VANGUARD

®

FTS 370d, 370w, 370r

LED Medium Intensity Obstruction Lighting System

Flash Technology, 332 Nichol Mill Lane, Franklin, TN 37067

Reference Manual

Part Number F7913702

SERIAL NUMBER

www.flashtechnology.com

(615) 261-2000

FTS 370d/w/r INSTALLATION CHECKLIST

System Controller (SC) 370

The SC 370 is mounted away from radio frequency interference (RFI).

The SC 370 is mounted upright.

Lightning protection is grounded to the site grounding system.

2 AWG (min.) is used from the SC 370 grounding lug to the site lightning grounding system (tested for 1ohm or less).

The bend radius for all ground wires is greater than 8" (avoid bending ground wires if possible).

Important! It is recommended that all exposed ground connections are coated with a corrosion inhibitor (NO-OX or

equivalent).

There are no holes punched or drilled in the top or sides of the enclosure.

Airflow can properly circulate around the enclosure (allow 8” min. of unused space on both sides).

Room allowed for door access (multi-unit installations).

The input power (and frequency for AC systems) matches the voltage specified on the unit’s data label.

Electrical connections, and inside cabinet hardware mounts have been double-checked for tightness before powering up.

All wire connections are installed properly into the terminal blocks (TB1 and TB2).

ALL PCB connectors are securely plugged into the board (Phoenix Connectors).

All PCB connector wires are properly inserted and screws are tightened.

RS 485 Data cables are installed on PCB1 J4 and routed between System Controllers (multi-unit installations).

Circuit Breakers are securely fastened to din rail.

The “Binding Procedure” has been performed on each SC 370 installed in the system.

(See Section 3 “Local Tower Config” for special instructions regarding the binding procedure.)

PCB1 Intensity select switch is in the “Auto” position on the System Controller (s).

The SC 370 designated as System 1 is connected to the top flashhead and programmed as AOL.

The flashhead cable is connected to TB2, and corresponds to the internal wiring diagram and color guides on the

terminal block.

Flashhead CABLE

Flashhead cable is NOT spliced except at the marker interface enclosure, if installed.

Flashhead individual conductor insulation has not been nicked.

A service loop for the flashhead cable is placed at the base of the tower near the System Controller (5 feet).

Service loop is attached to the H-Frame or Wall vertically.

The flashhead cable is properly secured to the tower so the insulation won’t become cut or damaged with wind and time.

Using the Flash Technology’s two supplied tapes and the 2-3-4 layer method, secure the cable to the tower (Not

exceeding 5’ in-between)

A service loop is placed just below the beacon.

Service loop is secured at (2) points to the tower structure using the 2-3-4 tape method.

The flashhead cable is not pulled tight against sharp edges.

1-3” of space should be between the cable and tower leg flanges or obstructions.

FTS 370d/w/r Revision 19 – 05/23/2018 a

Flashhead

The LED beacon is wired correctly.

The wires are positioned so no arcing can occur and wire colors match the terminal designations, and flashhead cable

is secured in the terminal block.

The dome nut of the beacon’s cable strain relief is tightened for cable support and to prevent moisture intrusion.

Drip loop is present for the LED beacon.

The LED beacon is securely closed with both latches in place.

The LED beacon at the top of the tower has a lightning rod(s) provided at least 36” above the top of the beacon, and a

minimum of 18” away from the beacon.

The LED beacon is level (Use separate leveling tool).

8 AWG (min.) insulated ground wire is used from the LED beacon grounding lug to the tower structure.

The LED beacon is mounted in an FAA approved location (No obstructions; allowing a 360° view of the beacon).

Marker Interface Junction Box (SC 370d or SC370r)

The Marker Interface Enclosure is mounted at the marker tier level.

Flash Technology provided hardware used for mounting the Marker Interface Enclosure (4 points of contact to Universal

Mounting brackets).

Both latches are secured to prevent water intrusion.

Marker Interface Enclosure is grounded to the tower.

8 AWG (min.) insulated ground wire is used from the Marker Interface Enclosure grounding lug to the tower structure.

Side marker cable connections match all PCB labels (Connections are polarity sensitive, correct wiring is critical).

Service loop for the flashhead cable to the ground is present near the base of the Marker Interface Enclosure.

Service loop for the flashhead cable to the flashhead is present near the base of the Marker Interface Enclosure.

MARKERS (Red LED sidelights, side-markers, or obstruction lights L-810)

Only Flash Technology provided 24 Volt DC Marker Fixtures are installed.

The dome nuts of the cable strain reliefs are tightened for cable support and to prevent moisture intrusion.

PHOTODIODE (PHD 516)

The PHD 516 is connected to PCB2 (Surge Board) P-6 (White, Black, and Drain wires correspond to the label on board).

The PHD 516 is mounted vertically to prevent water entry.

The PHD 516 cable is protected through conduit so it will not be stepped on or damaged.

The PHD 516 is facing north and no artificial lights (security lights, street lights, lighted signs, or direct sunlight) will affect

its operation.

ALARMS and ALARM WIRING

NO alarm LEDs are lit on PCB1 of the SC 370.

The display located on PCB1 of the SC 370 is showing “Status OK” along with the correct configuration of the system type

installed (Dual or White with the correct number of beacons, and markers if applicable).

A Lighting Inspection has been performed via the User Interface Panel.

Call 1-800-821-5825 if additional TECHNICAL or INSTALLATION assistance is needed.

b Revision 19 – 05/23/2018 FTS 370d/w/r

Front Matter

Abstract

This manual contains information and instructions for installing, operating and maintaining the

FTS 370d, 370w and 370r LED Medium Intensity Obstruction Lighting Systems with the

following input voltages: 120-240V AC, 24V DC and 48V DC. All model variants support

IR (infrared) output.

Copyright

Copyright © 2018, Flash Technology, Franklin, TN, 37067, U.S.A.

All rights reserved. Reproduction or use of any portion of this manual is prohibited without

express written permission from Flash Technology and/or its licenser.

Trademark Acknowledgements

Flash Technology and Vanguard are registered trademarks of SPX Corporation.

All other trademarks and product names mentioned are properties of their respective

companies, and are recognized and acknowledged as such by Flash Technology.

Applicable Specifications

This equipment meets or exceeds requirements for the following FAA Types: L-864/865, L-

865, L-866/885, L-866 and L-885.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Patent Information

FH 370, described within this document, is covered by the following patent: Patent No.

8,926,148

MKR 371, described within this document is, covered by the following patent: Patent No.

8.998.443

Additional patents pending.

Disclaimer

While every effort has been made to ensure that the information in this manual is complete,

accurate and up-to-date, Flash Technology assumes no liability for damages resulting from any

errors or omissions in this manual, or from the use of the information contained herein. Flash

Technology reserves the right to revise this manual without obligation to notify any person or

organization of the revision.

In no event will Flash Technology be liable for direct, indirect, special, incidental, or

consequential damages arising out of the use of or the inability to use this manual.

Warranty

With proper installation and with normal operating conditions, Flash Technology warrants all

lighting components of the LED lighting system for 5 years from the date of shipment from

Flash Technology. Monitoring components such as modem or battery, if present, are only

covered by 1–2 years warranty from the date of shipment.

FTS 370d/w/r Revision 19 – 05/23/2018 i

Parts Replacement

The use of parts or components, in this equipment, not manufactured or supplied by Flash

Technology voids the warranty and invalidates the third party testing laboratory certification

which ensures compliance with FAA Advisory Circulars 150/5345-43H, 150/5345-53D, and

Engineering Brief No. 67D. The certification is valid as long as the system is maintained in

accordance with FAA guidelines (FR doc. 04-13718 filed 6-16-04).

Personnel Hazard Warning

Dangerous Voltages

Dangerous line voltages reside in certain locations in this equipment. Also, this equipment

may generate dangerous voltages. Although Flash Technology has incorporated every

practical safety precaution, exercise extreme caution at all times when you expose circuits and

components, and when you operate, maintain, or service this equipment.

Avoid Touching Live Circuits

Avoid touching any component or any part of the circuitry while the equipment is operating.

Do not change components or make adjustments inside the equipment with power on.

Dangerous Voltages Can Persist with Power Disconnected

Under certain conditions, dangerous voltages can be present because capacitors can retain

charges even after the power has been disconnected.

Protect yourself — always turn off the input (primary) power and wait for storage capacitors

to drain their charge. Then check the system controller’s TB2 output terminals with a voltmeter

for any residual charge before touching any circuit element or component.

