Fleetguard Diesel Pro FH236 Series, Diesel Pro FH235 Series, Diesel Pro FH241 Series Installation Instructions Manual

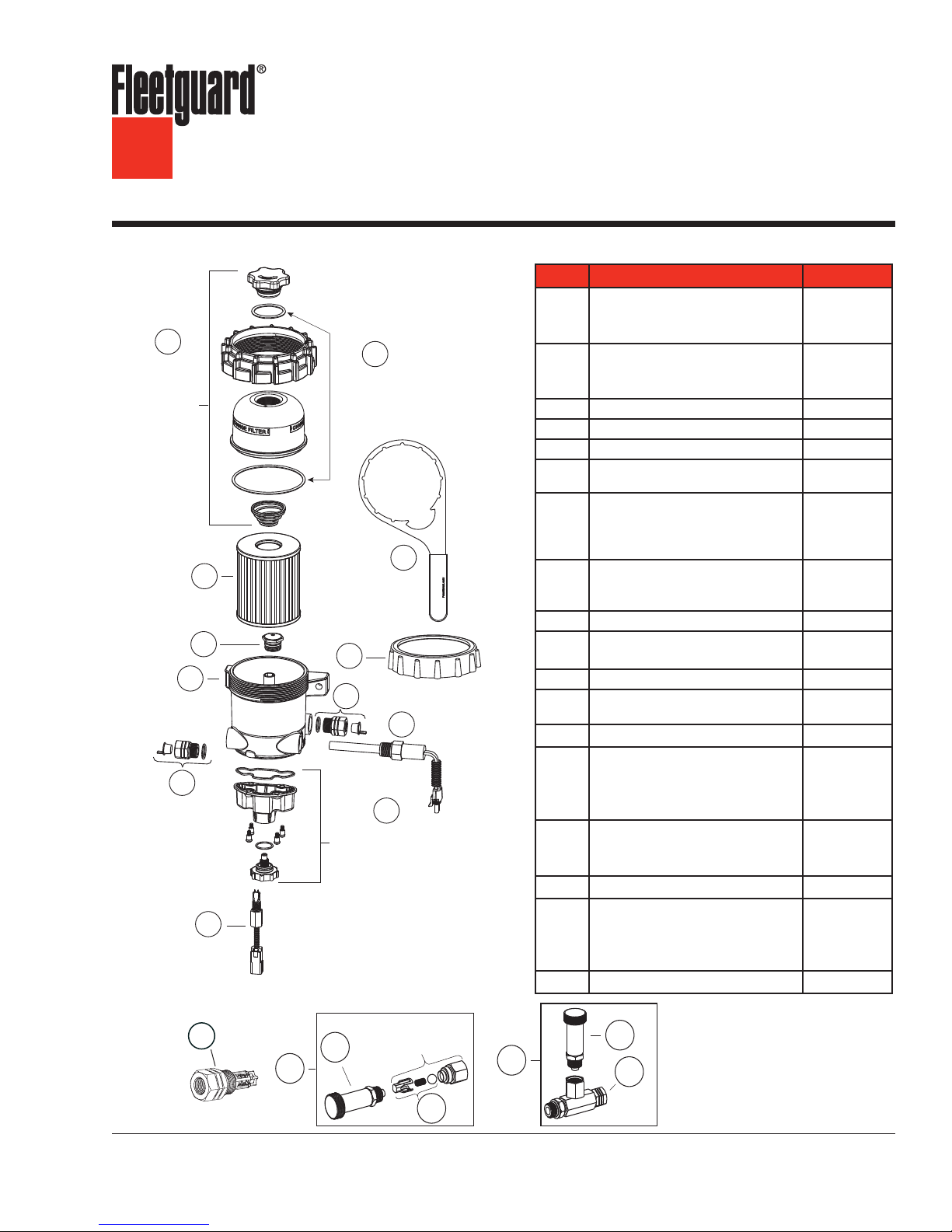

A

FH235 Cover

Assembly

Includes

Vent Cap,

Vent Cap O-Ring,

Collar, Cover,

Cover O-Ring,

and Spring

F

Diesel Pro® FH235, FH236 and FH241

Series Filter/Separator/Warmer

Installation Instructions

Parts ListDiesel Pro® 235

Part Description Part Number

FH235 Cover Assembly (includes Vent

Cap, Vent Cap O-Ring, Collar, Cover,

A

Cover O-Ring, and Spring)

