8 Amp Micro Stepping

Pro Series CNC Controller

Hardware Guide

Midwest Office

444 Lake Cook Road, Suite 22

Deerfield, IL 60015

Phone (847) 940-9305 Fax (847) 940-9315

www.flashcutcnc.com

Revised 11/02/2010

© 1998-2010 WPI, Inc.

Table of Contents

1. GETTING STARTED ....................................................................................................................................... 6

ABOUT THIS MANUAL ................................................................................................................................................ 6

TURNING OFF THE CONTROLLER ............................................................................................................................... 6

SAFETY AND USAGE GUIDELINES ............................................................................................................................... 7

2. STEPPER CNC CONTROLLER ..................................................................................................................... 8

FRONT PANEL............................................................................................................................................................. 8

REAR PANEL .............................................................................................................................................................. 9

3. SYSTEM CONNECTIONS ............................................................................................................................ 13

4. REMOVING THE TOP COVER ................................................................................................................... 14

5. SIGNAL GENERATOR ................................................................................................................................. 15

INPUT ................................................................................................................................................................ ....... 15

OUTPUT .................................................................................................................................................................... 16

JUMPER SETTINGS .................................................................................................................................................... 17

JP83 – DB to USB Ground ................................................................................................................................ 18

JP84/JP85 – Input Power Select ........................................................................................................................ 18

JP 86 – USB to Chassis Ground ........................................................................................................................ 19

JP 87 – Internal Signal to Chassis Ground ...................................................................................... 20

INTERNAL CONNECTIONS ......................................................................................................................................... 20

JP30 – Auxiliary Inputs ..................................................................................................................................... 21

JP31 – Status LEDs ........................................................................................................................................... 21

JP32 – Bus Expansion ....................................................................................................................................... 22

JP33 – Step & Direction .................................................................................................................................... 22

JP40 – Input Aux Header ................................................................................................................................... 23

JP50 – Output Aux Header ................................................................................................................................ 23

JP80 – Rear Panel Power .................................................................................................................................. 24

JP81 – Rear Panel Fuse .................................................................................................................................... 24

JP82 – Front Panel Switch .......................................................................................................... 24

AXIS PLUG-IN INTERFACES ...................................................................................................................................... 24

6. DRIVE SETTINGS .......................................................................................................................................... 26

CONFIGURING THE DRIVES ....................................................................................................................................... 27

Selecting a Motor............................................................................................................................................... 27

Setting the Current ............................................................................................................................................. 29

Setting Idle Current ............................................................................................................................................ 29

Load

Inertia ........................................................................................................................................................ 30

Step Size ................................................................................................................................... 30

STEP PULSE NOISE FILTERING .................................................................................................................................. 32

SELF TEST ................................................................................................................................................................ 33

ALARM CODES ......................................................................................................................................................... 33

7. MOTOR SIGNAL SETTINGS ....................................................................................................................... 34

8. STEPPER MOTOR CABLING ..................................................................................................................... 35

MOTOR WIRING FOR OTHER STEPPER MOTORS ....................................................................................................... 35

9. POWER BOARD ............................................................................................................................................. 37

10. DRIVER MODULE UPGRADES .................................................................................................................. 39

11. APPENDIX ....................................................................................................................................................... 45

SAMPLE WIRING DIAGRAMS .................................................................................................................................... 45

Typical Output Line Circuit ............................................................................................................................... 45

Typical Input Line Circuit – Internal Power ...................................................................................................... 46

Typical Input Line Circuit – External Power ................................................................ ................................ ..... 47

Signal Generator Board Layout ......................................................................................................................... 49

Connector Pin-Out Table ............................................................................................................ 50

POWER ..................................................................................................................................................................... 52

OUTPUTS .................................................................................................................................................................. 53

INPUTS ..................................................................................................................................................................... 54

CONNECTORS ........................................................................................................................................................... 55

AXIS PLUG-IN INTERFACE ........................................................................................................................................ 56

12. INTERNAL CONNECTIONS ........................................................................................................................ 57

CONNECTION SCHEMATIC ........................................................................................................................................ 58

REVISION HISTORY .................................................................................................................................................... 1

6

1. Getting Started

Always turn off the CNC Controller when it is not in use.

About This Manual

FlashCut CNC is a unique application involving hardware and software. We

recommend that you read all of these instructions before using the product.

Since automated machining is potentially dangerous, please take

the time to completely read through this manual and the software

User’s Guide to understand the operation of the electronics,

software and machine before cutting a part.

FlashCut CNC Section 1 Getting Started

Turning Off The Controller

FlashCut CNC Section 1 Getting Started

7

When running an automated machine tool, safety is of the utmost

importance. For proper and safe use of the FlashCut CNC program and

your CNC machine, the following safety guidelines must be followed:

1. Never let the machine tool run unattended.

2. Require any person in the same room as a running machine tool to

wear safety goggles, and to stay a safe distance from the machine.

3. Allow only trained operators to run the machine tool. Any operator

must have:

Knowledge of machine tool operation.

Knowledge of personal computer operation.

Knowledge of Microsoft Windows.

Good common sense.

4. Place safety guards around the machine to prevent injury from flying

objects. It is highly recommended that you build a safety shield

around the entire tool envelope.

5. Never place any part of your body within the tool envelope while the

machine is online, since unexpected machine movement can occur at

any time.

6. Always keep the tool envelope tidy and free of any loose objects.

7. Be on alert for computer crashes at all times.

FlashCut CNC, Inc. is not responsible for the safe installation and use of

this product. You and only you are responsible for the safety of yourself

and others during the operation of your CNC machine tool. FlashCut CNC

supplies this product but has no control over how it is installed or used.

Always be careful!

FlashCut CNC, Inc. or its affiliates are not responsible for damage to any

equipment or workpiece resulting from use of this product.

If you do not understand and agree with all of the above safety guidelines,

do not use this product.

Safety and Usage Guidelines

FlashCut CNC Section 2 Stepper CNC Controller

8

2. Stepper CNC Controller

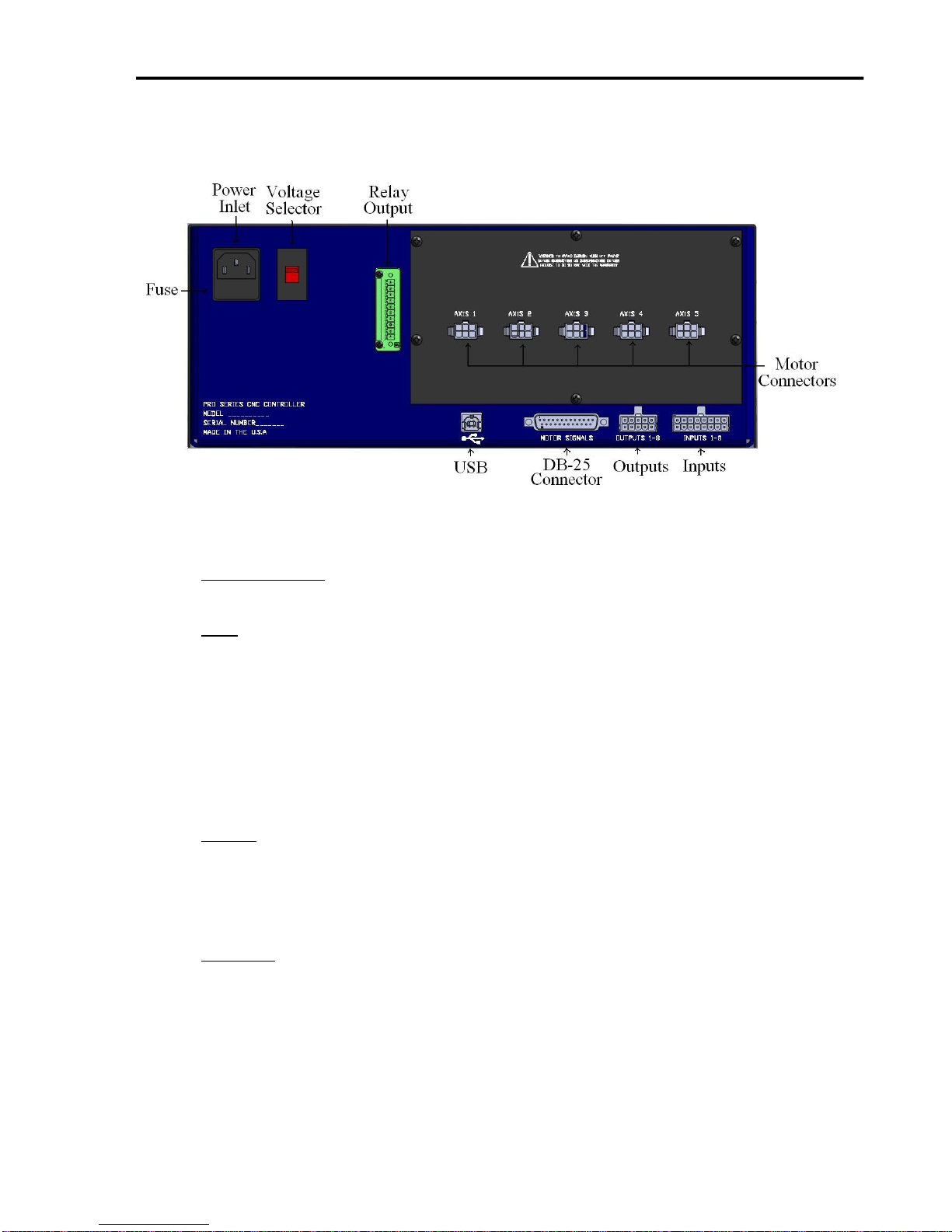

Front Panel

The front panel of the CNC controller has the power switch, the fan and 7 LED’s with the

following functions:

AXIS LED’s 1, 2, 3, 4, 5 – Turns green when the respective axis is moving.

USB LED– Turns yellow when connected to the host PC USB port.

POWER LED– Turns green when the power switch is turned on.

POWER SWITCH – Turns the unit on and off. “I” is on and “O” is off. If there is ever a

communications error while running FlashCut CNC, turn the switch off and on to reset

the internal microprocessor.

9

Rear Panel

The rear panel has connectors for input and output signals as described below.

FlashCut CNC Section 2 Stepper CNC Controller

POWER INLET – Receptacle for the power supply. The unit is shipped with a standard

grounded power cable for use with a 115VAC wall outlet.

USB – USB connector for communication with the USB port on the host PC. Use a USB-A

to B cable with a maximum length of 3 meters to make the connection. For the most robust

communication, plug the cable directly into PC, as opposed to a USB repeater or a hub. If

the FlashCut software loses communication with the Signal Generator, electrical noise may

be the cause. To reduce electrical noise problems, try using a shorter USB cable, or attach

one or more ferrite chokes to the USB cable. Toroid-shaped chokes are more effective than

snap-on cylindrical chokes. If you need more than 3m of USB cable length, you can use an

active extension cable which comes in 4.5m lengths. Note that when running an active

extension cable, the USB will run in Full Speed mode.

INPUT – The connector for up to 8 input lines. The most common use of the input lines

is for limit or safety switches. These lines are all TTL- and CMOS-compatible optically

isolated inputs. When a switch is open, its input signal is high (+5V). When the switch is

closed, its input signal is grounded low (0V). If you need more than 8 input lines, an I/O

extension board is available.

OUTPUT – The connector for up to 8 output lines. These lines are all compatible with

TTL/CMOS level outputs. The Output ports are not setup to drive a 24V external system

unless it accepts TTL/CMOS levels. They are all driven by HCT family logic. Output

logic high is normally 5V and can go down to 3.9V at full load. Output logic low is

normally 0V and can go up to 0.3V at full load. Each of these signals can provide up to

20mA of current. If you need more than 8 output lines, an I/O extension board is

available.

