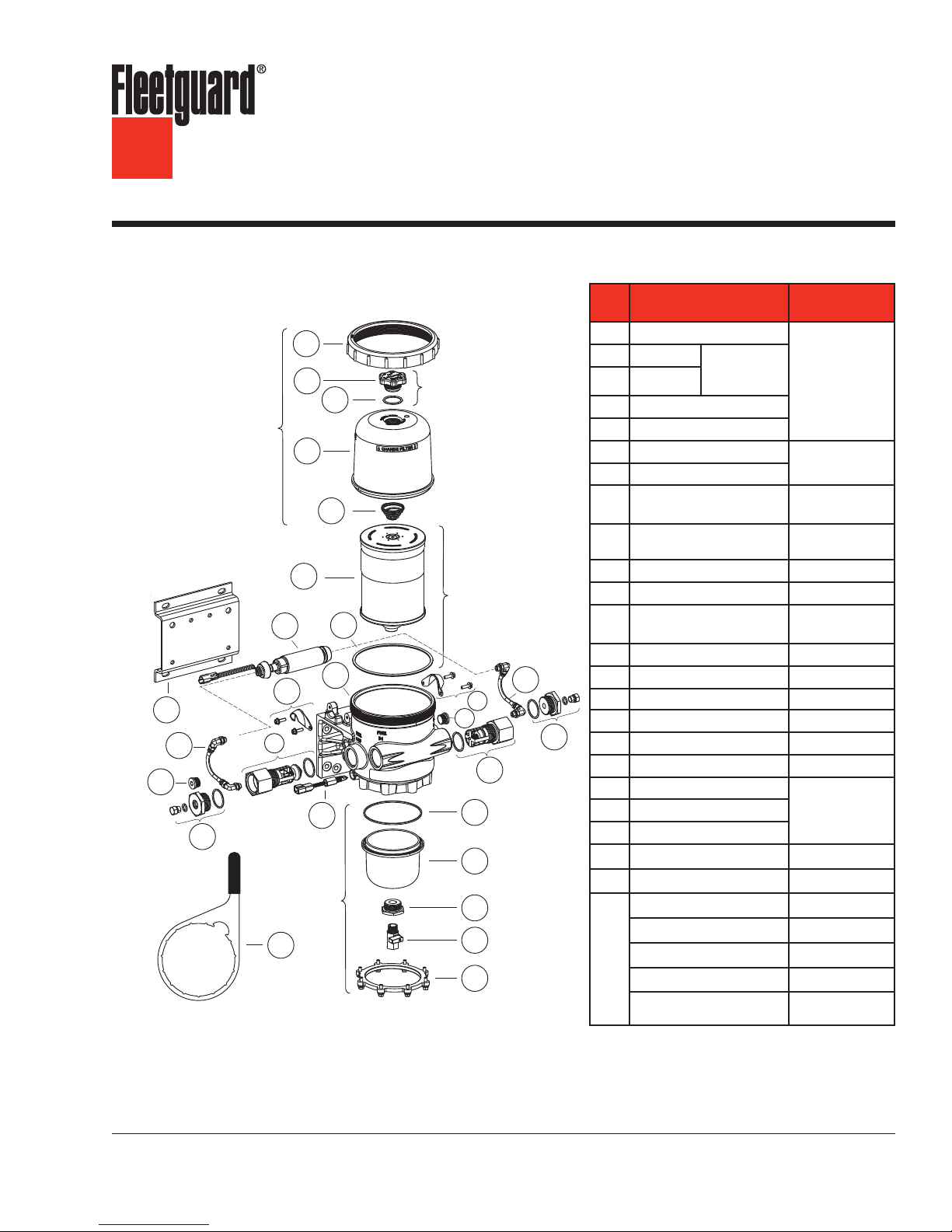

Industrial Pro® FH239 Series

Filter/Separator/Warmer

Installation Instructions

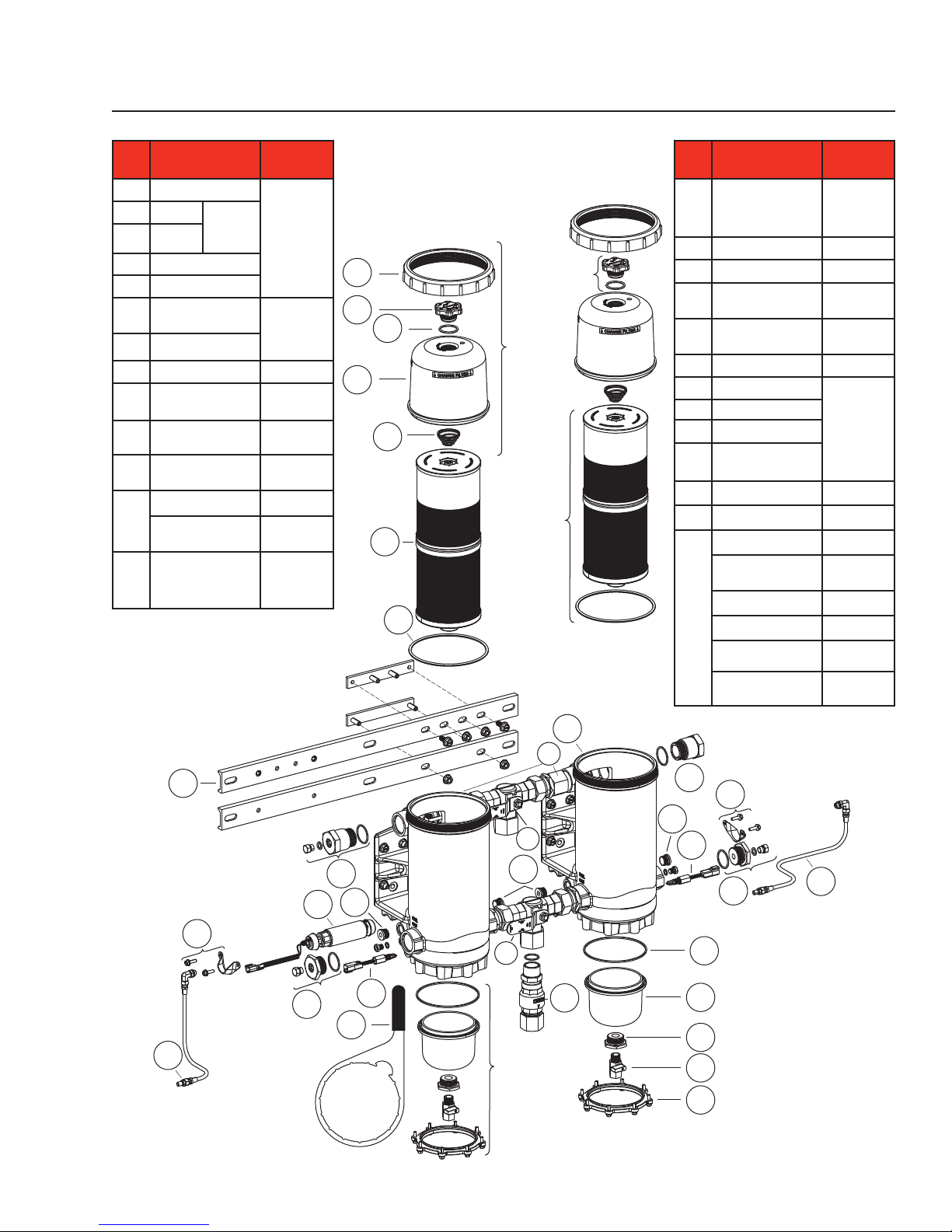

Industrial Pro® Single Short

A

B

C

Cover Assembly

D

E

F

P

Bottom

Bowl

Assembly

G

J

M

H

I

K

L

N

O

W

Vent Cap Assembly

Filter Element Assembly

(includes part C)

I

M

Q

R

S

T

U

V

Part Description

A

Collar

B

Vent Cap

C

O-Ring

D

Cover

E

Filter Spring

F

Filter Element (includes Part C)

G

O-Ring

Priming Pump (includes

H

Isolators)

