Fleetguard FH23916, FH23905, FH23901, FH23906, FH23913 Installation Instructions Manual

...

Industrial Pro® FH239 Series

Filter/Separator/Warmer

Installation Instructions

M

K

L

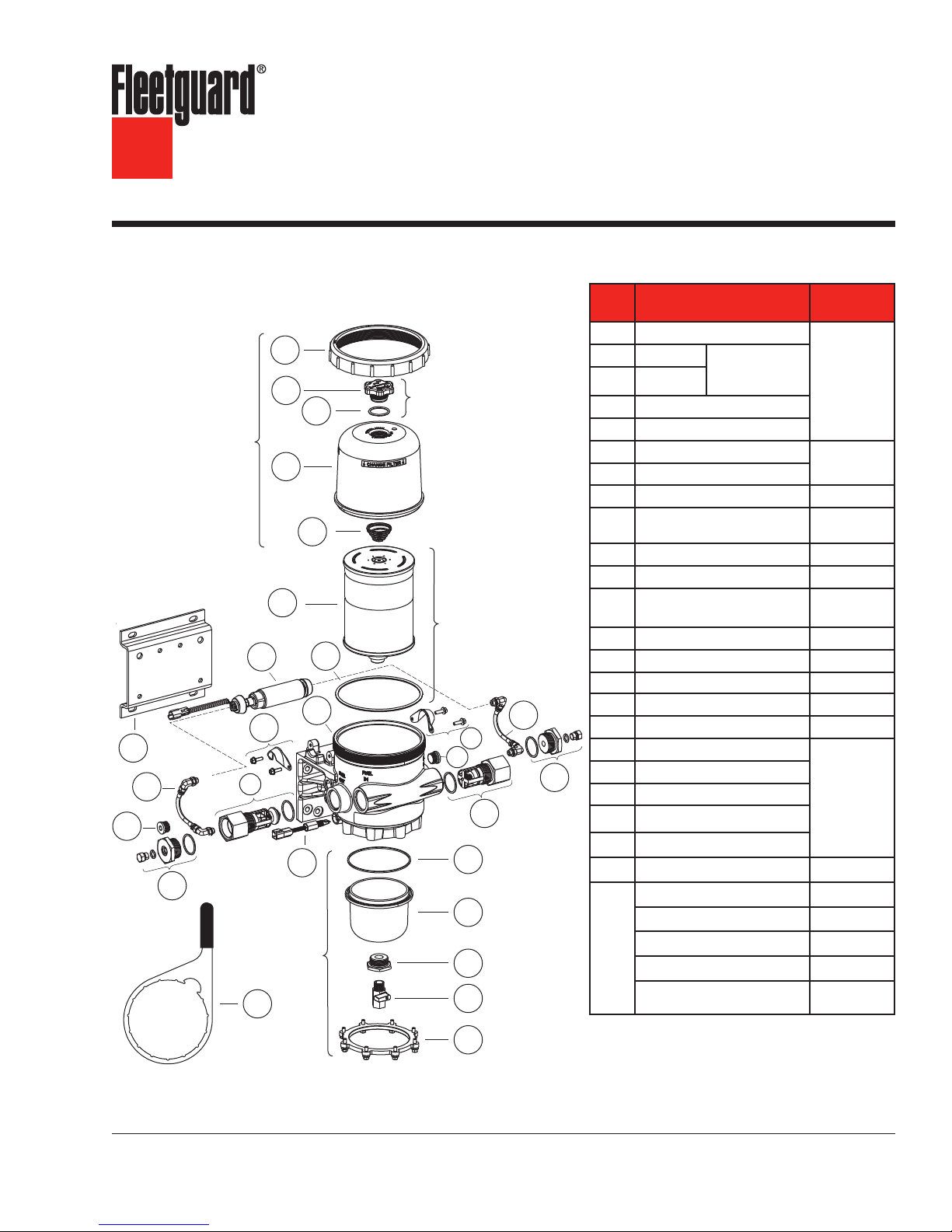

Industrial Pro® Single Short

Cover Assembly

O

H

N

W

A

B

D

F

I

Bottom

Assembly

P

Bowl

E

C

Part Description

A

Collar

B

Vent Cap

C

Vent Cap Assembly

Filter Element Assembly

(includes part C)