FlashCut CNC Section 2 Stepper CNC Controller

10

FUSE – In this drawer is a 250V/ 10Amp slow blow fuse. If you have chronic fuse

problems, please call FlashCut CNC or your distributor for assistance.

RELAY OUTPUT – This connector is a back compatible relay output. Connection

should be made in pins 7 and 8 of the 10 pin Phoenix terminal block. Output provides an

optically isolated switch closure for controlling both AC and DC devices. Max current

loading is 0.5 Amps for this non-polarity sensitive connection.

115-230 VAC SELECTION SWITCH– This switch allows you to use an external power

source of 115 or 230 VAC. If your building is wired for 230VAC, then simply flip the

switch with a flat-head screwdriver so that “230V” is clearly visible. If your building is

wired for 115 VAC, then flip the switch until “115V” is clearly visible. Note that severe

damage can occur if you have 115 selected and your building is wired for 230VAC.

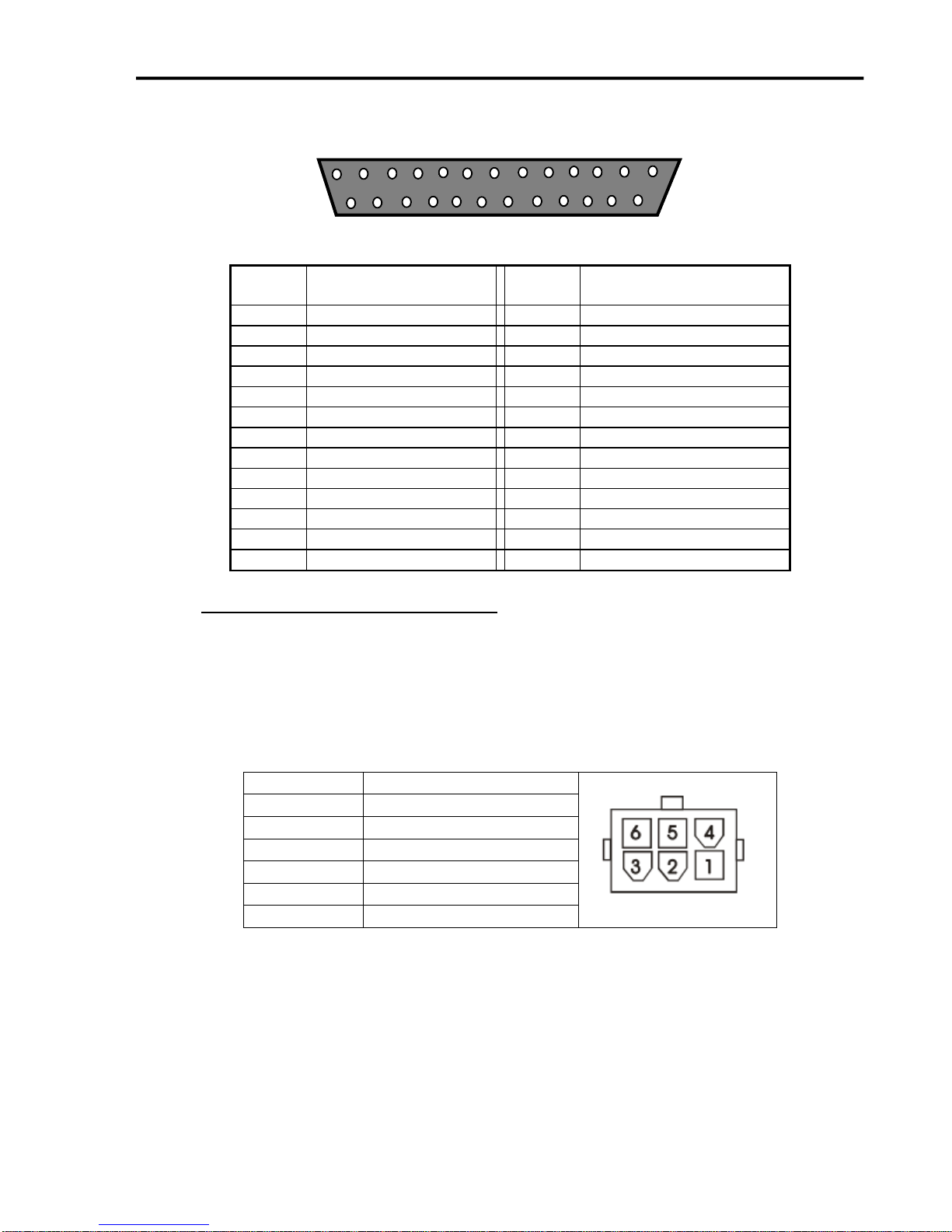

DB-25 CONNECTOR FOR MOTOR SIGNALS – This uses a DB-25 Cable to send step

and direction signals from the FlashCut CNC Signal Generator to an additional external

drive box. The pin assignments are as follows:

FlashCut CNC Section 2 Stepper CNC Controller

11

1

13

14

25

DB25

Pin No.

Signal

DB25

Pin No.

Signal

1

OUTPUT 1

14

ENABLE ALL

2

OUTPUT 2

15

INPUT 1

3

STEP AXIS 5

16

INPUT 2

4

DIRECTION AXIS 5

17

INPUT 3

5

INPUT 5

18

INPUT 4

6

INPUT 6

19

DIRECTION AXIS 4

7

INPUT 7

20

DIRECTION AXIS 3

8

INPUT 8

21

DIRECTION AXIS 2

9

DIRECTION AXIS 1

22

Internal VCC +5V

10

STEP AXIS 4

23

OPT VCC (INPUT)

11

STEP AXIS 3

24

Internal GND

12

STEP AXIS 2

25

OPT GND (INPUT)

13

STEP AXIS 1

Molex Pin

Wire

1 B 2

Cable Ground Shield

3 A 4

B~ 5 No Connection

6

A~

POWER CONNECTOR TO MOTORS – The motors for axes 1-5 plug into these

connectors. The motor lines 1-5 are correlated to any combination of the X, Y, Z, A

and/or B axes in the Motor Signal Setup menu in the FlashCut CNC software. A dummy

plug as installed on any unused motor connector for units with less than 5 axes. Each

motor connector is a Molex Mini Fit Jr. 6 Pin Receptacle with Male Pins (See Section on

Motor Cabling for Mating Connector Information). The pin assignments for the Motor

Connector are as follows (looking from the rear of the unit):

FlashCut CNC Section 2 Stepper CNC Controller

12

Never connect or disconnect motor cables while the power

is on. This will result in damage to the driver box.

The mating motor cable connector is a Molex - Waldom 6-Pin Mini-Fit Jr. Receptacle Housing

Part # 39-01-2060 with Female Pins Part # 39-00-0039 or 39-00-0047. Please see the section on

Stepper Motor Cabling later in this manual for more information.