(2) Priming Pump Clamp and

I

(4) Screws

J

Industrial Pro

K

Bracket with Fasteners SP1131

(2) Priming Pump Hoses and

L

(4) Fittings

M

Plug 1/2" STOR SP1125

N

L

O

Bypass Check Valve SP1121

O Diagnostic Plug Fitting

P

Water-In-Fuel (WIF) Sensor SP1123

Q

Check Valve SP1120

R

O-Ring 3945215 S

S

Bottom Bowl

T

Drain Flange

U

Drain Valve

V

Bottom Bracket and Bolts (8)

W

Wrench SP1076

WIF Wiring Harness

WIF LED

Not

Electric Pre-heater

Shown

Adapter Fitting, 3/4" to 1-1/4"

Adapter Fitting, 1-1/4" NPT

to M42 x 1.5

Vent Cap

Assembly

SP1053

®

Part

Number

Cover

Assembly

SP1127

FS53015

(includes Part C)

SP1124

SP1133

See page 14

SP1128

SP1130

Bottom Bowl

Assembly (Includes

Part R)

SP1134

3950729 S

3946670 S

See page 9

SP1135

3956561 S

CAUTION: These instructions are intended for use by professional mechanics who are trained in the proper use of

power and hand tools, using appropriate safety precautions (including eye protection).

page 2

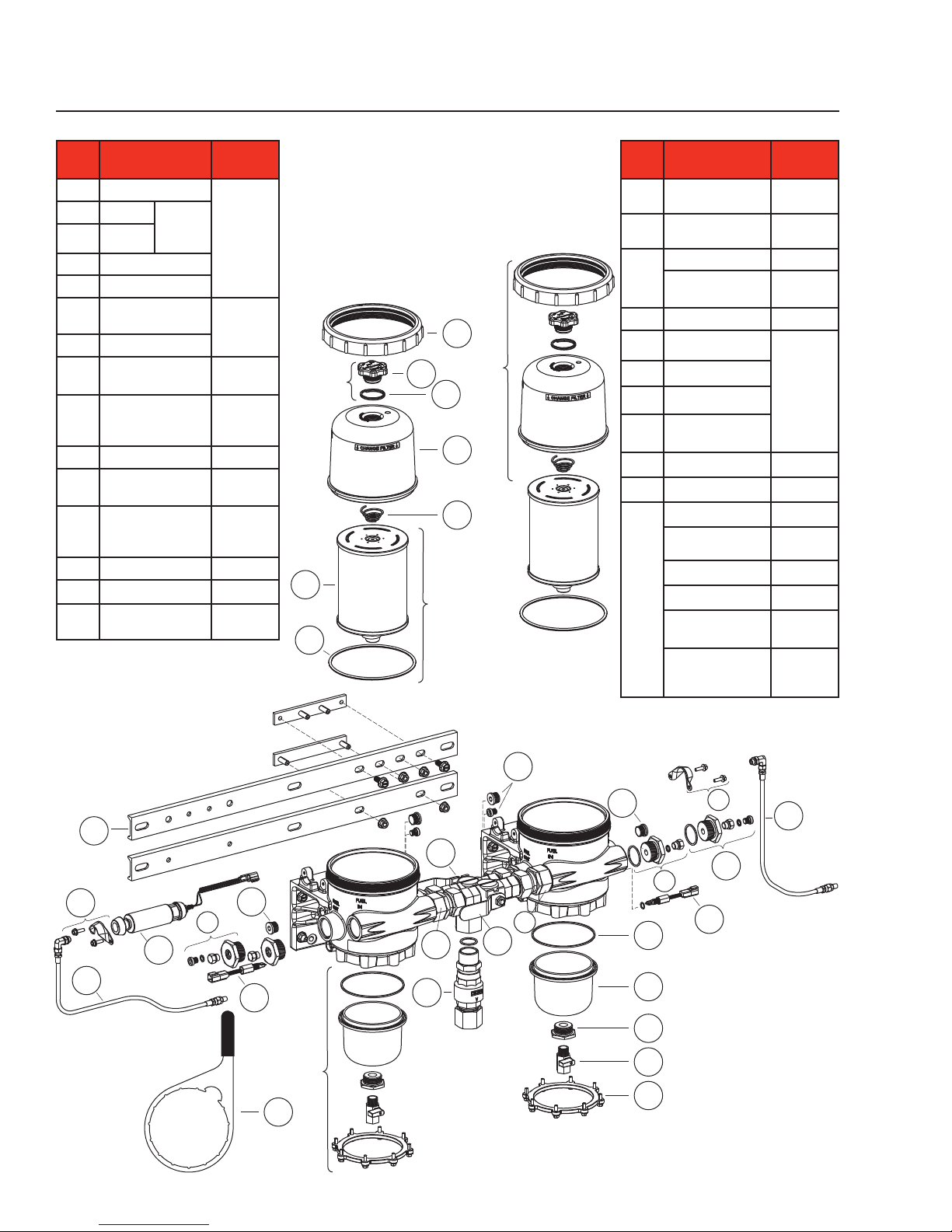

Part Description

A

Collar

B

Vent Cap

C

O-Ring

D

Cover

E

Filter Spring

Filter Element

F

(includes Part C)

G

O-Ring

Priming Pump

H

(includes Isolators)

(2) Priming Pump

I

Clamp and

(4) Screws

J

Industrial Pro

Bracket with

K

Fasteners

(2) Priming Pump

L

Hoses and

(4) Fittings

M

Plug 1/2" STOR SP1125

N Bypass Check Valve

Fuel In Diagnostic Plug

O

Fitting

Vent Cap

Assembly

SP1053

®

Part

Number

Cover

Assembly

SP1127

FS53015

(includes

Part C)

SP1124

SP1133

See page 14

SP1429

SP1430

SP1447

SP1130

Industrial Pro® Duplex Short

A

Vent

Cap

Assembly

F

G

B

Cover

Assembly

C

D

E

Filter

Element

Assembly

(includes

part C)

Part Description

Fuel Out Diagnostic

P

Plug Fitting

Water-In-Fuel (WIF)

Q

Sensor

Check Valve

R

Fuel In Fitting

(no check valve)

S

O-Ring 3945215 S

T

Bottom Bowl

U

Drain Flange

V

Drain Valve

Bottom Bracket and

W

Bolts (8)

X

Three-way Valve SP1431

Y

Wrench SP1076

WIF Wiring Harness

Dual WIF Harness

(Duplex only)

WIF LED

Not

Electric Pre-heater

Shown

Adapter Fitting, 3/4"

to 1-1/4"

Adapter Fitting,

1-1/4" NPT

to M42 x 1.5

Part

Number

SP1444

SP72026

SP1446

SP1486

Bottom

Bowl and

Drain Valve

Assembly

(Includes

Part S)

SP1134

3950729 S

SP72028

3946670 S

See page 9

SP1135

3956561 S

K

I

M

P

H

L

Q

Bottom

Bowl

Assembly

Y

N

R

M

M

I

L

J

O

P

Q

X

R

S

T

U

V

W

Caution:

Do not attempt to

remove or relocate

manifolding on

duplex units. Doing

so will void the

warranty.