B

Biodiesel O-Ring Pack

Includes Vent Cap O-Ring

and Cover O-Ring

K

C

D

J

E

F

G

Shown

H

Bottom Bowl Assembly

Includes Bottom

Bowl Seal,

Bottom Bowl, Screws,

Drain Valve O-Ring,

and Drain Valve

I

Manual Primer Pumps

Biodiesel O-Ring Pack – only

required for >B5 fuel (includes Vent

B

Cap O-Ring and Cover O-Ring)

Filter Element See page 9

C

Check Valve Assembly

D

Diesel Pro® FH235, Unheated See page 12

E

Adapter - 7/8"-14 to M16 x 1.5

F

Adapter - 7/8"-14 to 3/8" NPT

Pre-Heater, 12 V, 195 W, WP Connector

Pre-Heater, 24 V, 195 W, WP Connector

G

Pre-Heater, 24 V, 195 W, Tyco Connector

120 VAC, 75 W Heater

Bottom Bowl Assembly (includes

Bottom Bowl Seal, Bottom Bowl, Screws,

H

Drain Valve O-Ring, and Drain Valve)

Water-In-Fuel (WIF) Sensor

I

Collar for Reduced Clearance

J

Applications (optional)

Collar Wrench, Metal

K

WIF Wiring Harness

Not

WIF LED

Manual Primer Pump Plunger

L

Primer Pump Check Valve (M16)

Primer Pump Check Valve (M18)

M

Primer Pump Check Valve (3/8")

Primer Pump Check Valve (7/8")

Primer Pump Service Kit (M16)

Primer Pump Service Kit (M18)

N

Primer Pump Service Kit (3/8")

Primer Pump Service Kit

O

Check Valve Assembly (M18)

Check Valve Assembly (M16)

P

Check Valve Assembly (7/8")

Check Valve Assembly (3/8")

Check Valve Assembly Kit

Q

3973506 S

3950444 S

SP1413

3973689 S

3980209 S

SP1312

SP1313

SP1314

3980208 S

3972255 S

3957158 S

3945059 S

3944458 S

3950729 S

3946670 S

3975110 S

3981659 S

3981660 S

SP1642

3975109 S

3979203 S

3979202 S

SP1632

3975111 S

SP72127

SP72128

SP72129

SP72130

SP1644

M

O

CAUTION: These instructions are intended for use by professional mechanics who are trained in the proper

use of power and hand tools, using appropriate safety precautions (including eye protection).