FlashCut CNC Section 3 System Connections

13

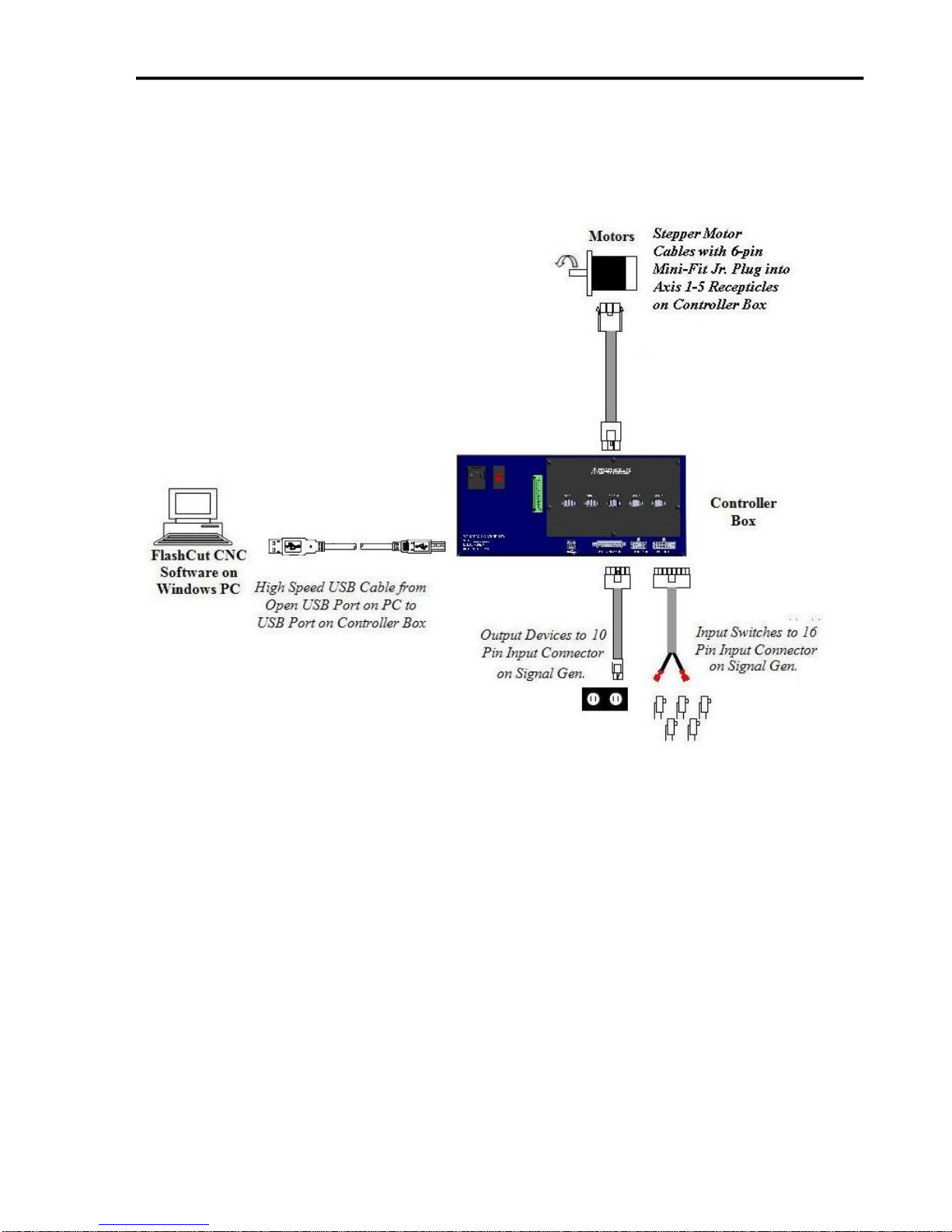

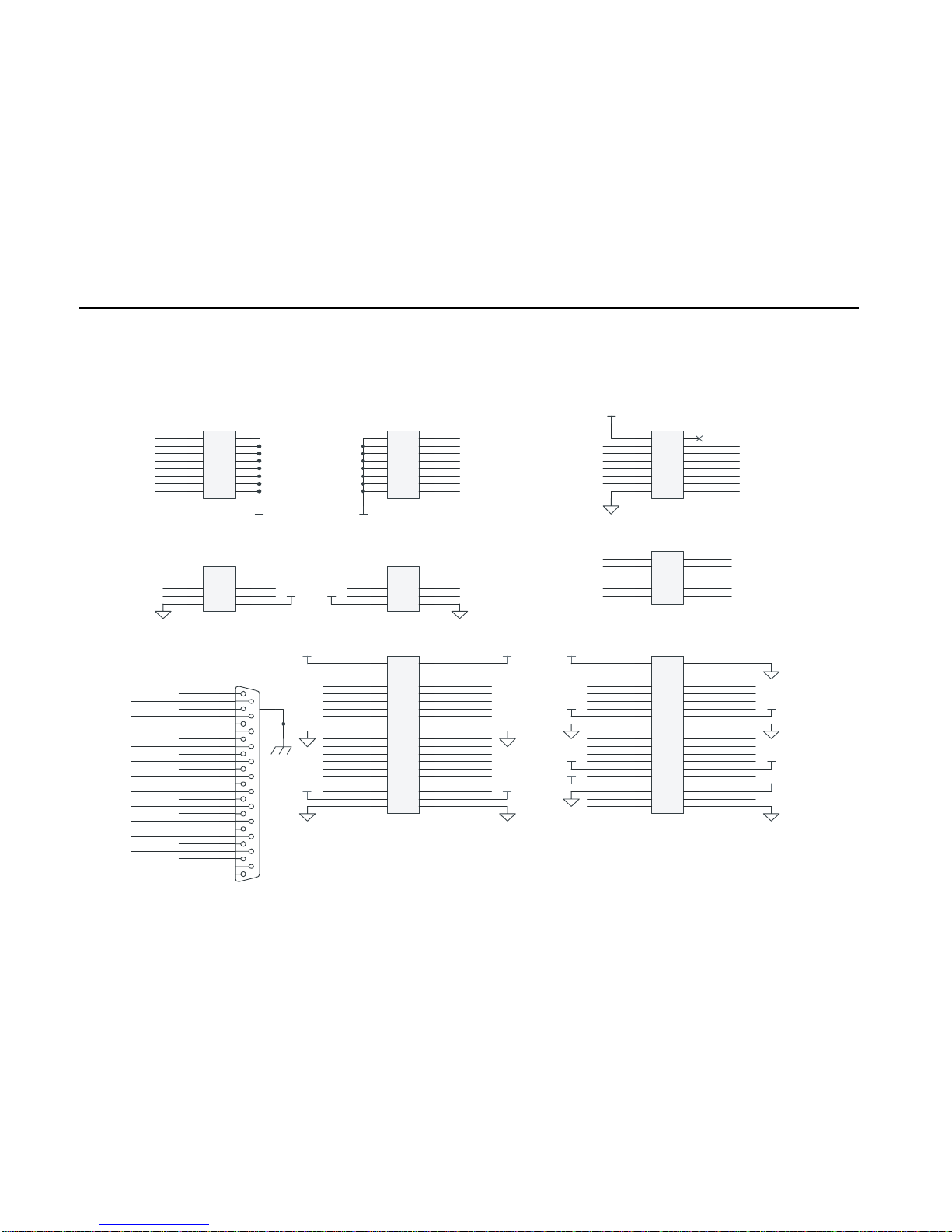

3. System Connections

FlashCut CNC Section 4 Removing the Top Cover

14

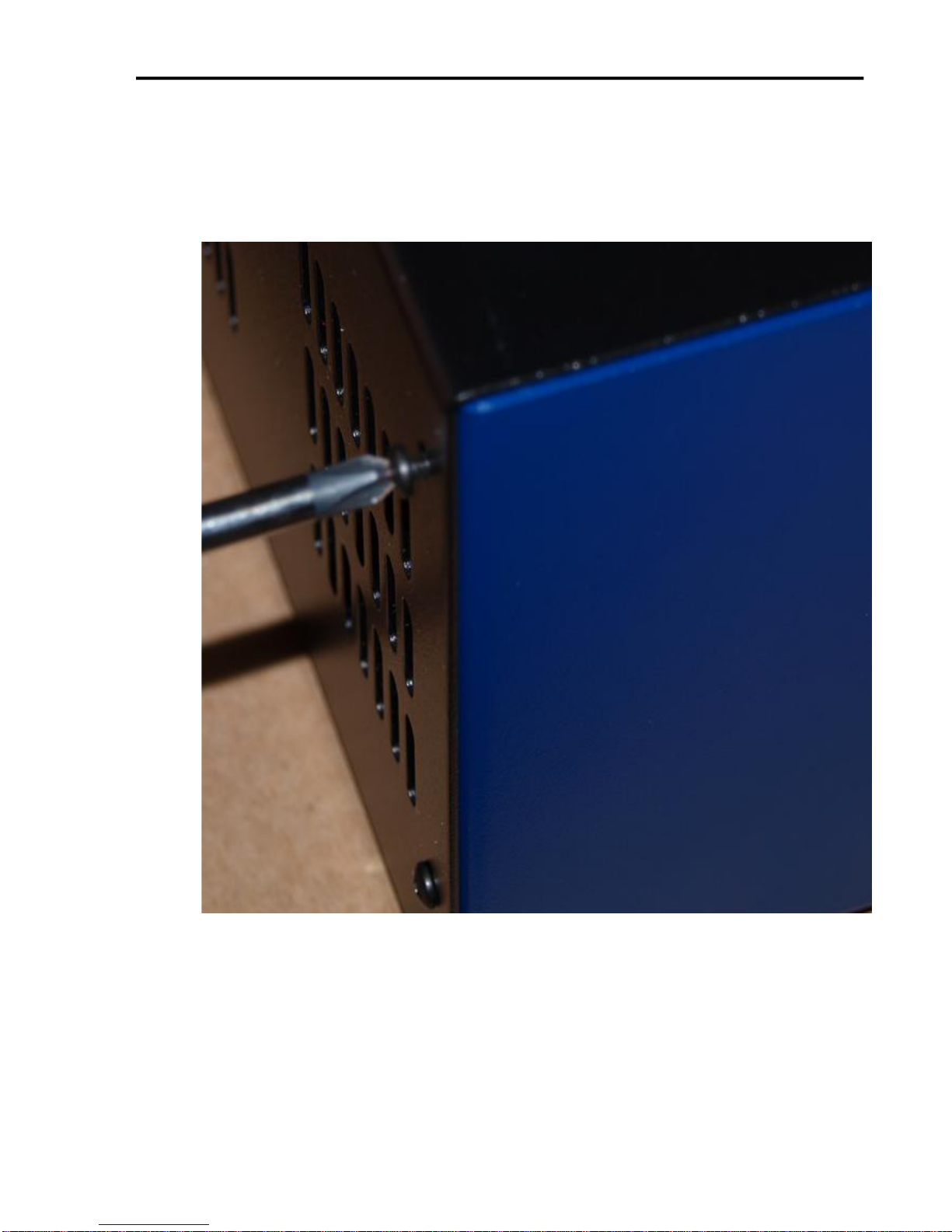

4. Removing the Top Cover

To remove the cover from the unit remove the 8 total screws located on the left and right

sides of the unit. There are 4 screws on either side. Then lift the top cover off.

FlashCut CNC Section 5 Signal Generator

15

5. Signal Generator

Input

The default setting for each of the input lines is normally closed (NC). The input line

settings can be individually changed between normally closed (NC) or normally open

(NO) input lines using FlashCut CNC software. Please refer to the FlashCut CNC

User’s Guide under “Input Line Settings” for further information.

In the FlashCut CNC software, the Input Line Status dialog displays "OPEN" for a

high-level input voltage, or open switch, and "CLOSED" for a low-level input voltage

or closed switch.

The input lines are all optically isolated. Jumpers J84 and J85 enable you to choose

between the internal power of the Signal Generator and isolated power from an

external source. Both jumpers must be set on the same pair of pins (either both must

be on pins 1 and 2 or both must be on pins 2 and 3).

Internal Power- This is the most convenient option and works well for most

applications, but negates some of the signal isolation. When JP84 shorts pins 1

and 2, OPT VCC gets its power from the Internal 5V power source. When JP85

shorts pins 1 and 2, OPT GND is directly connected to the Internal GND.

External Isolated Power

For the best noise immunity, connect an external 5V-24V power supply to the

LED side of the optical couplers. When JP84 shorts pins 2 and 3, OPT VCC gets

its optically isolated power from the TB-VCC. When JP85 shorts pins 2 and 3,

OPT GND is directly connected to the TB-GND.

Choose only one of the following methods to supply power:

1. Connect a power source to the TB 40 screw terminal.

2. Connect a power source through pins 23 and 25 of the DB-25 connector.

If you are providing an external voltage through pins 23 and 25 of the DB25

Motor Signal connector or via TB-40, then you must have both JP84 and

JP85 jump pins 2 and 3, OTHERWISE SEVERE DAMAGE COULD

RESULT.

BE VERY CAREFUL WHEN DOING ANY WIRING. IMPROPER

WIRING WILL DAMAGE THE SIGNAL GENERATOR.

Input lines 1, 2, 3 & 4 are also connected through pins 15, 16, 17 & 18 respectively of

the Motor Signal connector, and input lines 5, 6, 7 & 8 are also connected through

pins 5, 6, 7 & 8 respectively of the Motor Signal connector. This makes it convenient

to send any signals from an external motor driver box, such as limit lines or servo

position error signal, back to the Signal Generator through the DB25 cable without

FlashCut CNC Section 5 Signal Generator

16

Mini-Fit Jr.

Pin No.

Signal

Mini-Fit Jr.

Pin No.

Signal

1

OPT-GND

9 INPUT 1

2

OPT-GND

10

INPUT 2

3

OPT-GND

11

INPUT 3

4

OPT-GND

12

INPUT 4

5

OPT-GND

13

INPUT 5

6

OPT-GND

14

INPUT 6

7

OPT-GND

15

INPUT 7

8

OPT-GND

16

INPUT 8

16 15 14 13 12 11 10 9

◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦

◦ ◦ ◦ ◦ ◦ ◦ ◦ ◦

8 7 6 5 4 3 2 1

using a separate input cable. Note that if an input line is being used through the

Motor Signal connector, that line must remain open in the Input connector.

The receptacle that plugs into this connector is a Molex-Waldom Mini-Fit Jr. Series

16 pin receptacle (part number 39-01-2160), with female pins (part number 39-000039 or 39-00-0047 for 22 gauge or thinner wires).

The Molex 63811-1000 for 14-24 AWG universal or Molex 11-01-0197 Crimp Tools

are recommended for installing the pins. Kits containing connectors and pins are

available through FlashCut CNC or an electronics distributor.

The input lines as seen from the back of the box are arranged as follows (all

connections denoted by “OPT-GND” are optically isolated ground.):

Output

This connector is for up to 8 output lines. These lines are all compatible with

TTL/CMOS level outputs. The Output ports are not setup to drive a 24V external

system unless it accepts TTL/CMOS levels. They are all driven by HCT family

logic. Output logic high is normally 5V and can go down to 3.9V at full load.

Output logic low is normally 0V and can go up to 0.3V at full load. Each of these

signals can provide up to 20mA of current.

Two additional pins on this connector are provided for your output lines: ground and

+5V. These are connected to GND and +5V and are not optically isolated. This 5V

circuit can source up to 100 mA. Any larger current demand would require a larger

power source.

FlashCut CNC Section 5 Signal Generator

17

Mini-Fit Jr.

Pin No.

Signal

Mini-Fit Jr.

Pin No.

Signal

1

OUTPUT 1

6 OUTPUT 2

2

OUTPUT 3

7 OUTPUT 4

3

OUTPUT 5

8 OUTPUT 6

4

OUTPUT 7

9 OUTPUT 8

5

+5V

10

GROUND

10 9 8 7 6

◦ ◦ ◦ ◦ ◦

◦ ◦ ◦ ◦ ◦

5 4 3 2 1

BE VERY CAREFUL WHEN DOING ANY WIRING. IMPROPER WIRING

WILL DAMAGE THE SIGNAL GENERATOR.

The output lines are all initialized to low (0V) when you turn on the Signal

Generator. Output lines 1 and 2 are also connected through pins 1 and 2 respectively

of the Motor Signal connector. This makes it convenient to connect up to 2 output

signals to an external motor driver box to drive devices such as solid-state relays that

might be in an external motor driver box.

The receptacle that plugs into this connector is a Molex-Waldom Mini-Fit Jr. Series

10 pin receptacle (part number 39-01-2100), with female pins (part number 39-000039 or 39-00-0047 for 22 gauge or thinner wires).

