Flatfire Solas, SL-26N, SL-26P Installation & Operation Manual

Installation & Operation Manual

This appliance may be installed in an aftermarket, permanently located manufactured

home (USA only) or in a mobile home, where

not prohibited by local codes.

This appliance is for use only with the type of

gas indicated on the rating plate. This appliance is not convertible for use with other gases,

unless a certified conversion kit is used.

Ce manual est disponsible en Français sur demande.

Report # 361-F-01-5

INSTALLER: Leave this manual with the appliance

CONSUMER: Retain this manual for future reference

This manual specifies the installation and

operation requirements for the Flatfire Model

Nos. SL-26N, SL-26P.

WARNING: If the information in these

instructions is not followed exactly, a fire

or explosion may result causing property

damage, personal injury or loss of life.

- Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas

supplier, call the fire department.

- Installation and service must be

performed by a qualified installer, service

agency or the gas supplier.

AVERTISSEMENT: Assurez-vous de bien suivre

les instructions données dans cette notice pour

réduire au minimum le risque d’incindie ou

d’explosion ou pour éviter tout dommage

matériel, toute blessure ou la mort.

- Ne pas entreposer ni utilizer d’essence ni

d’autres vapeurs ou liquides inflammables dans

le voisinage de cet appareil ou de tout autre

appareil.

- QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE

GAZ:

Ne pas tenter d’allumer d’appareil.

Ne touchez à aucan interrupteur. Ne pas

vous servir des téléphones se trouvant

dans le bâtiment où vous trouvez.

Appelez immédiatement votre

fournisseur de gaz depuis un voisin.

Suivezles instructions du fournisseur.

Si vous ne pouvez rejoindre le fournisseur

de gaz, appelez le service des incindie.

- L’installation et l’entretien doivent être assurés

par un installateur ou un service d’entretien

qualifié ou par le fournisseur de gaz.

Cet appareil peut être installé dans une maison

préfabriquée (mobile) déjà installée à demeure

si kes règlements locaux le permettent.

Cet appareil doit être uniquement avec las type

de gaz indiqué sur la plaque signalétique. Cet

appareil ne peut être converti à d’autres gaz,

sauf si une trousse de conversion est utilisée.

Ne pas utiliser cet appareils’il a été plongé,

meme partiellement, dans l’eau. Appeler un

technician qualifié pour inspecter l’appareail et

remplacer toute partie du système de commande

et toute commande qui a été plongée dans /’eau.

Attention. Au moment de l’entretien des commandes, étiquetez tous les fils avant de les débrancher. Des erreurs de la câblage peuvent entraîner un fonctionnement inadequate et dangereux.

S’assurer que l’appareil fonctionne adéquatement une fois l’entretien terminé.

AVERTISSEMENT. Ne pas utiliser l’appareil

si le panneau frontal en verre n’est pas en place,

est craqué ou brisé. Confiez le remplacement du

panneau à un technician agree.

INSTALLATEUR: Laissez cette notice avec l’appareil.

COMSOMMATEUR: Conservez cette notice pour consultation ultérieur.

2

TABLE OF CONTENTS

IMPORTANT SAFETY INFORMATION 4

SPECIFICATIONS 5

INSTALLATION 6

MASSACHUSETTS REQUIREMENTS 7

VENTING 8

ASSEMBLY & INSTALLATION 16

GAS CONNECTION 21 & 26

LIGHTING AND OPERATION 31

MAINTENANCE 33

REPLACEMENT PARTS LIST 34

MAINTENANCE LOG FORMS 35

CONTROL SCHEMATIC 36

INSTALLATION RECORD FORM 37

WE STRONGLY SUGGEST THAT YOU READ THIS MANUAL THOROUGHLY BEFORE BEGININNG THE INSTALLATION OF THE SOLAS DIRECT VENT GAS FIREPLACE. ALTHOUGH THE BASIC REQUIREMENTS FOR THE INSTALLATION OF ALL DIRECT VENT

GAS FIREPLACES ARE SIMILAR, EACH SPECIFIC PRODUCT HAS ITS OWN UNIQUE SETUP AND INSTALLATION REQUIREMENTS THAT MUST BE FOLLOWED EXACTLY. PLAN

YOUR INSTALLATION IN ADVANCE BY CAREFULLY REVIEWING ALL THE INFORMATION CONTAINED IN THIS MANUAL.

3

IMPORTANT SAFETY INFORMATION

The installation must conform with local codes or, in the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1 or the Canadian Installation Code, CAN/CGA B149.

A manufactured home (USA only) or mobile home OEM installation must conform with the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280 or when such a standard is not applica-

ble, the Standard for Manufactured Home Installations, ANSI/BCSBCS A225.1, or Standard for Gas

Equipped Recreational Vehicles and Mobile Housing, CSA Z240.4.

The appliance and its appliance main gas valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the gas supply piping system by closing its equipment shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5

kPa).

The installation must provide for adequate ventilation air to the appliance.

This gas appliance must not be connected to a chimney flue serving a separate solid-fuel burning appliance.

The appliance, when installed, must be electrically grounded in accordance with local codes, or, in the

absence of local codes, with the National Electrical Code ANSI/NFPA 70, or the Canadian Electrical Code,

CSA C22. 1.

The appliance area must be kept clear and free from combustible materials, gasoline and other flammable

vapors and liquids.

The flow of combustion and ventilation air must not be obstructed.

Do not use this appliance if any part has been under water. Immediately call a qualifed service technician

to inspect the appliance and to replace any part of the control system and any gas control which has been

under water.