page 3

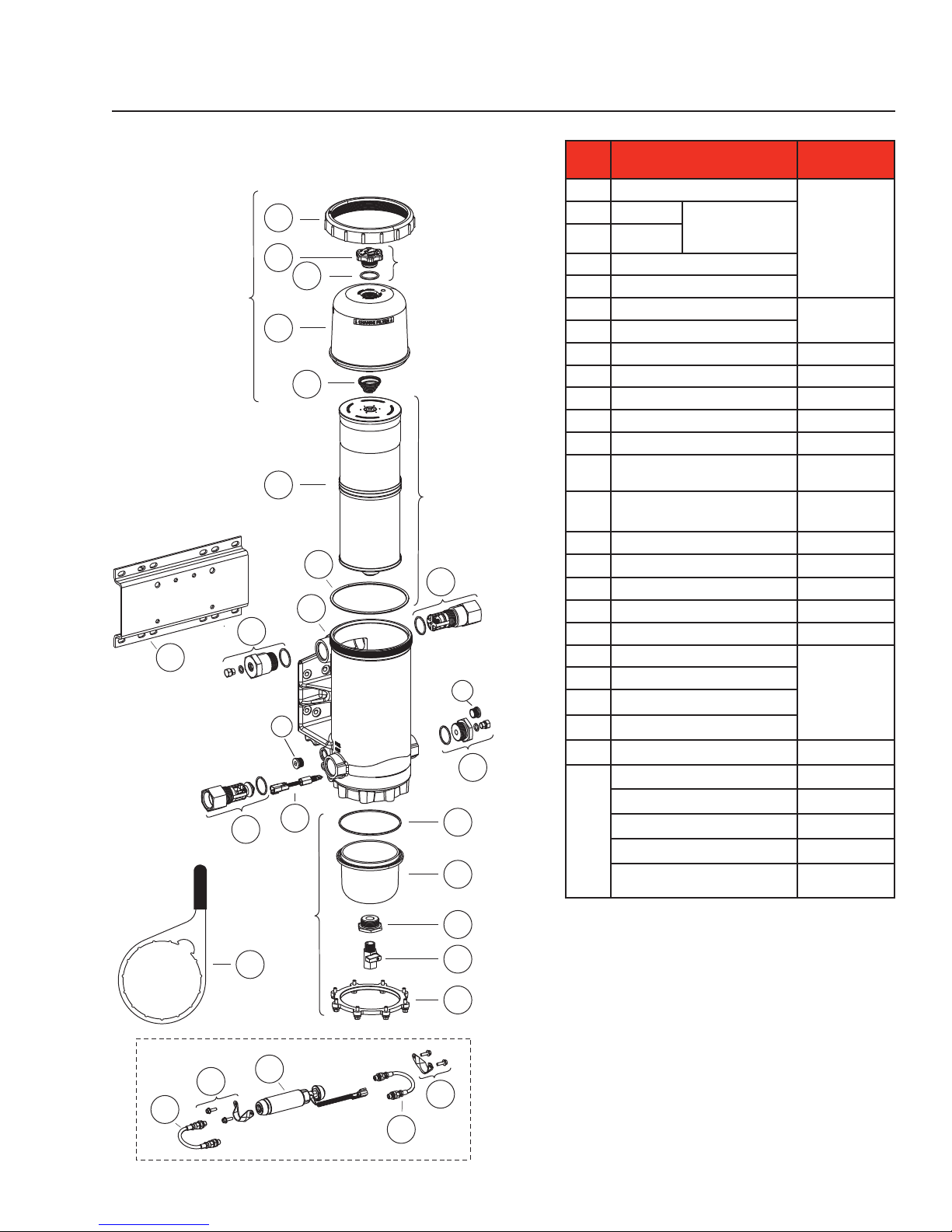

Cover Assembly

I

N

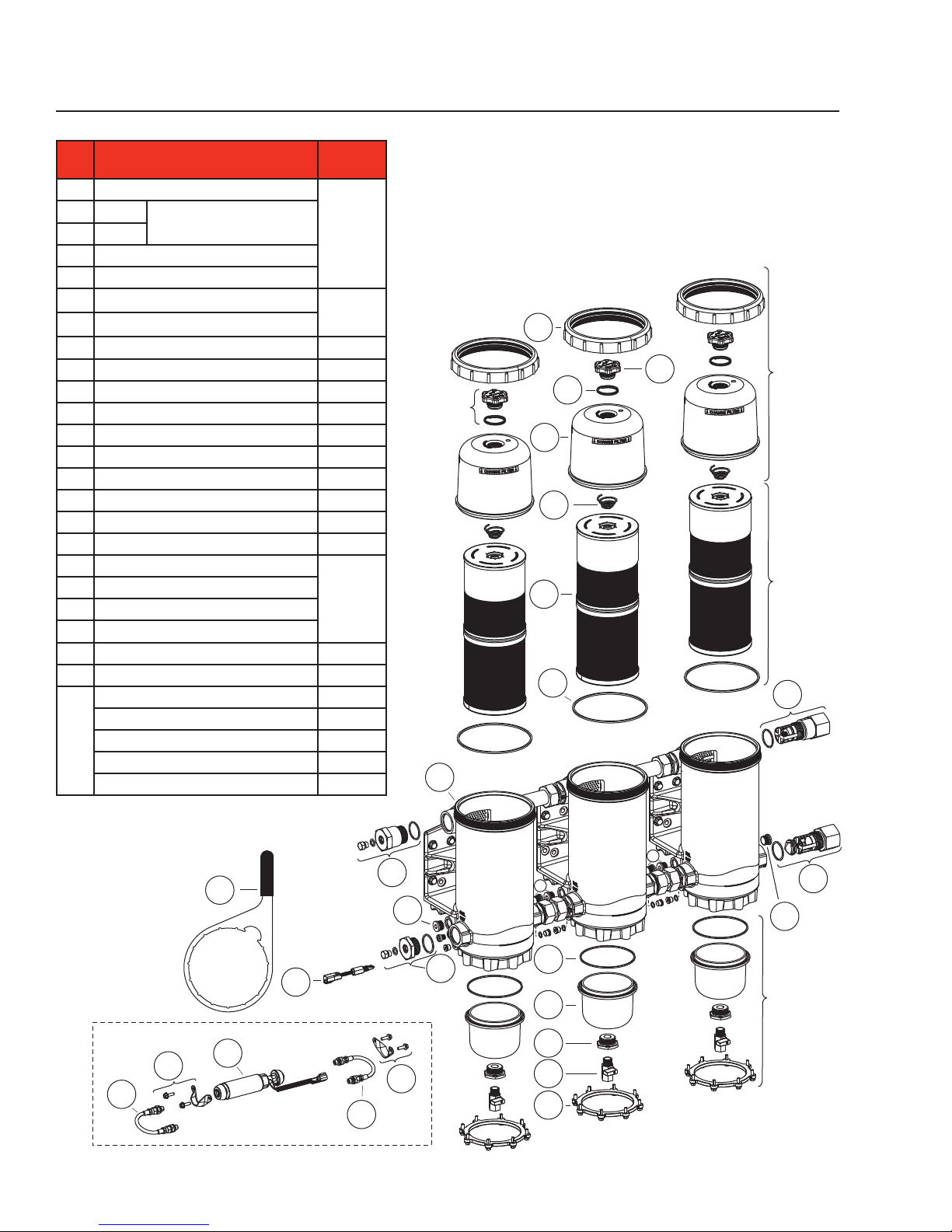

Industrial Pro® Single Tall

A

M

K

J

P

B

C

D

E

F

G

H

O

Q

Bottom

Bowl

Assembly

Vent Cap Assembly

Filter Element Assembly

(includes part C)

L

M

O

S

T

U

R

N

Part Description

A

Collar

B

Vent Cap

C

O-Ring

D

Cover

E

Filter Spring

F

Filter Element (includes Part C)

G

O-Ring

H

Industrial Pro

I

Bracket with Fasteners SP1132

J Diagnostic Plug Fitting - Extended

K

Priming Pump (includes Isolators) SP1124

L

Check Valve - Extended SP1206

(2) Priming Pump Clamps and

M

(4) Screws

(2) Priming Pump Hoses and

N

(4) Fittings

O

Plug 1/2" STOR SP1125

P Bypass Check Valve

Q

Water-In-Fuel (WIF) Sensor SP1123

R Diagnostic Plug Fitting

S

O-Ring 3945215 S

T

Bottom Bowl

U

Drain Flange

V

Drain Valve

W

Bottom Bracket and Bolts (8)

X

Wrench SP1076

WIF Wiring Harness

WIF LED

Not

Electric Pre-heater

Shown

Adapter Fitting, 3/4" to 1-1/4"

Adapter Fitting, 1-1/4" NPT

to M42 x 1.5

Vent Cap Assembly

SP1053

®

Part

Number

Cover Assembly

SP1127

FS53014

(includes Part C)

See page 14

SP1205

SP1133

SP1129

SP1121

SP1130

Bottom Bowl

and Drain

Valve Assembly

(Includes Part S)