The Molex 63811-1000 for 14-24 AWG universal or Molex 11-01-0197 Crimp

Tools are recommended for installing the pins. Kits containing connectors and pins

are available through FlashCut CNC or an electronics distributor.

The output lines as seen from the back of the box are arranged as follows:

Jumper Settings

Pin 1 of all jumpers is indicated by a small white dot printed on the PCB.

FlashCut CNC Section 5 Signal Generator

18

JP83 – DB to USB Ground

This connects the DB 25 ground to the USB ground. By default pins 1 and 2, 3 and

4, and 5 and 6 are jumped as pairs

.

JP84/JP85 – Input Power Select

These two jumpers enable you to choose between the internal power of the Signal

Generator and isolated power from an external source. Both jumpers must be set on

the same pair of pins (either both must be on pins 1 and 2 or both must be on pins 2

and 3).

Internal Power

This is the most convenient option and works well for most applications, but

negates some of the signal isolation. When JP84 shorts pins 1 and 2, OPT VCC

gets its power from the Internal 5V power source. When JP85 shorts pins 1 and

2, OPT GND is directly connected to the Internal GND.

FlashCut CNC Section 5 Signal Generator

19

DB25 PIN22

DB25 PIN23

DB25 PIN24

DB25 PIN25

TB40

OPT-GRD

TB-VCC

OPT-VCC

TB-GRD

+5V

1

2

3

JP84

VCC

JP85

GRD

1

2

3

2

1

DB25 PIN22

DB25 PIN23

DB25 PIN24

DB25 PIN25

OPT-GRD

TB-VCC

OPT-VCC

TB-GRD

+5V

1

2

3

JP84

VCC

JP85

GRD

3

2

1

External Isolated Power

For the best noise immunity, connect an external 5V-24V power supply to the

LED side of the optical couplers. When JP84 shorts pins 2 and 3, OPT VCC

gets its optically isolated power from the TB-VCC. When JP85 shorts pins 2

and 3, OPT GND is directly connected to the TB-GND.

Choose only one of the following methods to supply power:

1. Connect a power source to the TB 40 screw terminal.

2. Connect a power source through pins 23 and 25 of the DB-25 connector.

3. Check the resistor value in RP41 to make sure it matches the voltage in

TB40.

If you are providing an external voltage through pins 23 and 25 of the

DB25 Motor Signal connector or via TB-40, then you must have both JP84

and JP85 jump pins 2 and 3, OTHERWISE SEVERE DAMAGE COULD

OCCUR.

JP 86 – USB to Chassis Ground

This jumper connects the USB shield to the chassis ground of the Signal Generator

when jumped.

TB40 Voltage RP41 Value (10 pin 9 Resistor SIP)

5V 3.9k (Default)

12V 11k

24V 22k

20

FlashCut CNC Section 5 Signal Generator

JP 87 – Internal Signal to Chassis Ground

This jumper connects the internal signal ground to the chassis ground of the Signal

Generator when jumped.

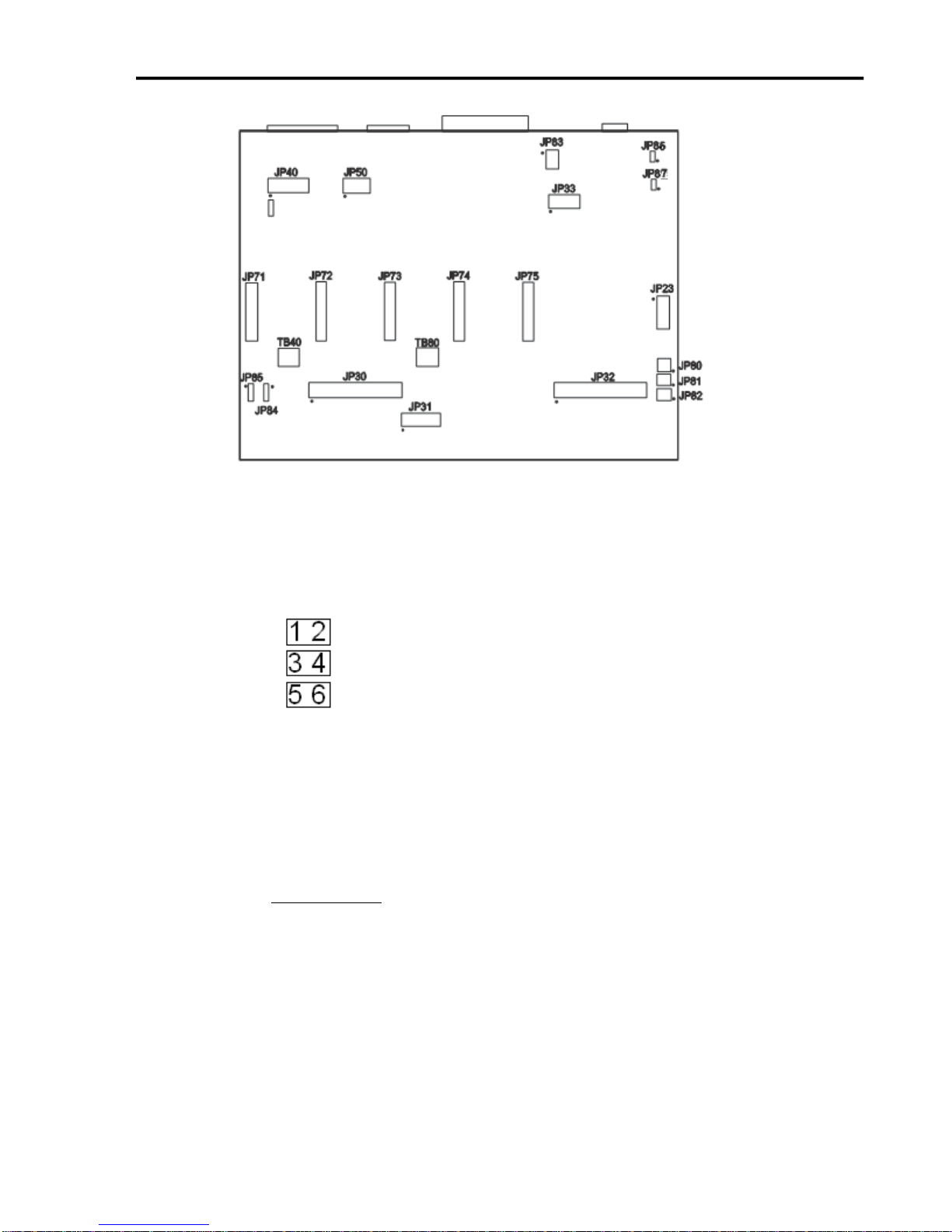

Internal Connections

The diagram below shows the locations of the internal connectors. The top of the

diagram corresponds to the back side of the signal generator (where the external

connectors are located). The small dot next to some of the connectors designates

the number 1 pin position.

On the following diagrams, the positions of the connectors will be highlighted in

black.

Connectors JP30, JP31, JP32, JP33

21

This contains all of the Input

Signals 1-8 which come out of

the 501A board and Input

Signals 9-32 which come out

of the I/O Expansion board.

+3.3V

1 2 +3.3V

GPI32

3 4 GPI1

GPI31

5 6 GPI2

GPI30

7 8 GPI3

GPI29

9

10

GPI4

GPI28

11

12

GPI5

GPI27

13

14

GPI6

GPI26

15

16

GPI7

GPI25

17

18

GPI8

GND

19

20

GND

GPI24

21

22

GPI9

GPI23

23

24

GPI10

GPI22

25

26

GPI11

GPI21

27

28

GPI12

GPI20

29

30

GPI13

GPI19

31

32

GPI14

GPI18

33

34

GPI15

GPI17

35

36

GPI16

+3.3V

37

38

+3.3V

GND

39

40

GND

This is for connecting wired

LEDs from a custom chassis

to the 501A LED signals.

+5V

1 2 N/C

LED-DIR1

3 4 LED-STEP1

LED-DIR2

5 6 LED-STEP2

LED-DIR3

7 8 LED-STEP3

LED-DIR4

9

10

LED-STEP4

LED-DIR5

11

12

LED-STEP5

LED-AUX

13

14

LED-USB

GND

15

16

LED-PWR

FlashCut CNC Section 5 Signal Generator

JP30 – Auxiliary Inputs

JP31 – Status LEDs

FlashCut CNC Section 5 Signal Generator

22

This contains signal and

address lines for the I/O

Expansion board.

+3.3V

1 2 GND

CS6

3 4 STATUS6

TXD2

5 6 FAULT6

RXD2

7 8 AUX1-STB

OUT-ENA

9

10

AUX2-STB

OUT2-STB

11

12

OUT1-STB

OUT4-STB

13

14

OUT3-STB

+5V

15

16

+5V

GND

17

18

GND

A0

19

20

A1

DATA1

21

22

DATA2

DATA3

23

24

DATA4

DATA8

25

26

DATA7

DATA6

27

28

DATA5

+7V

29

30

+7V

SPHOME

31

32

ENC CLK

+3.3V

33

34

ENC DIR

AGND

35

36

AV+

DAC2

37

38

DAC1

ADC1

39

40

AGND

This contains all of the step

and direction signals for 5

axes of motion.

STEP5

1 2 ENA

STEP4

3 4 DIR5

STEP3

5 6 DIR4

STEP2

7 8 DIR3

STEP1

9

10

DIR2

GND

11

12

DIR1

JP32 – Bus Expansion

JP33 – Step & Direction

FlashCut CNC Section 5 Signal Generator

23

This contains the same

signals as the Mini-Fit Jr.

Input Connector. It is

provided for the convenience

of using a different input

connector or an external input

connector on a custom

chassis.

GPI1

1 2 OPT-GND

GPI2

3 4 OPT-GND

GPI3

5 6 OPT-GND

GPI4

7 8 OPT-GND

GPI5

9

10

OPT-GND

GPI6

11

12

OPT-GND

GPI7

13

14

OPT-GND

GPI8

15

16

OPT-GND

This contains the same

signals as the Mini-Fit Jr.

Input Connector. It is

provided for the convenience

of using a different input

connector or an external input

connector on a custom

chassis.

GPO2

1 2 GPO1

GPO4

3 4 GPO3

GPO6

5 6 GPO5

GPO8

7 8 GPO7

GND

9

10

VCC

Connectors JP40, JP50

JP40 – Input Aux Header

JP50 – Output Aux Header

FlashCut CNC Section 5 Signal Generator

24

Connectors JP80, JP81, JP82

JP80 – Rear Panel Power

Connect the main power here. It can be 8.5V – 16V DC or AC. See

current draw chart for power requirements.

JP81 – Rear Panel Fuse

This is for an optional power fuse. The unit is shipped with a shunt

instead of a fuse. If you replace the shunt with a fuse, it should be sized

according to your power requirements.

JP82 – Front Panel Switch

Connect the main power switch here.

Axis Plug-In Interfaces

Axis Plug-Ins JP71 – JP75

FlashCut CNC Section 5 Signal Generator

25

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

Each of these plug-in cards is a SKT10X2 connector, with the

pin configuration on the left. Pin numbers 1-5, 7, 13, 15 and

17-20 perform the same function on each jumper.

Per the chart below, pins 6, 8-12, 14 and 16 have different

values of Status, Fault, InputA, Dir, InputB, Step, SCOM and

CS respectively for each plug-in card.

Pin

No.