Due to high temperatures, the appliance should be located out of traffic and away from furniture and

draperies.

Children and adults should be alerted to the hazards of high surface temperatures and should stay away to

avoid burns or clothing ignition.

Young children should be carefully supervised when they are in the same room as the appliance.

Clothing or other flammable material should not be placed on or near the appliance.

Any screen or guard removed for servicing an appliance must be replaced prior to operating the appliance.

Installation and repair should be done by a qualified service person. The appliance should be inspected

before use and at least annually by a professional service person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding material, etc. It is imperative that the control compartments,

burners and circulating air passageways of the appliance be kept clean.

WARNING: Do not operate the appliance with the glass door assembly removed, or if the glass is

cracked or broken. Replacement of the glass should be done by a qualified service

person.

WARNING: Use only glass assembly, P/N 26-510 which includes the glass panel, frame and gasket.

Do not use substitute materials. Do not strike or slam the glass front. Do not use

abrasive cleaners. Do not clean when hot.

4

INPUT Natural Gas Propane (LP)

Input Rating-Btu/hr 19,000 19,000

Min. Input-Btu/hr 11,000 11,000

Orifice-DMS 5/64” #55

GAS SUPPLY

Manifold Pressure 4.8”w.c. / 1.2kPa 10.0”w.c. / 2.5kPa

Min. Supply Pressure 5.5”w.c. / 1.4kPa 11.0”w.c. / 2.8kPa

Max. Supply Pressure 10.0”w.c. / 2.5kPa 13.0”w.c. / 3.3kPa

EFFICIENCY

Steady State Efficiency - % 65.0 61.4

Annual Fuel Utilization Efficiency (AFUE) - % 64.2 60.5

Canadian p.4 Efficiency - % 55.1 50.0

SPECIFICATIONS

It is recommended that the pilot flame be turned off if the appliance will not be in use for an extended

period of time.

This appliance is equipped for use with the fuel type indicated on the rating plate.

This appliance has been certified by OMNI-Test Laboratories, Inc. to ANSI Z21.88-2005 • CSA 2.33-2005

Vented Gas Fireplace Heaters and CAN/CGA-2.17-M91, Gas-Fired Appliances for Use At High Altitudes.

The is approved for installation at elevations up to 2000 feet in the U.S. and 1370 meters (4500 feet)

in Canada without change. If your installation is at an elevation greater than these, consult with the local

authority having jurisdiction for gas product installations to determine their specific requirements for high

altitude installations.

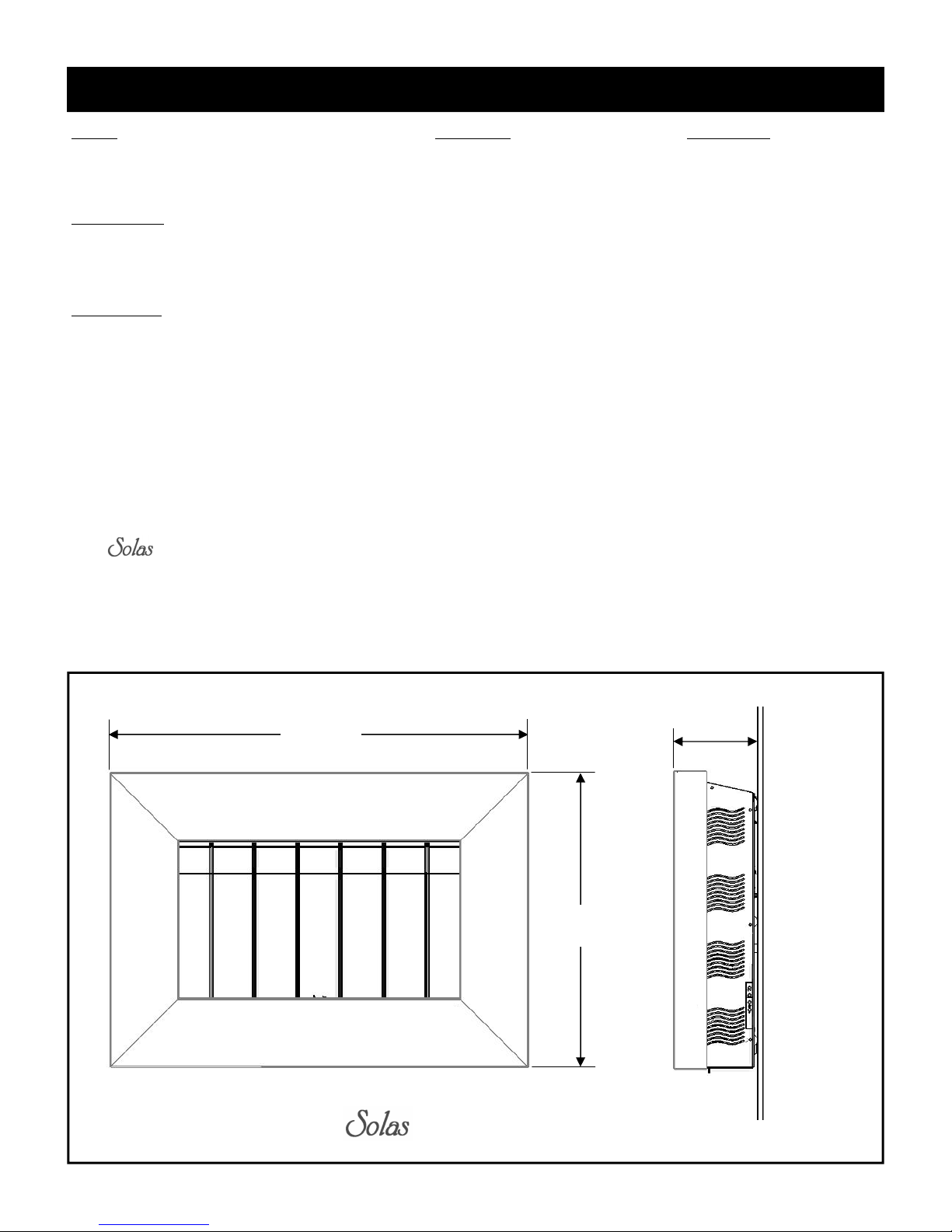

38 3/4””

