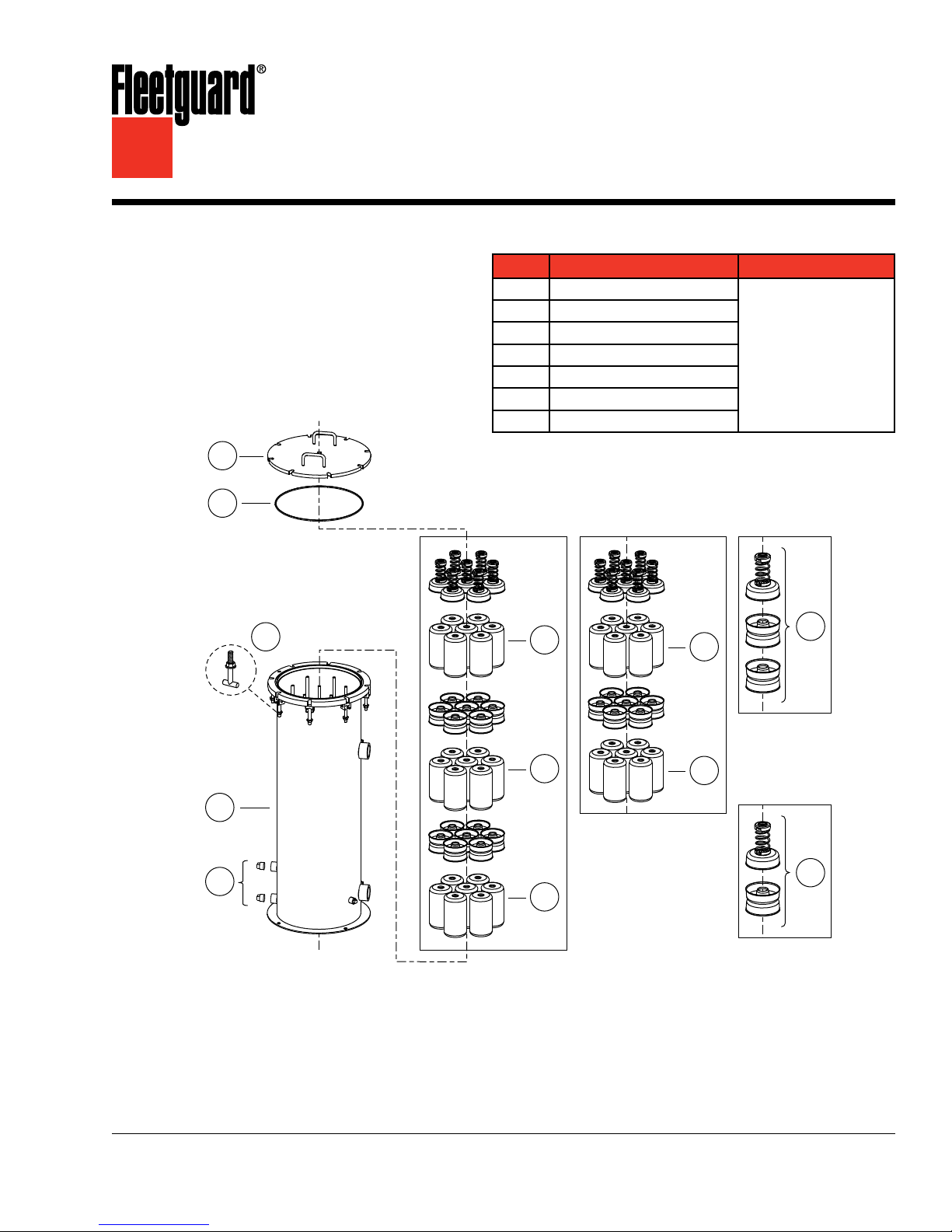

Winslow® – Liquid Fuel Filters

A

B

E

E

Internal

Component Kit

for 95830A

F

Internal

Component Kit

for 95730A

Internal Components

for 95730A

Internal Components

for 95830A

E

E

E

F

C

D

G

T-Bolt Kit

(includes

Washer,

Nut and

T-Bolt)