SP1134

3950729 S

3946670 S

See page 9

SP1135

3956561 S

X

M

K

N

V

W

M

N

page 4

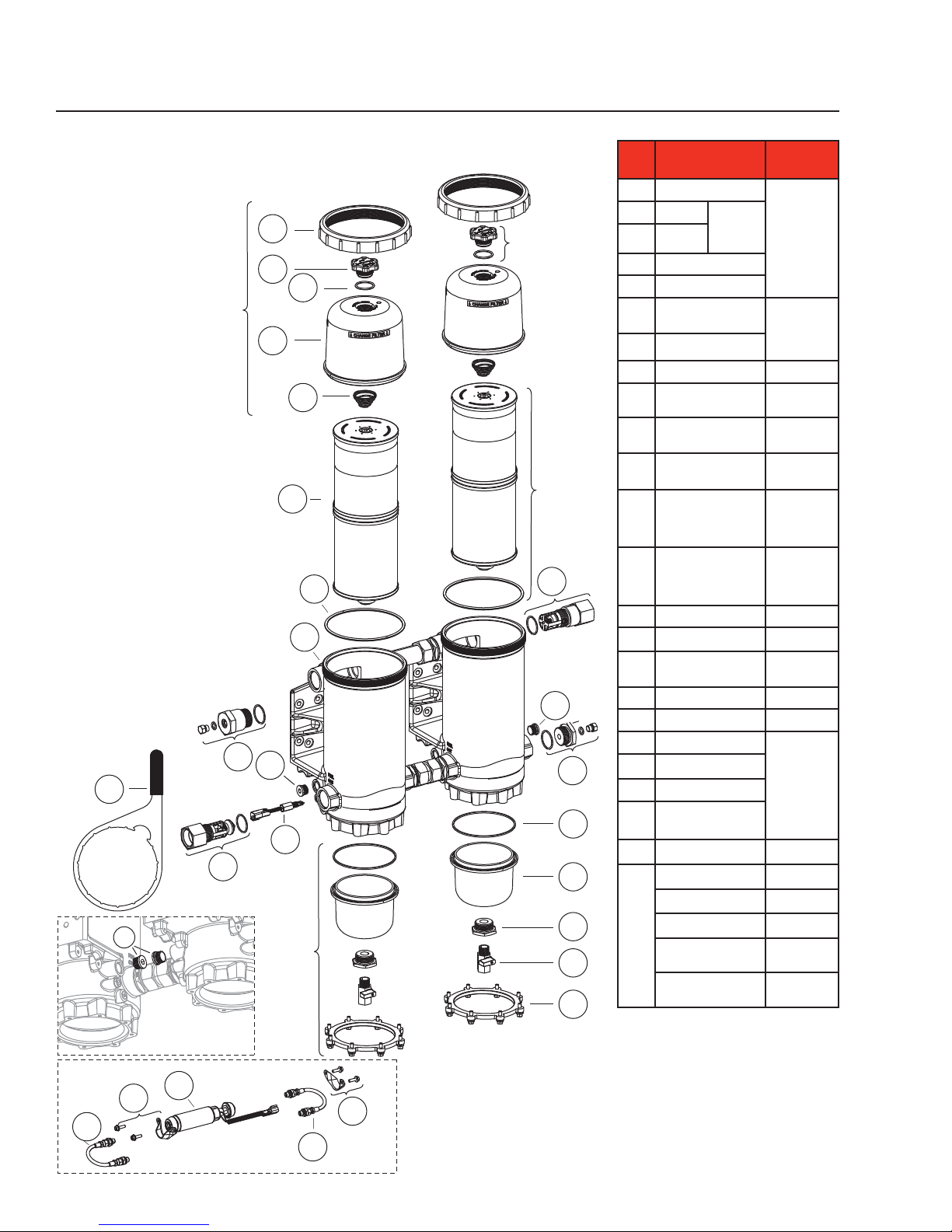

Industrial Pro® Dual Tall

A

B

C

Cover Assembly

D

E

F

G

L

L

M

H

J

I

N

W

P

O

N

Bottom

Bowl

Assembly

Vent Cap

Assembly

Filter

Element

Assembly

(includes

part C)

K

N

Q

R

S

T

U

V

Part Description

A

Collar

B

Vent Cap

C

O-Ring

D

Cover

E

Filter Spring

Filter Element

F

(includes Part C)

G

O-Ring

H

Industrial Pro

Diagnostic Plug Fitting

I

- Extended

Priming Pump

J

(includes Isolators)

Check Valve -

K

Extended

(2) Priming Pump

L

Clamps and

(4) Screws

(2) Priming Pump

M

Hoses and

(4) Fittings

N

Plug 1/2" STOR SP1125

O Bypass Check Valve

Water-In-Fuel (WIF)

P

Sensor

Q Diagnostic Plug Fitting

R

O-Ring 3945215 S

S

Bottom Bowl

T

Drain Flange

U

Drain Valve

Bottom Bracket and

V

Bolts (8)

W

Wrench SP1076

WIF Wiring Harness

WIF LED

Electric Pre-heater

Not

Shown

Adapter Fitting,

3/4" to 1-1/4"

Adapter Fitting, 1-1/4"

NPT to M42 x 1.5

Vent Cap

Assembly

SP1053

®

Part

Number

Cover

Assembly

SP1127

FS53014

(includes

Part C)

See page 14

SP1205

SP1124

SP1206

SP1133

SP1129

SP1121

SP1123

SP1130

Bottom Bowl

Assembly

(Includes

Part R)

SP1134

3950729 S

3946670 S

See page 9

SP1135

3956561 S

J

L

M

M

L

page 5

Part Description

A

Collar

B

Vent Cap

C

O-Ring

D

Cover

E

Filter Spring

Filter Element

F

(includes Part C)

G

O-Ring

H

Industrial Pro

Bracket with

I

Fasteners

Diagnostic Plug Fitting

J

- Extended

Priming Pump

K

(includes Isolators)

Check Valve SP1485

L

Fuel In Fitting

(no check valve)

(2) Priming Pump

M

Clamps and

(4) Screws

Vent Cap

Assembly

SP1053

®

Part

Number

Cover

Assembly

SP1127

FS53014

(includes

Part C)

See page 14

SP1429

SP1205

SP1124

SP1516

SP1133

Industrial Pro® Duplex Tall

A

B

C

D

E

F

G

Vent Cap

Assembly

Cover

Assembly

Filter

Element

Assembly

(includes

part C)

Part Description

(2) Priming Pump

N

Hoses and

(4) Fittings

O

Plug 1/2" STOR SP1125

P Bypass Check Valve

Water-In-Fuel (WIF)

Q

Sensor

Fuel Out Diagnostic

R

Plug Fitting

S

O-Ring 3945215 S

T

Bottom Bowl

U

Drain Flange

V

Drain Valve

Bottom Bracket and

W

Bolts (8)

X

Three-way Valve SP1431

Y

Wrench SP1076

WIF Wiring Harness

Dual WIF Harness

(Duplex only)

WIF LED

Not

Electric Pre-heater

Shown

Adapter Fitting, 3/4"

to 1-1/4"

Adapter Fitting, 1-1/4"

NPT to M42 x 1.5

Part

Number

SP1432

SP1447

SP72026

SP1444

Bottom Bowl

Assembly

(Includes

Part S)

SP1134

3950729 S

SP72028

3946670 S

See page 9

SP1135

3956561 S

N

H

L

I

J

M

O

K

X

J

O

O

Q

R

N

M

S

T

R

Q

X

P

Y

Bottom

Bowl

Assembly

U

V

W

Caution:

Do not attempt to

remove or relocate

manifolding on

duplex units. Doing

so will void the

warranty.

page 6

Part Description

A

Collar

B

Vent Cap

C

O-Ring

D

Cover

E

Filter Spring

F

Filter Element (includes Part C)

G

O-Ring

H

Industrial Pro

I Diagnostic Plug Fitting - Extended

J

Priming Pump (includes Isolators) SP1124

K

Check Valve - Extended SP1206

L

(2) Priming Pump Clamps and (4) Screws SP1133

M

(2) Priming Pump Hoses and (4) Fittings SP1129

N

Plug 1/2" STOR SP1125

O

Water-In-Fuel (WIF) Sensor SP1123

P Bypass Check Valve

Q

O-Ring 3945215 S

R

Bottom Bowl

S

Drain Flange

T

Drain Valve

U

Bottom Bracket and Bolts (8)

V

Wrench SP1076

W

Diagnostic Plug Fitting SP1130

WIF Wiring Harness

WIF LED

Not

Electric Pre-heater

Shown

Adapter Fitting, 3/4" to 1-1/4"

Adapter Fitting, 1-1/4" NPT to M42 x 1.5

Vent Cap Assembly

SP1053

®

Part

Number

Cover

Assembly

SP1127

FS53014

(includes

Part C)

See page 14

SP1205

SP1121

Bottom Bowl

Assembly

(Includes

Part Q)

SP1134

3950729 S

3946670 S

See page 9

SP1135

3956561 S

Vent Cap

Assembly

H

Industrial Pro® Triple Tall

A

B

C

D

E

F

G

Cover

Assembly

Filter

Element

Assembly

(includes

part C)

K

V

K

M

N

O

J

L

M

P

M

O

I

N

W

O

N

Q

Bottom

R

Bowl

Assembly

P

N

S

L

T

U

page 7

Fuel Processor Installation

This system must be installed between the fuel tank

and the transfer fuel pump on the suction side of the

fuel system.