(984mm)

27 1/4”

(692mm)

7 5/8””

(193mm)

OVERALL DIMENSIONS

5

INSTALLATION

Several issues must be addressed when selecting a suitable location for your fireplace. The minimum

clearances to combustible construction are listed below. In addition, access to the gas supply must be considered. The location of the fireplace will also affect the venting requirements and you must be certain the

location will allow compliance with the venting requirements shown on page 8. You must also insure that

your installation provides adequate accessibility clearance for servicing and proper operation.

Installation and repair should be done by a qualified service person. The appliance should be inspected

before use and at least annually by a professional service person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding material, etc. It is imperative that the control compartment,

burners and circulating air passageways of the appliance be kept clean.

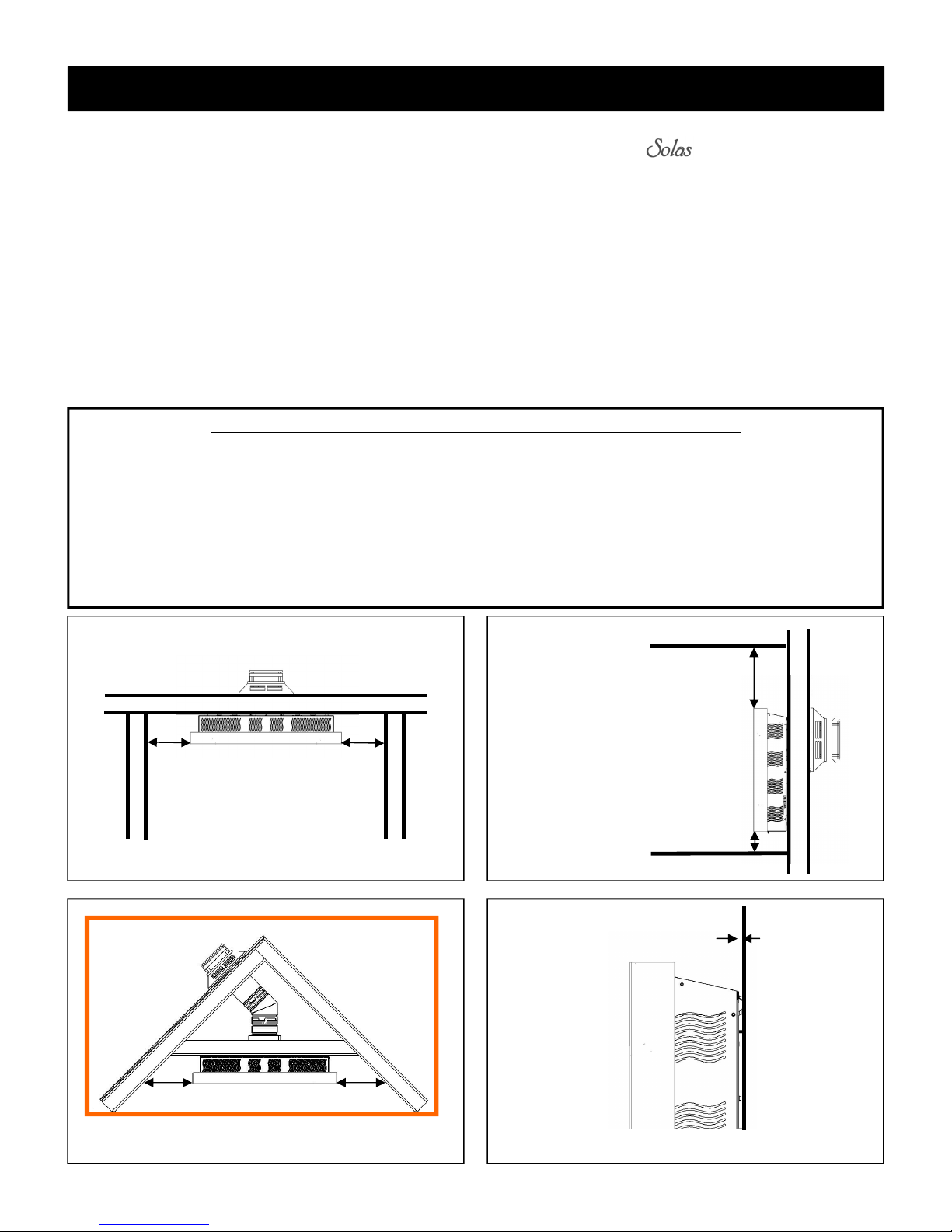

MINIMUM CLEARANCES TO COMBUSTIBLE CONSTRUCTION

Fireplace to L. Side Wall 6” (152mm) Fireplace to Ceiling 8” (203mm)

Fireplace to R. Side Wall 6” (152mm) Fireplace to Rear Wall 0” (0mm)*

Fireplace to Corner Wall 6” (152mm) Fireplace to Floor 3” (76mm)**

Vent Pipe to Adjacent Materials 1.5” (38mm)

*Mounting plate bosses contact the wall

**The minimum required clearance to be maintained from the fireplace to combustible flooring is measured from the top surface of carpeting, tile, etc.