L

N

L

P

Q

page 2

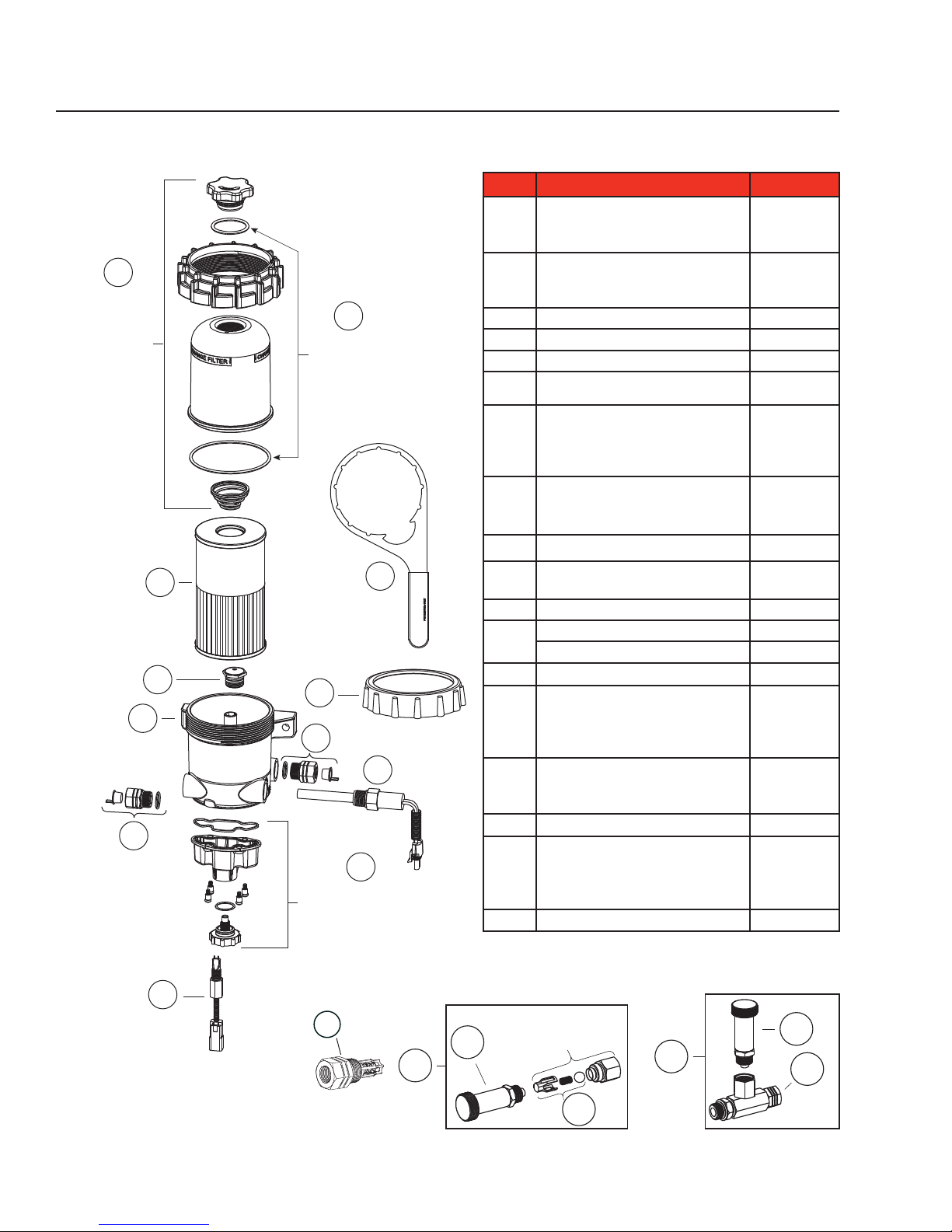

A

FH236 Cover

Assembly

Includes

Vent Cap,

Vent Cap O-Ring,

Collar, Cover,

Cover O-Ring,

and Spring

Parts ListDiesel Pro® 236

Part Description Part Number

FH236 Cover Assembly includes Vent

Cap, Vent Cap O-Ring, Collar, Cover,

A

Cover O-Ring, and Spring)

Biodiesel O-Ring Pack – only

required for >B5 fuel (includes Vent

B

Cap O-Ring and Cover O-Ring)

B

Biodiesel O-Ring Pack

Includes Vent Cap O-Ring

and Cover O-Ring

C

K

Shown

D

J

E

F

G

F

H

Bottom Bowl Assembly

Includes Bottom

Bowl Seal,

Bottom Bowl, Screws,

Drain Valve O-Ring,

and Drain Valve

Filter Element See page 9

C

Check Valve Assembly

D

Diesel Pro® FH236, Unheated See page 12

E

Adapter - 7/8"-14 to M16 x 1.5

F

Adapter - 7/8"-14 to 3/8" NPT

Pre-Heater, 12 V, 195 W, WP Connector

Pre-Heater, 24 V, 195 W, WP Connector

G

Pre-Heater, 24 V, 195 W, Tyco Connector

120 VAC, 75 W Heater

Bottom Bowl Assembly (includes

Bottom Bowl Seal, Bottom Bowl, Screws,

H

Drain Valve O-Ring, and Drain Valve)

Water-In-Fuel (WIF) Sensor

I

Collar for Reduced Clearance

J

Applications (optional)

Collar Wrench, Metal

K

WIF Wiring Harness

Not

WIF LED

Manual Primer Pump Plunger

L

Primer Pump Check Valve (M16)

Primer Pump Check Valve (M18)

M

Primer Pump Check Valve (3/8")