G

J

I

M

L

O

Q

R

S

T

U

O-Ring

D

Cover

E

Filter Spring

F

Filter Element (includes Part C)

G

O-Ring

H

Priming Pump (includes Isolators) SP1124

(2) Priming Pump Clamp and

I

(4) Screws

J

Industrial Pro

K

Bracket with Fasteners SP1131

(2) Priming Pump Hoses and

L

(4) Fittings

M

Plug 1/2" STOR SP1125

N

Bypass Check Valve SP1121

O Diagnostic Plug Fitting

P

Water-In-Fuel (WIF) Sensor SP1328

Q

Check Valve SP1120

R

O-Ring

S

Bottom Bowl

T

Drain Flange

U

Drain Valve

V

Bottom Bracket and Bolts (8)

W

Wrench SP1076

WIF Wiring Harness

WIF LED

Not

Electric Heater

Shown

Adapter Fitting, 3/4" to 1-1/4"

Adapter Fitting, 1-1/4" NPT

to M42 x 1.5

Vent Cap

Assembly

SP1053

®

Part

Number

Cover

Assembly

SP1127

FS53015

(includes Part C)

SP1133

See page 10

SP1128

SP1130

Bottom Bowl

Assembly

SP1134

3950729 S

3946670 S

See page 6

SP1135

3956561 S

E CAUTION: These instructions are intended for use by professional mechanics who are trained in the proper

use of power and hand tools, using appropriate safety precautions (including eye protection).

