Page 1

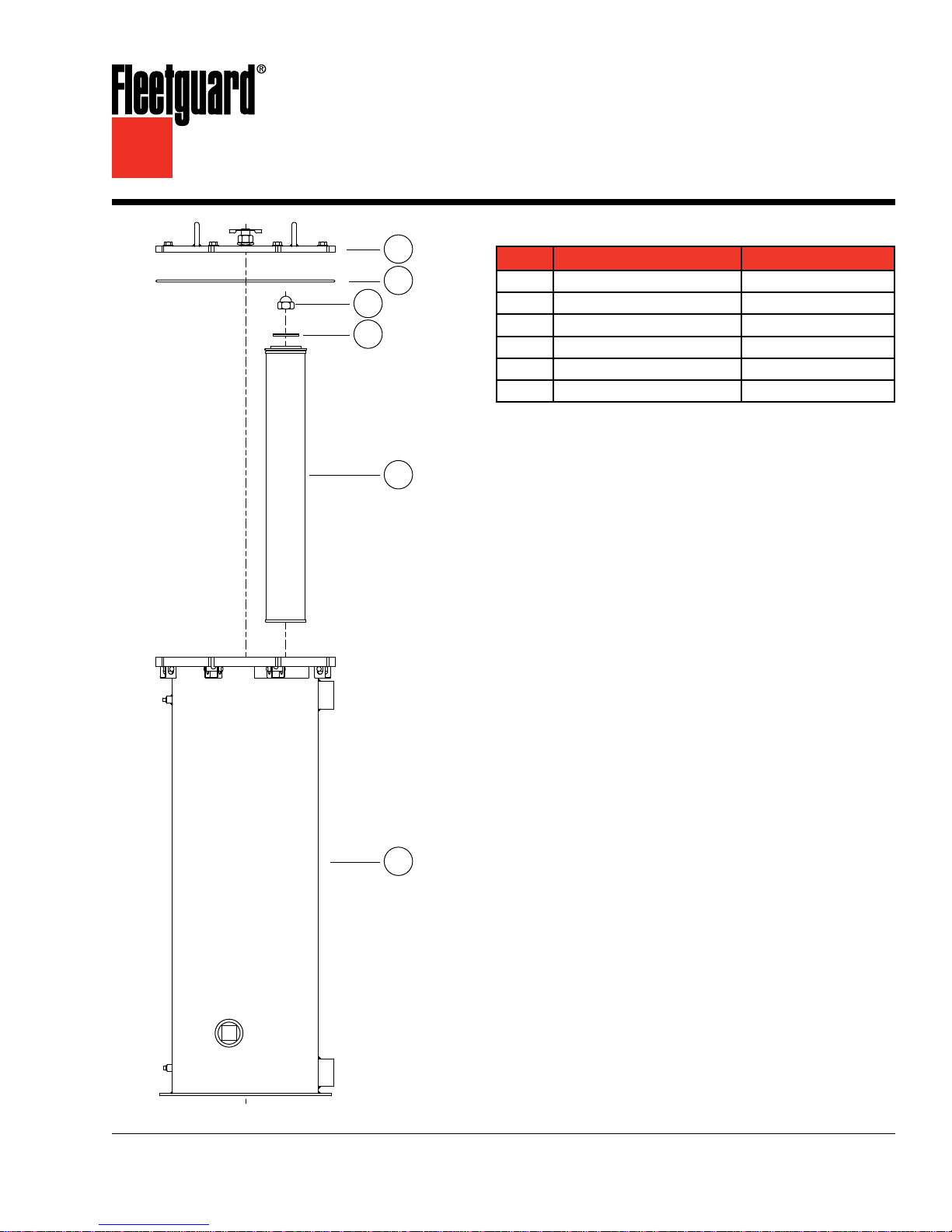

C

D

Winslow® Stationary Multiple

Element Design Fuel Coalescer

Service Instructions

Parts List

A

B

E

Part Description Part Number

Cover Assembly

A

O-Ring

B

Seal Nut Assembly

C

Gasket

D

Filter Element

E

Housing

F

Q80660A

Q79058

Q53779

Q58878

88472N

91292N

E CAUTION: These instructions are intended for use by professional mechanics who are trained in the proper

use of power and hand tools, using appropriate safety precautions (including eye protection).