Label

Function

JP-71

JP-72

JP-73

JP-74

JP-75

1

HV-PWR

High Voltage Power

HV-PWR

HV-PWR

HV-PWR

HV-PWR

HV-PWR

2

HV-PWR

High Voltage Power

HV-PWR

HV-PWR

HV-PWR

HV-PWR

HV-PWR

3

GND

Ground

GND

GND

GND

GND

GND

4

GND

Ground

GND

GND

GND

GND

GND

5

RxD2

Serial Com. Receive

RxD2

RxD2

RxD2

RxD2

RxD2

6

STATUS

Status

STATUS1

STATUS2

STATUS3

STATUS4

STATUS5

7

TxD2

Serial Com. Transmit

TxD2

TxD2

TxD2

TxD2

TxD2

8

FAULT

Fault Indicator

FAULT1

FAULT2

FAULT3

FAULT4

FAULT5

9

INPUTA

Input A

IN8

IN10

IN12

IN14

IN16

10

DR

Direction

DR1

DR2

DR3

DR4

DR5

11

INPUTB

Input B

IN9

IN11

IN13

IN15

IN17

12

ST

Step

ST1

ST2

ST3

ST4

ST5

13

SM0

SM0

SM0

SM0

SM0

SM0

SM0

14

SCOM

SCOM

SCOM1

SCOM2

SCOM3

SCOM4

SCOM5

15

SM1

SM1

SM1

SM1

SM1

SM1

SM1

16

CS

Chip Select

CS1

CS2

CS3

CS4

CS5

17

ENA

Enable

ENA

ENA

ENA

ENA

ENA

18

+5V

+5V

+5V

+5V

+5V

+5V

+5V

19

GND

GND

GND

GND

GND

GND

GND

20

GND

Ground

GND

GND

GND

GND

GND

The Axis plug-in interfaces are used to add additional functions to the main signal

generator board. For example, a stepper drive plug-in card or cable will enable

you to drive a stepper motor directly from the signal generator box.

FlashCut CNC Section 6 Drive Settings

26

6. Drive Settings

Inside of the controller box are the individual drive modules for axes 1-5.

Each drive module has Logic Connector for the Step, Direction, COM and Enable signals

coming from the Axis Plug-in connector on the Signal generator, a Motor Connector for

the A and B Coils of the motor, a Power Connector, and a group of DIP Switches for

configuring the drive for your specific requirements. The configuration of the DIP

switches vary depending on your application.

FlashCut CNC Section 6 Drive Settings

27

Configuring the Drives

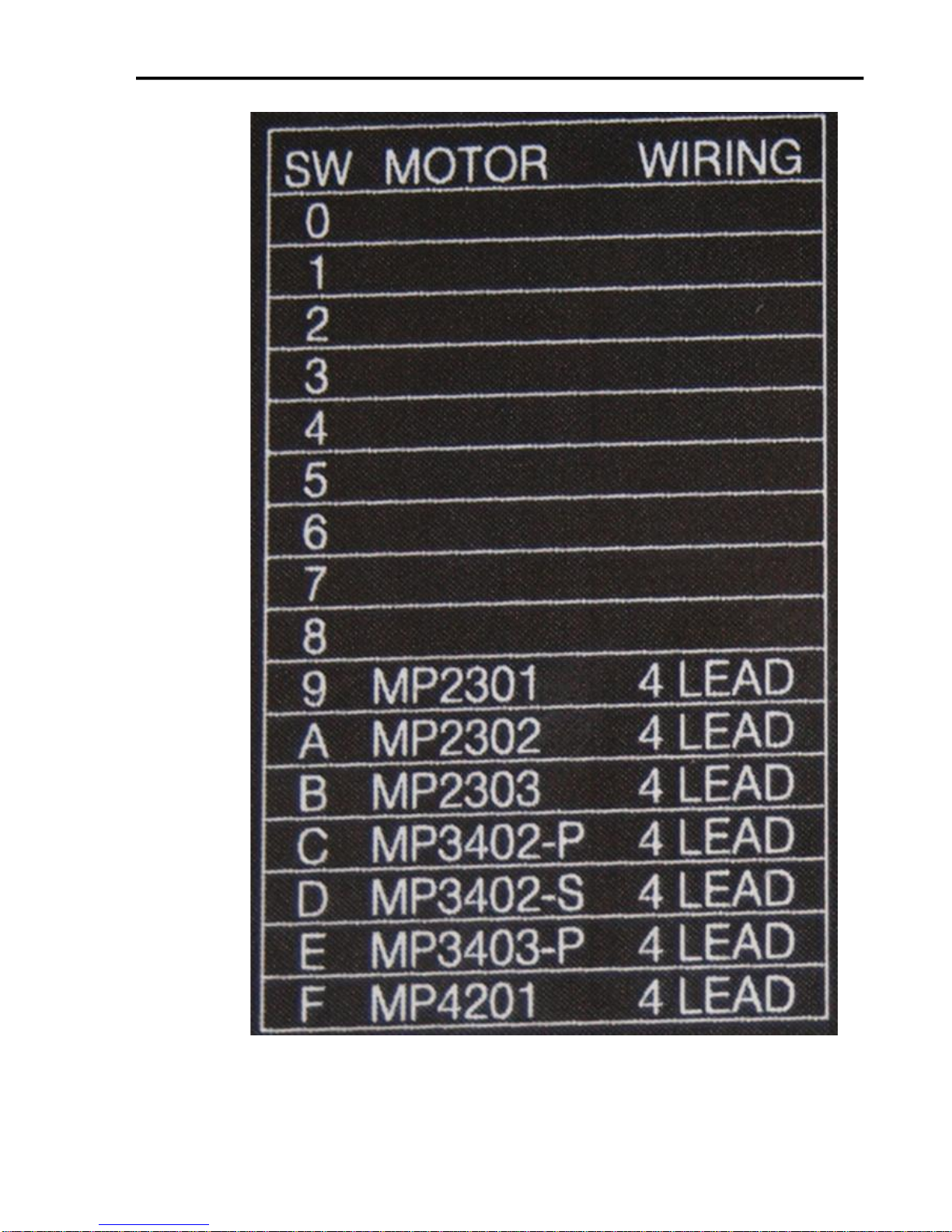

Selecting a Motor

The drives are optimized for use with selected variety of stepper motors.

Each setting matches the current and inertia of a given motor providing the

most power with minimum resonance. To select a motor, simply move the

rotary switch to the letter or number that corresponds to the motor of your

choice. Make sure the power is off before changing this setting, or damage

could occur to your motor or drive.

If your motor is not on the list please set the switch to a selection whose rotor

inertia, holding torque and current are within 10% of your motor.

FlashCut CNC Section 6 Drive Settings

28

FlashCut CNC Section 6 Drive Settings

29

Setting the Current

The maximum current for the motor you have selected is set automatically

when you set the rotary switch. But you may want to reduce the current to

save power or lower motor temperature. This is important if the motor is not

mounted to a surface that will help it dissipate heat or if the ambient

temperature is expected to be high.

Step motors produce torque in direct proportion to current, but the amount of

heat generated is roughly proportional to the square of the current. If you

operate the motor at 90% of rated current, you’ll get 90% of the rated torque.

But the motor will produce approximately 81% as much heat. At 70%

current, the torque is reduced to 70% and the heating to about 50%.

Two of the small switches on the front of the drive are used to set the percent

of rated current that will be applied to the motor: SW1 and SW2. Please set

them according to the illustration below. The factory default setting is 70%.

Setting Idle Current

Motor heating and power consumption can also be reduced by lowering the

motor current when it is not moving. The drive will automatically lower the

motor current when it is idle to either 50% or 90% of the running current.

The 50% idle current setting will lower the holding torque to 59%, which is

enough to prevent the load from moving in most applications. This reduced

motor heating by 75%. In some applications such as those supporting a

vertical load, it is necessary to provide a high holding torque. In such cases,

the idle current can be set to 90% as shown below. The default setting is for

50% idle current.

FlashCut CNC Section 6 Drive Settings

30

Load

Inertia

The drives include anti-resonance and electronic damping features which

greatly improve motor performance. To perform optimally, the drive must

understand the electromechanical characteristics of the motor and load. Most

of this is done automatically when you select the motor by setting the rotary

switch. To further enhance performance you must set a switch to indicate the

appropriate inertia ratio of the load and motor. The ranges are 0 to 4X and 5

to 10X. Simply divide the load inertia by the rotor inertia to determine the

ratio, then set switch 3 accordingly, as shown.

Step Size

The drive module requires a source of step pulses to command motion. This

may be a PLC, an indexer, a motion controller or another type of device. The

only requirement is that the device be able to produce step pulses whose

frequency is in proportion to the desired motor speed, and be able to

smoothly ramp the step speed up and down to produce smooth motor

acceleration and deceleration.

Smaller step sizes result in smoother motion and more precise speed, but also

require a higher step pulse frequency to achieve maximum speed. The

smallest step size of the drives is 1/20,000th of a motor turn while the

maximum step rate of the signal generator is typically between 50,000 and

FlashCut CNC Section 6 Drive Settings

31

100,000 steps/sec.Six different settings are provided in the drive module, as

shown in the table below. Please choose the one that best matches the

capabilities for your system.

At lower step resolutions such as 200 steps/revolution (full step) and 400

steps/revolution (half step), motors run a little rough and produce more

audible noise than when they are microstepped (2000 steps/revolution and

beyond). The drives include a feature called “microstep emulation”, also

called “step smoothing”, that can provide smooth motion from coarse

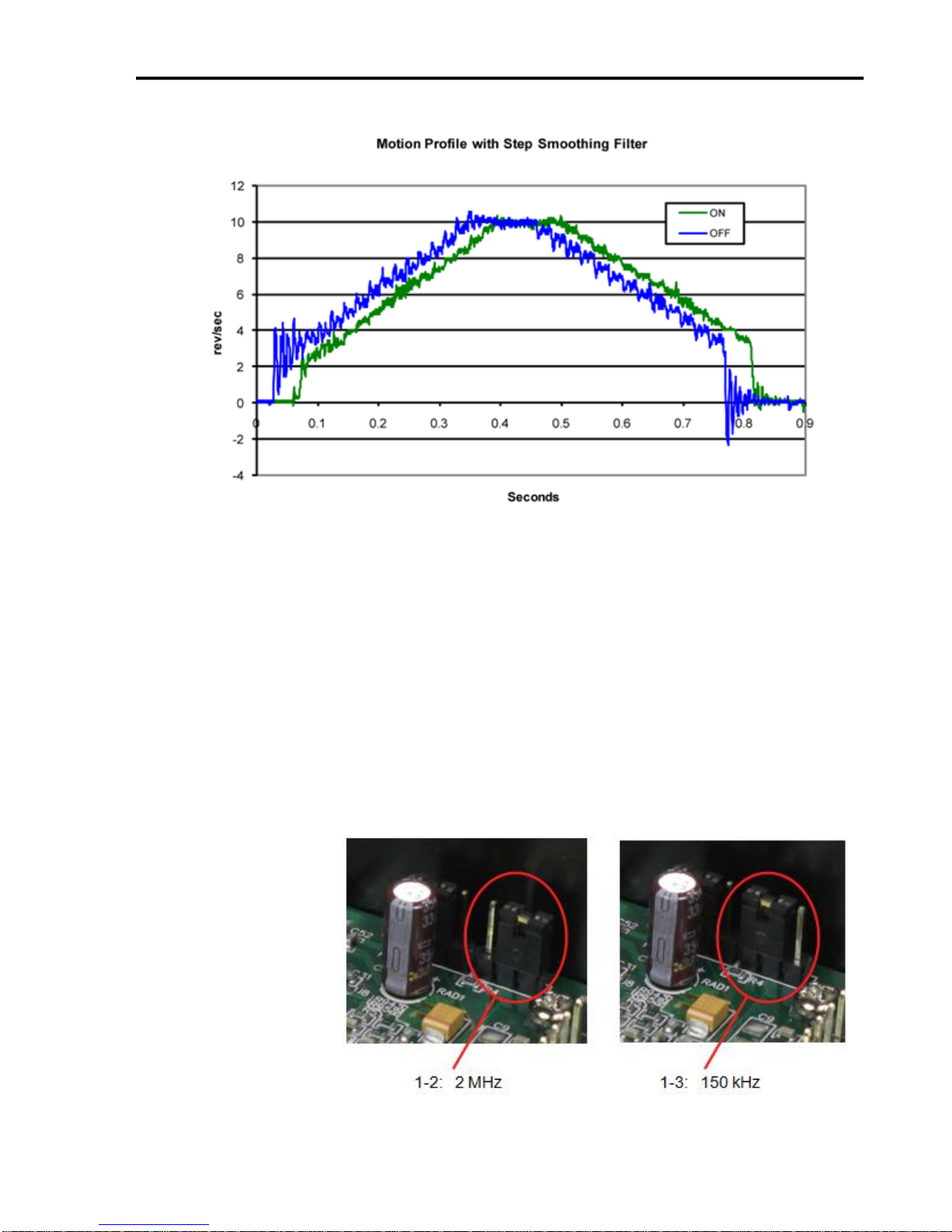

command signals. If you select “200 SMOOTH or 400 SMOOTH”, this

feature is automatically employed to provide the smoothest possible motion

from a less than ideal signal source.