A = 6” (152mm)

A

WALLS

B = 6” (152mm)

A

CEILING

C = 8” (203mm)

D = 3” (76mm)

FLOOR

E = 5/16” (8mm)

C

D

WALL

E

B B

CORNER

AIR SPACE BEHIND MOUNTING PLATE

6

INSTALLATION

The gas fireplace is shipped with a plugged 3/8” NPT connection. The gas supply piping should have a

separate gas shutoff valve and a 1/8” NPT plugged tapping upstream of the valve. The stove and its main

control valve must be disconnected from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2 psi (3.5 kPa). The stove must be isolated from the gas supply piping system by closing the main control valve during any pressure testing of the gas supply system at test

pressures equal to or less than 1/2 psi (3.5 kPa). After the gas supply has been connected, use a commercial

gas leak detector or apply a soapy water solution to all the fittings to check for gas leaks. Never use a

flame to test for leaks.

REQUIREMENTS FOR THE COMMONWEALTH OF MASSACHUSETTS

This product must be installed by a licensed plumber or gas fitter when installed within the Commonwealth of Massachusetts. If this appliance is installed in a dwelling, building or structure used in

whole or in part for residential purposes and the installation includes a horizontal vent termination

that is less than seven (7) feet above the finished grade in the area of the venting, including but not

limited to decks and porches, a hard-wired carbon monoxide detector with an alarm and battery

back-up must be installed on the floor level of the dwelling, building or structure where the appliance is to be installed.

Additionally, a hard-wired or battery operated carbon monoxide detector with an alarm must be installed on each additional level of the dwelling, building or structure served by the appliance. It shall

be the responsibility of the property owner to secure the services of qualified licensed professionals

for the installation of hard-wired carbon monoxide detectors.

In the event that the horizontally vented appliance is installed in a crawl space or attic, the hardwired carbon monoxide detector with alarm and battery back-up may be installed on the next adjacent floor level.

In the event that this requirement cannot be met at the time of completion of the installation of the

appliance, the owner shall have a period of thirty (30) days to comply with the requirement. However, during said thirty (30) day period, a battery operated carbon monoxide detector with alarm

must be installed.

Each carbon monoxide detector as required in accordance with the above provisions must comply

with NFPA 720 and be ANSI/UL 2034 and IAS certified.

In addition when the vent termination is less than seven (7) feet above finished grade a metal or plastic identification plate must be permanently mounted to the exterior of the building at a minimum

height of eight (8) feet above grade directly in line with the exhaust vent terminal. The sign shall

read, in print size no less than one-half (1/2) inch in size, “GAS VENT DIRECTLY BELOW. KEEP

CLEAR OF ALL OBSTRUCTIONS”.

A COPY OF THESE INSTRUCTIONS PLUS ALL VENTING INSTRUCTIONS WHICH INCLUDE PARTS LISTS, AND/OR ALL VENTING DESIGN INSTRUCTIONS MUST REMAIN

WITH THE STOVE AT THE COMPLETION OF THE INSTALLATION.

ATTENTION INSTALLERS: Mark below which venting system was used in the installation. These

instructions must remain with the Installation & Operation Manual.