V

page 2

Cover Assembly

J

N

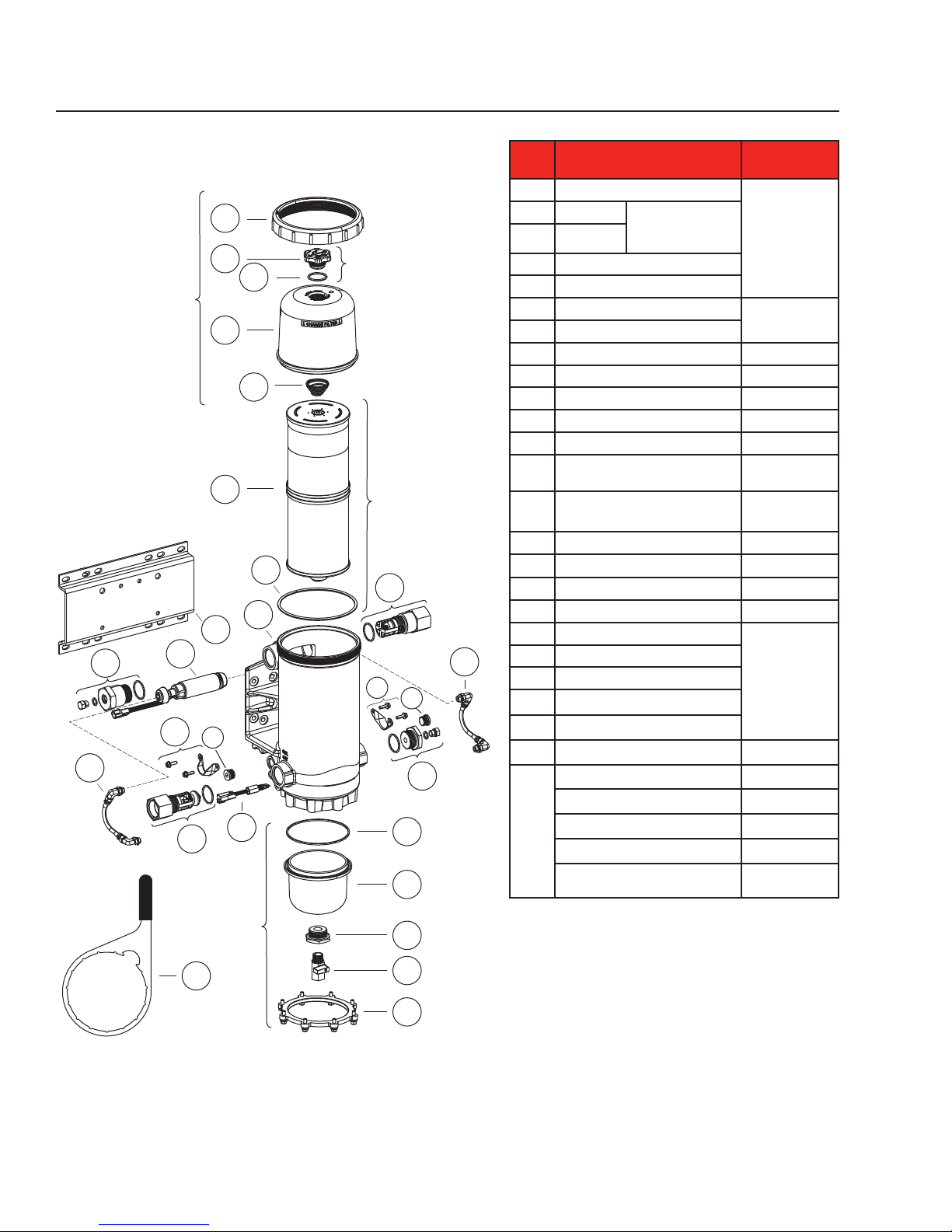

Industrial Pro® Single Tall

A

M

K

P

B

C

D

E

F

G

H

I

O

Q

Bottom

Bowl

Assembly

Vent Cap Assembly

Filter Element Assembly

(includes part C)

L

M

S

T

U

Part Description

A

Collar

B

Vent Cap

C

O-Ring

D

Cover

E

Filter Spring

F

Filter Element (includes Part C)

G

O-Ring

H

Industrial Pro

I

Bracket with Fasteners SP1132

J Diagnostic Plug Fitting - Extended

K

Priming Pump (includes Isolators) SP1124

L

Check Valve - Extended SP1206

(2) Priming Pump Clamps and

M

(4) Screws

(2) Priming Pump Hoses and

N

(4) Fittings

O

Plug 1/2" STOR SP1125

P Bypass Check Valve

Q

Water-In-Fuel (WIF) Sensor SP1328

R Diagnostic Plug Fitting

S

O-Ring

T

N

O

R

Bottom Bowl

U

Drain Flange

V

Drain Valve

W

Bottom Bracket and Bolts (8)

X

Wrench SP1076

WIF Wiring Harness

WIF LED

Not

Electric Heater

Shown

Adapter Fitting, 3/4" to 1-1/4"

Adapter Fitting, 1-1/4" NPT

to M42 x 1.5

Vent Cap Assembly

SP1053

®

Part

Number

Cover Assembly

SP1127

FS53014

(includes Part C)