F

Page 2

page 2

Introduction

Unlike mechanical separators, the Winslow® Fuel

Filter/Coalescer can be installed on either the

pressure or suction side of the transfer or fuel pump.

Pressure Side

Pressure side installation is preferred because it

reduces fuel flow problems by eliminating air trapped

in the housing. With the first installation, or when the

unit has been serviced with an element change, the

cover vent valve is opened when the fuel pressure

is applied. Once the air in the unit has been purged

and the housing is filled, the valve should be closed.

The cover should be inspected for any possible fuel

leaks.

Suction Side

The fuel level from a storage source should be

higher than the housing in order for the inlet to

the filter assembly to have the necessary positive

pressure.

If a positive pressure is not available and the fuel

source is lower than the housing, the suction lift

or rise should not exceed 10' (3 m) to the housing

due to possible negative pressure into the housing

exceeding one atmosphere (14.7 lb/in

sea level. Also, line lengths must be kept as short as

possible.

It is also recommended that a check valve be

installed in the suction line close to the fuel supply

to prevent drain back and facilitate adding fuel to the

housing when elements have been changed. The

filters will have to be manually refilled after servicing.

Secure all fittings and cover bolts to prevent air

entrainment.

Existing filters in the system can be left in place,

whether up- or down-stream from the Coalescer.

Up-stream filters protect the Coalescer element

from large dirt particles that can eventually clog the

Coalescer. The Coalescer can work indefinitely,

removing water, if it doesn't become plugged

with dirt.

2

(1 bar)) at

If installed on the suction (vacuum) side, the housing

must be filled with fuel before operating the engine.

If installed on the pressure side, priming is not

necessary, but recommended.

If the application is for fuel transfer or a dispensing

pump where there is head pressure on the

Coalescer, a flow control valve must be installed at

the inlet port.

Because the Coalescer functions similarly

to a particulate or conventional filter, similar

troubleshooting procedures should be followed.

Servicing the Water Drain

1. Turn off the pump engine.

2. To remove water from the sump, loosen the drain

valve and allow the collected water to drain. (For

suction (vacuum) side installations, open the vent

to allow drainage.)

3. Tighten the valve as soon as fuel begins to drain.

(For suction (vacuum) side installations, close the

vent.)

Servicing the Elements

Elements should be changed when the pressure

drop across the element reaches 8-10 PSID

(55.2-69.0 kPa), or when the maximum pressure

differential the system can tolerate is reached,

providing the pressure differential is less than or

equal to 8-10 PSID (55.2-69.0 kPa).

If a pressure gauge is not used, elements should

be changed every six months or when engine

performance declines, indicating insufficient fuel

supply to the engine. A vacuum or differential

pressure gauge is strongly recommended.

Element change-out frequency is dependent on the

degree of solid and semi-solid contaminants present

in the fluid being conditioned. The amount of water

in the fuel does not affect the element change-out

frequency. Barring contamination, the Coalescer

would continue to coalesce and separate water from

fuel indefinitely.

Installation

To install on an engine or Cummins® Fuel Regen

System, cut into the fuel line and install with proper

fittings to connect to the Coalescer. Mount the

Coalescer with enough space to service the water

drain and for element replacement.

If an excessive amount of asphaltines or gums in

the fuel being conditioned is suspected, it would be

evidenced by relatively short change-out cycles.

Page 3

page 3

Determining the Pressure Differential

If the housing is equipped with an upstream and

downstream pressure gauge, or a differential

pressure gauge assembly, the pressure differential is

determined as follows:

1. Read and record the pressure shown on the

upstream (inlet) gauge. This reading is the high

indication.