Do Not Depend on Interlocks

Never depend on interlocks alone to remove unsafe voltages. Always check circuits with a

voltmeter. Under no circumstances remove or alter any safety interlock switch.

ii Revision 19 – 05/23/2018 FTS 370d/w/r

Table of Contents

Front Matter ............................................................................................................................... i

Personnel Hazard Warning ....................................................................................................... ii

Table of Contents ..................................................................................................................... iii

List of Figures ............................................................................................................................v

List of Tables ........................................................................................................................... vi

Section 1 – Introduction and Operation .....................................................................................1

Introduction ............................................................................................................................1

System Overview ...............................................................................................................1

Specifications .....................................................................................................................2

SC 370 ....................................................................................................................................4

Operation Overview ...........................................................................................................4

PCB1 Controller Board ......................................................................................................5

PCB2 Surge Board ...........................................................................................................12

FH 370d/w/r .........................................................................................................................13

Marker Interface Enclosure..................................................................................................14

MKR 371 .............................................................................................................................15

Section 2 – Mounting and Installation .....................................................................................16

Controller Installation ..........................................................................................................16

Verify the Installation ......................................................................................................16

SC 370 Access .................................................................................................................16

Mounting ..........................................................................................................................16

Mounting Adapter Panel (Optional) ................................................................................16

Wiring ..............................................................................................................................17

Input Power ......................................................................................................................17

Photodiode Wiring ...........................................................................................................17

Photodiode Mounting.......................................................................................................17

Cellular Antenna ..............................................................................................................18

GPS Antenna ....................................................................................................................19

Communication Cable Kit ...............................................................................................21

Wi-Fi Option Antenna Installation ..................................................................................21

USB Wi-Fi (Optional)......................................................................................................23

Dry Contact Alarm Outputs .............................................................................................24

Flashhead Cable ...................................................................................................................24

Marker Interface Enclosure..................................................................................................26

Wiring Procedure .............................................................................................................26

Flashhead Installation ..........................................................................................................28

System Wiring Diagram Notes (D1 & D2)..........................................................................43

System Wiring Diagram Notes (E1 & E2) ..........................................................................45

System Wiring Diagram Notes (Catenary) ..........................................................................47

Section 3 – Information Display ..............................................................................................57

Navigating the Information Display ....................................................................................57

Ctrl Type ..............................................................................................................................58

Site Tower Config ................................................................................................................58

Local Tower Config .............................................................................................................62

Monitoring Config ...............................................................................................................64

Monitoring Status.................................................................................................................66

Local Diagnostics.................................................................................................................66

FTS 370d/w/r Revision 19 – 05/23/2018 iii

Lighting Inspection (LI) .......................................................................................................68

Mode Override .....................................................................................................................69

System Settings ....................................................................................................................69

Factory Diagnostics .............................................................................................................69

System X Firmware .............................................................................................................70

USB Firmware Update .........................................................................................................70

Information Display Alarms ................................................................................................71

Section 4– Web Interface .........................................................................................................73

Web Interface (Optional) .....................................................................................................73

Lighting Inspection (LI) .......................................................................................................74

Mode Override .....................................................................................................................75

Auxiliary Input .....................................................................................................................76

Event Log .............................................................................................................................76

Diagnostics ...........................................................................................................................77

Download Log File ..............................................................................................................77

Configuration .......................................................................................................................77

Tower Lighting ................................................................................................................78

System “X” ......................................................................................................................79

Monitoring .......................................................................................................................80

Network............................................................................................................................80

SNMP Labels ...................................................................................................................80

SNMP Settings .................................................................................................................81

Login Settings ..................................................................................................................83

System Settings ................................................................................................................83

Cellular Modem ...............................................................................................................83

Section 5 – Maintenance and Troubleshooting ........................................................................84

Safety ...................................................................................................................................84

Preventive Maintenance .......................................................................................................84

Storage .................................................................................................................................84

RFI Problems .......................................................................................................................84

Diagnostic Test ....................................................................................................................84

Component Testing ..............................................................................................................84

Troubleshooting ...................................................................................................................85

Component Removal and Replacement ...............................................................................88

Section 6 – Recommended Spare & Replaceable Parts ...........................................................89

Ordering Parts ......................................................................................................................89

RMA Policy .........................................................................................................................89

iv Revision 19 – 05/23/2018 FTS 370d/w/r

List of Figures

Figure 1-1 – SC 370 (AC) ......................................................................................................... 4

Figure 1-2 – PCB1 Controller Board ........................................................................................ 5

Figure 1-3 – Information Display and User Interface ............................................................... 6

Figure 1-4 – Alarm Interface & Mode Indicator Connections ................................................. 9

Figure 1-5 – PCB 3 with GPS ................................................................................................. 11

Figure 1-6 – PCB2 Surge Board (PN 2420600 or 2420601) .................................................. 12

Figure 1-7 – FH 370d/w/r ....................................................................................................... 13

Figure 1-8 – Marker Interface PCB ........................................................................................ 14

Figure 1-9 – MKR 371 ............................................................................................................ 15

Figure 2-1 – Antenna Mounting Bracket with PHD 516, Cellular and GPS Antennas .......... 20

Figure 2-2 – Antenna Mounting Options ................................................................................ 20

Figure 2-3 – Wi-Fi Antenna Installation ................................................................................. 22

Figure 2-4 – USB Wi-Fi Installation ...................................................................................... 23

Figure 2-5 – SC 370 Flashhead Cable Connection ................................................................. 24

Figure 2-6 – Marker Interface Wiring .................................................................................... 27

Figure 2-7 – Flashhead Leveling ............................................................................................ 28

Figure 2-8 – Flashhead Cable Terminal Block ....................................................................... 29

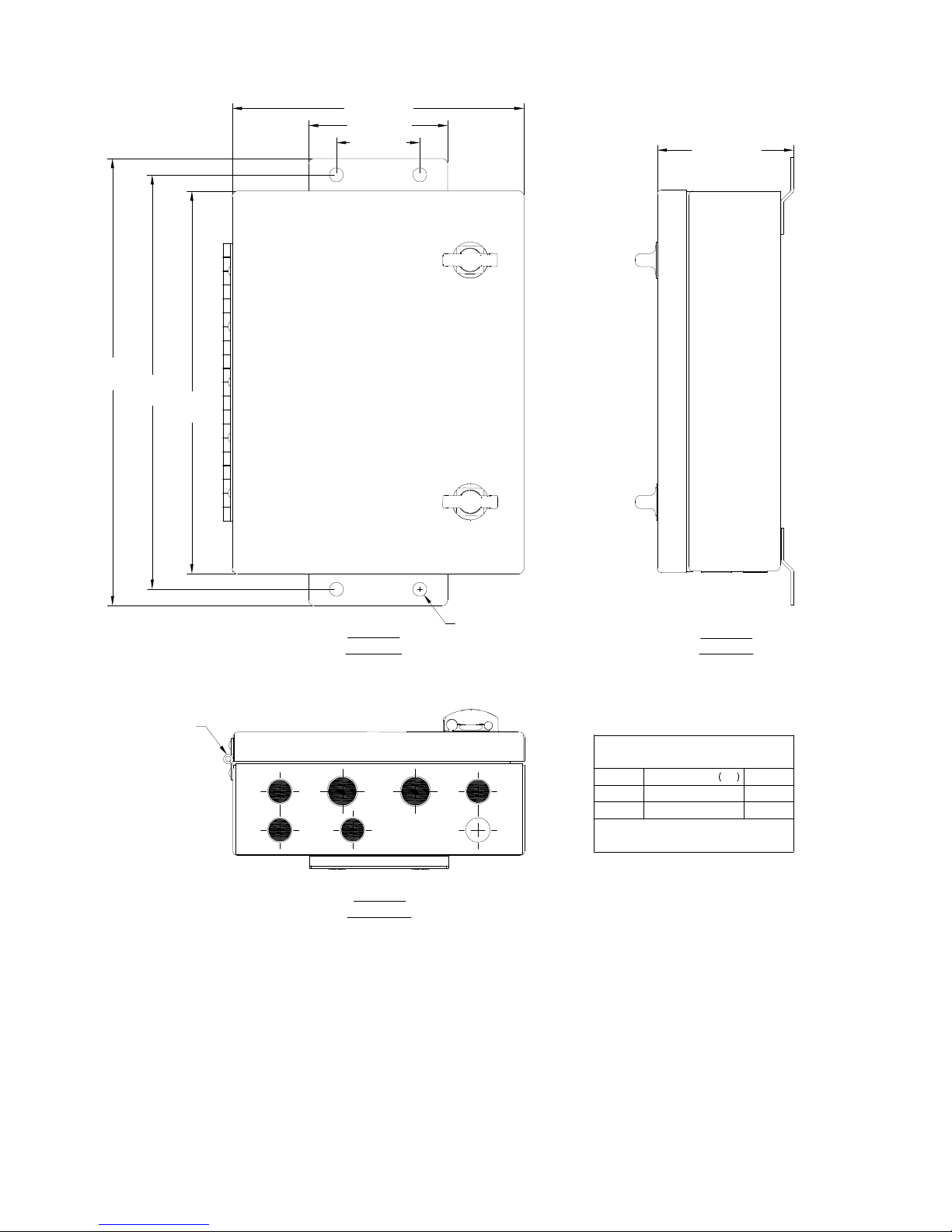

Figure 2-9 – SC 370 Mounting and Outline (Painted Aluminum Option) ............................. 30