Standard Design Type 2

Service Instructions

Parts List

Part Description Part Number

Cover

A

O-Ring

B

Housing

C

Plugs

D

Filter Elements

E

Internal Component Kit

F

T-Bolt Kit

G

See Ordering Information

on Page 5

CAUTION: These instructions are intended for use by professional mechanics who are trained in the proper E

use of power and hand tools, using appropriate safety precautions (including eye protection).

page 2

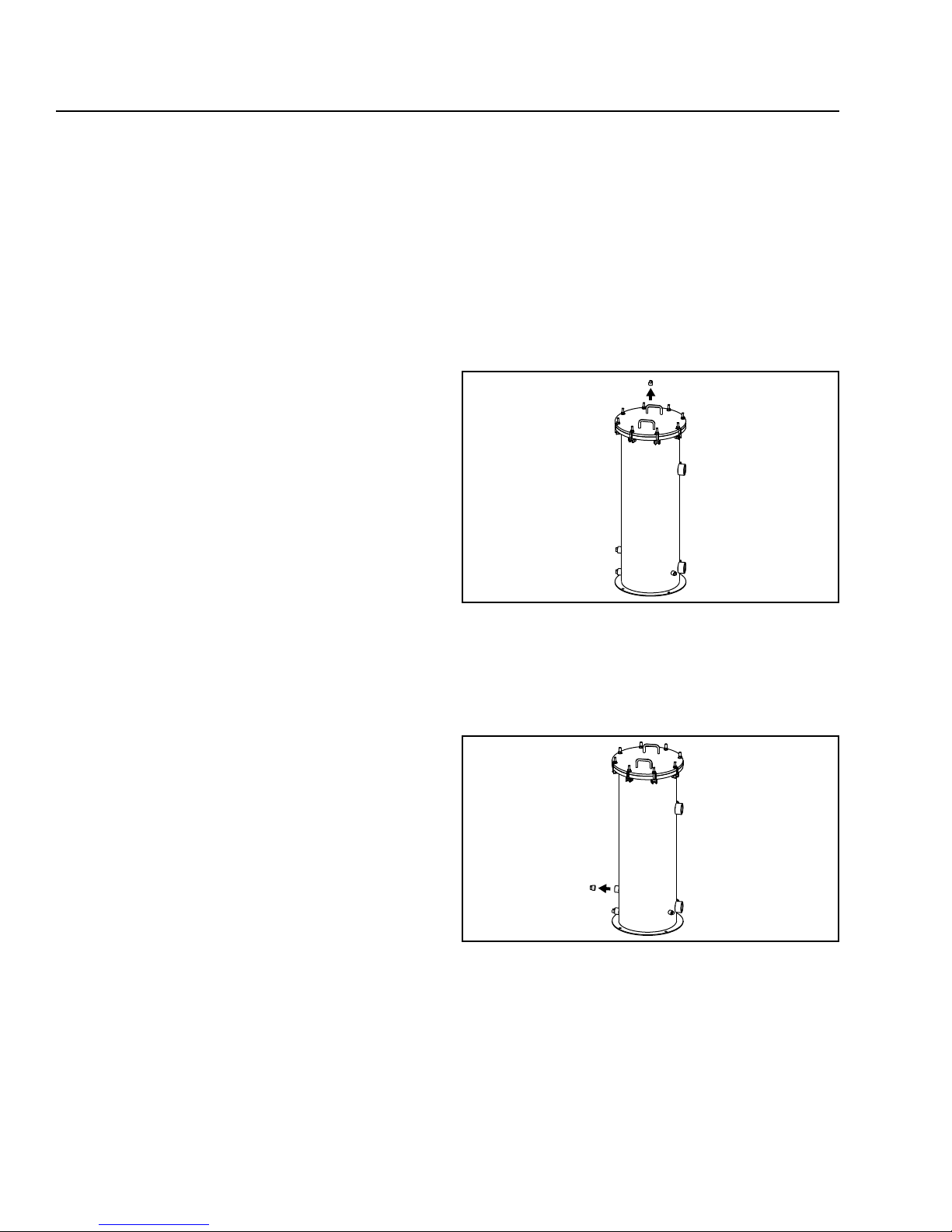

Vent Plug

“Dirty Oil”

Drain Plug

Introduction

Winslow® filter elements must be changed

periodically to assure the high level of filtering

efficiencies required. We recommend that the

elements be changed when the pressure differential

across the filter reaches the maximum allowable

pressure drop as recommended by the engine

manufacturer. Excessive pressure differential across

the elements could result in reduced flow.