Simpson DuraVent GS/PRO® Selkirk Direct-Temp®

AmeriVent Direct™ Metal Fab Direct Vent

Security Secure Vent™

ICC Direct Vent

7

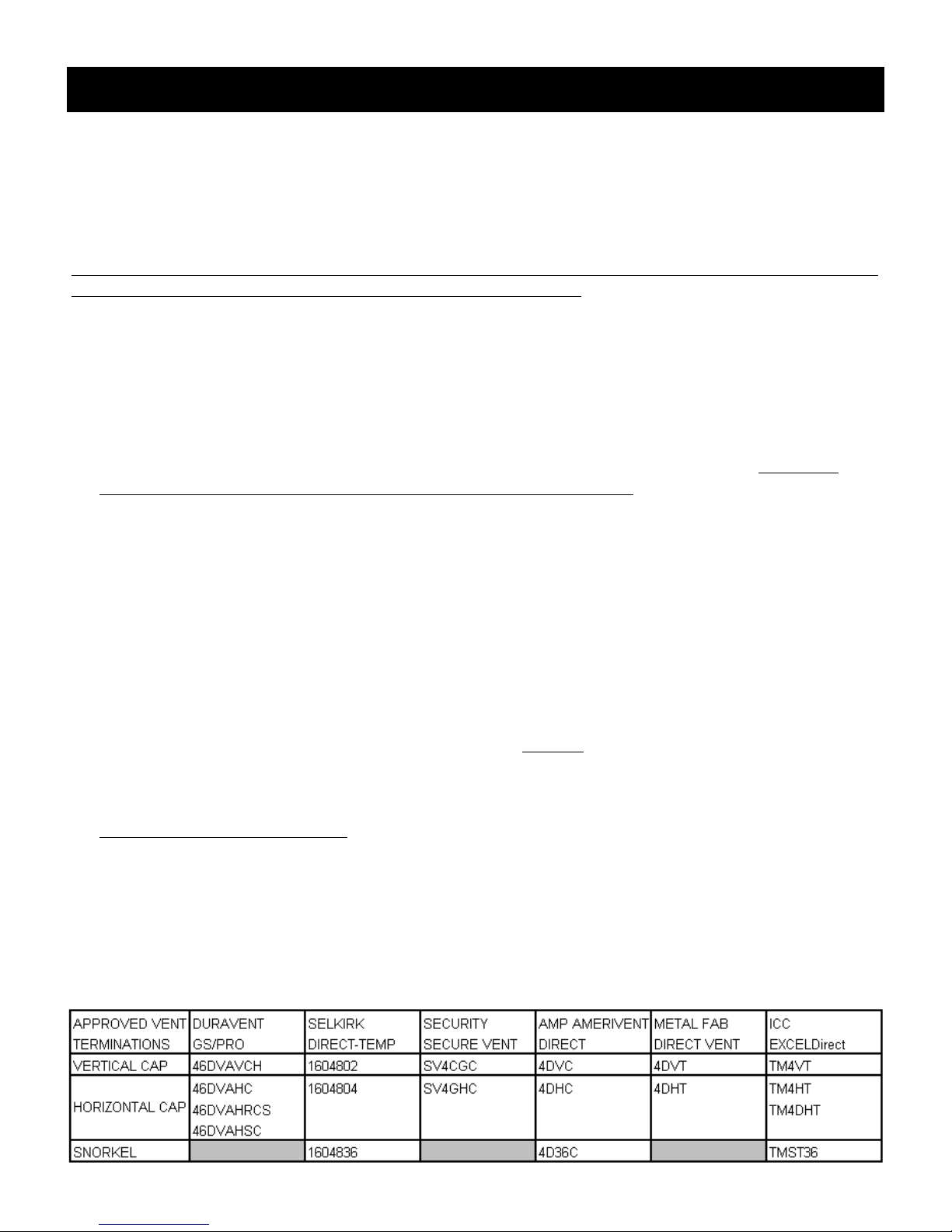

VENTING

The Solas Direct Vent Gas Fireplace has been tested and listed for installation with 4” X 6 5/8” Simpson

DuraVent GS/Pro®, Selkirk Direct-Temp

and ICC EXCELDirect venting components. Although you may the pipe components (straight pipe, elbows,

®

, Security Secure Vent™, AmeriVent Direct™, Metal Fab Direct Vent

etc.) from any of the listed manufacturers, you may only use the vent terminations (caps) listed in the chart

on page 9. For installations where a snorkel is needed, please note that only three snorkels are approved for

use. Please plan your installation accordingly.

For all specific venting installation requirements, follow the installation instructions included by the venting

manufacturer with the venting system components you have chosen.

Please note:

For venting configurations that include no vertical rise, a total horizontal vent run of up to 30 inches

(and including one 45° elbow) is allowed. However, if your installation has room to add a vertical pipe

section, we suggest adding at least one foot of vertical rise to the system.

For venting configurations that include vertical rise, it is assumed that the installation will include at

least one 90° elbow. Up to three additional 90° elbows (or equivalent 45° elbows) may also be used.

The total venting may not exceed 20 feet of vertical rise and/or 10 feet horizontal run. Refer to the

venting charts starting on page XX for specific details while you plan your installation. Note: The

number of elbows impacts the maximum allowable horizontal vent run.

Many installations will involve venting directly through standard 2 X 4 or 2 X 6 construction exterior

wall (parallel wall installation) to a horizontal vent termination (cap). The vent starter pipe has been

designed to accommodate those two common installations without the use of any additional venting

components other than a standard horizontal cap. See the chart at the bottom of this page for a list of

approved vent caps.

A special corner installation kit (Part Number CK-26-1) is also available that will allow the Solas fire-

place to be mounted in a corner without constructing a 45° partition wall. This kit is available from

your Solas dealer and has its own installation instructions. Please refer to those instructions for specific

details regarding the installation using the kit.

If the fireplace will be installed on an interior wall or other location that precludes venting directly

through an outside wall to a horizontal vent cap, or if the distance to the outside wall exceeds 30”, one

or more elbows will be required to allow addition of the required vertical venting to the installation.

When vertical venting is required, the fireplace venting may be terminated with either a vertical or horizontal vent cap depending on the specifics of the installation. Refer to the venting charts starting on

page XX for specific venting requirements and see the chart on page YY for a list of approved vent caps

before you plan your installation.

A minimum clear space of 1 1/2” must be maintained around the vent pipe where it penetrates the wall

adjacent to the fireplace (either the outside wall for the direct-through-the-wall installation or the partition wall for the 45° or other interior wall installations). A minimum clear space of 1 1/2” must also be

maintained where the vent pipe penetrates any other interior wall, exterior wall, ceiling or roof.

The location of the vent termination must meet the requirements of the current edition of ANSI Z223.1/

NFPA 54, National Fuel Gas Code or CAN B419.1, Natural Gas and Propane Installation Code and the

requirements shown on page ZZ of this manual.