See page 10

SP1205

SP1133

SP1128

SP1121

SP1130

Bottom Bowl

and Drain Valve

Assembly

SP1134

3950729 S

3946670 S

See page 6

SP1135

3956561 S

X

V

W

page 3

N

M

X

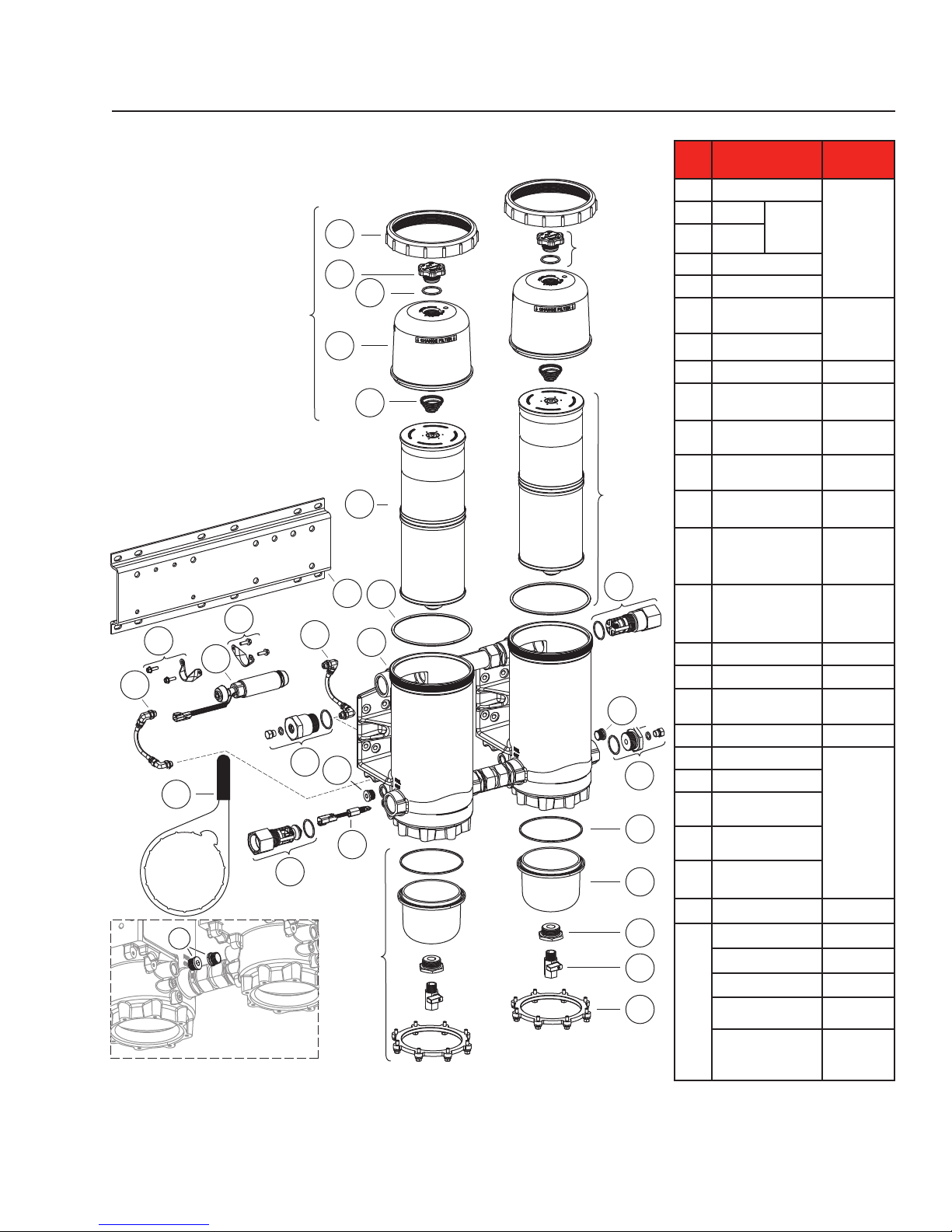

Industrial Pro® Dual Tall

A

B

C

Cover Assembly

D

E

F

I

G

M

N

H

K

J

O

Q

P

O

Bottom

Bowl

Assembly

Vent Cap

Assembly

Filter

Element

Assembly

(includes

part C)

L

O

R

S

T

U

V

W

Part Description

A

Collar

B

Vent Cap

C

O-Ring

D

Cover

E

Filter Spring

Filter Element

F

(includes Part C)

G

O-Ring

H

Industrial Pro

Bracket with

I

Fasteners

Diagnostic Plug Fitting

J

- Extended

Priming Pump

K

(includes Isolators)

Check Valve -

L

Extended

(2) Priming Pump

M

Clamps and

(4) Screws

(2) Priming Pump

N

Hoses and

(4) Fittings

O

Plug 1/2" STOR SP1125

P Bypass Check Valve

Water-In-Fuel (WIF)