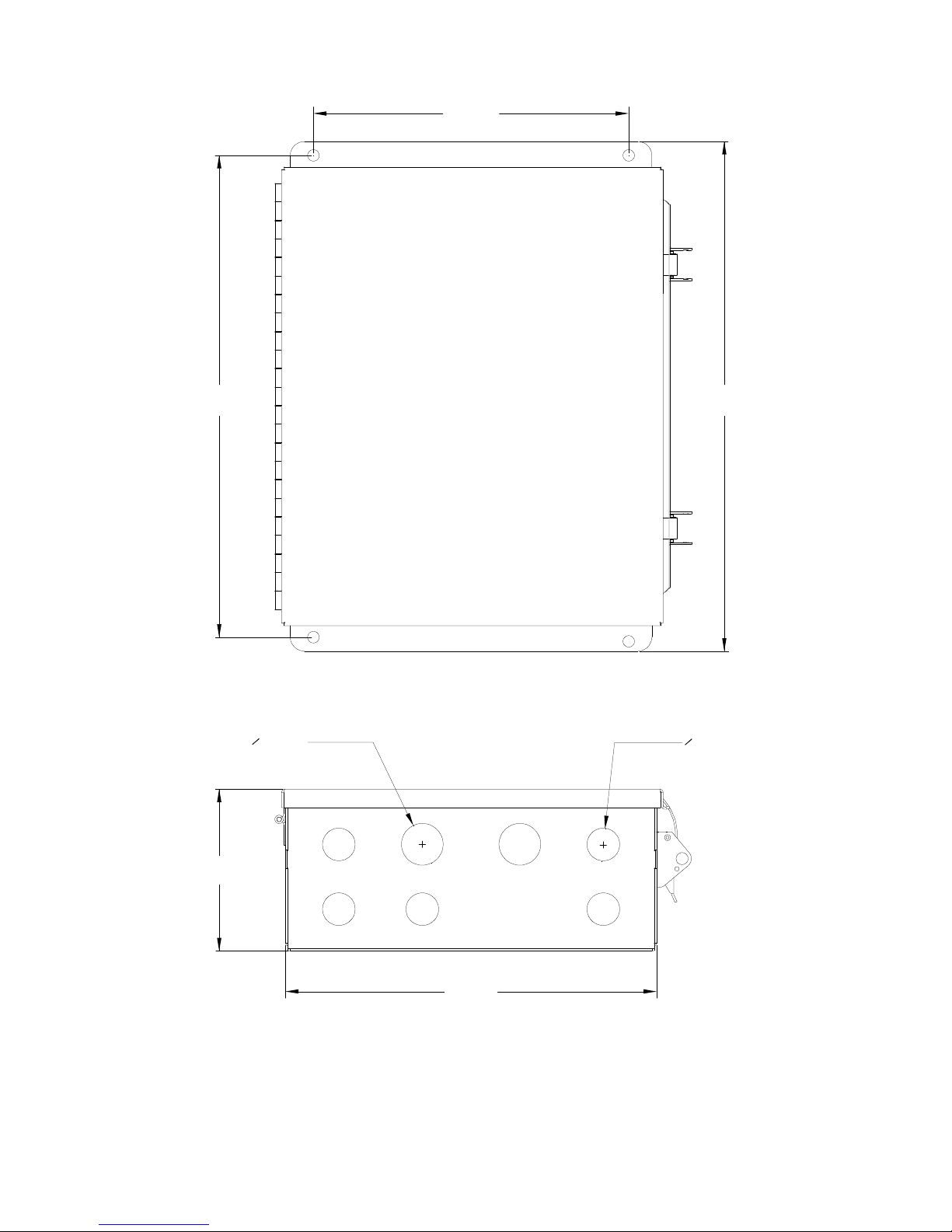

Figure 2-10 – SC 370 Mounting and Outline (Stainless Steel Option) .................................. 31

Figure 2-11 – Adapter Mounting Panel Mounting and Outline (Optional) ............................ 32

Figure 2-12 – Photodiode Mounting and Outline ................................................................... 33

Figure 2-13 – Flashhead Dimensions and Mounting Outline ................................................. 34

Figure 2-14 – MKR 371 Mounting and Outline ..................................................................... 35

Figure 2-15 – Marker Interface Mounting and Outline (Painted Aluminum Option) ............ 36

Figure 2-16 – Marker Interface Mounting and Outline (Stainless Steel Option) ................... 37

Figure 2-17 – Typical E1/D1 Component Locations .............................................................. 38

Figure 2-18 – Typical E2/D2 Component Locations .............................................................. 39

Figure 2-19 – Typical E2/D2 Avian Component Locations (AC 70/7460-1L) ...................... 40

Figure 2-20 – Typical Catenary Component Locations .......................................................... 41

Figure 2-21 – Typical D1 & D2 System Wiring Diagram...................................................... 42

Figure 2-22 – Typical E1 & E2 System Wiring Diagram ...................................................... 44

Figure 2-23 – Typical Catenary System Wiring Diagram ...................................................... 46

Figure 2-24 – SC 370 (AC) Internal Wiring Standard System ............................................... 48

Figure 2-25 – SC 370 (AC) Internal Wiring with Smart Board Option ................................. 49

Figure 2-26 – SC 370 (AC) Internal Wiring with Modem Options ........................................ 50

Figure 2-27 – SC 370 (AC) Internal Wiring with Modem & Wi-Fi Options ......................... 51

Figure 2-28 – SC 370 (AC) Internal Wiring with Wi-Fi Option ............................................ 52

Figure 2-29 – SC 370 (DC) Internal Wiring Standard System ............................................... 53

Figure 2-30 – SC 370 (DC) Internal Wiring with Smart Board Option ................................. 54

Figure 2-31 – SC 370 (DC) Internal Wiring with Modem Option ......................................... 55

Figure 2-32 – Marker Interface Enclosure Wiring Diagram .................................................. 56

Figure 3-1 – Information Display ........................................................................................... 57

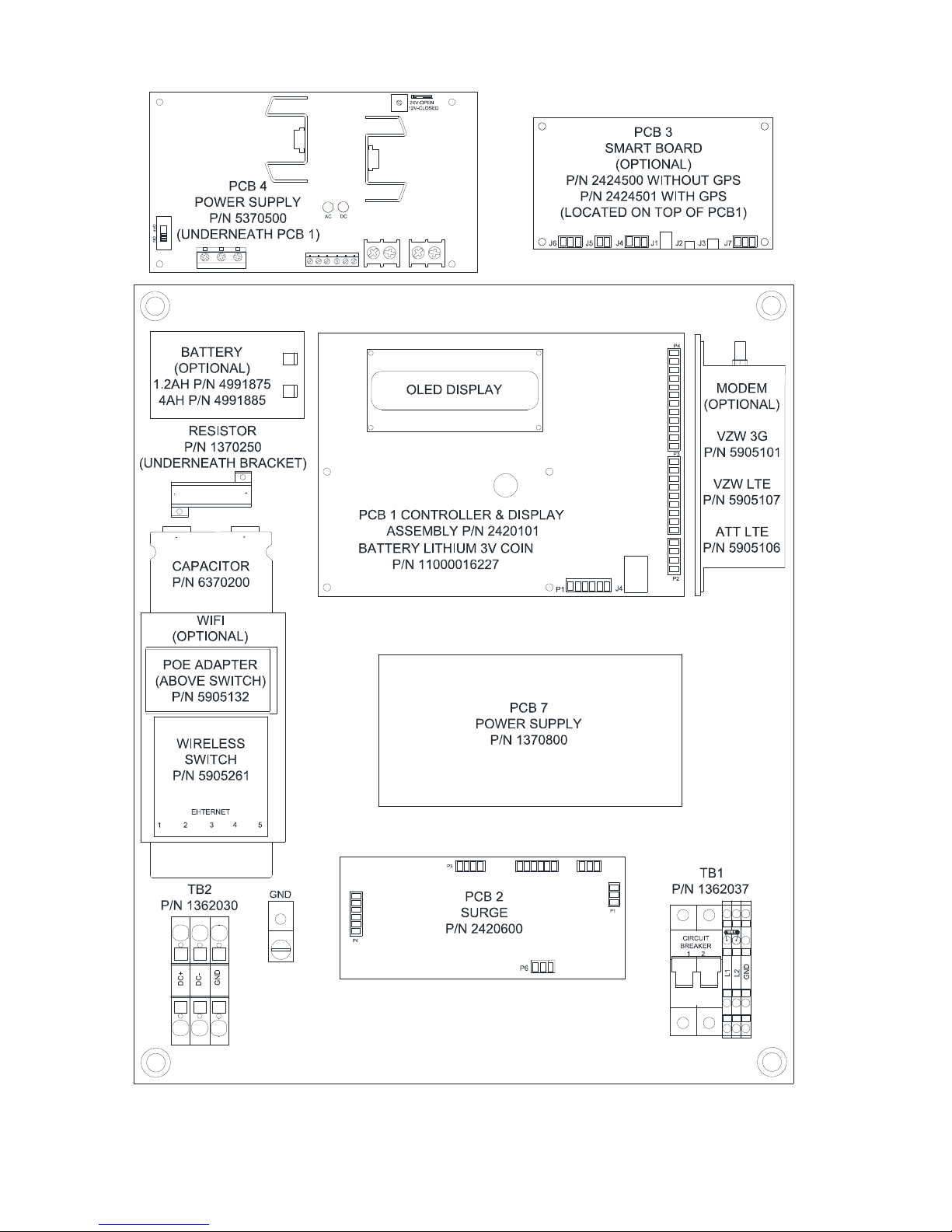

Figure 6-1 – SC 370 (AC) Component Locations .................................................................. 90

Figure 6-2 – SC 370 (DC) Component Locations .................................................................. 92

FTS 370d/w/r Revision 19 – 05/23/2018 v

List of Tables

Table 1-1 – Physical Specifications ...........................................................................................2

Table 1-2 – Performance Specifications ....................................................................................3

Table 1-3 – Status & Alarm LEDs .............................................................................................7

Table 1-4 – Multitech Modem LEDs .........................................................................................8