Winslow Fuel Filters are designed to be mounted

on the pressure side of a low pressure (< 75 PSI

(517.1 kPa)) fuel pump, however they can be

mounted on the suction side of a low pressure pump

if sized properly. Housing restriction for suction side

applications must be less than 1 PSID (6.9 kPa).

Pump specifications regarding inlet restriction

should be followed and supersede other general

recommendations.

To determine the correct pressure differential:

Note the pressure drop between the filter inlet •

and outlet when clean elements are installed

and the system is up to normal operating flow,

temperature, and pressure.

Periodically check the gradual increase of •

the filter differential pressure as the filter

accumulates hours of operating service.

If no engine specification is known or given, filters

should be changed out at 5-7 PSID (34.5-48.3 kPa)

above initial differential pressure. Initial differential

pressure should be 2-3 PSID (13.8-20.7 kPa)(an

initial differential pressure less than 3 PSID

(20.7 kPa) is acceptable, but a smaller filter could

probably be used).

Servicing the Filter

Removing the Filter Elements

Shut off the flow to the filter. Isolate the filter, if 1.

possible, by closing the main upstream valve and

then the main downstream valve.

Shut off electrical power to any accessories 2.

attached to the vessel.

Remove the air vent plug to equalize the 3.

pressure in the tank.

Figure 1 – Removing the Air Vent Plug

Remove the “dirty oil” drain plug (upper plug) and 4.

completely drain the filter chamber.

E

CAUTION Fluid may be hot!

The filter design includes a sludge and water sump

section. A drain is provided at the bottom of the

sump for use when the elements require changing.

Figure 2 – Removing the “Dirty Oil” Drain Plug

page 3

Loosen Nuts

Swing T-Bolts

Lift

Cover

Straight

Up

Element

Support

Posts

Element

Support

Posts

Dirty

Elements

Seal Cups

Dirty

Elements

Internal

Components

(vary according

to housing)

Loosen the nuts on the cover until the T-bolts are 5.

free to swing out of position.

Figure 3 – Freeing the Cover

Lift the cover STRAIGHT UP.6.

E

CAUTION To prevent damage to the cover

gasket and the sealing surfaces,

DO NOT SLIDE THE COVER OFF.

Loosen the hex nuts on the element support 8.

posts to free the internal components.

Figure 5 – Freeing the Internal Components

Loosen and remove the internal components, 9.

including the dirty elements (components vary

according to housing – see page 1). Pull the

elements straight up to remove. Dispose of the

elements in an environmentally responsible

manner, according to state and/or federal (EPA)

recommendations.

Figure 4 – Lifting the Cover Off

Place the cover UPSIDE DOWN on a clean work 7.

surface. Be careful not to nick or scratch the

bottom edge of the sealing surface.

Figure 6 – Removing the Internal Components

E

CAUTION To prevent damage to your engine

or equipment, do not allow dirt

to fall through the opening of the

element support post and into the

clean outlet area.

page 4

Element

Support

Post

Spent

Elements

Seal Cups

Spent

Elements

Internal

Components

(vary according

to housing)

O-Ring

Cover Seal

Flange

Groove

Replace

Cover

Straight

Down

Reassembling the Filter

Reinstall the internal components, including the 10.

new elements. Note the direction of the arrow

on each element and insert the proper end into

the housing first. If seal cups are included as

part of the internal components, they must be

reinstalled, as well.

Replace the O-ring cover seal. (If necessary, 12.

as long as there are no permanent surface

deformations, swelling, nicks, and cracks

present, the seal can be reused.)

Figure 9 – Replacing the O-Ring Cover Seal

Seat the O-ring cover seal into the flange groove.13.

Carefully replace the cover STRAIGHT DOWN 14.

and align the bolt slots in the cover flange with

the slots in the housing flange.

Figure 7 – Reinstalling the Internal Components

Replace the hex nuts onto the element support 11.

posts and tighten until the threads bottom-out.

