Fleetwood PSA-15HD, PSA-25HD Instruction Manual

ONE YEAR LIMITED WARRANTY

The original registered owner of this product

should contact SKYFOOD EQUIPMENT LLC at 305-868-1603 for any

warranty problems or service. SKYFOOD EQUIPMENT LLC will repair

or replace parts at our option for period of one year if unit fails to perform due

to defects in material or workmanship. Freight if required is at owner's

expense. Warranty does not include misuse or damage due to abuse as

determined by SKYFOOD EQUIPMENT LLC inspection. Units that are

70 lbs., or less are considered carry in and should be taken to an authorized

service facility.

Please read all safety instructions.

SERIAL #______________MODEL_______________

DETACH AND KEEP TOP PORTION

-------------------------------------------------------------------------------------

LIMITED WARRANTY REGISTRATION

ETL LISTED

C

US

3146459

CONFORMS TO UL STD 763; NSF STD 8

CERTIFIED TO CSA C 22.2 STD N°195

OWNERS NAME

BUSINESS

ADDRESS

MODEL # SERIAL #

PURCHASED FROM

FILL OUT ABOVE INFORMATION AND MAIL OR FAX TO

SKYFOOD EQUIPMENT LLC:

Office: 12550 Biscayne Blvd. Suite 800-3, North Miami , FL 33181-3230 –

Phone: 305 868 1603– Fax: 305 866 2704

Sales & Warehouse: 71 Bloomfield Ave, Newark, NJ 07104 –

Phone: 973 482 5070 – Fax: 973 482 0725

commercial@skyfood.us www.skyfood.us

TOLL FREE 800 445 6601

–

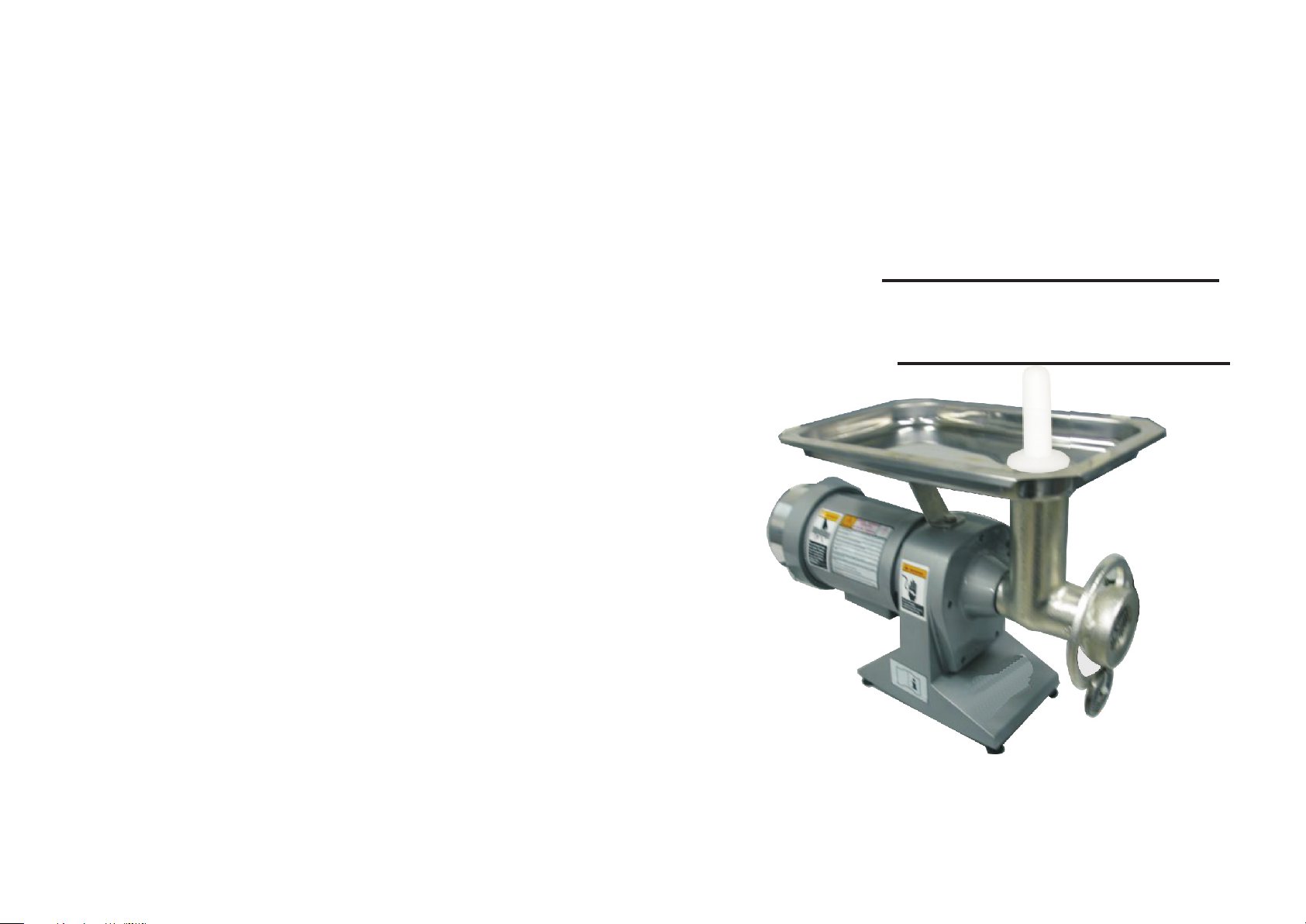

INSTRUCTIONS MANUAL

MEAT GRINDER

MODELS:

PSA-15HD

PSA-15HD

PSA-25HD

PSA-25HD

UG 0051

SUMMARY / SOMMAIRE

1. ENGLISH 01

2. FRANÇAIS 12

PSA-15HD

PSA-15HD

PSA-25HD

PSA-25HD

SUMMARY

1. Introduction 02

1.1 Safety 02

1.2 Main Components 03

1.3 Technical Characteristics 04

5.3 Ajustage et Substitiution des Composants

5.2.1 Aiguisement du Couteau et de la Plaque

Un bon aiguisement des couteaux et des plaques , a comme résultat que la