WARNING: When diesel fuel is circulated

through an operating engine, it

can become very hot. To prevent

personal injury:

Scalding hazard! Do not allow heated liquid fuel

to come in contact with eyes or unprotected

skin.

Heated diesel fuel can form combustible vapor

mixtures in the area around the fuel source. To

eliminate the potential for fire, keep open flames,

sparks or other potential ignition sources away

from the work area, and do not smoke during

filter replacement or service operations which

could result in the escape of diesel fuel or fuel

vapors.

CAUTION: Always perform engine or vessel

fuel system maintenance in a well

ventilated area that is kept free of

bystanders.

To ensure priming pump hoses are not kinked

by mishandling, do not lift or handle the fuel

processor by the hoses. Do not allow the weight

of the processor to rest on the hoses.

Installation Steps

1. With the engine shut down and at ambient

temperature, close the fuel shutoff valve (if

equipped) and place a suitable container under

the fuel filters.

2. Remove the primary fuel filter element assembly,

sedimenter, and/or water separator. Drain

the used element and dispose of it in an

environmentally responsible manner, according

to state and/or federal (EPA) recommendations.

The fuel can be returned to the tank.

Installation of the Industrial Pro must be on the

suction side of the fuel system. Do not exceed 2.2 lb/

2

in

(15 kPa) inlet pressure to the fuel processor.

3. Mount the Industrial Pro

keeping the following points in mind:

®

in the desired location

a. Mounting the Industrial Pro directly on the

engine is NOT ALLOWED.

b. Mount vertically with the cover and element

pointing up.

c. Make sure there is enough top and side

clearance for the cover to be conveniently

removed for filter replacement.

d. Filter service clearance:

Single Short: 3.5" (89 mm) minimum

Duplex Short: 3.5" (89 mm) minimum

Single Tall: 6.0" (152 mm) minimum

Duplex Tall: 6.0" (152 mm) minimum

Dual Tall: 6.0" (152 mm) minimum

CAUTION: The Industrial Pro functions BEST

when installed so that the Filter

Element is above the "FULL" level

of the fuel tank. The housing can

be installed up to 6' (1.8 m) below

the “FULL” level of the fuel tank.

Installing below the “FULL” level

causes the starting level to be

higher than normal. If mounted

below full tank level, a shut off

valve will be required at the inlet

to allow filter changes without

overflow of fuel. Mounting below 6'

(1.8 m) eliminates the SEEING IS

BELIEVING® functionality.

4. Route the fuel supply line from the fuel tank to

the Industrial Pro inlet (see Figure 1). Route a

fuel line from the Industrial Pro outlet to the fuel

pump inlet.

CAUTION: To avoid fuel line water traps that

can freeze in cold conditions and

restrict, or block, the flow of fuel

to the engine, be certain that there

are no low spots in the hoses

when routing them in the engine

compartment.

page 8

Fuel In

Fuel Tank

High

Pressure

Pump

To Injectors/Rail

Low Pressure

Pump

On Engine Filtration

Fuel Out

Figure 1 - Industrial Pro Connections

Note: When the engine is shut off, fuel levels may

drop until the engine is restarted.

5. To minimize restriction, observe the following

guidelines when plumbing the system.

a. Keep the fuel line routing as smooth as

possible with no low hanging loops which

can trap water.

b. Use 90° elbows only when necessary.

c. If the fuel hoses are made to length on

the job, be sure that the inner liner of the

fuel hose is not cut by the fitting, creating

potential check valve effects. Ensure hoses

are clean and free of debris before installing.

CAUTION: To avoid damaging the aluminum

fuel housing, do not overtighten fuel

lines or line fittings. Do not exceed

65 ft-lbs (88 N.m). See the table of

torque values on page 13.

6. Apply liquid thread sealant to the inlet and outlet

hose threads and connect the hoses to the unit.

Installing a WIF (Water In Fuel) Sensor With

Optional Indicator (LED)

Note: Drain the unit before installing or sevicing any

components on the unit.

1. Install the WIF Probe (SP1123 for all models except

for the Industrial Pro Duplex Short and industrial

Pro Duplex Tall; for the Industrial Pro Duplex Short

and Industrial Pro Duplex Tall, use SP72026) into

the side of the Industrial Pro

Torque to

20-24 in-lbs (2.3-2.7 N·m).

®

(see Figure 2).

WIF Probe

(install either

side)

Figure 2 - WIF Probe Installation

2. Install the WIF wiring harness (3950729 S) on

the WIF Probe. The harness has the following

connections: 12" (304.8 mm) black ground lead

with a 3/8" (9.53 mm) diameter loop end and a

72" (1828.80 mm) green WIF wire.

Note: For the Industrial Pro Duplex Short and

Industrial Pro Duplex Tall configurations, a

Dual WIF wiring harness (SP72028) is included

to run both sensors in parallel. To ensure

proper readings, the Y harness must be

installed.

3. Drill 1/2" (12.70 mm) hole in the control panel

where the WIF LED (3946670 S) is to be located.

a. Installation must have 1.5" (38.10 mm) of

clearance behind dash or control panel.

b. Use caution not to damage nearby

components when drilling.

4. Install WIF LED by pressing firmly into the

drilled hole.

5. Connect the 4" (101.60 mm) black ground

wire on WIF LED to a ground source. Attach

additional black wire as needed.

6. Connect the 12" (304.8 mm) black ground lead

with a 3/8" (9.53 mm) diameter loop end on the

WIF wiring harness to ground source near Fuel

Processor (if applicable).

7. Connect 72" (1828.80 mm) green signal wire

on WIF wiring harness to 4" (101.60 mm) green

signal wire on WIF LED. Use additional green

wire as needed.

8. Locate 12 VDC or 24 VDC power source. Run

red wire from power source to 4" (101.60 mm)

red wire on WIF LED. Add a 1 A in-line fuse

(not included). (See Figure 3.)

WIF

(WaterIn-Fuel)

Sensor

page 9

WIF Light

(LED )

Red

Green

WIF

Harness

1 A

Fuse

+–

Figure 3 - WIF Wiring

Note: Use appropriate connectors to attach the

wires. To test the WIF indicator, pour water

into the body of the fuel processor until it

covers the WIF probe. The WIF LED should

illuminate. The volume of fluid necessary to

turn the WIF indicator on is 1500 ml.

Installing an Optional Electric Pre-heater

Note: Drain the unit before installing or servicing

any components on the unit.

All units come with pre-drilled ports to allow for preheaters (dual/duplex units require two pre-heaters):

Single Short: One port

Duplex Short: Two ports (one per body)

Single Tall: Two ports

Duplex Tall: Four ports (two per body)

Dual Tall: Four ports (two per body)

Triple Tall: Six ports (two per body)

Table 1 – 12 and 24 VDC Pre-heaters

Part Number Description

SP1312 12 VDC Pre-heater

SP1313 24 VDC Pre-heater

Pre-heater

Figure 4 - Pre-heater Installation

To install, thread the pre-heater into housing and

torque to 15-30 ft-lbs (20.3-40.7 N·m). Follow the

wiring diagram in Figure 5.

Refer to equipment owner's manual for more

specific information related to wiring diagrams of the

equipment to which the unit will be applied.

Note: When wiring the electric pre-heater, use a

fuse NOT a circuit breaker.

Key Controlled

Battery

Without Relay

Fuse*

Battery

With Relay

Use a relay if the available keyed circuit

will not handle a minimum of 25 A.