Primer Pump Check Valve (7/8")

Manual Primer Pump (M16)

Manual Primer Pump (M18)

N

Manual Primer Pump (3/8")

Primer Pump Service Kit

O

Check Valve Assembly (M18)

Check Valve Assembly (M16)

P

Check Valve Assembly (7/8")

Check Valve Assembly (3/8")

Check Valve Service Kit

Q

3974145 S

3950444 S

SP1413

3973689 S

3980209 S

SP1312

SP1313

SP1314

3980208 S

3972255 S

3957158 S

3945059 S

3944458 S

3950729 S

3946670 S

3975110 S

3981659 S

3981660 S

SP1642

3975109 S

3979203 S

3979202 S

SP1632

3975111 S

SP72127

SP72128

SP72129

SP72130

SP1644

Manual Primer Pumps

I

M

O

L

L

N

P

Q

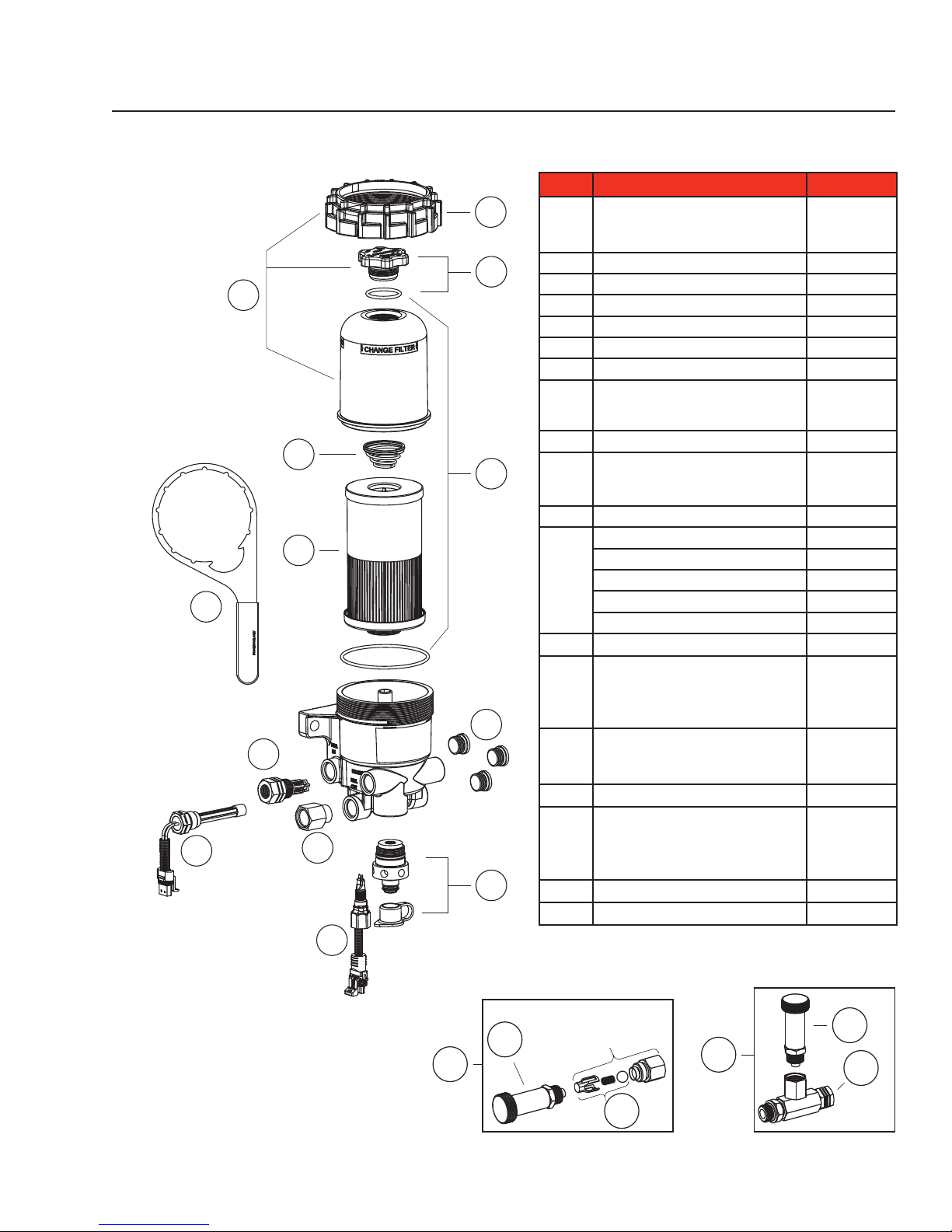

FH241 Cover

Assembly

Includes

Vent Cap,

Vent Cap O-Ring,

Collar, Cover,

Cover O-Ring,

and Spring

R

J

page 3

Parts ListDiesel Pro® 241

Part Description Part Number

F

D

A

E

B

C

Shown

G

M

H

I

FH241Cover Assembly includes Vent

Cap, O-Ring, Collar, Cover, Cover O-Ring,

A

and Spring)

O-Ring Pack – (Vent Cap and Collar)

B

Filter Element See page 9

C

Vent Cap Service Kit

D

Filter Spring

E

Reduced Clearance Collar

F

Diesel Pro® FH241, Unheated See page 13

G

Adapter - 7/8" to M16

Adapter - 7/8" to M18

H

Adapter - 7/8" to 3/8"

Drain & Cap

I

Pre-Heater, 24V, 195 W, Tyco Connector

Pre-Heater, 24V, 195 W, WP Connector

J

Over Night Heater, 120 V

Water-In-Fuel (WIF) Sensor

K

WIF Wiring Harness

WIF LED

Not

ESOC/Drain Valve

Drain Valve Service Kit

WIF Port Plug

Manual Primer Pump Pump

L

Primer Pump Check Valve (M16)

Primer Pump Check Valve (M18)

M

Primer Pump Check Valve (3/8")

Primer Pump Check Valve (7/8")

Primer Pump Service Kit (M16)

Primer Pump Service Kit (M18)

N

Primer Pump Service Kit (3/8")

Primer Pump Service Kit

O

Check Valve Assembly (M18)

Check Valve Assembly (M16)

P

Check Valve Assembly (7/8")

Check Valve Assembly (3/8")