machine travaille avec moins d' effort et par conséquence augmente la vie utile des

composants. Pourtant , cherchez l' Assistant Téchnique le plus proche pour les aiguiser

correctement .

2. Installation and Pre Operation 04

2.1 Installation 04

2.2 Pre Operation 04

3. Operation 05

3.1 Head Assembling 05

3.2 Operating Procedures 05

3.3 Starting 06

3.4 Cleaning 06

4. General Safety Practices 06

4.1 Basic Operation Procedures 07

4.2 Safety Procedures and Notes Before Switching the

Machine On 08

4.3 Routine Inspection 08

4.4 Operation 09

4.5 After Finishing the Work 09

4.6 Maintenance 09

4.7 Advices 09

5.2.2 Boite à Engrenages

Les Hacheurs Model PSA-15HD et PSA-25HD travaillent avec une boite à

engrenage lubrifié avec de l' huile .

5. Analyses and Problem Solving

10

5.1 Problems, Cause and Solutions 10

5.2 Components Adjustment and Replacement 11

01

22

5. Analyse et Solution de Problèmes

1. Introduction

1. Introduction

5.1 Problèmes Causes et Solutions

Les Hacheurs ont été projetés pour que le minimum d' entretient soit

nécéssaire , toutes fois , quelques irrégularités dans leurs fonctionnement peuvent se

produire, suite à l' usage continu de l'equipement .

En cas de problème vérifier la Table No. 02 , où nous décrivons quelques

solutions recommandés .

Table - 02

PROBLÉME

* Le produit travaillé sort

écrasé.

* La machine s’arréte

pendant le travail.

* Odeur de brulé ou fumée.

* La machine démarre, mais les

composant internes da la Tête de

Hachage, ne tournent past tout de

suite.

* Bruits anormaux.

CAUSE SOLUTIONS

* Un des composants internes

de la Tête de Hachage manque,

ou est incorrectement monté.

* Couteau ou plaques mal

aiguisés.

* Courant électrique coupé.

* Probléme dans les circuits

électriques internes ou externes

da la machine.

* Engrenages usés ou cassés.