Table 1-5 – Alarm Interface & Mode Indicator Connections ....................................................9

Table 3-1 – Controller Display Buttons 1 ................................................................................57

Table 3-2 – Top Level Menu Options 1 ...................................................................................57

Table 3-3 – Information Display Status and Alarm Definitions ..............................................71

Table 3-3 – Information Display Status and Alarm Definitions (continued) ..........................72

Table 5-1 – Troubleshooting – Initial Inspection ....................................................................85

Table 5-2 – Troubleshooting – System Voltage ......................................................................85

Table 5-3 – Troubleshooting - Flashhead. ...............................................................................86

Table 5-4 – Troubleshooting – L810 Side Markers (SC 370 Information Display) ................86

Table 5-5 – Troubleshooting – Marker Interface Box .............................................................87

Table 5-6 – Troubleshooting – GPS Synchronization .............................................................87

Table 6-1 – SC 370 (AC) Replacement Parts ..........................................................................91

Table 6-2 – SC 370 (DC) Replacement Parts ..........................................................................93

Table 6-3 – FH 370 Replacement Parts ...................................................................................94

Table 6-4 – Marker Interface Replacement Parts ....................................................................94

Table 6-5 – System Replacement Parts ...................................................................................95

vi Revision 19 – 05/23/2018 FTS 370d/w/r

Section 1 – Introduction and Operation

Introduction

FTS 370d and FTS 370w are LED Medium

Intensity Obstruction Lighting Systems.

FTS 370d series are Dual Lighting Systems

(red/white) for L-864/865 applications.

FTS 370w series are White Lighting

Systems for L-865 applications.

FTS 370 series lighting systems may also

be configured for Catenary operation.

Catenary lighting systems require three

levels (tiers) of lights. One tier is installed

at each of the following three locations: top

of the structure, lowest point of the catenary

and half way between the upper and lower

levels. Each level must be lit to provide

360-degree coverage. The flash rate is 60

flashes per minute in all modes and the

flash sequence is as follows: middle – top

– bottom.

FTS 370d Catenary series are Dual

Lighting Systems for L-866/885

applications. FTS 370w Catenary series are

White Lighting Systems for L-866

applications. FTS 370r series are Red

Lighting Systems for L-885 Catenary

applications only.

lighting system. Optional GPS

synchronization is available if additional

SC 370s are required.

The light source for the flashhead is

comprised of LEDs (Light Emitting

Diodes). The LED control circuitry and

drivers are located in the flashhead. Power

Line Communication is utilized as the

communication link between the SC 370

and the flashhead; simplifying installation

and minimizing the number of conductors

required. Installation of FTS 370d systems

(L-864/865) requiring L-810 markers is

simplified by requiring only one cable run

for both markers and flashhead. The

flashhead may be located up to 850’ (cable

length) from the controller.

Any SC 370 in the lighting system may be

configured as the control unit which is

referred to as System 1. This unit provides

overall system control including mode

control, synchronization, and alarm

collection and notification. Robust and

highly reliable communication between

multiple SC 370 units is provided by RS-

485.

System Overview

The FTS 370d, FTS 370w and FTS 370r

LED Lighting Systems have been designed

for long life, reducing the need for service.

Ease of installation and service is enhanced

by simple wiring, setup, and diagnostics.

Increased safety is provided with operating

voltages of less than 60VDC.

Each Lighting System consists of one or

more SC 370d, SC 370w or SC 370r, here

after referred to as SC 370, power and

control unit(s) and its associated flashhead.

Each flashhead requires its own SC 370. A

maximum of six (6) SC 370s and associated

flashheads may be connected to form one

FTS 370d/w/r Revision 19 – 05/23/2018 1

SC 370 systems may be ordered configured

for operation by AC or DC input power. AC

systems are not sensitive to input power

phase and have an operational voltage

range of 120-240 VAC, 50/60 Hz with no

modification necessary to the input power

module. DC powered systems are available

configured for 24 or 48 VDC. The DC input

voltage must be specified when ordering.

This manual provides guidance and

recommendations for the installation,

operation, and troubleshooting of the

lighting system. Please read this document

in its entirety before installation.

Specifications

Table 1-1 – Physical Specifications

Equipment Model Physical Specifications

SC 370 System Controller (Standard):

Dimensions H x W x D (millimeters)

Weight (kilograms)

SC 370 System Controller

(Stainless Option):

Dimensions H x W x D (millimeters)

Weight (kilograms)

Marker Interface (Standard):

Dimensions H x W x D (millimeters)

Weight (kilograms)

Marker Interface (Stainless Option):

Dimensions H x W x D (millimeters)

Weight (kilograms)

FH 370 Flashhead:

Dimensions H x D (millimeters)

Weight (kilograms)

Aerodynamic Wind Area (cm2)

23.82 x 17.25 x 8.51 in (605 x 438.3 x 216.2)

39 lb (18.1)

23.00 x 17.13 x 6.44 in (584.2 x 435.1 x 163.6)

40 lb (18.1)

16.1 x 10.5 x 4.91 in (408.9 x 266.7 x 124.8)

10.1 lb (4.6)

13.75 x 11.05 x 4.36 in (349.3 x 280.7 x 110.7)

11.7 lb (5.3)

7.5 x 15.75 in (190.5 x 400)

26.3 lb (11.9)

99.13 in2 (639.5)

MKR 371:

Dimensions H x W x D (millimeters)

Weight (kilograms)

PHD 516 Photodiode:

Dimensions H x W x D (millimeters) 4.27 x 2.02 x 1.31 in (108.4 x 51.3 x 33.3)

9.0 x 2.75 x 2.13 in (228.6 x 69.9 x 54.1)

1.6 lb (0.7)

2 Revision 19 – 05/23/2018 FTS 370d/w/r

Table 1-2 – Performance Specifications

Parameter Lighting Type

FAA

CAR 621

L-864/L-865

CL-864/CL-865

L-866/ L-885

CL-866/ CL-885

Flash Intensity (ECD ± 25%):

White Day 20,000 20,000 20,000 min. Red Night 2,000 2,000 2,000 White Night 2,000 2,000 2,000 4,000 nom.

Flash Rate (flashes per minute):

White Day 40 60 20/30/40 Red Night 20/30/40 60 20/30/40/Stdy

White Night 40 60 20/30/40 40

Primary Power

120V - 240V AC, 50/60 Hz (3A - 1.5A Peak)

+/- 24 V DC (20–30 V) (16A Peak)

+/- 48 V DC (40-60 V) (8A Peak)

Power Consumption3 (Watts ±5%)

White Day 65

Red Night 35

White Night 35

Environmental

Complies with FAA specifications in AC 150/5345-43H

55

35

35

80

60

40

40

40

40

for continuous operation which includes the following:

Temperature

Storage/shipping: -67° to 130° F / -55° to 55° C

Operating: -40° to 130° F / -40° to 55° C

Humidity

95% relative humidity

ICAO

Type A/B

Type A/C

2

80

35

2

55

40 45

4K White

Night

-

Flashhead cable

6-375 ft.

6-600 ft.

6-850 ft.

PN 4210000, 10 AWG

PN 4370000, 8 AWG

PN 4206000, 6 AWG

Notes:

1. For 60 fpm, enable Catenary, Middle

2. ICAO Type C, Steady on.

3. Power measurements are for IR and non-IR Flashheads.

FTS 370d/w/r Revision 19 – 05/23/2018 3

SC 370

Operation Overview

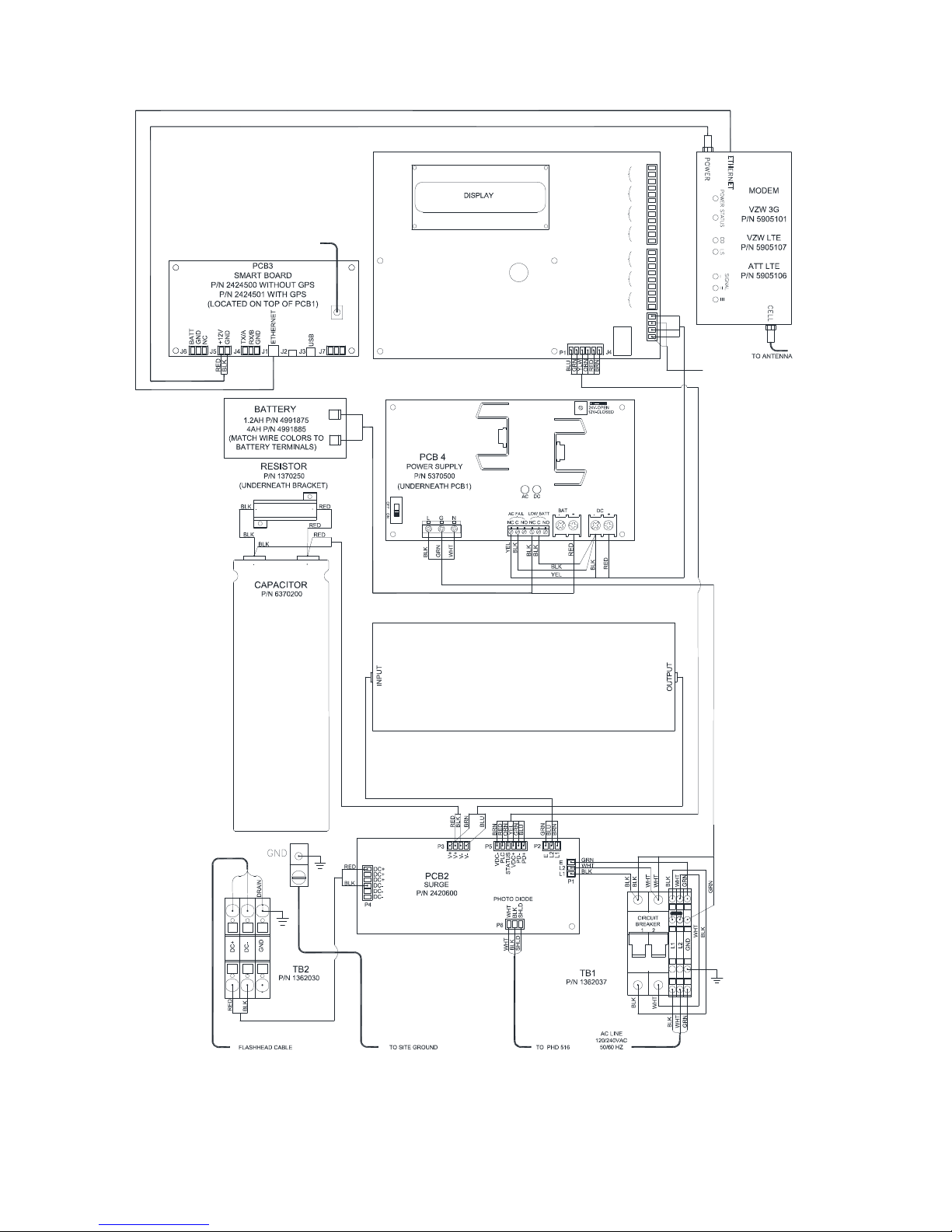

An internal view of the SC 370 is shown in

Figure 1-1. Component layout diagrams

with part names and numbers are shown in

Figures 6-1 (AC) and 6-2 (DC). Internal

wiring diagrams are shown in Figures 2-24

– 2-28 (AC) and 2-29 – 2-31 (DC).

Input power is connected to terminal block

TB1. Mounted on TB1 is a Metal Oxide

Varistor (VR1) which reduces line surges

and transients. Input power Circuit

Breakers are also mounted on TB1.

Disconnect power from the SC 370 before

servicing Circuit Breakers or MOV.

Flag Indicator on the 2-pole Circuit

Breakers is clearly marked with green OFF

and red ON.

The power supplies located in each SC 370

unit convert input power to the correct DC

operating voltages for the system. (Shown

with single power supply below).

The control PCB (PCB1) supervises system

operation. A User Interface with

alphanumeric display and pushbuttons

provides system configuration and alarm

notification.

Note: Shown with Modem and Wi-Fi options.

4 Revision 19 – 05/23/2018 FTS 370d/w/r

Figure 1-1 – SC 370 (AC)

Interface

Override

Connections

PCB1 Controller Board

PCB1 controls and monitors operation of

the SC 370 and its associated flashhead.

Each section of PCB1, outlined in the photo

Status &

Alarm LEDs

OLED

Display

below, is discussed in the following

subheadings.

Manual

Control

Alarm

Interface

& Mode

Indicator

PCB 3

(Optional)

Figure 1-2 – PCB1 Controller Board

Important! Do not install or remove

wires from terminal blocks or PCB’s until

DC voltage indicator on PCB2 has been

extinguished. This applies especially to

connection at PCB1 P1. If it is necessary

to remove connection or make other

wiring adjustments, power the system

down and wait until the LED on PCB2 is

off.

P1 Photodiode

& PLC Input

(See Important

Note Below)

PCB1 P1

Auxiliary Input

& PCB Input

Power

J4 RS 485

Communication

Cable Connection

FTS 370d/w/r Revision 19 – 05/23/2018 5

PCB1 Information Display and User Interface

A multi-line OLED (Organic LightEmitting Diode) display provides system

status, alarm and programming

information. Three pushbuttons located to

the immediate right of the display provide

the user interface for the system. The top

and bottom buttons move the cursor

position (*) up and down on the display.

The center button selects the action at the

cursor position. The information display

defaults to show the current system status

as well as the basic configuration for the

unit. See Section 3 for a detailed

description for all menu functions of the

information display. See Table 3-3 for a

complete list of alarms provided by the

information display.

Figure 1-3 – Information Display and User Interface

Manual Override

The Manual Mode switch

provides temporary

control of the system’s

operating mode. When

the manual mode switch

of the unit is moved to

either MAN DAY or

MAN NIGHT, the display reads “M-DAY”

or “M-NIGHT” respectively and the

corresponding Mode LED blinks. Manual

mode expires 30 minutes after initiating the

mode override. Each change to the manual

mode switch restarts the 30 minute timer.

The Manual Mode switch must be moved

after power up to activate mode override.

The switch has no effect if it is set to Day

or Night before power up.

Status and Alarm LEDs

Twelve Status and Alarm LEDs are

provided for immediate visual reference of

the current status of the unit. Table 1-3

describes the function of each LED.

6 Revision 19 – 05/23/2018 FTS 370d/w/r

Table 1-3 – Status & Alarm LEDs

LED Indication

Red to indicate one or more of the following conditions:

DAY ALARM

NIGHT ALARM

MARKER ALARM

PHOTODIODE

COMM ALARM

GPS SYNC

DAY MODE

RED NIGHT

WHITE NIGHT

1. The connected beacon is experiencing a failure in Day mode.

2. The beacon is not communicating with the SC 370. The Day Alarm will

be accompanied by the Night Alarm and the Comm. Alarm in this instance.

Red to indicate one or more of the following conditions:

1. The connected beacon is experiencing a failure in Night mode.

2. The beacon is not communicating with the SC 370. The Night Alarm

will be accompanied by the Day Alarm and the Comm. Alarm in this

instance.

3. Beacon IR failure. Activation of Night Alarm due to IR failure requires

that “IR Enable” and “IR Alarm Is Night Alarm” are set to “Yes”. See

Section 3 “Site Tower Config.” for additional information.

Red to indicate one or more of the following conditions:

1. One or more L-810 markers have failed.(FTS 370d L-864/865 only)

2. The marker interface board is not communicating with the SC 370 *.

* The Marker Alarm will be accompanied by the Comm. Alarm in this

instance.

Red when more than 19 hours have passed since the system has

changed modes via the photodiode input.

Red to indicate a communications failure in one or more of the following

conditions:

1. One or more connected units (Systems 2 – 6) are not communicating

with System 1.

2. The connected beacon is not communicating with the SC 370. The

Comm. Alarm will be accompanied by the Day Alarm and Night Alarm.

3. The connected marker tier is not communicating with the SC 370. The

Comm. Alarm will be accompanied by the Marker Alarm.

More than one hour has passed since the unit received a GPS Sync.

pulse.

Green continuous when unit is in DAY mode, blinking when the unit is in

manual DAY mode.

Green continuous when unit is in RED NIGHT mode, blinking when the

unit is in manual RED NIGHT mode.

Green continuous when unit is in WHITE NIGHT mode, blinking when the

unit is in manual WHITE NIGHT mode.

485 TX Red blinking when the unit is sending data to other units in the system.

485 RX Red blinking when the unit is receiving data from other units in the system.

FLASH

Note: See Table 3-3 for a complete list of alarms provided by the information display.

Active only if GPS is enabled. Blinks approximately once per minute when

SAT lock is achieved.

FTS 370d/w/r Revision 19 – 05/23/2018 7

Table 1-4 – Multitech Modem LEDs

LED Indication

POWER On Solid: The modem is properly powered

STATUS On Solid: Modem is starting up or saving its configuration.

Blinking: Modem initialization is complete and ready for use

CD On Solid: A data connection has been established. ON during normal

operation

LS ATT Modem:

On Solid: Not registered on the

network

Slow Blinking: Registered and

connected to the network

SIGNAL 1 Bar: Very weak signal

2 Bars: Weak Signal

3 Bars: Good Signal

Verizon Modem:

Fast Blinking: Not registered on the

network or is searching for connection

Slow Blinking: Registered and connected

to the network

On Solid: Modem is transmitting or

receiving

8 Revision 19 – 05/23/2018 FTS 370d/w/r

Alarm Interface & Mode Indicator Connections

P3

P4

Dry contact alarm connections, located on

PCB 1, are available regardless of any

additional monitoring method used. The

available dry contact alarm outputs are

listed in Table 1-5 and shown in Figure 1-

4. Each contact may be wired as normally

open or normally closed. The contacts are

labeled to indicate their state with the

system powered on without an alarm

present.

Mode indicator contacts are available on P4

terminals 10 – 12. When powered on, an

open contact between COM and NO

indicates the system is operating in Night

mode and a closed contact indicates the

system is operating in Day mode. An open

contact between COM and NC indicates the

system is operating in Day mode and a

closed contact indicates the system is

operating in Night mode. The mode

indicator contacts do not differentiate

between manual and automatic operation as

determined by the Manual Mode Switch.

Figure 1-4 – Alarm Interface & Mode Indicator Connections

Table 1-5 – Alarm Interface & Mode Indicator Connections

Connector Alarm Terminal Function

P3

P3

P3

P4

P4

P4

P4 Mode

Day

Alarm

Night

Alarm

Marker

Alarm

PhotoDiode

Alarm

GPS

Sync.

