Fleetguard CV50108, CV50109, CV50110, CV50111, CV50112 Installation Instructions Manual

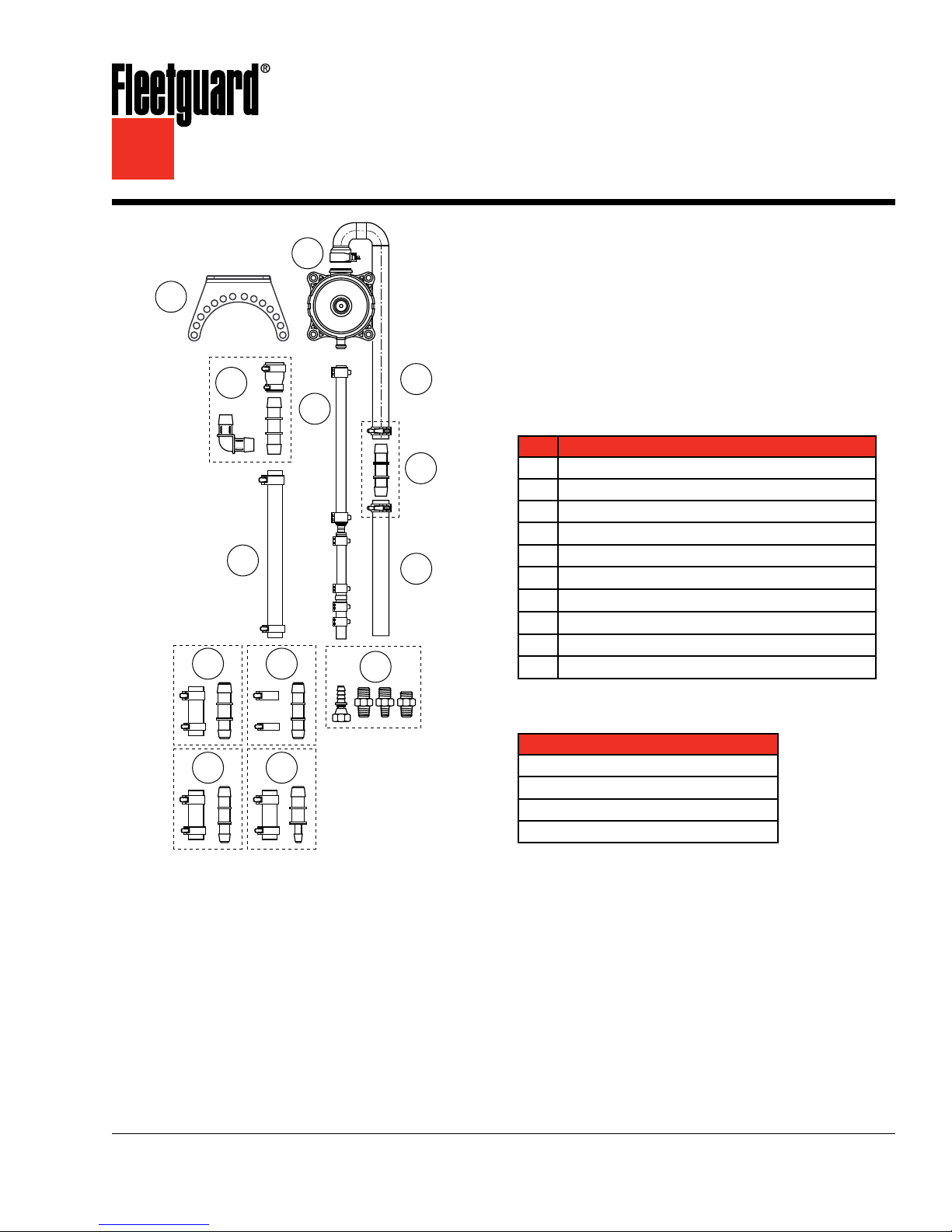

A

J1 J2

H

Fleetguard® Open

Crankcase Ventilation (OCV) Kit

Installation Instructions

Installation Instructions for:

B

C

G

D

I

E

F

CV50108 60-90 HP Applications

CV50109 91-120 HP Applications

CV50110 121-160 HP Applications

CV50111 161-220 HP Applications

CV50112 221-300 HP Applications

Parts List

Part Description

A

Mounting Bracket (not included in the kit)

B

Breather Assembly (CV Unit) and Mounting Hardware

C

Vent Hose

D

Vent Hose Connector and Clamps

E

Vent Hose Extender

F

Cylinder Block Insert Fittings and Coupler

G

Drain Hose Assembly

H

Breather (CV Unit) Hose Connections and Clamps

I

Inlet Hose Assembly

J

Inlet Hose Connections and Clamps

Tools Required

Description

J3 J4

Hose Clamp Pliers

Hose Cutter

3/8" to 1" Ratchet and Socket Set

3/8" to 1" Wrench Set

E CAUTION: Use of this application will

cause an increase in the engine

crankcase pressure. The installer

is responsible for the verification

that this application is appropriate

and that related crankcase

pressure issues do not arise.

E CAUTION: These instructions are intended for use by professional mechanics who are trained in the proper

use of power and hand tools, using appropriate safety precautions (including eye protection).

page 2

Crankcase Ventilation Kit Installation

Preinstallation

The Fleetguard® OCV Kit can be installed on many

different engine platforms. Since engine design

varies broadly, connection and fitting sizes will also

vary by engine. To accommodate a broad range of

applications, the kit includes extra fittings, connectors,

clamps, and hoses. These parts have been packaged

in different packs to assist you in choosing the right

parts for your specific application. Since many of

these parts appear to be very similar, we strongly

suggest not opening the individual packs until you

have determined what specific parts you will need

for your engine application. Each pack is identified

with a label (e.g. J1, J2) to reference its use in the

appropriate installation step.

In some engine applications, the crankcase drain

fitting for connecting and routing the drain line to

the crankcase may need to be purchased from the

engine manufacturer. We strongly suggest not drilling

into the engine block or oil pan to use one of the

fittings included in this kit. Check to determine if one

of the fittings included in pack “F” can properly be

installed in the engine block before proceeding.

14"

Figure 1 – Mounting Location

3. Install the mounting bracket (if used) to the

mounting location selected. The mounting bracket

can be attached to the breather assembly at four

different positions by simply rotating the bracket.

Attach the breather assembly to the bracket using

the hardware provided. Ensure that the breather

assembly is mounted vertically with the oil drain

outlet directed downward.

A

Locating and Mounting the Breather Assembly

1. Check both sides of the cylinder block to

determine the most suitable oil return option.

Select a threaded boss or another entry option

that will allow the drain hose, when installed, to

run directly from the breather assembly to the

crankcase. The drain hose must be free of any

loops, kinks or abrupt bends to ensure proper oil

drainage.

2. Find a mounting location for the breather

assembly and bracket at least 14" (350 mm)

above the oil level in the crankcase and a

minimum of 4" (102 mm) from both the exhaust

manifold and exhaust piping. The “cold side” of

the engine is preferred. The breather assembly

must be mounted vertically (as shown) for proper

operation.

B

Figure 2 – Installing the Mounting Bracket Installing

the Insert Fitting

4. Locate the selected threaded boss at the bottom

of the cylinder block (above the pan rail) for

installation of the cylinder block insert fitting.

Check the boss opening ID to determine if any of

the fittings included in the "F" pack can be used.

If none of the fittings can be used, check with the

engine manufacturer on the proper insert fitting

to gain access to the crankcase. Once the proper

crankcase fitting has been selected, proceed with

Step 5.

Loading...

Loading...