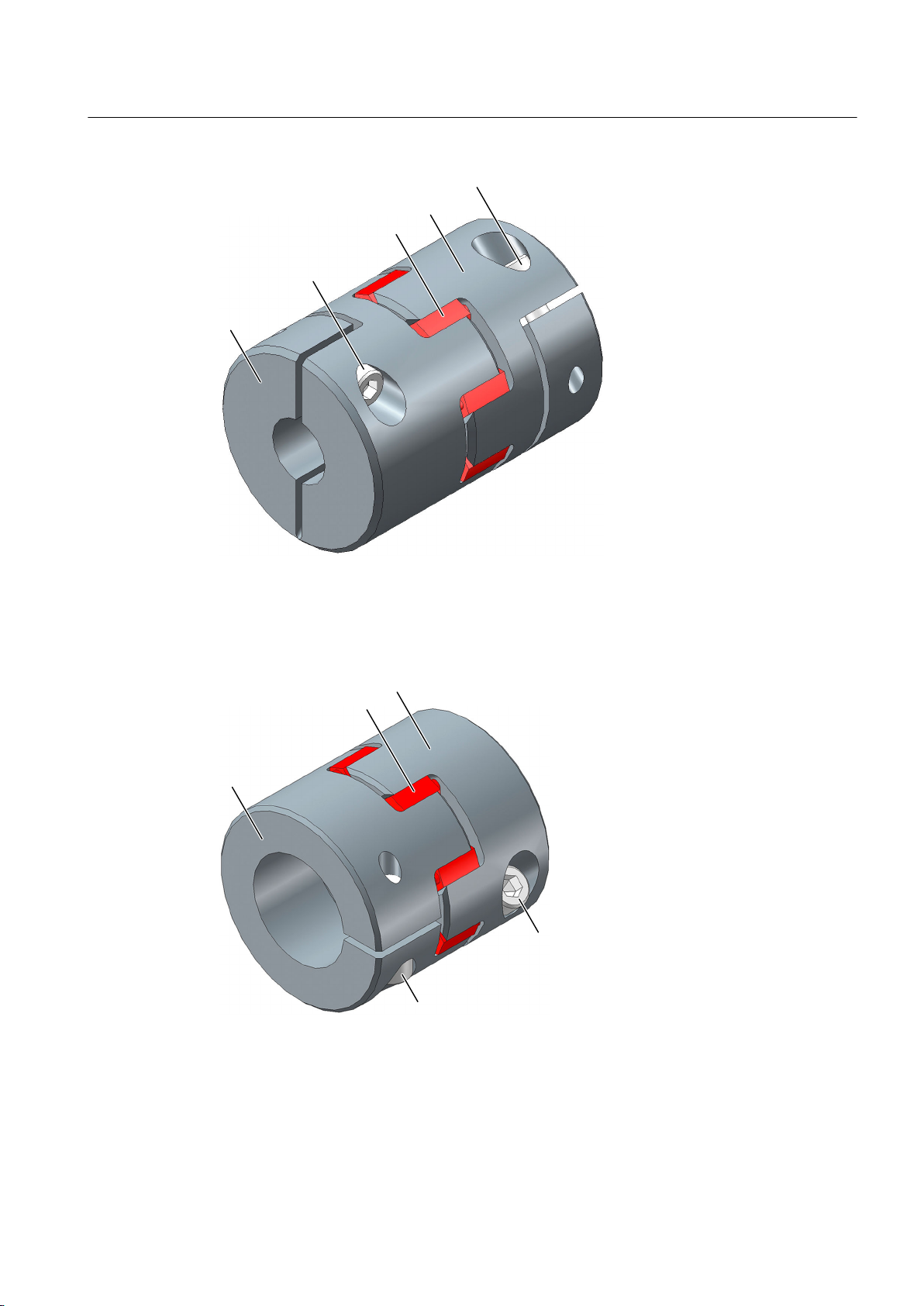

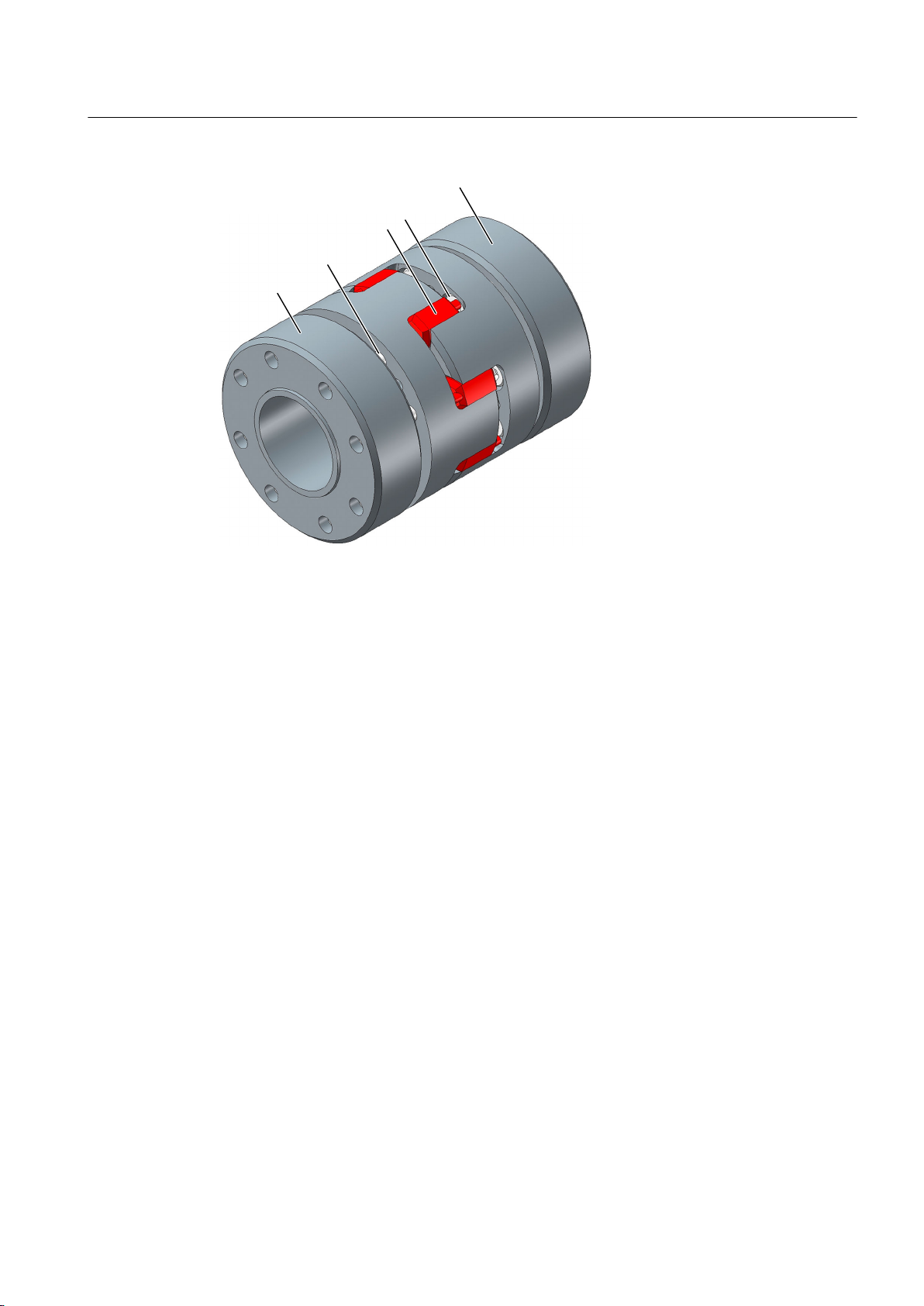

2 Coupling part G

12 Cylinder-head screw

20 Cam ring

Figure 3-2 Type BGG

3 Coupling part C

12 Cylinder-head screw

20 Cam ring

Figure 3-3 Type BCC

BIPEX-S 3410en

Operating Instructions 10/2017 17