Alarm

Comm.

Alarm

COM (1)

NO (2)

NC (3)

COM (4)

NO (5)

NC (6)

COM (7)

NO (8)

NC (9)

COM (1)

NO (2)

NC (3)

COM (4)

NO (5)

NC (6)

COM (7)

NO (8)

NC (9)

COM (10)

NO (11)

NC (12)

Common

Closes to indicate an alarm in day mode.

Opens to indicate an alarm in day mode.

Common

Closes to indicate an alarm in night mode.

Opens to indicate an alarm in night mode.

Common

Closes to indicate a marker alarm.

Opens to indicate a marker alarm.

Common

Closes to indicate a photodiode alarm.

Opens to indicate a photodiode alarm.

Common

Closes to indicate a Sync Alarm.

Opens to indicate a Sync Alarm.

Common

Closes to indicate a Comm. failure.

Opens to indicate a Comm. failure.

Common

Open indicates Night mode. Closed indicates Day mode.

Open indicates Day mode. Closed indicates Night mode.

FTS 370d/w/r Revision 19 – 05/23/2018 9

P2 Auxiliary Input

The Auxiliary Input (previously labeled

LOW BAT) allows an external device, such

as a radar system, to inhibit the output of

the beacon. Control via the Auxiliary Input

is limited to systems consisting of a single SC

370 power and control unit. Control is

supplied by a dry contact from the external

device connected to “Aux In” (P2 terminal

3) and “DC –” (P2 terminal 1). The fail-safe

design requires a closed contact to inhibit

the output of the beacon.

Any unused dry contact may be reassigned

to provide confirmation that the system is

operating normally while the beacon output

is inhibited. See Figure 1-4 and Table 1-5

for available dry contacts.

J4 Communication Cable Connection

FTS 370 systems

consisting of more than

one SC 370 unit require

connection of a

communication cable

between units. J4,

located on the lower

right of PCB1, provides

connection for two RJ 45

connectors. The double RJ 45 connector

allows the communication cables to be

daisy chained from System 1 to each

subordinate unit. Either port may be

utilized as an input to or output from PCB

1. See “Communication Cable Kit” in

Section 2 for additional connection and

cable routing information.

Auxiliary Input configuration

programming is located in the “Site Tower

Configuration” menu of the controller

programmed as System 1. See Section 3 for

additional information regarding this

feature.

Note: Firmware 2.9 or above is required for

Auxiliary Input Control. The beacon output

may also be controlled by Modbus. See

Section 3 and Technical Bulletin “SC 370

SMART Modbus interface” (part number

7904502) for additional information.

10 Revision 19 – 05/23/2018 FTS 370d/w/r

PCB3 Smart Board

The optional PCB3 “Smart Board” (PN

2424500) is installed on top of PCB1 of the

SC 370 programmed as System 1. It

provides an interface to the following

advanced monitoring capabilities not

available on the standard system: Cellular

Eagle 2.0, RS 485 Modbus RTU, Ethernet

SNMP, Ethernet Eagle 2.0 and Ethernet

Modbus. The GPS enabled Smart Board

(PN 2424501), shown in Figure 1-5,

provides the same capabilities as the

standard Smart Board with the addition of

GPS synchronization. Either Smart Board

is required for the optional cellular modem

and/or Wi-Fi interface. The GPS enabled

Smart Board is strongly recommended for

Catenary systems.

GPS Sync. Kit

The FTS 370 system can be ordered with

GPS Synchronization factory installed. It is

also available as an upgrade for existing

FTS 370 systems. The kit (PN 1370185)

includes instructions and all components

necessary for installation. Antenna

installation instructions are provided in

Section 2 “GPS Antenna” for systems

ordered with GPS Sync factory installed.

Two LEDs: Antenna Open and Antenna

Short, provide status of the GPS antenna.

The Ant. Open will be lit if the GPS

antenna is not connected or is not properly

connected to the antenna connector. It will

also indicate a broken or damaged wire to

the antenna. The Ant. Short will be lit if the

antenna cable is shorted. Neither LED

should be lit in if the antenna is functioning

correctly.

USB Port

The USB port provides access to update the

system’s firmware and to interface with an

optional USB Wi-Fi adaptor. See Section 3

USB Firmware Update for additional

information regarding this feature.

GPS Antenna

Ethernet

Connection

Status LEDs

USB

Port

GPS Synchronization

(PN 2425401 Only)

GPS Antenna

Connector

FTS 370d/w/r Revision 19 – 05/23/2018 11

Figure 1-5 – PCB 3 with GPS

PCB2 Surge Board

to TB2

The PCB2 “Surge Board” (AC PN

2420600, DC PN 2420601) is installed in

the bottom of the SC 370. PCB2 has

multistage surge protection which

provides protection to the controller from

negative and positive strikes.

The Photodiode connection is at connector

P6 on the PCB2 surge board. This

connection is polarity sensitive, so it is

critical to verify wiring is as shown in

Figures 2-24 to 2-31. The board also has

screen printed labels in white text to assist

with installation.

The surge board shown in Figure 1-6 has a

Power LED. The LED will illuminate

indicating the system is operating with full

DC Voltage output (60VDC). Once AC

power is removed from the system the

LED will turn off after approx. 5-10

seconds to indicate a full voltage

discharge. It is important to verify the

output voltage is fully depleted before

replacing any circuit boards or reterminating any wires inside the system

controller as damage could occur if

voltage is still present.

60VDC Output

60VDC Input from

Power Supply(s)

If a replacement is necessary complete the

following steps:

1. Remove AC power by turning off the

breaker.

2. Verify TB2 voltage is below 5VDC.

3. Remove all green Phoenix connectors.

4. Remove the (4) mounting screws on the

outer corners of the board.

5. Install the replacement in reverse order.

Wire Harness

Connects to PCB1

ACV Output to

Power Supply(s)

Power LED

Figure 1-6 – PCB2 Surge Board (PN 2420600 or 2420601)

(This is a direct replacement for PN 2420500 or PN 2420501)

12 Revision 19 – 05/23/2018 FTS 370d/w/r

Photodiode

Input

ACV Input

from TB1

FH 370d/w/r

FH 370d/w/r, shown in Figure 1-7, is

divided into two sections: light engine, and

base assembly. The light engine is

comprised of highly efficient LEDs which

are focused by Fresnel optics to produce the

required output per FAA specifications for

the following types: L-864/865 (dual),

L865 (white), L-866/885 (dual Catenary),

L-885 (white Catenary) or L-866 (red

Catenary) beacons. ICAO, CAR621 and

4000 Candela Red Night versions are also

available.1 In the event service is required,

the light engine is field replaceable as a

single assembly. The base assembly

contains a terminal block for connection of

the flashhead cable and a surge protection

PCB that is placed in line between the

output of the terminal block and input to the

light engine.

FH 370d IR1 (Infrared) is visually identical

to Figure 1-7. It incorporates all features of

the FH 370d and adds 12 infrared LEDs.

The addition of IR ensures visibility of the

obstruction to pilots aided by NVG (night

vision goggles). The combination of

standard Red (620nm) LEDs and IR

(850nm) LEDs ensures maximum visibility

to pilots in all circumstances.

1. The application type must be specified when

ordering a flashhead or replacement light engine.

Figure 1-7 – FH 370d/w/r

FTS 370d/w/r Revision 19 – 05/23/2018 13

Marker Interface Enclosure

J1 & J2

J3 & J4

LEDs

Status LEDs

(SC 370d - L-864/865 only)

Operation Overview

The Marker Interface Enclosure mounting

diagram is shown in Figure 2-15 (Stainless

Steel option shown in Figure 2-16) and the

wiring diagram is shown in Figure 2-32.

Operational power for the Marker Interface

PCB and connected L-810 markers is

supplied by the flashhead cable. TB1,

located in the marker interface enclosure,

provides a splice point for the flashhead

cable which then continues to its

Marker Outputs

termination point at the flashhead. Marker

connections are provided at terminals J1 –

J4 located on the Marker Interface PCB.

Marker programming, control and status

are accessed through the User Interface

located on PCB 1 of the SC 370d. Power

Line Communication over the flashhead

cable is utilized as the communications link

between the SC 370d and the Marker

Interface PCB. LEDs located on the Marker

Interface PCB provide operational status

during service.

Marker Alarm

Marker Outputs

Operational Voltage

Status LEDs

14 Revision 19 – 05/23/2018 FTS 370d/w/r

Input Power

(From TB1)

Communication

Figure 1-8 – Marker Interface PCB

Power Line

MKR 371

(SC 370d L-864/865 only)

MKR 371 DC, shown in Figure 1-9, is a

24V DC LED L-810 marker. The

innovative design combines three highly

efficient LED’s and Fresnel optics into a

compact cast aluminum base which is easy

to install; requiring minimal hardware.

MKR 371 DC IR (Infrared), which is

visually identical to MKR 371 DC, adds

three IR LEDs. The addition of IR ensures

visibility of the obstruction to pilots aided

by NVG. The combination of standard

Red (620nm) LEDs and IR (850nm) LEDs

ensures maximum visibility to pilots in all

circumstances.

Operational power is supplied by the

Marker Interface Enclosure discussed in

the previous heading. A mounting diagram

for the MKR 371 is provided in Figure 2-

14. Complete installation diagrams and

instructions are provided with the marker

kit.