Key

Controlled

Circuit

Circuit

Fuse*

Relay

Industrial

Pro

B

*24 V heaters use a 15 A fuse

12 V heaters use a 25 A fuse

Industrial

8730/51

8586

Pro

B

*24 V heaters use a 15 A fuse

12 V heaters use a 25 A fuse

Figure 5 – Pre-heater Wiring Options

page 10

For systems with multiple Industrial Pro

®

units, the

pre-heater power supply wiring must be split in the

Junction Box. See Figure 6 for wiring a Dual system.

Dual System

To Circuit or

Relay

Junction

Box

Black

To Industrial Pros / Pre-heaters

Red

Figure 6 – Wiring Dual Filter Systems

Filter Change Procedure

Note: Change the filter only when the fuel level

reaches and remains at the top of the black

band on the filter. The filter may become

dark, however, there is additional filter

capacity and restriction will remain low until

the fuel reaches the black band.

1. Turn off the engine.

2. Shut off the fuel supply to the unit you are

working on if using a duplex unit (see the Valve

Operation section).

3. Remove the vent cap and dispose of the O-ring.

Clean the threads of the vent cap and on the top

of the cover. Set the vent cap aside.

4. Open the drain valve and drain the fuel

completely from the unit, then close the drain

valve. The unit must be completely drained to

prevent contamination of the clean side of the

filtration system.

5. Using the Collar Wrench (part number SP1076),

loosen the collar.

6. Remove the clear cover and collar from the

Industrial Pro. Discard the cover O-ring and

install a new O-ring (supplied with the filter) on

the cover.

7. Clean the threads on the collar and body of the

Industrial Pro.

Figure 7 – Collar Wrench

8. Install the new O-ring on the vent cap (supplied

with the filter).

9. Remove the filter element(s) from the Industrial

Pro by pulling upward.

10. Install the new filter element. Figure 8 shows a

key on the filter which fits into a keyway on the

center boss. Position the filter element so the

filter element key is lined up with the keyway on

the center boss of the housing and press the

filter element into the housing. Ensure the filter

element is fully seated by firmly pushing on the

top end plate.

Table 2 – Industrial Pro Replacement Filters

Part Number Description

FS53014

FS53015

Key

EleMax™ NanoNet™ 5 micron (tall)

EleMax NanoNet 5 micron (short)

Keyway

Figure 8 – Key and Keyway

11. After checking to make sure the new O-ring seal

is seated correctly on the base of the cover,

install the cover and collar. Simultaneously apply

modest pressure to the top of the cover and turn

the collar until it no longer spins freely.

12. Using the collar wrench, tighten the collar the

distance of two additional ribs.

13. Prime the fuel system according to the steps

in the "Priming the Fuel System" section in this

manual. (The vent cap will be returned to the

Industrial Pro during the priming process).

page 11

Valve Operation (DUPLEX UNIT ONLY)

1. For single unit flow, rotate both valve handles

either to the left or right, depending on which

unit is being used. Point the handle toward the

unit you want to isolate. See Figure 9.

2. For dual flow, rotate the valve 180° from the

shutoff position. See Figure 9.

3. To shut off flow, rotate the valve handle 180°

from the dual flow position. See Figure 9.

ON ON

Both ON

ON ON

Single Unit Flow Single Unit Flow

OFF OFF

Both OFF

OFFOFF

Figure 9 – Valve Operation

"On the Fly" Filter Change Requirements

(DUPLEX UNIT ONLY)

Warning: Filter changes require the housing

to be isolated from fuel flow. Do

not attempt to change the filter on

the active housing during engine

operation.

1. If the Duplex unit is being used in Duplex mode:

a. Rotate both valve handles into the Dual

Mode position (Both ON) until fuel is flowing

through both units. See Figure 9.

b. Rotate both handles to isolate the unit that

requires the filter change. The handles should

now point to this unit. See Figure 9.

c. Follow the filter change procedure.

2. If the Duplex unit is being used in Dual mode:

a. Bring the engine to idle before servicing the

units.

b. Rotate both valve handles to isolate either

the left or right unit. The Duplex unit is now

in Dual mode. See Figure 9.

c. Follow the filter change procedure to service

the isolated unit.

d. After the filter change procedure is complete

for this unit, rotate both valve handles into

the Dual Mode position (Both ON) until fuel is

flowing through both units. See Figure 9.

e. Rotate both valve handles to isolate the other

unit that requires filter change. The valve

handles should now point to this unit. See

Figure 9.

f. Follow the filter change procedure.

Priming the Fuel System

Caution: Running the priming pump dry for

more than 30 seconds can cause

the pump to fail and void the

warranty. Follow the steps in this

section to prevent pump damage.

1. Check to make sure the drain valve at the base

of the Industrial Pro

2. Close the fuel shutoff valve (if equipped). If using

a duplex unit, shut off the fuel supply to the unit

you are working on.

3. Remove the vent cap from the top of the clear

cover.

4. Fill the Industrial Pro full of fuel.

5. Tighten the vent cap (tighten by hand only) until it

“clicks.”

6. Open the fuel shutoff valve and/or duplex valves

(if equipped).

7. Start the engine.

8. When the lubrication system reaches its normal

operating pressure, increase engine speed to

high idle for one to two minutes.

9. Loosen the vent cap until the fuel level drops to

just above the collar.

10. Tighten the vent cap (tighten by hand only) until it

“clicks.”

Note: The clear filter cover will not fill completely

during engine operation. It will gradually fill

over time and the fuel level will rise as the

filter becomes clogged.

®

is closed.

page 12

Draining Water Contaminants

1. Shut off the fuel supply to the housing that

requires draining and open the vent cap.

2. Place a suitable container under the drain valve

at the base of the Industrial Pro and open the

drain valve.

3. Water and contaminants will flow into the

container. When fuel begins to flow out of the

drain, close the drain valve.

4. Tighten the vent cap by hand until it “clicks.”

5. Start the engine. Raise the RPM for one minute

to purge the air from the system.

Servicing the Primer Pump

1. Remove the fitting on the end of the pump using

two wrenches to hold the end stationary as the

fitting is loosened.

2. The washer on the fittings MUST be in place

when reassembled.

Washer

Figure 10 – Removing the Primer Pump Fitting

Suggested Preventive Maintenance

Weekly – Drain water.

Every Filter Change – Change o-rings.

Every 12 Months – Check all electrical connections

for corrosion. Check all fuel fittings for leaks.

Extreme winter or salt corrosion environments may

require lubrication of the top collar threads with antiseize lubricant every 180 days.

Changing the Fuel Inlet Direction

for Industrial Pro Single and Dual

Configurations

To change the fuel inlet from the left to right, or from

the right to left, exchange the inlet fitting (including

check valve) with the threaded plug on the opposite

side of the housing. Torque both of the fittings to

55-65 ft-lb (74.6-88.1 N·m).

Changing the Fuel Outlet Direction for

Single Configurations Only

Note: Drain the unit before installling or servicing

any components on the unit.

To change the fuel outlet from the left to right,

or from the right to left, both the fittings and the

priming pump require a directional change as

follows:

1. Remove the outlet fitting with the bypass valve

attached.

2. Remove the outlet plug from the opposite side of

the housing.

3. Exchange the fitting and plug to the opposite

sides and torque to 55-65 ft-lb (74.6-88.1

N·m). Ensure the bypass valve head is seated

correctly.

4. Disconnect the hoses attaching the priming

pump to the housing.

5. Remove the bolts securing the priming pump

straps.

6. Turn the priming pump to ensure that the arrow

etched on the pump housing is pointed in the

direction of the outlet of the housing.

7. Reinstall bolts securing the priming pump straps

and torque to 8-10 ft-lb (10.8-13.6 N·m).

8. Reinstall the hoses and torque to 10-15 ft-lb

(13.6-20.3 N·m).

FUEL

OUT

Figure 11 – Primer Pump Fitting

page 13

Changing the Fuel Outlet Direction for

Dual and Triple Configurations Only

The same procedure applies to the dual and triple

configuration as with the single configuration,

but the priming pump must also be moved to the

housing with the fuel outlet fitting attached. Again,

ensure the flow direction arrow is pointed toward

the outlet fitting.