8

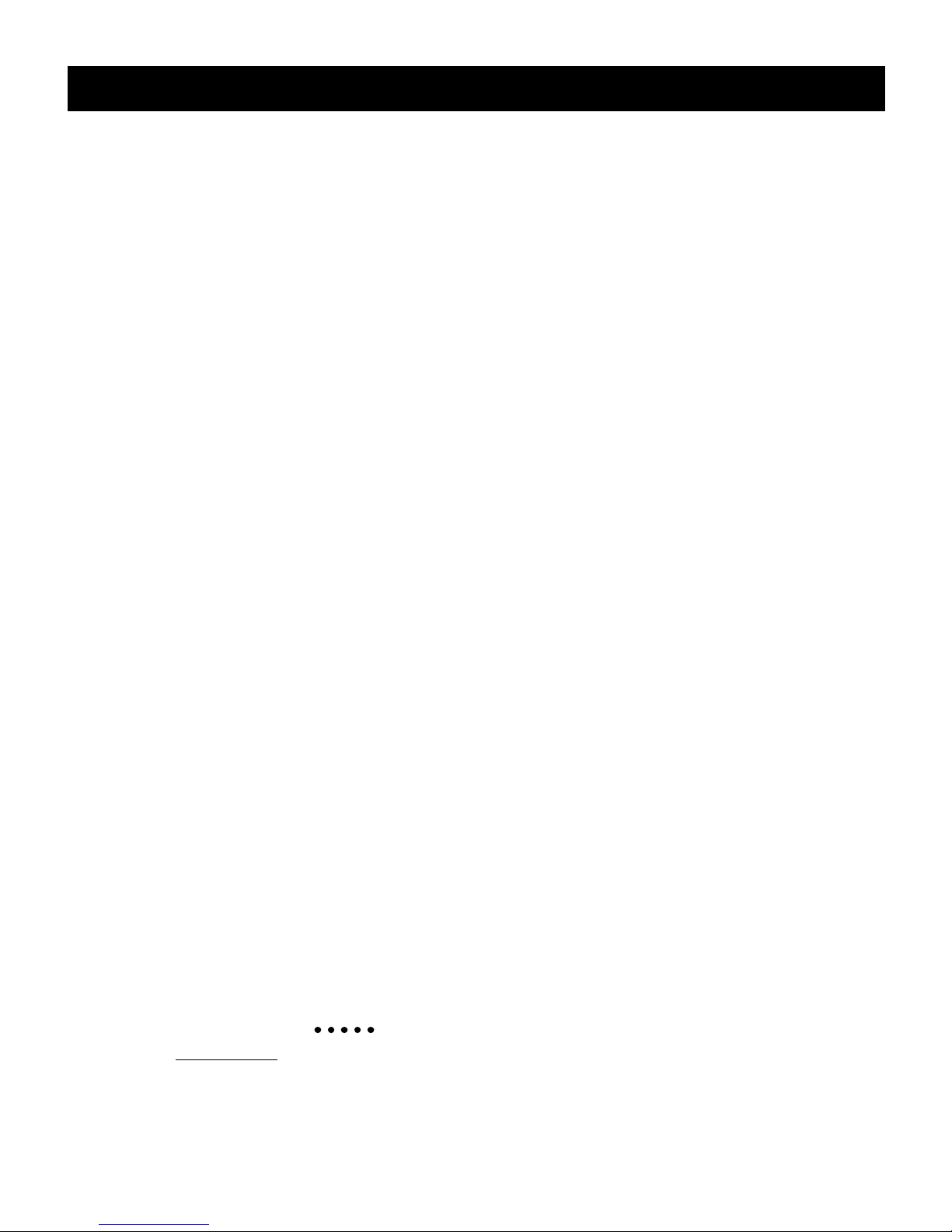

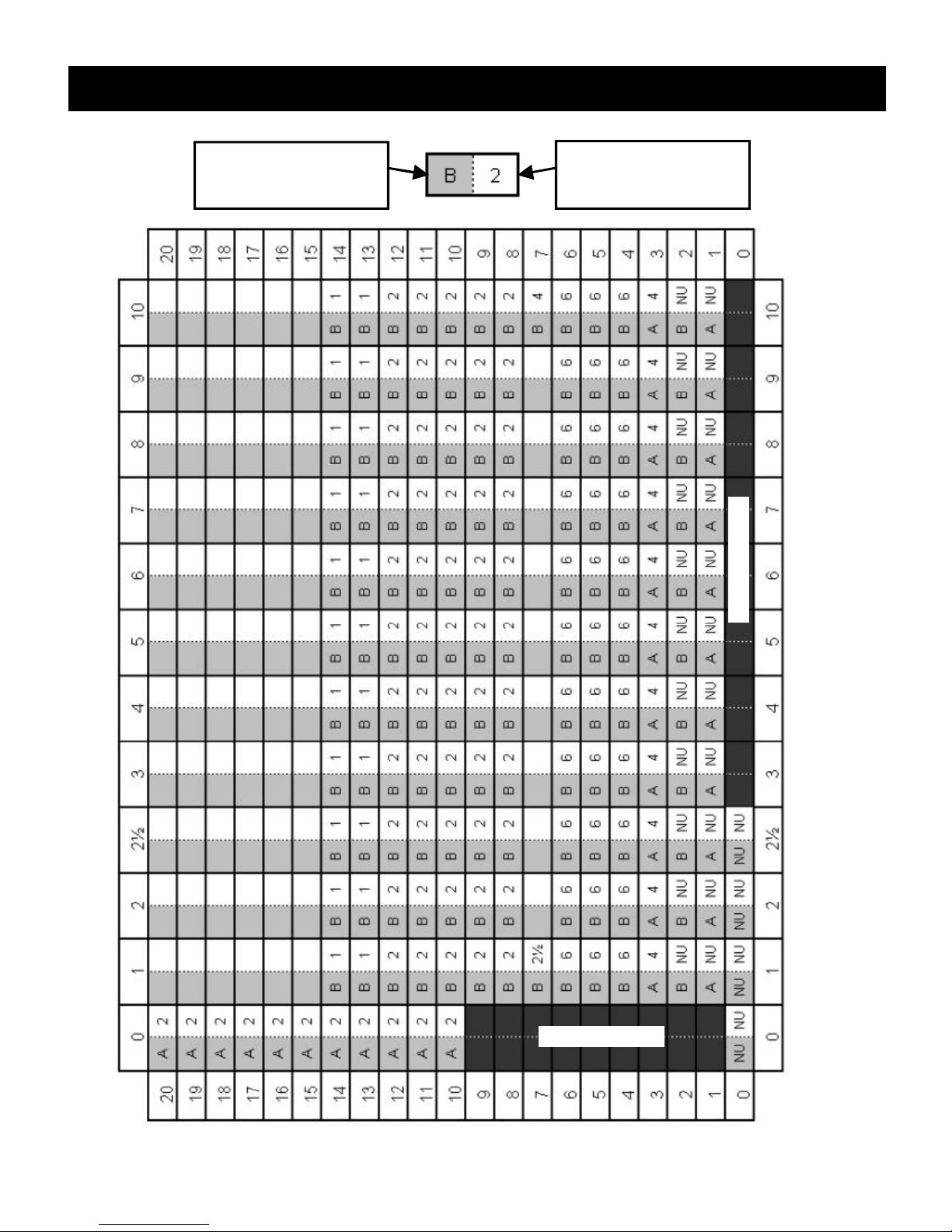

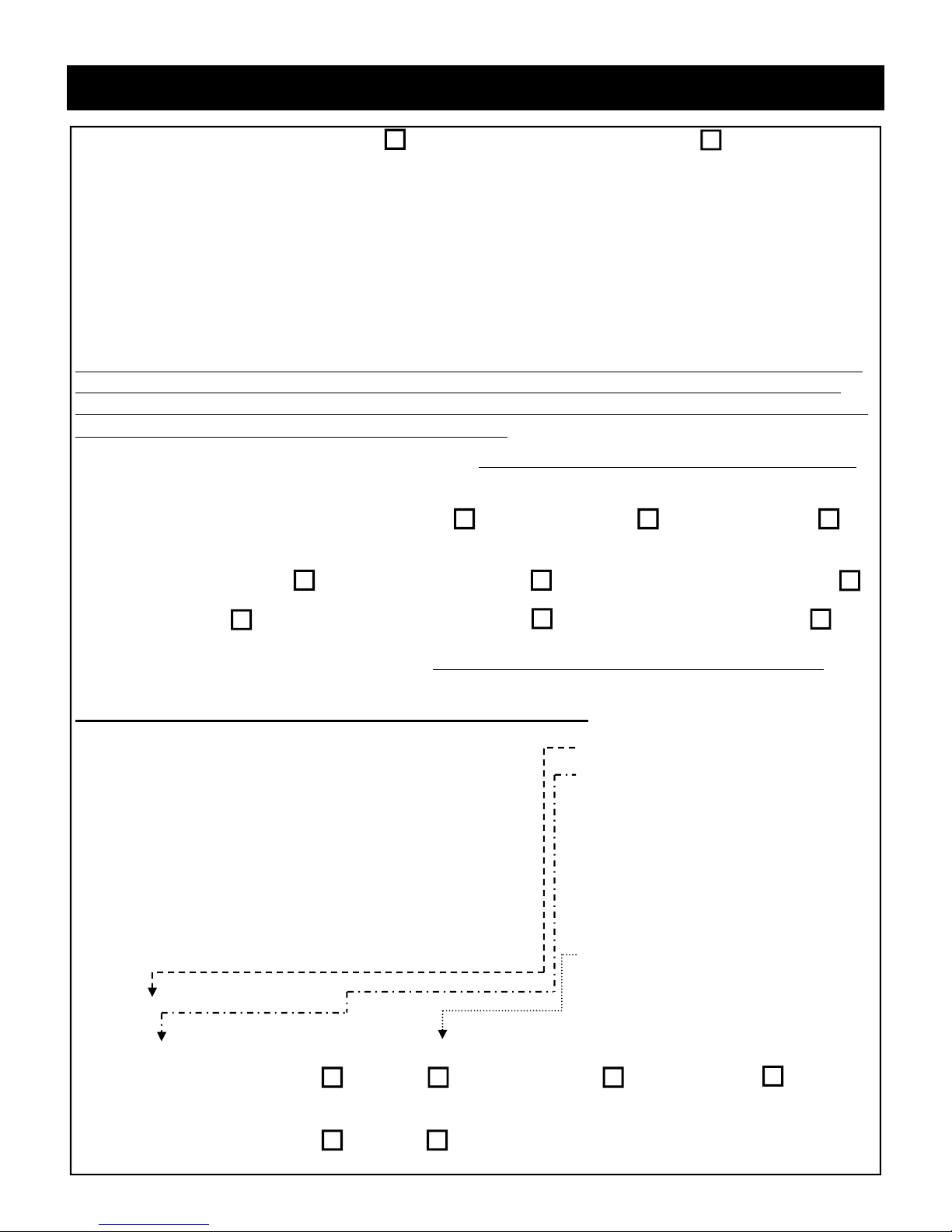

USING THE VENTING CHARTS

The venting charts on pages 10 and 11 provide an easy means for determining whether your specific installation requires inlet air or exhaust restrictors or both. To make the determination about whether air or exhaust restrictors are needed, a venting chart worksheet is provided on page 12. Follow the instructions and

fill in the worksheet for your particular installation. This will allow you to determine the recommended

restrictor setting for you exact installation. This might appear to be a complicated process but it is really

quite straight-forward. Several examples are shown on page 13 to help guide you.

Please be sure to note that:

1. There are separate venting charts for Natural Gas and LP Gas. Refer to the appropriate chart for your

fuel type to determine your specific restrictor requirements. The settings in the charts have been determined based on extensive testing.