Note: Refer to “Vanguard® Marker Installation” (Part # 7904214) for specific information

regarding cable connection to the MKR 371.

FTS 370d/w/r Revision 19 – 05/23/2018 15

Figure 1-9 – MKR 371

Section 2 – Mounting and Installation

Unpacking

Inspect shipping cartons for signs of damage

before opening. Check package contents

against the packing list and inspect each item

for visible damage. Report damage claims

promptly to the freight handler.

Note: Record equipment serial numbers

for future reference.

Recommended Tools

Flash Technology recommends the following

tools for installation and maintenance:

• Single Beacon Installation kit.

(Part # F1370990)

o Double-eye support grip

o Small slot screwdriver

o “T” level

• 1/8” non-flared flat blade screw driver

• 9 or 12 inch, flat blade #2 screwdriver

• #2 Phillips® head screwdriver

• Set of combination wrenches

• Assorted nut driver handles: 1/4”,

5/16”, 3/8” recommended

• Long-nose pliers

• Wire Strippers

• Digital volt-ohm meter

• Level

• Cable Ties

• Tin Snips

• Camera (for documentation)

Controller Installation

WARNING!

Read the warning on Page ii now. Disconnect

primary power before opening enclosures.

Verify the Installation

Upon completion of the system installation,

verify that the Information Display, located

on PCB1, shows the correct configuration for

System 1 and each subordinate unit installed

in the system. See Section 3 for a detailed

description of the menu and all functions of

the information display.

SC 370 Access

The cover is hinged and secured with knobs

that rotate (clockwise) to latch. Rotate the

knobs counterclockwise and swing the cover

open for internal access.

Note: The stainless steel enclosure is

secured with latches.

Mounting

The SC370 enclosure mounting outline and

dimensions are shown in Figure 2-9

(Stainless Steel option shown in Figure 2-10).

Mounting hardware is not provided unless it

is ordered as part of an installation kit. Use

the following guidelines for mounting the SC

370:

• Ensure that adequate space exists around

the equipment for access during

installation, maintenance and servicing.

• Allow space for airflow around the

controller (approximately 8” separation

between enclosures).

Mounting Adapter Panel (Optional)

The optional Mounting Adapter Panel,

shown in Figure 2-11, allows for easier

installation of the FTS 370d/w/r system by

removing the need for modifying the existing

outdoor H-Frame when upgrading from

previously installed Flash Technology

products. The H-Frame may require

adjustment when upgrading from non-Flash

Technology lighting products if the adapter

panels are requested. Please contact the Flash

Technology parts department at 1-800-8215825 if this option is desired.

16 Revision 19 – 05/23/2018 FTS 370d/w/r

Wiring

Typical E1/D1 & E2/D2 component location

diagrams are shown in Figures 2-17 and 2-18.

A D1/D2 system wiring diagram is shown in

Figure 2-21 and an E1/E2 wiring diagram is

shown in Figure 2-22. A typical Catenary

component location diagram is shown in

Figure 2-20 with a wiring diagram shown in

Figure 2-23. Installation notes for system

types shown in Figures 2-21 - 2-23 are

located after each figure. Installation

instructions concerning MKR 371 L-810

marker fixtures are supplied with the marker

kit. The system installation diagrams

provided in this manual may not contain all

of the required wiring information for

installation at your site.

Important! If installation drawings

prepared specifically for your site disagree

with information provided in this manual,

the site installation drawings should take

precedence. Consult any site-specific

installation wiring diagrams supplied with

your equipment.

Flash Technology wiring diagrams define

only minimum requirements

recommended for satisfactory equipment

operation. It is the responsibility of the

installer to comply with all applicable

electrical codes.

All communication wiring should have an

insulation rating of 300 volts minimum. All

power wiring should have an insulation

rating of 600 volts. Input power wiring must

be sized to satisfy the load demand of all

connected SC 370 systems. Read the notes on

the installation wiring diagrams supplied

both in this manual and with the equipment.

Input Power

Input power conductor size depends on the

service voltage, distance from the source and

the number of units installed in the system.

Assume 340 VA per SC 370 in the

system. Connect the input power to L1, L2

(AC units) or +, - (DC units) and Ground

terminals of TB1 located in the lower right of

the cabinet.

Important! For proper operation and

optimal protection from Lighting and EMI,

ensure that Earth Ground is wired to the

Ground (Green) Terminal.

Photodiode Wiring

The photodiode must be connected to the SC

370 designated as System 1. The photodiode

connections are located on PCB2 at terminal

block P6. The white wire is connected to the

terminal marked “WHT”, the black wire is

connected to the terminal marked “BLK”,

and the drain wire is connected to the

terminal marked “SHLD”. Only one

photodiode is required per system. It may be

located any practical distance from System 1.

The standard photodiode (Part # 1855516) is

supplied with 20’ of cable. Photodiodes with

cable lengths up to 75’ are available. Also,

the cable may be spliced to provide additional

length.

Photodiode Mounting

The photodiode, also referred to as PHD 516,

is shown in Figure 2-1 and mounting and

outline dimensions are shown in Figure 2-12.

The photodiode uses a female 1/2” NPT for

mounting. Use the following guidelines to

mount the photodiode:

• Locate the photodiode where it has an

unobstructed view of the polar sky.

• It must not view direct or reflected

artificial light.

• The photodiode may be mounted at the

top end of a vertical length of rigid

conduit or to the optional Antenna

Mounting Bracket kit (P/N 1905355). It

should not be mounted underneath the

controller where it could be shadowed.

• Ensure that the installation is watertight.

FTS 370d/w/r Revision 19 – 05/23/2018 17

Note: See Cellular Antenna and GPS

Antenna for additional information

regarding the Antenna Mounting Bracket

Kit.

Cellular Antenna

A Cellular antenna is required with either of

the optional cellular modems shown in

Figure 2-1. The supplied antenna mounting

bracket accommodates bulkhead mount style

antenna as shown in Figure 2-2. Figure 2-1

shows the bulkhead mount style antenna

installed with the photodiode and GPS

antennas. The antenna connects directly to

the modem as shown in Figures 2-26 and 2-

31. Follow the method below to install the

antenna.

The system is shipped with the antenna

preinstalled and the antenna cable’s SMA

connector torqued to specification onto the

modem’s antenna connector for optimal

performance; do not remove or disconnect

unless replacing the modem or antenna.

Important! For best communication

performance and to minimize potential for

surge damage to the modem radio module,

it is very important that the supplied

antenna mounting bracket be used for

mounting the antenna and that the bracket

be grounded with a minimum 14 AWG

Ground wire connected to the site

Grounding System. Also, if any excess

antenna cable is coiled up, the coil

diameter must not be less than 18 inches.

Maximum torque for the antenna’s SMA

connector must not exceed 8 inch-pounds

(90 N-cm) using a 5/16’” torque wrench.

Damage to the modem may occur if the

connection is over tightened.

Choose a location for mounting the cellular

antenna that will provide optimal reception.

The included mounting bracket can

simultaneously accommodate a Vanguard

Photodiode, Cellular Antenna, and GPS

Antenna as shown in Figure 2-1.

Note: The antenna must be mounted

outdoors to ensure optimal reception. See

“Photodiode Mounting” and “GPS

Antenna” for additional considerations

when selecting a mounting location for the

Antenna Mounting Bracket.

1. Mount the Antenna Mounting Bracket

using one of the following methods:

a. Wall Mount: Use screws (not

included) to mount to the outside wall

of a shelter.

b. Horizontal Unistrut Mount: Use

spring-nuts (not included) to mount to

unistrut.

Vertical Pole or H-frame post Mount:

Use 3” U-bolt (included) to mount to

pole or H-frame post. The bracket

permits use of larger U-bolts, up to

5”.

Important! Regardless of the mounting

method selected, the antenna bracket

must be grounded with a minimum 14

AWG Ground wire connected to the site

Grounding System. Observe proper

Grounding procedures.

2. The cellular antenna must be mounted at

the center of the bracket as shown in

Figures 2-1 and 2-2. Follow the location

recommendations noted in “Photodiode

Mounting” and “GPS Antenna” if it is

installed along with the photodiode

and/or GPS antenna.

3. To install the bulkhead mount style

antenna, loosen the antenna mounting nut

and washer and slide the antenna mount

through the bracket’s center slot. Tighten

the hardware.

4. Secure the antenna cable to the mounting

structure using cable ties.

5. Coil up any unused antenna cable inside

the SC 370 enclosure. The diameter of

the coil should be as large as possible.

6. Tighten the cable strain relief on the

bottom of the SC 370 enclosure securely.

18 Revision 19 – 05/23/2018 FTS 370d/w/r

GPS Antenna

The GPS antenna, shown in Figure 2-1, is

required with the GPS enabled PCB3 Smart

Board shown in Figure 1-5. Follow the

method below to install the GPS antenna.

Important! The GPS antenna must be

mounted outdoors with an unobstructed

view of the sky.

1. For best reception and synchronization,

choose a location for mounting the GPS

antenna with an unobstructed view of the

sky. The included mounting bracket can

simultaneously accommodate a

Vanguard Photodiode, Cellular Antenna,

and GPS Antenna (see Figure 2-1).

Note: See “Photodiode Mounting” and

“Cellular Antenna” for additional

considerations when selecting a mounting

location for the Antenna Mounting Bracket.