Description

4 Coupling part H

12 Cylinder-head screw

20 Cam ring

Figure 3-4 Type BHH

BIPEX-S 3410en

18 Operating Instructions 10/2017

Description

5 Coupling part K

12 Cylinder-head screw

20 Cam ring

Figure 3-5 Type BKK

BIPEX-S 3410en

Operating Instructions 10/2017 19

Description

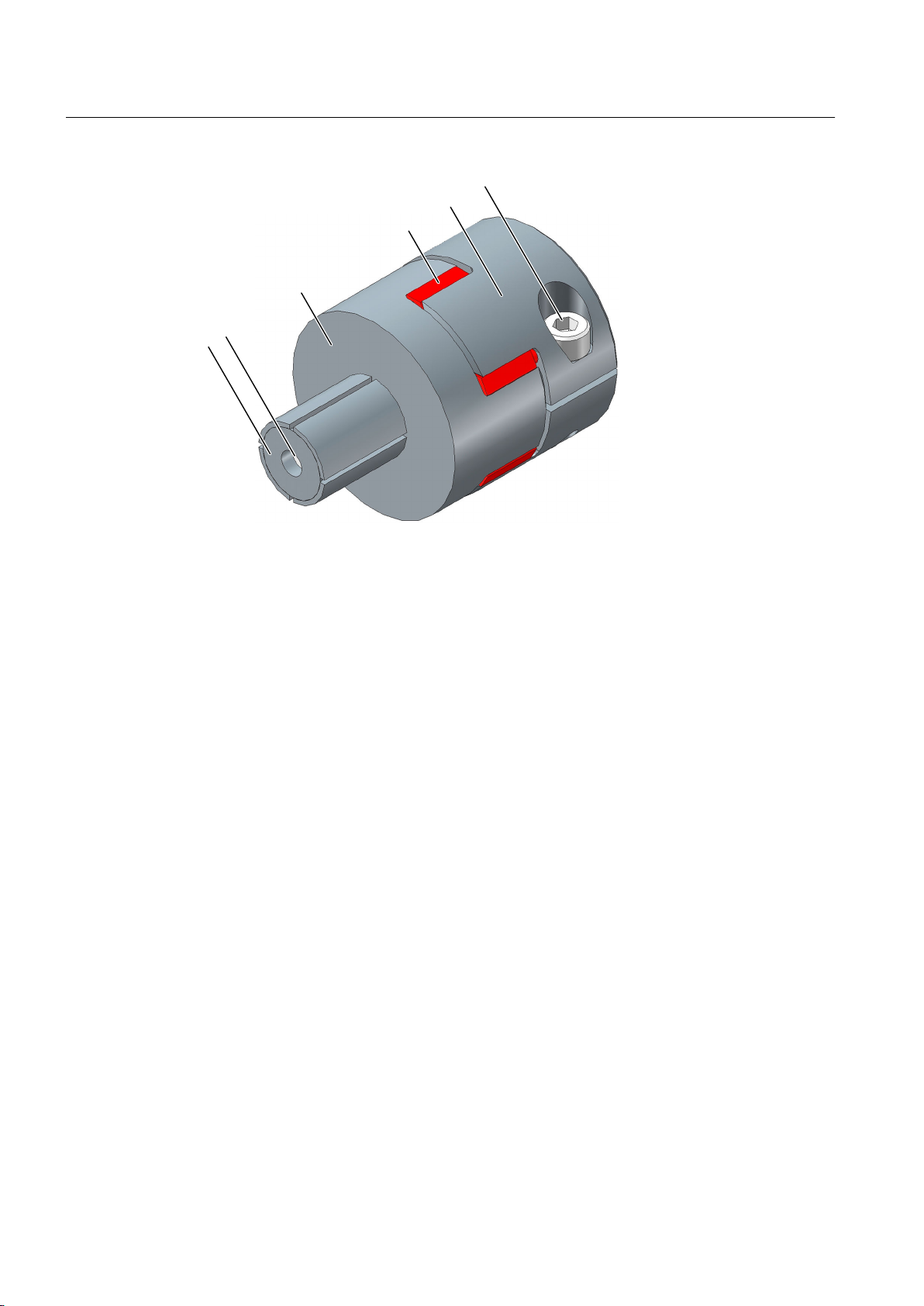

3 Coupling part C

6 Coupling part S

12 Cylinder-head screw

13 Cylinder-head screw

20 Cam ring

61 Clamping taper

Figure 3-6 Type BCS

BIPEX-S 3410en

20 Operating Instructions 10/2017

Loading...

Loading...