Q

Sensor

R Diagnostic Plug Fitting

S

O-Ring

T

Bottom Bowl

U

Drain Flange

V

Drain Valve

Bottom Bracket and

W

Bolts (8)

X

Wrench SP1076

WIF Wiring Harness

WIF LED

Electric Heater

Not

Adapter Fitting, 3/4"

Shown

to 1-1/4"

Adapter Fitting, 1-1/4"

NPT

to M42 x 1.5

Vent Cap

Assembly

SP1053

®

Part

Number

Cover

Assembly

SP1127

FS53014

(includes

Part C)

See page 10

SP1329

SP1205

SP1124

SP1206

SP1133

SP1128

SP1121

SP1328

SP1130

Bottom Bowl

Assembly

SP1134

3950729 S

3946670 S

See page 6

SP1135

3956561 S

page 4

Fuel Processor Installation

This system must be installed between the fuel tank

and the transfer fuel pump on the suction side of the

fuel system.

E WARNING: When diesel fuel is circulated

through an operating engine, it

can become very hot. To prevent

personal injury:

E Scalding hazard! Do not allow heated

liquid fuel to come in contact with eyes or

unprotected skin. Always allow the engine

and fuel to cool to ambient temperature

before replacing the fuel filter or performing

service operations which could result in the

spillage of fuel from the fuel system. If this is

not possible, protective clothing (face shield,

insulated hat, gloves, apron) must be worn.

E Heated diesel fuel can form combustible

vapor mixtures in the area around the fuel

source. To eliminate the potential for fire,

keep open flames, sparks or other potential

ignition sources away from the work area,

and do not smoke during filter replacement

or service operations which could result in

the escape of diesel fuel or fuel vapors.

E Always perform engine or vessel fuel system

maintenance in a well ventilated area that is

kept free of bystanders.

E CAUTION: To ensure priming pump hoses

are not kinked by mishandling,

do not lift or handle the fuel

processor by the hoses. Do not

allow the weight of the processor

to rest on the hoses.

Installation Steps

1. With the engine shut down and at ambient

temperature, close the fuel shutoff valve (if

equipped) and place a suitable container under

the fuel filters.

2. Remove the primary fuel filter element assembly,

sedimenter, and/or water separator. Drain

the used element and dispose of it in an

environmentally responsible manner, according

to state and/or federal (EPA) recommendations.

The fuel can be returned to the tank.

Installation of the Industrial Pro should be on

the suction side of the fuel system. Do not

exceed 2.2 lb/in2 (15 kPa) inlet pressure to the

fuel processor.

3. Mount the Industrial Pro® in the desired location

keeping the following points in mind:

a. Mounting the Industrial Pro directly on the

engine is NOT RECOMMENDED.

b. Mount vertically with the cover and element

pointing up.

c. Make sure there is enough top and side

clearance for the cover to be conveniently

removed for filter replacement.

d. Filter service clearance:

Single Short: 3.5" (89 mm) minimum

Single Tall: 6.0" (152 mm) minimum

Dual Tall: 6.0" (152 mm) minimum

E CAUTION: The Industrial Pro functions BEST

when installed so that the Filter

Element is above the "FULL" level

of the fuel tank. The housing can

be installed up to 6' (1.8 m) below

the “FULL” level of the fuel tank.

Installing below the “FULL” level

causes the starting level to be

higher than normal. If mounted

below full tank level, a shut off

valve will be required at the inlet

to allow filter changes without

overflow of fuel. Mounting below

6' (1.8 m) eliminates the SEEING

IS BELIEVING® functionality.

4. Route the fuel supply line from the fuel tank to

the Industrial Pro inlet (see Figure 1). Route a

fuel line from the Industrial Pro outlet to the fuel

pump inlet.

E CAUTION: To avoid fuel line water traps

that can freeze in cold conditions

and restrict, or block, the flow

of fuel to the engine, be certain

that there are no low spots in the

hoses when routing them in the

engine compartment.

Loading...

Loading...