Fleetguard REN Installation Instructions Manual

Liquid Level Switch Installation

LEVEL SWITCH

LISTED

U

L

®

TM

Instructions

CAUTION: These instructions are intended for use by professional mechanics who are trained in the

oper use of po

pr

F1302

wer and hand tools, using appropriate safety precautions (including eye protection).

page 2

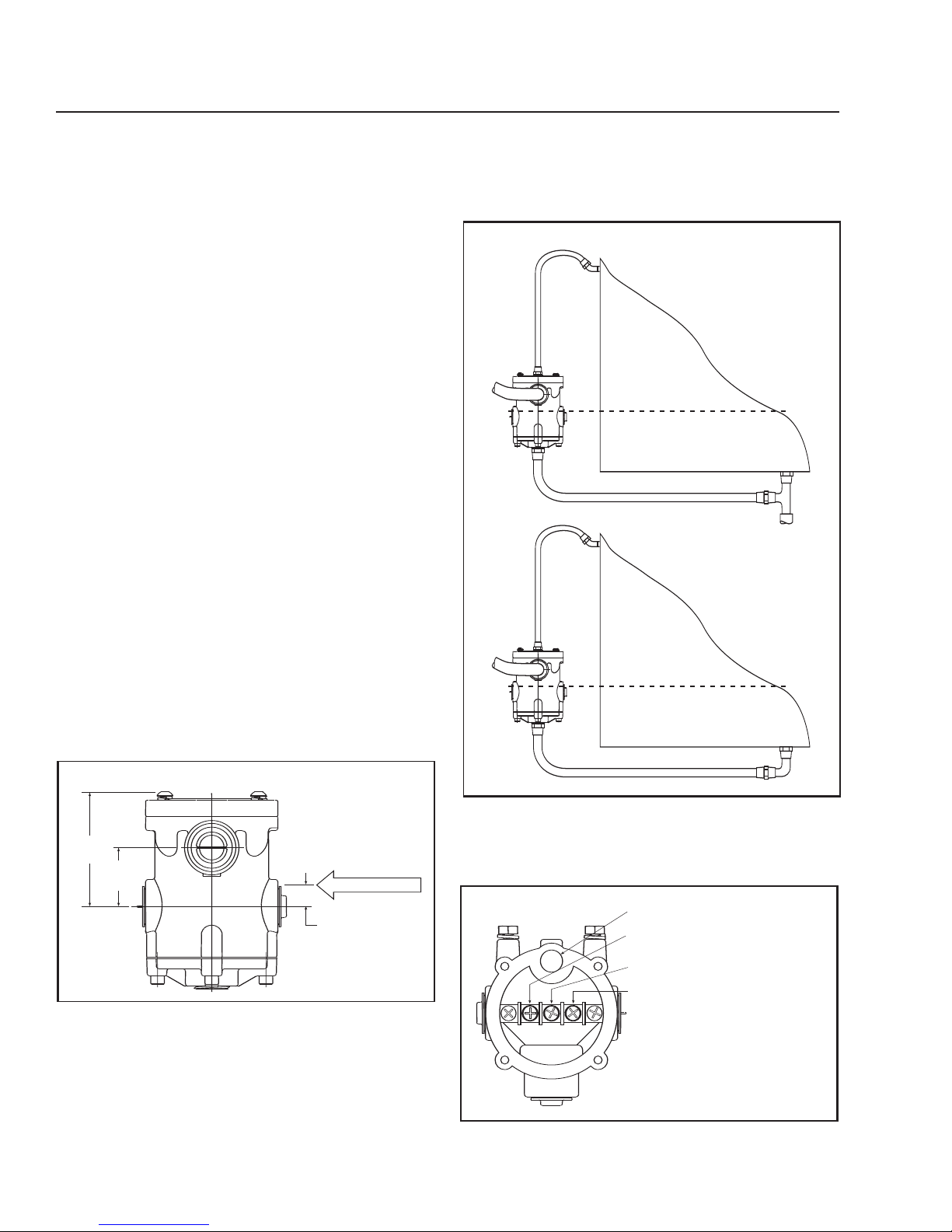

1.37

(34.80)

Liquid Level Switch

2.68

(68.07)

0.345

(8.76)

Switching Level

S

witching Level

Switching Level

L

iquid Tank

Stationary Engine

S

ensing Liquid Level

Top (Cover Removed)

N.C. C. N.O.

Top Liquid or Vent Connection 1/4" NPT

Closed on Low Terminal (N.O. Contact)

(Contacts open when fluid is above

switching level)

Common Electrical Terminal

Open on Low Terminal (N.C. Contact)

(Contacts closed when fluid is above

switching level)

Introduction

The REN™ Liquid Level Switch is used to indicate

levels of engine oil, hydraulic fluid and coolant

antifreeze. The switch can be used in most

applications where the level of a container, high or

low, or the absence of fluid in a line needs to be

detected. A single pole, double throw, magnetically

actuated switch is double sealed from explosive

environments through the use of two barriers; a

stainless steel housing and a hermetically sealed

glass switch housing. Four inlet / outlet ports and an

adjustable mounting pad allow great flexibility in

installation. Wiring is simple using the unit's

removable electrical housing cover.

Preinstallation Notes

• The Liquid Level Switch is designed for

stationary applications only.

• Use pipe or hose material appropriate to the

application for which it is being used.

• Route pipes and cables away from heat

sources and moving components.

Step 3 - Run a 3/8" (9.53 mm) ID minimum line from

the vent on the top of the Liquid Level Switch to the

container at or near the highest point on the

c

ontainer (see Figure 2).

Installing a Low Level or High

Level Switch in a Container

Step 1 - Mount the Liquid Level Switch to a solid

structure so that the switching level (see Figure 1) is

equal to the le

Step 2 - Run a 3/8" (9.53

the container at a level below the switch point to one

of the ports on the bottom of the Liquid Level Switch.

vel that the switch needs to activate.

Figure 1 - Switching Le

mm) ID minim

el

v

um line from

Figure 2 - Sensing Liquid Level

e the screws securing the electrical

Step 4 - Remo

v

housing cover and remove the cover (see Figure 3).

Figure 3 - Liquid Level Switch Terminals

F1302

Loading...

Loading...