For instance, if changing from a fuel out left

configuration to a fuel out right configuration, the

priming pump must be moved from the left housing

to the right housing.

Left Right

Figure 12 – Changing From a Fuel Out Left to a Fuel Out

Right Configuration

Torque Values

Application

WIF Probe to Housing

Fuel Connection Fittings to

Housing Body

Pre-heater to Housing

Drain Valve to Bowl

Primer Pump Strap to Body

Primer Pump Fittings to Housing

Body

Pump Inlet/Outlet Hose to Fittings

Assembly to Mounting Bracket

Collar to Bottom Bowl

Torque

in-lb ft-lb

20-24 1.67-2.0 2.3-2.7

55-65 74.6-88.1

15-30 20.3-40.7

10-15 13.6-20.3

8-10 10.8-13.6

13-15 17.6-20.3

10-15 13.6-20.3

35-50 47.5-67.8

8-10 10.8-13.6

N•m

page 14

Industrial Pro® Ordering Information

Housing Part

Number

FH23900 FS53015

FH23904 FS53015

FH23916 FS53015

FH23917 FS53015

FH23901 FS53014

FH23903 FS53014

FH23905 FS53014

FH23906 FS53014

FH23912 FS53014

FH23913 FS53014

FH23914 FS53014

FH23915 FS53014

FH23907 FS53014*

FH23908 FS53014*

FH23910 FS53014*

FH23911 FS53014*

FH23918 FS53014*

FH23919 FS53014*

FH23920 FS53014*

FH23921 FS53014*

FH23926 FS53015*

FH23927 FS53015*

FH23922 FS53014*

FH23923 FS53014*

FH23930 FS53014**

* Requires two filter elements

** Requires three filter elements

Filter

Element

Short/

Primer

Tall

Pump WIF

Short Yes Yes Yes Yes No Yes Yes In Right/Out Left 1-1/4" NPTF

Short Yes Yes Yes Yes No Yes Yes In Left/Out Right 1-1/4" NPTF

Short No Yes Yes Yes No Yes No In Right/Out Left 1-1/4" NPTF

Short No Yes Yes Yes No Yes No In Left/Out Right 1-1/4" NPTF

Tall Yes Yes Yes Yes No Yes Yes In Left/Out Right 1-1/4" NPTF

Tall Yes Yes Yes Yes No Yes Yes In Right/Out Left 1-1/4" NPTF

Tall Yes Yes Yes Yes No Yes Yes In Left/Out Left 1-1/4" NPTF

Tall Yes Yes Yes Yes No Yes Yes In Right/Out Right 1-1/4" NPTF

Tall No Yes Yes Yes No Yes No In Right/Out Left 1-1/4" NPTF

Tall No Yes Yes Yes No Yes No In Left/Out Right 1-1/4" NPTF

Tall No Yes Yes Yes No Yes No In Left/Out Left 1-1/4" NPTF

Tall No Yes Yes Yes No Yes No In Right/Out Right 1-1/4" NPTF

Tall Yes Yes Yes Yes No Yes Yes In Right/Out Right 1-1/4" NPTF

Tall Yes Yes Yes Yes No Yes Yes In Right/Out Left 1-1/4" NPTF

Tall Yes Yes Yes Yes No Yes Yes In Left/Out Right 1-1/4" NPTF

Tall Yes Yes Yes Yes No Yes Yes In Left/Out Left 1-1/4" NPTF

Tall No Yes Yes Yes No Yes No In Right/Out Left 1-1/4" NPTF

Tall No Yes Yes Yes No Yes No In Left/Out Right 1-1/4" NPTF

Tall No Yes Yes Yes No Yes No In Left/Out Left 1-1/4" NPTF

Tall No Yes Yes Yes No Yes No In Right/Out Right 1-1/4" NPTF

Short No Yes Yes Yes No No No In Center/Out Center 1-1/4" NPTF

Short Yes Yes Yes Yes No Yes Yes In Center/Out Center 1-1/4" NPTF

Tall No Yes Yes Yes No No No In Center/Out Center 1-1/4" NPTF

Tall Yes Yes Yes Yes No Yes Yes In Center/Out Center 1-1/4" NPTF

Tall Yes Yes Yes Yes No Yes Yes In Right/Out Right 1-1/4" NPTF

Clear

Bowl

Bracket

Included

Single

Dual

Duplex Short

Duplex Tall

Triple Tall

Pre-

heater

Check

Valve

Bypass

Valve

Fuel In &

Fuel Out Port Size

page 15

Industrial Pro® Specifications

Specification Single Short Single Tall Dual Tall Triple Tall

Height Overall 20" (508 mm) 28" (711 mm) 28" (711 mm) 28" (711 mm)

Depth Overall 12" (305 mm) 12" (305 mm) 12" (305 mm) 12" (305 mm)

Width, max 11.2" (284 mm) 13.9" (352 mm) 23.8" (604 mm) 35.5" (902 mm)

Weight (Dry) 29 lbs (13.2 kg) 39 lbs (17.7 kg) 75 lbs (34.0 kg) 151 lbs (68.5 kg)

Weight (Wet) 37 lbs (16.8 kg) 57 lbs (25.6 kg) 112 lbs (50.8 kg) 213 lbs (96.6 kg)

Fuel Capacity (w/o filter)

Fuel Connections 1-1/4" NPT 1-1/4" NPT 1-1/4" NPT 1-1/4" NPT

Fuel Flow Rate

Bottom Bowl Water Holding Capacity 29 fl oz (857 ml) 29 fl oz (857 ml) 58 fl oz (1715 ml) 87 fl oz (2573 ml)

Filter Service Clearance Min. 3.5" (89 mm) Min. 6.0" (152 mm) Min. 6.0" (152 mm) Min. 6.0" (152 mm)

Electrical Pre-heater Options 12 VDC or 24 VDC

Primer Pump Supply Voltage: 24 VDC, 6 A

Fuel Types Compatible for use with Diesel #1, Diesel #2, Kerosene, Biodiesel B20, and JP8

1.1 gal (4.3 L) 2.5 gal (9.5 L) 5.0 gal (19 L) 7.5 gal (28.5 L)

300 gal/hr

(18.9 L/min)

600 gal/hr

(37.9 L/min)

1200 gal/hr

(75.7 L/min)

1200 gal/hr

(75.7 L/min)

Specification Duplex Short Duplex Tall

Height Overall 20" (508 mm) 28" (711 mm)

Depth Overall 12.4" (314 mm) 12" (305 mm)

Width, max 32" (813 mm) 32" (813 mm)

Weight (Dry)

Weight (Wet)

Fuel Capacity (w/o filter)

Fuel Connections 1-1/4" NPT 1-1/4" NPT

Fuel Flow Rate

Bottom Bowl Water

Holding Capacity

Filter Service Clearance Min. 3.5" (89 mm) Min. 6.0" (152 mm)

Electrical Pre-heater Options 12 VDC or 24 VDC

Primer Pump

Fuel Types

71 lbs (32.2 kg) w/ check valve

66 lbs (29.9 kg) w/o check valve

87 lbs (39.5 kg) w/ check valve

82 lbs (37.2 kg) w/o check valve

2.2 gal (8 L) 5.0 gal (19 L)

300 gal/hr Duplex mode (18.9 L/min)

600 gal/hr Dual mode (37.9 L/min)

29 fl oz (857 ml) Single mode

58 fl oz (1715 ml) Dual mode

Supply Voltage: 24 VDC, 6 A

Compatible for use with Diesel #1, Diesel #2, Kerosene, Biodiesel B20, and JP8

91 lbs (41.3 kg) w/ check valve

86 lbs (39.0 kg) w/o check valve

127 lbs (57.6 kg) w/ check valve

122 lbs (55.3 kg) w/o check valve

600 gal/hr Duplex mode (37.9 L/min)

1200 gal/hr Dual mode (75.7 L/min)

29 fl oz (857 ml) Single mode

58 fl oz (1715 ml) Dual mode

Specifications subject to change without notice.

page 16

Dimensions

Industrial Pro® Single Short

20.00

(508.0)

Max.