Check Valve Service Kit

Q

Collar Wrench, Metal

R

3974145 S

3945061 S

SP1053

3944441 S

3945059 S

3973689 S

SP1643

3980209 S

SP1647

SP1314

SP1313

3945121 S

3957158 S

3950729 S

3946670 S

SP1645

SP1646

SP1125

3975110 S

3981659 S

3981660 S

SP1642

3975109 S

3979203 S

3979202 S

SP1632

3975111 S

SP72127

SP72128

SP72129

SP72130

SP1644

3944458 S

K

Manual Primer Pumps

L

L

O

N

P

Q

page 4

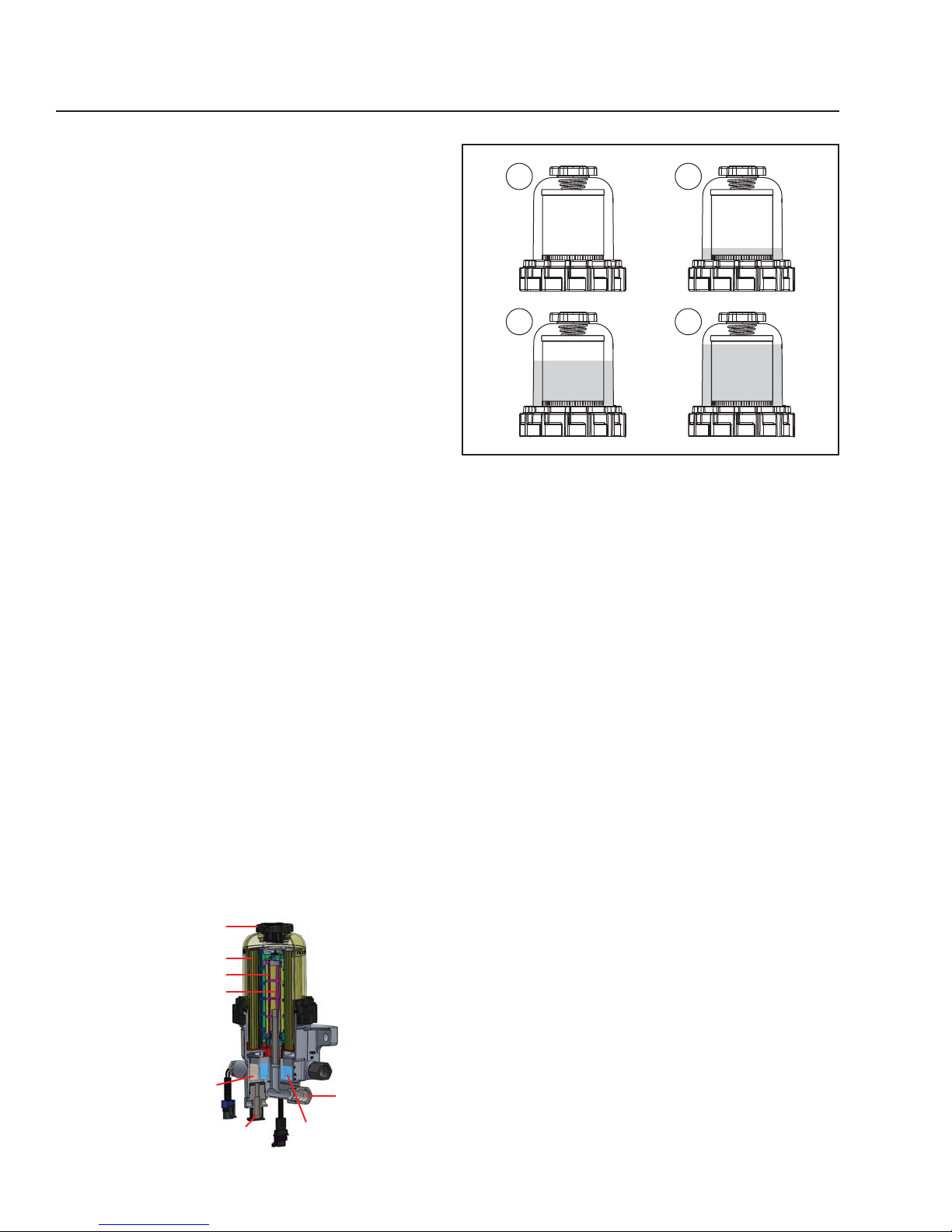

Introduction

How It Works

• Fuel from the tank enters the Diesel Pro® body

(suction side of the fuel system).

• Large contaminants and “free” water are

separated from the fuel and remain in the

body.

• Fuel rises into the clear cover.

• Contaminants and emulsified water are

captured by the filter media.

• Fuel level rises to maintain a fuel path

through the clean filter media and with lowest

restriction.

• Clean, water-free fuel exits the Diesel Pro and

flows to the lift pump.

“Seeing Is Believing”

• See when NOT to change the fuel filter.

• See the condition of the fuel. Seeing

what collects on the filter media or what’s

happening inside the clear cover can

help diagnose many fuel and mechanical

conditions.

• “Filter on Top” configuration. Water and

debris removed from the fuel falls to the lower

chamber and stays away from the filter media

resulting in longer filter life.

• Built-in protection when priming the fuel filter.

Unfiltered fuel is kept on the “dirty” side of the

filter media during priming ensuring only clean

fuel reaches the engine.

• Patented media. The “Best in Class”

StrataPore™ media removes 95% of free

and emulsified water. This performance far

exceeds that of cellulose media.

1 2

3 4

Figure 1 - “Seeing Is Believing”

1. When new, the fuel level in the filter will be

very low with minimal restriction. As the filter

is used, contaminants collect on the filter from

the bottom up. Fuel rises on the filter indicating

remaining filter life.

2. Fuel level increases in clear cover. As

contaminants collect on the filter, the fuel rises

to a non-contaminated section of the filter,

providing optimal filtration while maintaining

lowest restriction.

3. Fuel level at filter wrap level. Even though

the fuel level is now more than half of the filter

element, the fuel is still flowing through clean

media at minimal restriction levels. The filter still

has significant life remaining.