Because a command filter is used as part of the step smoothing process, there

will be a slight delay, or “lag” in the motion. If this delay is objectionable for

your application, please choose the non-filtered setting “200” or “400”. The

chart on the next page shows an example of the delay that can occur from

using the step smoothing filter. If you are using the smoothing feature, you

must have all axis in the same smoothing mode, otherwise there will be a

timing problem with multi-axis interpolation.

FlashCut CNC Section 6 Drive Settings

32

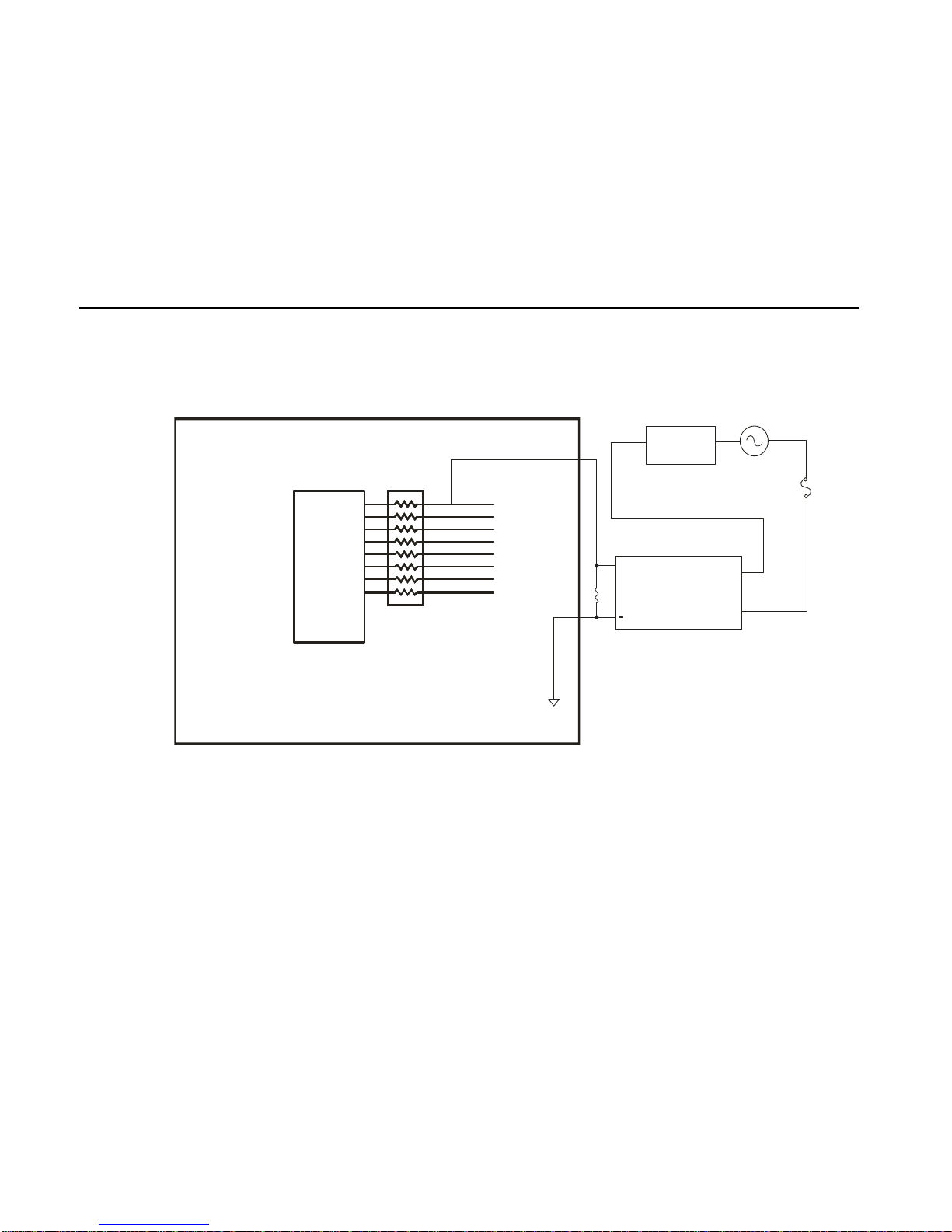

Step Pulse Noise Filtering

Electrical noise can affect the STEP signal in a negative way, causing the

drive to think that one step pulse is two or more pulses. This results in extra

motion and inaccurate motor and load positioning. To combat

this problem the drives include a digital noise filter on the STEP and DIR

inputs. The default factory setting of this filter is 150 kHz, which works well

for most applications.

However as discussed in “Step Size” of this section, if you are operating the

drive module at a high number of steps/revolution and at high motor speeds

you will be commanding the drive at step rates above 150 kHz. In such cases

you should remove the cover and move jumper S4 from the 150 kHz position

(1-3) to the 2 MHz position (1-2) as shown

below.

33

.

Self Test

FlashCut CNC Section 6 Drive Settings

Your maximum pulse rate will be the highest motor speed times the

steps/revolution. For example, 40 revolutions/second at 20,000

steps/revolution is 40 X 20,000 = 800 kHz. Please consider this when

deciding if you must increase the filter frequency,

If you are having trouble getting your motor to turn you may want to try the

built-in self test. Anytime switch 8 is moved to the ON position, the drive

will automatically rotate the motor back and forth, two turns in each

direction. This feature can be used to confirm that is correctly wired, selected

and otherwise operational.

Alarm Codes

In the event of a drive fault or alarm, the green LED will flash one or two

time, followed by a series of red flashes. The pattern repeats until the alarm

is cleared.

FlashCut CNC Section 7 Motor Signal Settings

34

7. Motor Signal Settings

The motor settings in the Motor Signal Setup Screen in the FlashCut CNC software need

to be properly set according to the driver box that you have. Please refer to Motor Signal

Setup section of the User’s Guide for the best way to set up your drive for your software

version.

For this drive, the best signals are as follows:

Driver Model: 8A Pro Micro Stepper (6501-X-080-M

Step Pulse: High

Step Pulse Width: 5

Min. Time Between Steps: 5

Direction-Step Setup: 5

Min. Step-Direction Lag: 5

Enable Signal Polarity: High

FlashCut CNC Section 8 Stepper Motor Cabling

35

Molex Pin

Motor Wire

1 B 2

Cable Ground Shield

3

A

4

B~

5

No Connection

6

A~

8. Stepper Motor Cabling

Motor Cable - 2 Twisted pair (one pair for A coil and one pair for B Coil) 22 gauge and

shielded (18 gauge for 6A motors). Shield is only connected to noted pin on MolexWaldom connector and should not be connected to motor end. Use Belden - M 8723 CM

2PR22 Shielded Cable or equivalent.

Connector - Molex - Waldom 6-Pin Mini-Fit Jr.

Receptacle Housing Part # 39-01-2060.

Female Pins Part # 39-00-0039 or 39-00-0047

Motor Wiring for Other Stepper Motors

If you have your own stepper motor, you can use the following charts for your

wiring. Note that the motor wire colors will vary.

FlashCut CNC Section 8 Stepper Motor Cabling

36

A to A~

About 1-10 ohms (Equal to B to B~)

B to B~

About 1-10 ohms (Equal to A to A~)

A or A~ to B or B~

No Continuity

A Center to A or A~

½ the resistance of A to A~

B Center to B or B~

½ the resistance of B to B~

B Center to A or A~

No Continuity

A Center to B or B~

No Continuity

6 Lead Motor – ½ Coil Bipolar 6 Lead Motor – Series Bipolar

8 Lead Motor – Parallel Bipolar 8 Lead Motor – Series Bipolar

Unknown Motor Wiring

If you are uncertain which is the A pair and which is the B pair, you can use an

ohm meter and the following chart to determine the pairs (and the center taps on a

6- wire motor)

If the A and A~ or the B and B~ are reversed, the motor will spin the opposite

direction. This can easily be corrected by changing the motor polarity in the

Setup…Motor Settings menu in the FlashCut CNC software.

37

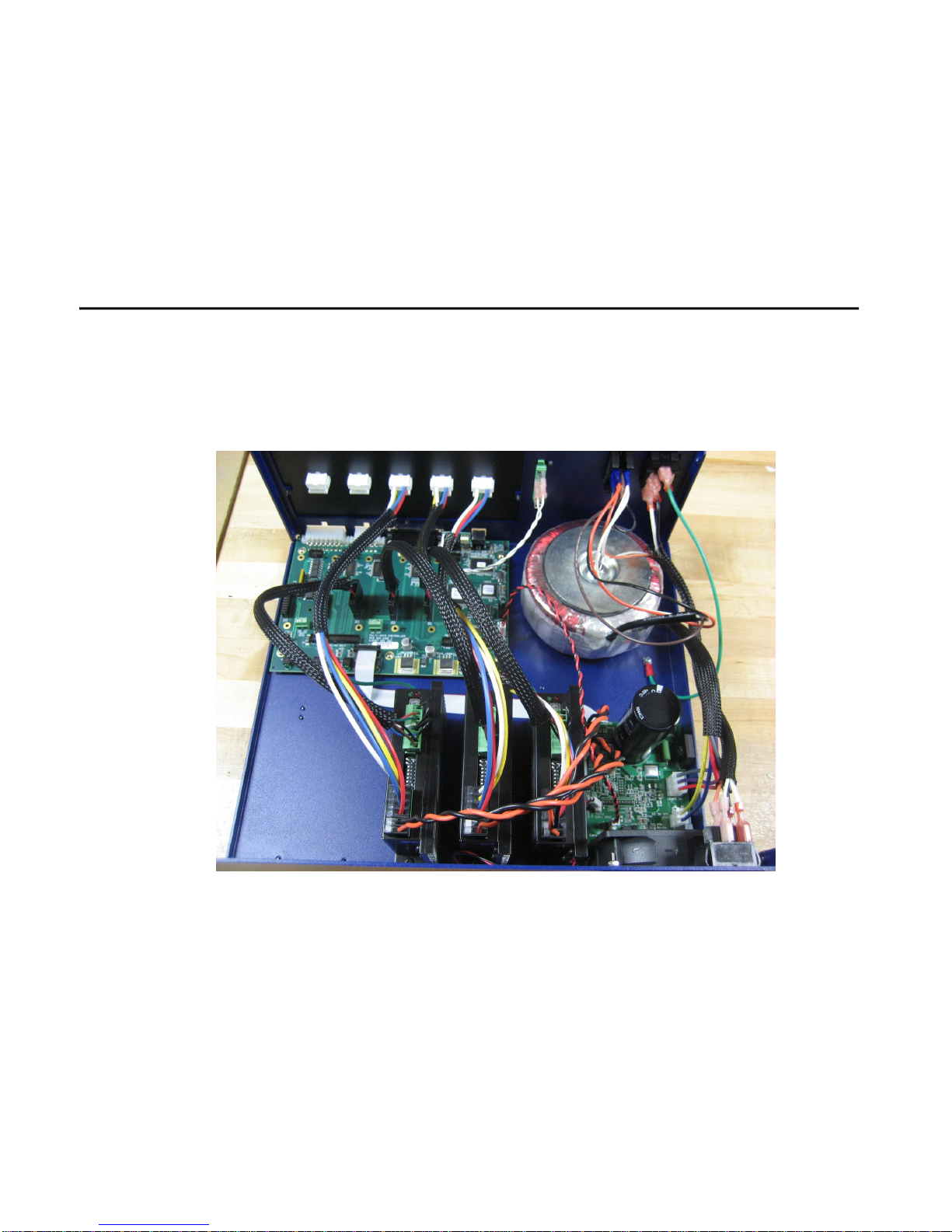

9. Power Board

FlashCut CNC Section 9 Power Board

The function of the Power Board is to supply DC voltage to the drive modules as well

as to the cooling fan and logic signals to the Signal Generator. The power enters the

board in the form AC voltage from a transformer; the AC voltage is then converted to DC

voltage. The Power Board also contains the indication LED’s:

AXIS LED’s 1, 2, 3, 4, 5 – Turns green when the respective axis is moving.

