Fleetguard Winslow 95250A, Winslow 95300A, Winslow 95200A, Winslow 95350A Service Instructions Manual

Winslow® – Liquid Fuel Filters

A

B

C

G

D

F

E

Vent

Plug (NPT)

Drain

Plug (NPT)

Internal

Component Kit

(varies according

to housing)

Standard Design Type 1

Service Instructions

Parts List

Part Description Part Number

Cover Assembly

A

O-Ring

B

Band Clamp

C

Housing

D

Filter Element

E

Internal Component Kit

F

See Ordering Information

on Page 5

CAUTION: These instructions are intended for use by professional mechanics who are trained in the proper E

use of power and hand tools, using appropriate safety precautions (including eye protection).

page 2

Vent Plug

Drain Plug

Band Clamp

Loosen

Nut

Cover Assembly

Introduction

Winslow® filter elements must be changed

periodically to assure the high level of filtering

efficiencies required. We recommend that the

elements be changed when the pressure differential

across the filter reaches the maximum allowable

pressure drop as recommended by the engine

manufacturer. Excessive pressure differential across

the elements could result in reduced flow.

Winslow Fuel Filters are designed to be mounted

on the pressure side of a low pressure (< 75 PSI

(517.1 kPa)) fuel pump, however they can be

mounted on the suction side of a low pressure pump

if sized properly. Housing restriction for suction side

applications must be less than 1 PSID (6.9 kPa).

Pump specifications regarding inlet restriction

should be followed and supersede other general

recommendations.

To determine the correct pressure differential:

Note the pressure drop between the filter inlet •

and outlet when clean elements are installed

and the system is up to normal operating flow,

temperature, and pressure.

Periodically check the gradual increase of •

the filter differential pressure as the filter

accumulates hours of operating service. When

(at normal operating conditions) the filter

differential increase is close to, or has arrived

at, the maximum differential pressure, the

elements must be changed.

If no engine specification is known or given, filters

should be changed out at 5-7 PSID (34.5-48.3 kPa)

above initial differential pressure. Initial differential

pressure should be 2-3 PSID (13.8-20.7 kPa)(an

initial differential pressure less than 2 PSID

(13.8 kPa) is acceptable, but a smaller filter could

probably be used).

Servicing the Filter

Removing the Filter Element

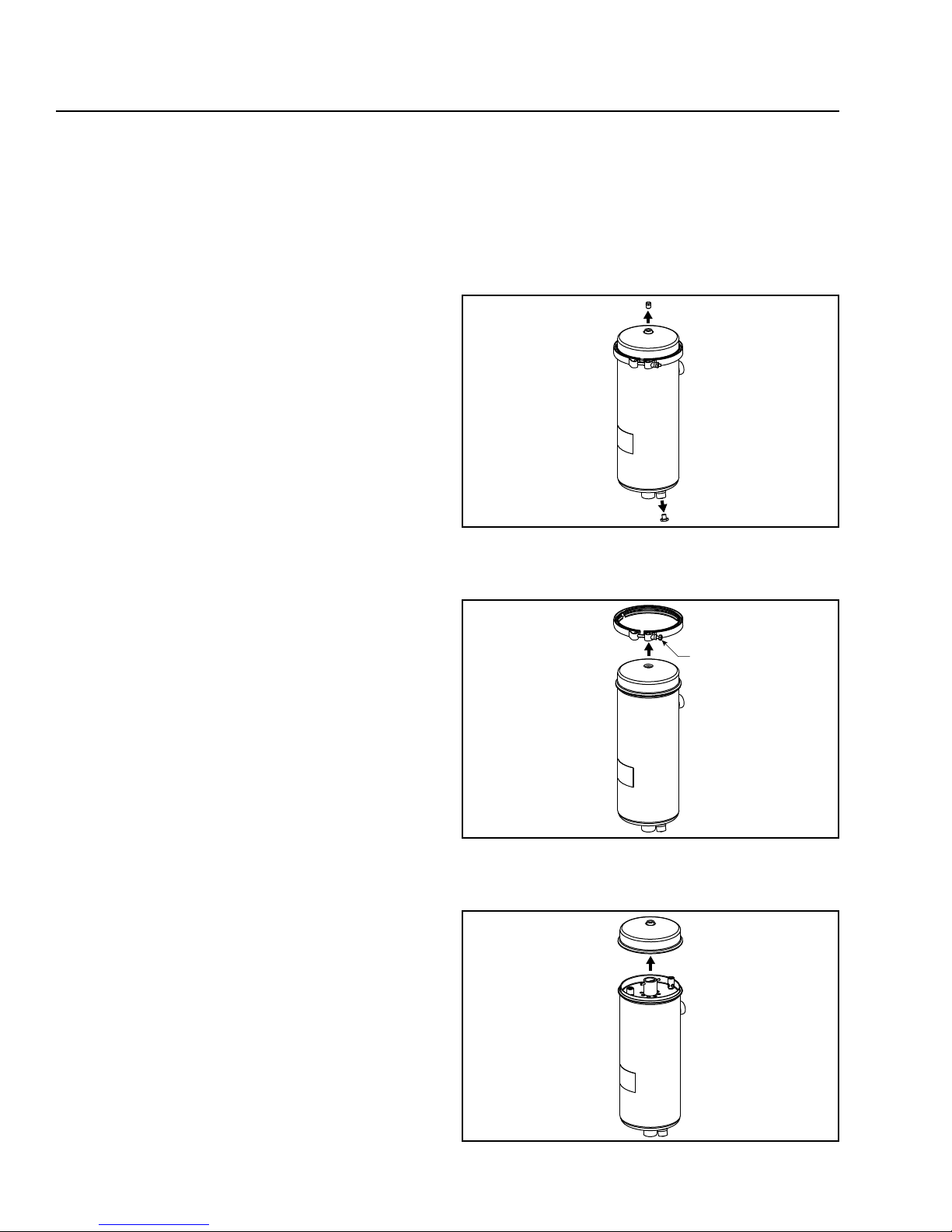

Remove the air vent plug and drain plug to drain 1.

the filter.

CAUTION Fluid may be hot!

E

Figure 1 – Removing the Air Vent and Drain Plugs

Loosen and remove the band clamp.2.

Figure 2 – Removing the Band Clamp

Remove the cover assembly.3.

Figure 3 – Removing the Cover Assembly

Loading...

Loading...