4. The filter element is now completely covered

by fuel. At this point, all of the media’s surface

area is utilized. Restriction is increasing and the

filter element should be changed at the next

scheduled maintenance interval.

Vent Cap

Media

Coalescent Layer

Hydrophobic Layer

Water Sump

Dirty Side

Drain Valve

(ESOC Compatible)

Water Sump

Clean Side

Fuel OUT

FH241 Series Advanced Water Separation

Architecture

The FH241 Series has a new water separation

architecture providing higher water separation

performance than the FH235 or FH236 series. The

FS20081 cartridge has additional coalescing and

hydrophobic layers that provide the performance

required for T4F and EPA2017 midrange engines.

The new water separation concept introduces two

additional steps (coalescing on an additional layer,

repelling on a hydrophobic layer), improving overall

water separation performance.

page 5

Service Kit Installation

This system must be installed between the fuel

tank and the transfer fuel pump. If approved by the

manufacturer, this system can be used as the only

fuel filter in the fuel system by removing the existing

filter and heads, or by removing the filters only and

replacing them with special Diverter Caps (sold

separately - see Table 1).

®

Note: If the Diesel Pro

is used as the primary filter

and a secondary filter is required, secondary

filter life may be extended.

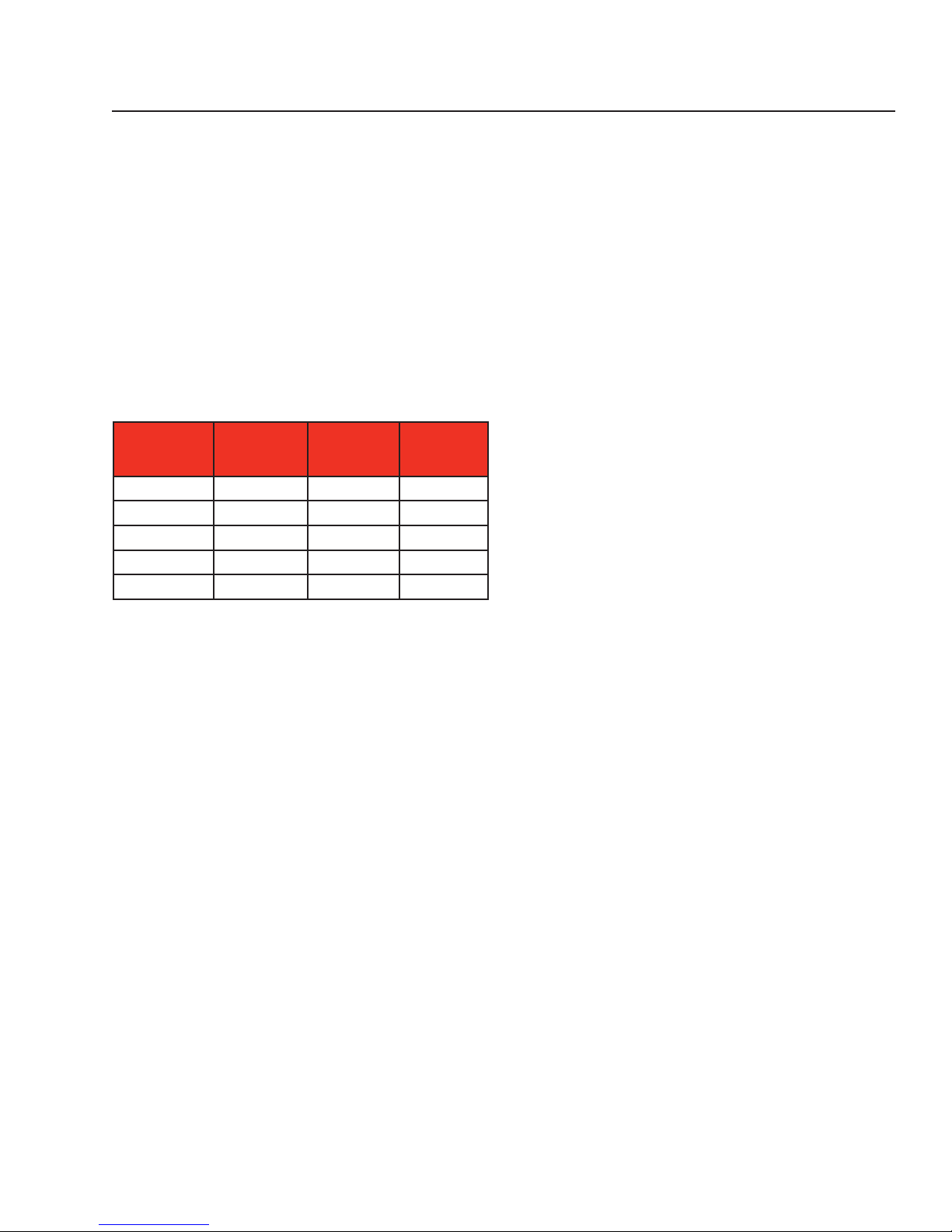

Table 1 - Diverter Caps

Diverter Cap

Part Number

3945182 S

3945183 S

3945184 S

3945185 S

3945186 S

Required Filter

Head Stud Size

1"-14 2.475 (62.865) 2.895 (73.533)

1"-14 3.225 (81.915) 3.435 (87.249)

M16 x 1.5 2.475 (62.865) 2.895 (73.533)

3/4" x 16 2.475 (62.865) 2.895 (73.533)

7/8" x 14 2.475 (62.865) 2.895 (73.533)

Required Filter

Head Seal ID

in (mm)

Required Filter

Head Seal OD

in (mm)

WARNING: When diesel fuel is circulated

through an operating engine, it

can become very hot. To prevent

personal injury:

Scalding hazard! Do not allow heated

liquid fuel to come in contact with eyes or

unprotected skin. Always allow the engine

and fuel to cool to ambient temperature

before replacing the fuel filter or performing

service operations which could result in the

spillage of fuel from the fuel system. If this is

not possible, protective clothing (face shield,

insulated hat, gloves, apron) must be worn.

Fire hazard! Heated diesel fuel can form