2. Read and record the pressure shown on the

downstream (outlet) gauge. This reading is the

low indication.

3. Subtract the downstream pressure from the

upstream pressure. This difference is the back

pressure, or differential pressure caused by the

element.

Note: The upstream (inlet) pressure must always be

higher than the downstream (outlet) pressure.

If not, check the gauges for accuracy.

Note: The differential pressure gauge assembly is

equipped with a single gauge and indicates

the differential pressure in the housing

directly.

4. As the Coalescer accumulates hours of operating

service, the pressure difference between the

upstream and downstream pressure readings will

become higher. When the pressure differential

reaches the maximum allowable value of 8-10

PSID (55.2-69.0 kPa), the element must be

replaced in order to maintain high water removal

efficiency.

Replacing the Elements

1. Shut off the engine or fuel supply.

2. Close the inlet and outlet valves.

3. Loosen the vent valve.

4. Open the drain valve and drain the fuel and

water.

5. Release the cover plate clamping bolts and

remove the top cover plate, o-ring, seal nut and

gasket.

6. Check all gaskets for wear and replace as

needed.

7. Remove both the coalescing and the separator

elements.

8. Clean the canister by flushing it with #2 fuel oil.

9. Install the new separator element(s) first, making

certain they are centered.

10. Install the Coalescer element by lowering it inside

the separator element. Make certain the bottom

gasket contacts the end cap and seats properly.

11. Inspect the seal nut gasket and replace, if worn.

Lubricate and install the seal nut gasket.

12. Screw the seal nut down as far as possible by

hand, pushing the Coalescer element down with

one hand while tightening the seal nut with the

other.

13. Torque the seal nut to 10-12 ft-lbs (14-16 N·m) to

ensure a good seal.

14. Fill the canister with fuel.

15. Lubricate and replace the o-ring.

16. Replace the top cover plate.

17. Replace the cover plate clamping bolts and

torque evenly in a cross pattern to 70-80 ft-lbs

(95-109 N·m).

18. Tighten the vent valve.

19. Open the Inlet and outlet valves.

20. If it is a pressure side application, loosen the vent

valve to bleed off any air and completely fill the

canister with fuel. Close the vent valve when fuel

begins to ooze out.

21. Start the engine or fuel system.

22. Check for leaks or air locks.

Troubleshooting

1. Leaks - check for:

a. Worn gaskets

b. Improperly closed clamps

c. Open valves

d. Loose connections

2. No Fuel to the Engine (Air Locks)

a. Open the vent valve, remove the cover and

fill with fuel (see Step 19 above).

b. Check the inlet and outlet connections to

make sure they are not plugged.

Suggested Preventive Maintenance

Every Filter Change – Replace gaskets.

Every 12 Months – Check all fittings for leaks.