Figure 8 – Replacing the Hex Nuts

E

CAUTION To prevent damage to the cover

gasket and the sealing surfaces,

DO NOT SLIDE THE COVER ON.

Figure 10 – Replacing the Cover

page 5

Tighten Nuts

Swing T-Bolts

Dirty Oil

Drain Plug

Vent Plug

Swing the T-bolts into position and tighten all 15.

the nuts in a star pattern (similar to replacing lug

nuts on an automobile wheel) to assure a uniform

seal.

Figure 11 – Securing the Cover

When the vessel is full, reinstall the “dirty oil” 16.

drain plug.

Figure 12 – Reinstalling the “Dirty Oil” Drain Plug

Refill the filter manually or by slowly opening the 17.

main upstream valve.

When the vessel is full, reinstall the vent plug.18.

Figure 13 – Replacing the Vent Plug

Increase the pressure in the filter slowly. Inspect 19.

for leaks around the cover gasket area. If no

leaks are visible, increase to operating pressure.

Inspect for leaks again.20.

Reconnect electrical power to any accessories.21.

Slowly open the downstream valve, if applicable, 22.

placing the unit in service.

Read and record the pressure differential of the 23.

clean elements.

The filter is now operational.24.

Suggested Preventive Maintenance

Ordering Information

C

Housing*

95730A Q80660A Q79058 Q69009 82375A

95830A Q80660A Q79058 Q69009 82375A

* Designed for 75 lb/in2 (517.1 kPa) continuous operating conditions.

Table corresponds to Parts List on cover page.

A

Cover

B

O-Ring

D

Plugs

Every Filter Change – Replace the O-ring cover

seal.

Every 12 Months – Check all fittings for leaks.

E

Filter

Element

Number of

Elements

14

21

F

Internal

Component Kit

990441K 990449K

990442K 990449K

G

T-Bolt

Kit

page 6

2" NPT

Outlet

2" NPT

Intlet

Thermometer

Port

1/2" NPT

Dirty Oil

Drain

1" NPT

Clean Oil

Drain

1" NPT

All dimensions are in inches (millimeters)

Vent

3/4" NPT

A

B

19.3 (490.2)

Mounting Holes in Base

16 (406.4) Required for

Element Replacement

∅.562 (1.43)

(4X) on

18.00 (457.2)

Bolt Center

15.75 (400.1)

5.0

(127.0)

Replacement Filter Element

Part

Number

82375A

= 2 Full-Flow Lube Depth Element

b

5

Description

Filter Specification

Composed of a high flow cotton/wood media blend to provide b5 = 2 solid

contamination control.

Specifications

Housing Part

Number

95730A

95830A

* Flow rate based on #2 Diesel fuel with a maximum viscosity of 4.63 mm2/s. For residual and heavy fuel blends, Contact

Cummins Filtration®.

Notes:

1. Designed for 75 lb/in

2. Initial assembly differential pressure should not exceed 3 PSID (20.7 kPa) on the pressure side (downstream) of the pump.

3. Change element after initial differential pressure increases 3-4 PSID (20.7-27.6 kPa), depending on engine age and operating

oil pressures. A maintenance professional should make the appropriate application decision.

4. Terminal assembly differential pressure should not exceed 7 PSID (48.3 kPa).

Specifications subject to change without notice.

Flow Rate*

gal/min (L/min)

70 (265.0)

100 (378.5)

2

(517.1 kPa) continuous operating conditions.

Element

Number

82375A 82371A

82375A 82371A

Chemically

Treated Part

Number

Number of

Elements

14

21

Efficiency

(Particulate

Control)

b

= 2

5

b

= 2

5

Capacity

Capacity Exceeds

SAE Time

Constraints

Mounting/Dimensions

Housing*

Part

Number

95730A

95830A

* Designed for 75 lb/in2 (517.1 kPa) continuous operating conditions.

Overall

Height

in (mm)

47.0 (1193.8) 34.0 (863.6)

63.0 (1600.2) 50.0 (1270.0)

A

B

Inlet

Height

in (mm)

LT36077

©2008 Cummins Filtration

Printed in the U.S.A.

For more information, please visit us at cumminsfiltration.com

Loading...

Loading...