combustible vapor mixtures in the area

around the fuel source. To eliminate the

potential for fire, keep open flames, sparks

or other potential ignition sources away from

the work area, and do not smoke during filter

replacement or service operations which

could result in the escape of diesel fuel or

fuel vapors.

Inhalation hazard! Always perform engine

or vessel fuel system maintenance in a

well ventilated area that is kept free of

bystanders.

The ignition key must be in the OFF position.

Installing the Diesel Pro Service Kit

1. With the engine shut down and at ambient

temperature, close the fuel shutoff valve (if

equipped) and place a suitable container under

the fuel filters.

2. Remove the primary fuel filter element assembly,

sedimenter, and/or water separator. Drain

the used element and dispose of it in an

environmentally responsible manner, according

to state and/or federal (EPA) or national

recommendations. The fuel can be returned to

the tank.

3. For a one-filter system, select the required

secondary filter head diverter cap from those

listed in Table 1. The required part number is

determined by the size of the spin-on filter stud

and the filter sealing surface diameter.

Install the diverter cap on the secondary filter

head as follows:

a. Remove the secondary fuel filter element,

drain and dispose of it in an environmentally

responsible manner according to government

regulations (i.e., state/province, federal, etc.).

The fuel can be returned to the tank.

b. Lightly lubricate the seal on the top of the

diverter cap with clean engine oil.

c. Thread the adapter onto the secondary filter

stud and tighten by hand only.

d. Install the "Do Not Remove" sticker on the

diverter cap.

4. Mount the Diesel Pro in the desired location

using 3/8" (9.5 mm) Grade 8 hardware. Keep the

following points in mind:

a. Mounting the Diesel Pro directly on the

engine is NOT RECOMMENDED.

b. Mount vertically with the cover and element

pointing up.

c. Make sure there is enough top and side

clearance for the cover to be conveniently

removed for filter replacement

(1.5" (38.1 mm) minimum).

d. Bolt spacing is 5.25" (133.35 mm).

CAUTION: The Diesel Pro

so that the Filter Element is above

the "FULL" level of the fuel tank.

If mounted below full tank level,

a shut off valve will be required

at the inlet to allow filter changes

without overflow of fuel.

®

MUST be installed

Loading...

Loading...