10.78

(273.8)

2.53

(64.1)

0.32

(8.0)

Service Height

3.5 (88.9)

1.50

(38.1)

2.75 (69.9)

7/8"-14 UNF-2B

Optional Heater

O-Ring Boss Port

Fuel In

1-1/4"-11-1/2 NPTF

M14 Diagnostic Port

Optional Fuel Out

1.08 (27.4)

2.00 (50.8)

Industrial Pro® Single Tall

Service Height

11.92

(302.8)

27.600

(701.1)

Max.

8.32

(211.3)

7/8"-14 UNF-2B

Optional Heater

O-Ring Boss Port

6.0 (152.4)

Fuel In

1-1/4"-11-1/2

NPTF

2.77

(70.5)

.040

(10.2)

4.20 (106.7)

9.56

(242.7)

M14

Diagnostic

Port Optional

Fuel Out

1.20 (30.5)

2.00 (50.8)

0.75

(19.1)

.040

(10.2)

WIF

Sensor

5.08

(128.9)

5.20

(132.1)

5.97

(151.6)

5.97

(151.6)

All dimensions are in inches (millimeters)

∅ 0.22

(5.6)

(x4)

7.70

1.50

(195.6)

(38.1)

6.60

(167.6)

0.55 (14.0)

0.92 (23.4)

All dimensions are in inches (millimeters)

0.35

(8.9)

1.50 (38.1)

6.60

7.70

(167.6)

(195.6)

0.55 (14.0)

0.52 (13.2)

6.00

(152.4)

8.20

(208.3)

13.85

(351.8)

∅ 0.22

(5.6) (x12)

2.20

(55.9)

3.50

(88.9)

8.96

(227.6)

10.26

(260.60

12.46

(316.5)

0.35

(8.9)

1-1/4"-11-1/2

Fuel Out

0.75

(19.1)

0.40

(10.2)

M14

Diagnostic

Port

Optional

Fuel In

2.77

(70.5)

9.56

(38.1)

(242.7)

0.40

(10.2)

Fuel Out

NPTF

1-1/4"-11-1/2 NPTF

2.75

(69.9)

1.50

7.75

(196.8)

2.00

(50.8)

(Left-In, Right-Out Unit Shown)

7.75

(196.8)

4.20

(106.7)

2.00

(50.8)

(Left-In, Right-Out Unit Shown)

7/8"-14 UNF-2B

Optional Heater

O-Ring Boss Port

1.50

(38.1)

0.32

(8.0)

M14

Diagnostic

Port

Optional

Fuel In

7/8"-14 UNF-2B

Optional Heater

O-Ring Boss Port

Industrial Pro® Dual Tall

4.20

Service Height

Fuel In

1-1/4"-11-1/2

NPTF

11.92

(302.8)

27.600

(701.1)

Max.

8.32

(211.3)

.040

(10.2)

7/8"-14 UNF-2B

Optional Heater

O-Ring Boss Port

M14 Diagnostic

Port Optional

Fuel Out

6.0 (152.4)

2.77

(70.5)

(106.7)

1.20 (30.5)

2.00 (50.8)

5.08

(128.9)

Fuel In

12.69

(322.3)

5.97

(151.6)

Fuel Out

All dimensions are in inches (millimeters)

1.50

(38.1)

7.70

(195.6)

0.55

(14.0)

(12.7)

0.35

(8.9)

6.60

(167.6)

0.50

(227.6)

∅ 0.22

(5.6) (x12)

2.20

(55.9)

8.96

12.46

(316.5)

22.75

(577.9)

19.22

(488.2)

21.42

(544.1)

7.75

(196.8)

4.20

(106.7)

9.56

(242.7)

0.40

(10.2)

Fuel Out

1-1/4"-

11-1/2

NPTF

(Left-In, Right-Out Unit Shown)

2.00

(50.8)

M14

Diagnostic

Port

Optional

Fuel In

1.50

(38.1)

7/8"-14

UNF-2B

Optional

Heater

O-Ring

Boss Port

2.77

(70.5)

Dimensions

Industrial Pro® Duplex Short

page 17

(56.13)

2.75

(69.85)

M14

Diagnostic

Port

0.75

(19.05)

2.21

(231.98)

0.75

(19.05)

9.13

0.40

(10.16)

0.85

(21.59)

1.08 (27.43)

2.00 (50.80)

2.15 (54.61)

7.06

(179.39)

6.50

(165.10)

Industrial Pro® Duplex Tall

11.18

(284.06)

7.06

(179.38)

6.50

(165.10)

M14

Diagnostic

Port

Deutsch Connector

WIF Sensor 165 kΩ

Deutsch Connector

1.20 (30.48)

2.00 (50.80)

2.15 (54.61)

(242.70)

DT06-2S

DT04-2P

Harness

9.56

1-1/4"-11-1/2

1-1/4"-11-1/2

(228.83)

Fuel In

NPTF

Fuel Out

NPTF

Fuel In

1-1/4"-11-1/2

9.37

(238.08)

1-1/4"-11-1/2

18.75

(476.15)

18.02 (457.66)

9.01

NPTF

Fuel Out

NPTF

Deutsch Connector

DT04-2P Harness

3.33

(84.53)

3.33

(84.53)

Fuel In

Deutsch

Connector

DT06-2S

WIF Sensor

165 kΩ

9.13

(231.98)

Fuel Out

Deutsch Connector

DT04-2P Harness

All dimensions are in inches (millimeters)

15.00

(381.00)

All dimensions are in inches (millimeters)

15.00

(381.00)

15.00

(381.00)

0.75

(19.05)

16.00 (406.40)

15.00

(381.00)

0.75

(19.05)

16.00 (406.40)

20.23

(513.80)

3.60

(91.44)

Service Height

6.0 (152.4)

Ø0.56

(14.29)

Typ.

3.60

(91.44)

(39.12)

Service Height

3.50 (88.90)

0.75

(19.05)

2.21

(56.13)

2.75

(69.85)

0.85

(21.60)

1.54

1.20

(30.48)

2.00

(50.80)

2.15

(54.61)

M14

Diagnostic

Port

0.40

(10.16)

0.85

(21.59)

1.08 (27.43)

2.00 (50.80)

2.15 (54.61)

4.20

(106.68)

M14

Diagnostic

Port

(707.03)

9.56

(242.70)

0.40

(10.15)

27.84

Industrial Pro® Triple Tall

4.20

5.08

(106.7)

1.20 (30.5)

2.00 (50.8)

(128.9)

Fuel In

Service Height

6.0 (152.4)

M14

Diagnostic

Port

11.92

(302.8)

2.77

(70.5)

27.600

(701.1)

Max.

8.32

(211.3)

.040

(10.2)

7/8"-14 UNF-2B

Optional Heater

O-Ring Boss Port

M14 Diagnostic

Port Optional

Fuel Out

12.69

(322.3)

12.69

(322.3)

5.97

(151.6)

Fuel Out

7.70

(195.6)

(14.0)

0.55

(12.2)

6.60

(167.6)

0.48

All dimensions are in inches (millimeters)

35.44

0.35

(8.9)

(x16)

8.96

(227.6)

2.20

(55.9)

12.47

(316.6)

(900.2)

0.22

(5.6) (x16)

21.67

(550.3)

25.17

(639.3)

34.13

(866.9)

31.93

(811.0)

(106.7)

9.56

(242.7)

0.40

(10.2)

Fuel Out

1-1/4"-

11-1/2

NPTF

4.20

7.75

(196.8)

2.00

(50.8)

Fuel In

1-1/4"11-1/2

NPTF

1.50

(38.1)

7/8"-14

UNF-2B

Optional

Heater

O-Ring

Boss Port

2.77

(70.5)

page 18

Revisions

Revision Date Part Number

6 10/31/2017

7 12/01/2017 • SP1123 was SP1328

8 03/02/2018 • Reworded instructions on page 12.

9 06/04/2018

• Added 3945215 S as an individual Service Part

• Added Revision Block

• Fuel Flow Rate 18.9 L/min was 12.6 L/min; 75.7 L/min was 63.1 L/min; Bottom Bowl Water Holding Capacity 857 ml was

860 ml, 1715 ml was 1720 ml, 2573 ml was 2580

For more information, visit

cumminsfiltration.com

LT36333 Rev. 9

©2018 Cummins Filtration Inc.

Printed in the U.S.A.

Loading...

Loading...