USB LED– Turns yellow when connected to the host PC USB port.

POWER LED– Turns green when the power switch is turned on.

LOGIC AC INPUT- This connector takes in the power from the transformer for the logic

signals. The AC voltage from the transformer is then converted to a DC voltage to be

used for logic signals. The two contacts are labeled as follows: L is the hot, N is the

neutral.

MOTOR AC INPUT- This connector takes in the power from the transformer for the

drive modules. The AC voltage from the transformer is then converted to a DC voltage

of 40-80V, depending on the connection configuration, to be used for powering the drive

FlashCut CNC Section 9 Power Board

38

+5V

1 2 N/C

LED-DIR1

3 4 LED-STEP1

LED-DIR2

5 6 LED-STEP2

LED-DIR3

7 8 LED-STEP3

LED-DIR4

9

10

LED-STEP4

LED-DIR5

11

12

LED-STEP5

LED-AUX

13

14

LED-USB

GND

15

16

LED-PWR

modules. The three contacts are labeled as follows: R is the reserve, L is the hot, N is the

neutral. The reserve and the hot may be switched to vary the voltage. For example if R is

red and L is purple the resulting DC voltage is approximately 67 VDC, where if R is

purple and L is red the resulting DC voltage is approximately 80 VDC.

SIGNAL GENERATOR DC OUTPUT- This output sends a 9 VDC signal to power the

Signal Generator. When viewing the power board in the configuration above the top

contact of the signal generator DC output is positive and the bottom contact is negative.

FAN DC OUTPUT- This output sends a 24 VDC signal to power the fan for cooling the

box. When viewing the power board in the configuration above the top contact of the fan

DC output is positive and the bottom contact is negative.

MOTOR DC OUTPUT- This output sends a 40-80 VDC, depending on the connection

configuration, DC signal to power the drive modules. Power for up to 5 individually

powered drive modules. The contacts alternate positive and negative starting with

positive on the contact nearest the large capacitor.

LED INPUT- This input receives logic signal from the signal generator in order to

illuminate any of the 7 LED’s indicating axis movement, power or USB connectivity.

The contact connections for the LED input are as follows:

JP31 – STATUS LEDS

2 X 8 - 2MM SPACING

FlashCut CNC Section 10 Driver Module Upgrades

39

10. Driver Module Upgrades

To upgrade your CNC controller such as adding a 4th or 5th axis you should install the

new drive module(s) using the following instructions.

Improper wiring can cause damage to your driver box and/or motors. Please take

care in following these instructions properly. Please refer to the drawings below for

the correct logic connectors.

1. Set the Dip Switches to the appropriate settings for your application (default settings

pictured).

FlashCut CNC Section 10 Driver Module Upgrades

40

2. Mount the drive module to the driver box chassis using (2) 6-32 conducting screws.

FlashCut CNC Section 10 Driver Module Upgrades

41

3. Connect the power cable from the power board into V- and V+ on the drive making

sure to note polarity.

FlashCut CNC Section 10 Driver Module Upgrades

42

4. Connect the wires from the motor receptacle to the drive module motor connector

labeled B-, B+,A- and A+ on the drive module.

FlashCut CNC Section 10 Driver Module Upgrades

43

To properly ground your motor cable shield, connect Pin 2 of the motor cable

directly to the base of the drive module using the 6-32 hold down screw.

FlashCut CNC Section 10 Driver Module Upgrades

44

5. Connect the step, direction, enable and fault lines from the drive module to the signal

generator via the axis plug-in interface located on the PCB.

FlashCut CNC Section 11 Appendix

45

11. Appendix

Sample Wiring Diagrams

Typical Output Line Circuit

Signal Generator Model 501A

So lid State Relay

Continen tal In d u stries

S5 0 5-0SJ610-000

+ 3

Load

1

2

AC

Fuse

3.3K

4

OPT

GND

Output1

74ACT16373DL

Q8

U50A

Q1

Q4

Q6

Q7

Q5

Q3

Q2

GPO7

GPO6

GPO5

GPO4

GPO3

GPO2

GPO1

GPO0

22 OHM

11

9

10

13

12

14

R 51P

16

15

Output Line 1

Output Line 8

Output Line 5

Output Line 7

Output Line 6

Output Line 3

Output Line 4

Output Line 2

The above schematic shows a typical connection of one solid state relay controlled by output line 1 of the Signal

Generator. A typical load would be a spindle, a vacuum, a laser, etc. In this example, the solid-state relay used is a

Continental Industries model S505-0SJ610-000. It takes a 3 to 32VDC input and has an output of 24-330VAC.

Each of the output signals has a 22-ohm resistor in series with their outputs. This is to reduce any “ringing” at the

transient switching points. Ground and 5V are provided on this connector for your convenience. The FlashCut Spindle

On/Off Relay Box is wired as shown in the above schematic.

FlashCut CNC Section 11 Appendix

46

Typical Input Line Circuit – Internal Power

In p ut 8

In p ut 7

In p ut 6

In p ut 5

In p ut 4

In p ut 3

In p ut 2

In p ut 1

Signal G enerator M odel 501 A

DB25 Pin8

DB25 Pin7

DB25 Pin6

DB25 Pin5

DB25 Pin18

DB25 Pin17

DB25 Pin16

DB25 Pin15

O

P

T

G

N

D

OPT GND

NC-NO

U42

OPT_VCC

RP41

GPI0

GPI1

GPI2

GPI3

820

PS2501L-4

IN0

IN1

IN2

IN3

GPI4

GPI5

GPI6

GPI7

PS2501L-4

U41

VCC

IN4

IN5

IN6

2.7K

8

1236457

RP42

IN7

DB25 PIN22

DB25 PIN23

DB25 PIN24

DB25 PIN25

6

2143510879

TB40

OPT-GRD

TB-VCC

OPT-VCC

TB-GR D

+5V

1

2

3

JP84

VCC

JP85

GRD

1

2

3

2

1

9

10

FlashCut CNC Section 11 Appendix

47

Typical Input Line Circuit – External Power

In p u t 8

In p u t 7

In p u t 6

In p u t 5

In p u t 4

In p u t 3

In p u t 2

In p u t 1

Signal Generator M odel 501 A

DB25 P in8

DB25 P in7

DB25 P in6

DB25 P in5

DB25 P in18

DB25 P in17

DB25 P in16

DB25 P in15

O

P

T

G

N

D

OPT GND

NC-NO

U42

OPT_VCC

RP41

GPI0

GPI1

GPI2

GPI3

820

PS2501L-4

IN0

IN1

IN2

IN3

GPI4

GPI5

GPI6

GPI7

PS2501L-4

U41

VCC

IN4

IN5

IN6

2.7K

8

1236457

RP42

IN7

DB25 P IN22

DB25 P IN23

DB25 P IN24

DB25 P IN25

6

2143510879

TB40

OPT-GRD

TB-VCC

OPT-VCC

TB-GRD

+5V

1

2

3

JP84

VCC

JP85

GRD

1

2

3

2

1

9

10

FlashCut CNC Section 11 Appendix

48

The above schematic shows a typical connection of 5 normally closed switches. These switches are connected

between input lines 1-5 and ground. Lines 6-8 are connected directly to ground with jumper wires. All external

connections shown are made through the Input connector on the back of the Signal Generator. This resistor pack

(RP41) is socketed so that you can change the value if needed for your application.

The input lines are all optically isolated. In this example, JP84 and JP85 are shorted using the internal power

to source the external side of the optical couplers. However, for the best isolation, JP84 and JP85 should be

open, and power should be provided through pins 23 and 25 of the DB25 Motor Signal connector. Input lines

1-4 and 5- 8 are internally connected to pins 15-18 and 5-8 respectively of the DB25 Motor Signal connector.

Note that the FlashCut CNC limit switch kit has the same wiring as shown in this example.

FlashCut CNC Section 11 Appendix

49

Signal Generator Board Layout

FlashCut CNC Section 11 Appendix

50

Connector Pin-Out Table

EXTERNAL CONNECTORS (RED)

CON1: STANDARD USB TYPE-A

CON3 – DB25F

GPO1

1

14

ENA

GP02

2

15

GPI1

STEP5

3

16

GPI2

DIR5

4

17

GPI3

GPI5

5

18

GPI4

GPI6

6

19

DIR4

GPI7

7

20

DIR3

GPI8

8

21

DIR2

DIR1

9

22

VCC

STEP4

10

23

OPT-VCC

STEP3

11

24

GND

STEP2

12

25

OPT-GND

STEP1

13 SHIELD

CON4 - INPUTS

OPT-GND

1 9 GPI1

OPT-GND

2

10

GPI2

OPT-GND

3

11

GPI3

OPT-GND

4

12

GPI4

OPT-GND

5

13

GPI5

OPT-GND

6

14

GPI6

OPT-GND

7

15

GPI7

OPT-GND

8

16

GPI8

CON5 - OUTPUTS

GPO1

1 6 GPO2

GPO3

2 7 GPO4

GPO5

3 8 GPO6

GPO7

4 9 GPO8

VCC

5

10

GND

INTERNAL CONNECTORS (ORANGE)

PIN 1 OF ALL HEADERS IS INDICATED

BY A SMALL WHITE DOT PRINTED ON

THE PCB.