Page 4

page 4

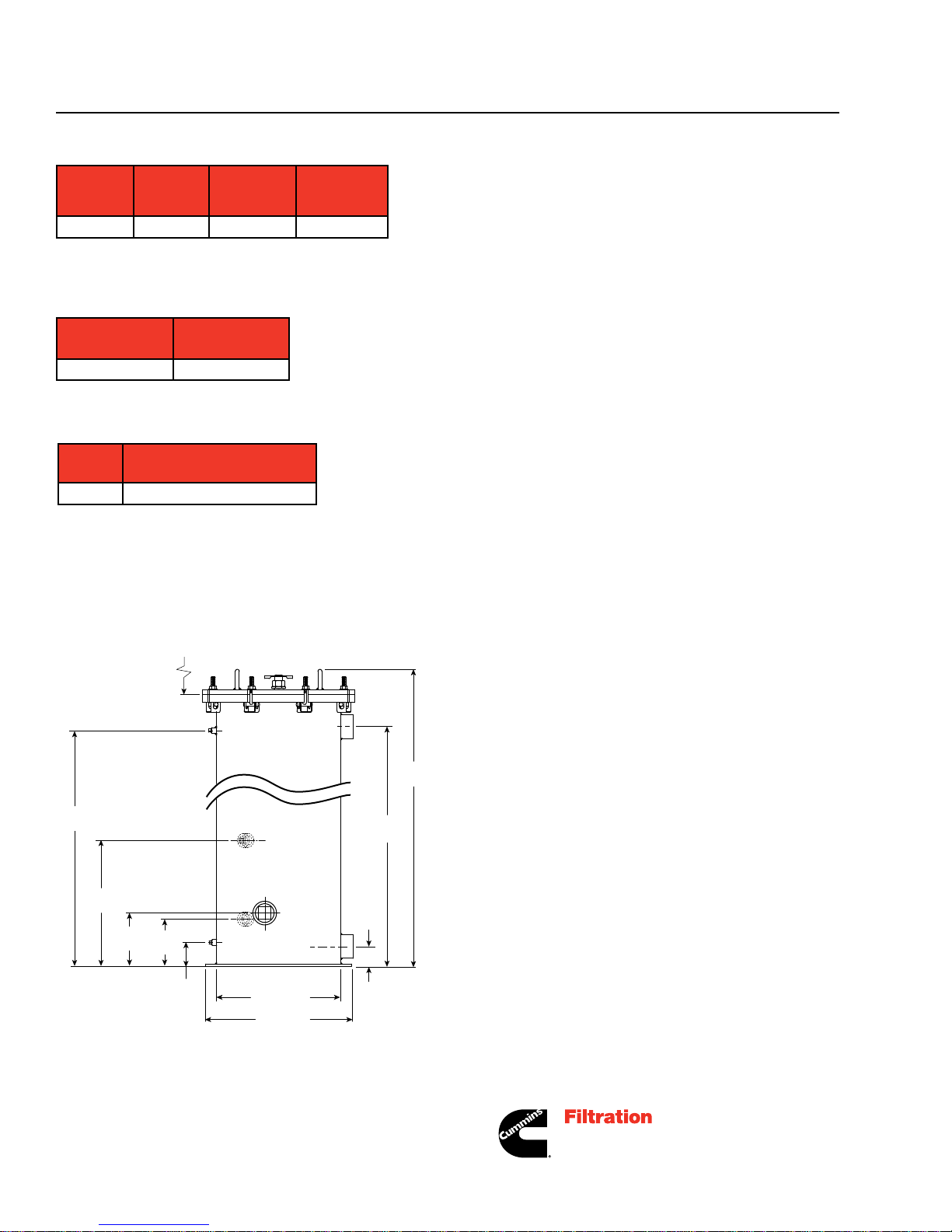

Specifications

Part

Number

91292N

* Clean filter at rated flow, based on #2 Diesel fuel.

** Change filter at 5 PSID (34.5 kPa) above initial pressure drop.

Design

Pressure

lb/in2 (kPa)

75 (517.1) 100 (378.5) 3.5 (11.9)

Flow Rate*

gal/min

(L/min)

Pressure

Drop**

in Hg (kPa)

Ordering Information

Housing Part

Number

Filter Element

91292N 88472N

Replacement Filter

Part

Number

88472N

Two-stage coalescing element

Description

Mounting/Dimensions

24 (609.6)

Required for

Element

Replacement

1/4" NPT

Pressure

Gauge Port

46.8

(1188.7)

39.00

(990.6)

13.00

(330.2)

6.75

(171.5)

6.00

(152.4)

3.00

(76.2)

1" NPT

Oil Drain

1" NPT

Water

Drain

1/4" NPT

Pressure

Gauge Port

15.75 (400.1)

19.3 (490.2)

2" NPT

Plug

2.50

(63.5)

39.50

(1003.3)

For more information, visit

cumminsfiltration.com

LT36200

©2011 Cummins Filtration Inc.

Printed in the U.S.A.

Loading...

Loading...