2. Determine the total vertical vent rise and total horizontal vent run for your installation. All measurements are made from the center of the vent opening in the back of the fireplace.

3. If your fireplace will not be venting directly though an outside wall to a horizontal termination or if

more than 30” of horizontal vent run is required, some vertical vent rise will be required for the fireplace to function and vent properly. Elbows will also be required for those installations. However, installations are limited to a maximum of four 90° elbows (or 45° elbow equivalents).

4. Note: Two 45° elbows equal one 90° elbow.

5. The recommended restrictor settings in the venting charts allow up to two 90° elbows (or 45° elbow

equivalents) to be used without affecting the restrictor settings. Additional elbows will require that you

calculate a new equivalent horizontal run for your installation to account for the additional flow resistance caused by the extra elbows. For the purposes of calculating the equivalent horizontal vent run,

each additional 90° elbow is equivalent to three feet of horizontal vent run. The total horizontal vent

run including elbow equivalents can not exceed 10 feet.

6. The maximum vertical vent rise can not exceed 20 feet.

7. There are two exhaust restrictors that are provided with your Solas fireplace. They are labeled “A” and

“B”. The A restrictor provides less exhaust restriction than B.

8. An air restrictor plate is also provided with your fireplace. It is a ring with bendable tabs that can be

set to adjust the amount of restriction in the air supply system.

PLEASE NOTE: If your specific venting configuration falls in a box in the venting charts (on pages 10 &

11) that is above the dotted line ( ), you must use one of the approved direct vent venting systems

that utilizes a stainless steel inner liner. The dotted line corresponds to a total vent length of 20 feet including vertical rise and horizontal run. This requirement is part of the ANSI standards and is based on testing

conducted to determine where the exhaust gas temperature drops to the point where condensation might occur in the vent pipe. The standards require the use of corrosion resistant liner materials if that specific total

vent length is exceeded.

9

NATURAL GAS VENTING CHART

KEY

EXHAUST RESTRICTOR

A or B

NU = NOT USED

AIR RESTRICTOR

1— 6 TABS OPEN

NU = NOT USED

NOT ALLOWED

NOT ALLOWED

HORIZONTAL RUN IN FEET

VERTICAL RISE IN FEET

10

LP GAS VENTING CHART

KEY

EXHAUST RESTRICTOR

A or B

NU = NOT USED

AIR RESTRICTOR

1— 6 TABS OPEN

NU = NOT USED

NOT ALLOWED

NOT ALLOWED

HORIZONTAL RUN (FEET)

VERTICAL RISE (FEET)

11

VENTING CHART WORKSHEET

A. FUEL TYPE: NATURAL GAS

LP GAS (PROPANE)

B. TOTAL VERTICAL VENT RISE (MEASURED FROM HORIZONTAL CENTERLINE OF VENT

OPENING ON THE BACK OF THE FIREPLACE TO THE HORIZONTAL CENTERLINE OF THE

VENT CAP (FOR HORIZONTAL VENT CAPS) OR TO THE FLANGE ON THE CAP (FOR VERTICAL CAPS)): _____________ FEET

C. TOTAL HORIZONTAL VENT RUN (MEASURED FROM THE VERTICAL CENTERLINE OF

THE VENT OPENING ON THE BACK OF THE FIREPLACE TO THE FLANGE ON THE CAP (FOR

HORIZONTAL CAPS) OR TO THE VERTICAL CENTERLINE OF THE CAP (FOR VERTICAL

CAPS)): _____________ FEET

NOTE: THE VERTICAL VENT RISE AND HORIZONTAL VENT RUN ARE THE OFFSETS IN THE LOCATIONS OF VENT CAP RELATIVE TO THE VENT OPENING ON THE FIREPLACE. VENT PIPE

THAT RUNS AT 45° HAS BOTH A VERTICAL RISE AND HORIZONTAL RUN. SNORKEL CAPS HAVE

BUILT-IN VERTICAL RISE THAT MUST BE COUNTED.

D. TOTAL NUMBER OF 90° ELBOWS: _______ NOTE: SNORKELS COUNT AS 2- 90° ELBOWS

E. TOTAL NUMBER OF 45° ELBOWS: _______

TERMINATION (CAP) TYPE: HORIZONTAL VERTICAL

SNORKEL

VENT BRAND:

Simpson DuraVent GS/Pro® Selkirk Direct-Temp

®

Security Secure Vent™

AmeriVent Direct™ Metal Fab Direct Vent

ICC EXCELDirect

VENT CAP MODEL NO: _______________ NOTE: SEE APPROVED VENT CAPS ON PAGE 8

EXHAUST AND AIR INLET RESTRICTORS CALCULATOR

A. Fuel Type ________

B. Total Vertical Vent Rise: ________ feet

C. Total Horizontal Vent Run (Actual): ________ feet

D. 90° Elbows Needed: ________

E. 45° Elbows Needed: ________

F. Total 90° Elbows Equivalent: D +(E x ½) = ________

G. 90° Elbows in Excess of 2: F - 2 = ________

H. Additional Horiz. Feet Equivalent: G x 3 = ________ feet

I. Horizontal Vent Run (Equivalent): C + H = ________ feet

Find _____ Chart Settings for:

B._________ feet Vertical Rise and I.__________ feet Horizontal Run (Equivalent).

Exhaust Restrictor Required: N Y IF YES: A or B

Air Restrictor Required: N Y IF YES: Number of Tabs Open: _______

12

Loading...

Loading...