* Prob l éme a u mote u r

électrque, ou d’autres parties

électriques de la machine.

* Condensateur de démarrege

du moteur abimé .

* Composants internes de la

Tête de hachage en mauvaise

* Engrenages mal ajustés.

* Veri fier l ’as sem blage

conformemente figure-02 .

* Lire, s’il vous plait, la

posi t i on 5. 2 . 1 de c e s

intructions.

* Verifier si la fléche est dans

sa prise, ou s’il manque de

l’électricité.

* Ap pel er l ’as sitance

téchnique.

* Ap pel er l ’as sitance

téchnique.

* Ap pel er l ’as sitance

téchnique.

* Ap pel er l ’as sitance

téchnique.

* Corriger la position des

composants internes comme

expliqué à la figure 02.

* Ap pel er l ’as sitance

téchnique.

1.1 Safety

1.1 Safety

When not properly used the Meat Grinder Model PSEE-98MHD can be

When not properly used the Meat Grinder Model PSEE-98MHD can be

potentially DANGEROUS. Servicing, cleaning or any other operation shall be made by

potentially DANGEROUS. Servicing, cleaning or any other operation shall be made by

trained people.

trained people.

The following instructions must be observed in order to avoid accidents:

The following instructions must be observed in order to avoid accidents:

1.1.1 Always unplug the machine when cleaning, servicing or when any other operation

1.1.1 Always unplug the machine when cleaning, servicing or when any other operation

is needed.

is needed.

1.1.2 Never use tools that do not belong to the machine during operation.

1.1.2 Never use tools that do not belong to the machine during operation.

1.1.3 Before switching the machine on check if the Head Nº01 (Pic.01) is firm in its

1.1.3 Before switching the machine on check if the Head Nº01 (Pic.01) is firm in its

position, if all its internal components are assembled as well as if the Pan Nº04 (Pic.01)

position, if all its internal components are assembled as well as if the Pan Nº04 (Pic.01)

is mounted.

is mounted.

1.1.4 Never spray water or other liquid substances directly at motor, power switch or

1.1.4 Never spray water or other liquid substances directly at motor, power switch or

any other electrical components.

any other electrical components.

1.1.5 Never use loosen clothes specially shirts with loosen sleeves during operation.

1.1.5 Never use loosen clothes specially shirts with loosen sleeves during operation.

1.1.6 Never put your fingers or any other object but the Stomper Nº05 (Pic.01) inside

1.1.6 Never put your fingers or any other object but the Stomper Nº05 (Pic.01) inside

feeding throat.

feeding throat.

1.1.7 Keep hands off turning parts.

1.1.7 Keep hands off turning parts.

1.1.8 Never switch the machine on with wet clothes or wet shoes.

1.1.8 Never switch the machine on with wet clothes or wet shoes.

1.1.9 Before using the machine make use it is properly grounded.

1.1.9 Before using the machine make use it is properly grounded.

Your equipment is also protected against any eventual failure. Operator and

Your equipment is also protected against any eventual failure. Operator and

motor's integrity is maintained under this adverse condition. This protection is possible

motor's integrity is maintained under this adverse condition. This protection is possible

by means of a thermal overload switch. In case your equipment suddenly stops wait

by means of a thermal overload switch. In case your equipment suddenly stops wait

for a few minutes and press thermal overload switch button located at rear of machine.

for a few minutes and press thermal overload switch button located at rear of machine.

This protection is possible by means of a thermal overload switch. In case your

This protection is possible by means of a thermal overload switch. In case your

equipment suddenly stops wait for a few minutes and press thermal overload switch

equipment suddenly stops wait for a few minutes and press thermal overload switch

button located at rear of machine.

button located at rear of machine.

IMPORTANT

IMPORTANT

This equipment shall not be used by persons (including children) having reduced

This equipment shall not be used by persons (including children) having reduced

mental or physical capabilities, or having faulty experience or knowledge, unless

mental or physical capabilities, or having faulty experience or knowledge, unless

they have been previously supervised or instructed by a person responsible for

they have been previously supervised or instructed by a person responsible for

the equipment safety, about how to use it.

the equipment safety, about how to use it.

21

02

02

Loading...

Loading...