2. Mount the Antenna Mounting Bracket

using one of the following methods:

a. Wall Mount: Use screws (not

included) to mount to the outside wall

of a shelter.

b. Horizontal Unistrut Mount: Use

spring-nuts (not included) to mount to

unistrut.

c. Vertical Pole or H-frame post Mount:

Use 3” U-bolt (included) to mount to

pole or H-frame post. The bracket

permits use of larger U-bolts, up to

5”.

Important! Regardless of the mounting

method selected, the antenna bracket

must be grounded with a minimum 14

AWG Ground wire connected to the site

Grounding System. Observe proper

Grounding procedures.

3. Mount the GPS antenna onto the

mounting bracket using its large

mounting nut.

4. Connect the antenna cable connector to

the GPS antenna.

5. Secure the antenna cable to the mounting

structure using cable ties.

6. Coil up any unused antenna cable inside

the SC 370 enclosure. The diameter of the

coil should be as large as possible.

7. Tighten the cable strain relief on the

bottom the of SC 370 enclosure securely.

8. Verify that neither LED: Ant. Open or

Ant. Short, shown in Figure 1-5, are lit

once system power is restored. See

Section 1 GPS Sync. Kit for additional

information regarding the Ant. Open and

Ant. Short LEDs.

FTS 370d/w/r Revision 19 – 05/23/2018 19

frame post.

PHD 516

Cellular

Antenna

GPS

Antenna

Figure 2-1 – Antenna Mounting Bracket with PHD 516, Cellular and GPS Antennas

Wall Mount

Use screws to mount to the in-

side or outside wall of a shel-

ter.

(Screws are not included in

the kit.)

Horizontal Uni-strut Mount

Use spring-nuts to mount to

Uni-strut.

(Spring-nuts are not included

in the kit.)

Vertical Pole or H-frame post

Mount

Use 3” U-bolt (included) to

mount to pole or H-

The bracket permits use of

larger U-bolts, up to 5”.

Figure 2-2 – Antenna Mounting Options

20 Revision 19 – 05/23/2018 FTS 370d/w/r

Communication Cable Kit

A CAT 5 cable provides the RS 485

communications link between the SC 370

designated as System 1 and all subordinate

units installed in the system. Two

connections at J4 on PCB1 allow multiple

units to be daisy chained together. Either

port may be utilized as an input to or output

from PCB 1.

The required number of Communication

Cable Kits (P/N 4362039) is supplied with

each complete SC 370 system. Each kit

consists of a cable and two strain relief

connectors with inserts for the cable. One

strain relief is to be installed in System 1

and the other in System 2. Follow the

method below for routing the cable if

flexible conduit is not utilized for the

installation.

1. Install the ¾” cable strain relief on the

enclosure.

2. Install the connector insert over the

cable with tapered end facing away

from the connector.

3. Push the connector through the housing

from outside the enclosure.

4. Push the cable insert into the strain

relief housing.

5. Plug the cable into PCB1 and position

the cable, providing a small amount of

slack inside the cabinet to reduce stress

on the connector. Coil excess cable

equally between enclosures. Do not cut

and splice to remove excess cable.

6. Tighten the strain relief connector

dome nut.

7. Repeat steps 1-7 to connect additional

SC 370 units (3-6).

Wi-Fi Option Antenna Installation

All internal components of the optional WiFi access point are factory installed. The

antenna must be installed after the SC 370

is mounted. The following instructions are

provided to mount the antenna to the SC

370 enclosure using the supplied hardware

kit. Figure 2-3 provides a pictorial of the

installation. Connection to the Wi-Fi access

point is discussed in Section 4.

1. Locate the following items supplied

with the SC 370 system:

d. Wi-Fi Antenna (P/N 5905131)

e. Shielded CAT 5 Cable 6’

(P/N 4362028)

f. Antenna Mounting Kit (P/N

1370191)

o Conduit Hub with lock ring

o Conduit Nipple 0.75” x 12”

o Coupling

o Cable Strain Relief

o Custom Insert (Cable Strain Relief)

o (2) Adjustable Clamp 1 1/16” – 2”

2. Attach the conduit hub to one end of the

12” nipple and the coupling to the other

end.

3. Screw the strain relief into the coupling.

4. Locate and remove the access cover

from the back of the Wi-Fi antenna.

Remove the knockout that is located

below the ground terminal.

5. Center the Wi-Fi antenna on the conduit

assembly and attach using the two

adjustable clamps. The top of the Wi-Fi

antenna must be located nearest the

conduit hub.

6. Locate an available 0.88” hole on the

SC 370C unit and install the antenna

assembly. See Figure 2-9 for the SC

370 hole configuration.

7. Connect the CAT 5 cable to the RJ 45

connector located on the Wi-Fi antenna.

Route the other end of the CAT 5 cable

through the strain relief and into the SC

370. Leave a small drip loop between

the antenna and the conduit assembly.

8. Route the CAT 5 cable to the Power

Over Ethernet (POE) Injector and

connect to the terminal labeled “POE”.

9. Install a ground wire (8 AWG

recommended) from the antenna

ground terminal to the site ground.

10. Replace the access cover.

FTS 370d/w/r Revision 19 – 05/23/2018 21

SC 370c Enclosure

(P/N 4362028)

(8 AWG recommended)

(Bottom View)

Conduit Hub

(P/N 5991618)

Conduit Nipple ¾” x 12”

(P/N 5990290)

Adjustable Clamp 1 1/16” – 2” SS

(P/N 5990253)

Wi-Fi Antenna

(P/N 5905131)

Adjustable Clamp 1 1/16” – 2” SS

(P/N 5990253)

Conduit Coupling ¾”

(P/N 5991885)

Shielded

CAT 5 Cable

Cable Strain Relief ¾” NPT

(P/N 4900156) with Custom

Insert (P/N 5362009)

Remove to

Install GND wire

Install GND wire from

Antenna to Site GND

Figure 2-3 – Wi-Fi Antenna Installation

22 Revision 19 – 05/23/2018 FTS 370d/w/r

USB Wi-Fi (Optional)

Figure 2

-4 –

USB Wi

-FiInstallation

An optional USB Wi-Fi adapter can be

carried as a diagnostic tool and plugged

into the SC 370 while onsite and then

removed before leaving the site. The

adaptor should not be left onsite in the SC

370.

All SC 370 units operating with V3.1

Firmware or higher can interface with an

optional internal USB Wi-Fi adaptor.

Connection point is on PCB3 (shown in

Figure 2-4).

Must have PCB3 Smart Board (PN 2424500 or

2424501) to utilize this feature.

The USB Wi-Fi adaptor allows the ability

to program, troubleshoot, and view critical

information about the system without

interfacing with the main display screen.

All programming will be done via a web

page interface described in Section 4.

The adaptor can be purchased directly

from Flash Technology using PN

5905233.

FTS 370d/w/r Revision 19 – 05/23/2018 23

Dry Contact Alarm Outputs

Dry contact alarm outputs, located on

PCB1, are available regardless of any

additional monitoring method used. The

available dry contact alarm outputs are

listed in Table 1-5 and shown in Figure 1-

4. Each contact can be wired as normally

open or normally closed.

NOTE: The alarm relay contacts are

labeled to represent their state with the

unit powered on and with no alarms

present.

To ensure proper alarm monitoring,

Flash Technology recommends

monitoring contacts that are open in an

alarm condition.

Flashhead Cable

Flash Technology cable provides optimal

system performance while minimizing

vulnerability to Lightning and EMI

(Electromagnetic Interference).

The cable is comprised of two conductors

with an overall aluminized Mylar shield

and drain. The flashhead cable connects to

TB2 in the lower left of the SC 370 as

shown in Figure 2-5.

For shorter cable runs up to 375 ft.,

flashhead cable PN 4210000 (10 AWG)

can be used. This cable is lighter and

easier to work with than the larger gauge

cable required for longer runs, having

smaller conductors. Flashhead Cable PN

4370000 (8 AWG) permits cable lengths

up to 600 ft. Flashhead cable PN 4206000

(6 AWG) allows cable lengths of up to

850 ft.

3. Connect the three conductor flashhead

cable to terminal strip TB2 using a nonflared flat tip screwdriver:

a. Connect the red wire to the terminal

labeled DC+.

b. Connect the black wire to the

terminal labeled DC-.

c. Connect the bare drain wire to the

terminal labeled GND.

4. Leaving slack in the flashhead cable,

tighten the dome nut so that the cable is

held securely in place.

NOTE: Install a 5’ service loop in the

cable near the controller.

Figure 2-5 – SC 370 Flashhead

Cable Connection

Wiring Procedure

1. Prepare the flashhead cable:

a. Remove 6 inches of the outer

jacket.

b. Remove the exposed aluminized

Mylar shield and any filler material

between conductors.

2. Loosen the dome nut of the ¾” cable

strain relief located in the bottom of the

enclosure near TB2 and insert the cable.

24 Revision 19 – 05/23/2018 FTS 370d/w/r

Securing the Cable: 2-3-4 Tape Method

Flash Technology provides the material for

securing the flashhead cable to a skeletal

structure with the following technique.

Always adhere to local electrical codes that

could supersede this recommended

technique:

1. Run the cable along one of the tower

legs and wrap two full turns of two-inch

Scotchrap™ #50 tape, or the