JP30 – AUXILIARY INPUTS

2 X 20 - 2MM SPACING

+3.3V

1 2 +3.3V

GPI32

3 4 GPI1

GPI31

5 6 GPI2

GPI30

7 8 GPI3

GPI29

9

10

GPI4

GPI28

11

12

GPI5

GPI27

13

14

GPI6

GPI26

15

16

GPI7

GPI25

17

18

GPI8

GND

19

20

GND

GPI24

21

22

GPI9

GPI23

23

24

GPI10

GPI22

25

26

GPI11

GPI21

27

28

GPI12

GPI20

29

30

GPI13

GPI19

31

32

GPI14

GPI18

33

34

GPI15

GPI17

35

36

GPI16

+3.3V

37

38

+3.3V

GND

39

40

GND

JP31 – STATUS LEDS

2 X 8 - 2MM SPACING

+5V

1 2 N/C

LED-DIR1

3 4 LED-STEP1

LED-DIR2

5 6 LED-STEP2

LED-DIR3

7 8 LED-STEP3

LED-DIR4

9

10

LED-STEP4

LED-DIR5

11

12

LED-STEP5

LED-AUX

13

14

LED-USB

GND

15

16

LED-PWR

INTERNAL CONNECTORS (ORANGE)

JP32 – BUS EXPANSION

2 X 20 - 2MM SPACING

+3.3V

1 2 GND

CS6

3 4 STATUS6

TXD2

5 6 FAULT6

RXD2

7 8 AUX1-STB

OUT-ENA

9

10

AUX2-STB

OUT2-STB

11

12

OUT1-STB

OUT4-STB

13

14

OUT3-STB

+5V

15

16

+5V

GND

17

18

GND

A0

19

20

A1

DATA1

21

22

DATA2

DATA3

23

24

DATA4

DATA8

25

26

DATA7

DATA6

27

28

DATA5

+7V

29

30

+7V

SPHOME

31

32

ENC CLK

+3.3V

33

34

ENC DIR

AGND

35

36

AV+

DAC2

37

38

DAC1

ADC1

39

40

AGND

JP33 – STEP & DIRECTION

2 X 6 - 2MM SPACING

STEP5

1 2 ENA

STEP4

3 4 DIR5

STEP3

5 6 DIR4

STEP2

7 8 DIR3

STEP1

9

10

DIR2

GND

11

12

DIR1

FlashCut CNC Section 11 Appendix

51

INTERNAL CONNECTORS (ORANGE)

JP40 – INPUT AUX HEADER

2 X 8 - 2MM SPACING

GPI1

1 2 OPT-GND

GPI2

3 4 OPT-GND

GPI3

5 6 OPT-GND

GPI4

7 8 OPT-GND

GPI5

9

10

OPT-GND

GPI6

11

12

OPT-GND

GPI7

13

14

OPT-GND

GPI8

15

16

OPT-GND

JP50 – OUTPUT AUX HEADER

2 X 5 - 2MM SPACING

GPO2

1 2 GPO1

GPO4

3 4 GPO3

GPO6

5 6 GPO5

GPO8

7 8 GPO7

GND

9

10

VCC

JP53 – OUT 1&2 LOW SIDE DRIVER

1 X 6 - 2MM SPACING

+5V VCC

1

CLAMP for GP02

2

GPO2 Low Side Driver

3

GPO1 Low Side Driver

4

CLAMP for GP01

5

LOGIC GND

6

JP80 - REAR PANEL POWER

JP81 - REAR PANEL FUSE

JP82 - FRONT PANEL SWITCH

CONFIGURATION JUMPERS (BLUE)

PIN 1 OF ALL JUMPERS IS INDICATED BY

A SMALL WHITE DOT PRINTED ON THE

PCB.

JP83: DB TO USB GROUND

ALWAYS LEAVE PIN 1 JUMPED TO PIN

2, PIN3 JUMPED TO PIN 4 AND PIN 5

JUMPED TO PIN 6 UNLESS DIRECTED

OTHERWISE BY FLASHCUT TECH

SUPPORT.

JP84/JP85: INPUT POWER SELECT

SHOULD BE JUMPERED THE SAME

WAY…

1-2: INPUTS DRIVEN BY ON-BOARD

VCC

2-3: INPUTS BIASED BY VOLTAGE ON

TB40

JP86: USB GROUND

SHOULD BE JUMPED TO PULL USB

GROUND TO CHASSIS GROUND

JP87: CHASSIS GROUND

SHOULD BE JUMPED TO PULL

INTERNAL SIGNAL GROUND OF THE

SIGNAL GENERATOR TO CHASSIS

GROUND.

TERMINAL BLOCKS (GREEN)

TB40: ISOLATED INPUT POWER

VOLTAGE APPLIED HERE BIASES

INPUTS IF JP84/JP85 ARE SHORTED

PINS 2-3; DO NOT

EXCEED 5V ON THIS TERMINAL

UNLESS SPECIFICALLY ARRANGED

WITH FLASHCUT TECH SUPPORT.

TB80: SMC POWER (24V)

APPLY 24 VDC HERE TO BIAS THE

STEPPER MOTOR CONTROLLER

BOARD(S) PLUGGED INTO SLOTS

SMC1-SMC5

FlashCut CNC Section 11 Appendix

52

Power

+3.3V

3.3 V 3000 MA

1

2

TB80

MKDSN

LOGIC POWER

4.8 TO 15 V IN

HV-PWR

HV-GND

CHASSIS

HV-PWR

24-40 V AT UP TO 10 A FOR FUNCTION SLOTS

+5V

VCC

GND

POWER JUMPERS

UL CLASS C: 10 A @ 300 V WITH 14 AWG

1

2

JP87

10 A!

+5V

6.5 TO 25 V IN

5.0 V 3000 MA

9 - 24 VDC @ 2 A

LOW ESR LOW ESR

C85

0.1 UF

+

C82

22 UF

+

C83

22 UF

1

2

JP80

D80

TVS 26V 400W

1

2

JP81

FUSE

POWER

1

2

JP82

SWITCH

+7V

+3.3V

VIN3+5.0

2

+5.0

4

GND

1

U80

LM1085IS-5.0

FWB80

GBPC6005

1

2

TB40

MKDSN

TB-VCC

TB-GND

OPT-VCC

OPT-GND

NOTE 1.

FB80

434-6H-901

1

2

3

JP84

1

2

3

JP85

VIN3+3.3

2

+3.3

4

GND

1

U81

LM1085IS-3.3

NOTE 1.

UPPER RIGHT SCREW MOUNT HOLE IS CHASSIS

FOR U80

5734

FOR U81

5734

HEATSINK HEATSINK

+

C80

330 UF

C86

1 UF

+

C84

330 UF

C81

1 UF

1 2

3 4

5 6

JP83

Header 3X2

USBSHIELD

1

2

JP86

DBSHIELD USBSHIELD

SYSTEM GROUNDING OPTIONS

C87

0.001 UF

R87

1M

C88

0.1 UF

FlashCut CNC Section 11 Appendix

53

Outputs

GPO0

GPO1

GPO2

GPO3

GPO4

GPO5

GPO6

GPO7

LED-USB

LED-AUX

LED-PWR

OUT1-STB

OE

1

LE

48

D147Q1

2

D246Q2

3

D344Q3

5

D443Q4

6

D541Q5

8

D640Q6

9

D738Q7

11

D837Q8

12

U50A

74ACT16373DL

DATA0

DATA1

DATA2

DATA3

DATA4

DATA5

DATA6

DATA7

OE

24

LE

25

D136Q1

13

D235Q2

14

D333Q3

16

D432Q4

17

D530Q5

19

D629Q6

20

D727Q7

22

D826Q8

23

U50B

74ACT16373DL

VOH = 4.3 V

VOL = 0.44 V

AT 24 MA THRU 22 OHMS:

VOH = 3.8 V

VOL = 0.97 V

VBUS-OK

PANEL LED DRIVER

5V-OKVBUS OKAXIS1 AXIS2 AXIS3 AXIS4

12

CR51

GRN

12

CR52

GRN

12

CR53

GRN

12

CR54

GRN

12

CR57

YEL

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

RP51

22 OHM

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

RP54

470

+5V

AXIS5

12

CR55

GRN

CR61

ORG

FOR DEBUG

OUT-ENA

LED-ST1

LED-ST2

LED-ST3

LED-ST5

LED-ST4

SEE MAKO-IF SHEET FOR DIR LED DRIVE U52B

ENCODER DIR

LED-STEP1

LED-STEP2

LED-STEP3

LED-STEP4

LED-STEP5

R57

10K

+5V

+5V

12

CR58

GRN

STEP LEDS

S

1

2Y

6

1A

2

2A

7

VCC

8

GND

4

1Y

3

CLM

5

U53

SN75477D

+5V

1

2

3

4

5

6

JP53

RELAY DRIVE

24V 300MA

5-24V RAIL

LO-SIDE OUT0

LO-SIDE OUT1

FlashCut CNC Section 11 Appendix

54

Inputs

GPI 0

GPI 1

GPI 2

GPI 3

GPI 4

GPI 5

GPI 6

GPI 7

PS 2501L-4

U 42

PS 2501L-4

U 41

O P T-V C C

+3 .3 V

1

2

3

4

5

6

7

8

9

10

820

R P4 1

SOCKETED

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

2.7K

R P4 2

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

FlashCut CNC Section 11 Appendix

55

Connectors

1

2

3

4

5

6

7

8

9

10

WM 3904

CO N5

GP O0 GPO 1

GP O2 GPO 3

GP O4 GPO 5

GP O6 GPO 7+5 V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

WM 3907

CO N4

GPI 0

GPI 1

GPI 2

GPI 3

GPI 4

GPI 5

GPI 6

GPI 7

O P T-G N D

BAC K PANEL MINI- FI T JR.S

EN A

1

20

2

21

3

22

4

23

5

24

6

25

7

8

9

10

11

12

13

14

15

16

17

18

19

27

26

DB -25M

CO N3

+5V

OPT-V CC

GN D

OPT-G ND

SE E M AKO -IF. SC HDO C FOR

MA KO H EAD ERS 2 X10 (5 EA )

SE E M CU .SCH DO C FOR

SEE PO WE R.SC HDO C F OR

HV & 5 V TE RMIN AL BLO CK S

PWR & SH IELD ING JU MPER S

SEE US B.SCH DO C FO R

US B CO NN ECTO R 1X4

GPO 0

GPO 1

ST 5

DR 5

GPI 0

GPI 1

GPI 2

GPI 3

GPI 4

GPI 5

GPI 6

GPI 7

AN D PAC U

ST1

ST2

ST3

ST4

DR 1

DR 2

DR 3

DR 4

1 2

3 4

5 6

7 8

9 10

HD R5X 2

JP50

OU TPU T A UX HEAD ER

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

HD R8X 2

JP40

IN PU T A UX HEAD ER

O P T-G N D

+5 V

PINO UTS AR E FOR 1:1 MAP PING TO M INI-FIT JR. FO R JTAG HEAD ER 2 X5

GPO 0GPO 1

GPO 2GPO 3

GPO 4GPO 5

GPO 6GPO 7

EXP ANS ION

GPI 0

GPI 1

GPI 2

GPI 3

GPI 4

GPI 5

GPI 6

GPI 7

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

He ad er 2 0X2

JP30

ST ATU S6

FAUL T6

IN 8

IN 9

IN 11

IN 12

IN 13

IN 14

IN 15IN 16

IN 17

IN 18

IN 19

IN 20

IN 21

IN 22

IN 23<<

<

<

<

<

<

<

<>

>

>

>

>

>

>

>

>

+3 .3 V

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

HD R8X 2

JP31

ST AT US LED S (G EMV ISION )

LED- DR4

LED- DR5

LED -USBLED- AUX

LED -PW R

LED -ST 1

LED -ST 2

LED -ST 3

LED -ST 5

LED- DR1

LED- DR2

LED- DR3

LED -ST 4

+5 V

IN 24

IN 25

IN 26

IN 27

IN 28

IN 29

IN 30

IN 31

ENC OD ER DIR

MC U-D AC0MC U-D AC1

MC U-A DC0

OU T4 -STB

AU X1- STB

AU X2- STB

AN D PACU

DATA 0 DATA 1

DATA 2 DATA 3

DATA 4DATA 5

DATA 6DATA 7

OU T3-S TB

OU T2 -STB

+5 V

EX PAN SION

<

<

<

<>

>

>

>

>

+3 .3 V

ENC OD ER CL KSP HO ME

AGND

OU T1-S TB

OU T-ENA

+5 V

>

+3 .3 V

>

>

>

>

>

>

>

>

<

<

<

<

<

<

<

+3 .3 V

+3 . 3 V

+3 . 3 V

AG ND

AV+

<

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

35 36

37 38

39 40

He ader 20X2

JP32

+3 .3 V

Rx D2

TxD 2

FR OM M CU

TO M CU

>

<

<

>

>CS 6

<

IN 0

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 10

1 2

3 4

5 6

7 8

9 10

11 12

WM 18561

JP33

ST EP & DIR ( GEMV ISIO N)

ENA

GN D

ST 5

DR 5

ST 1

ST 2

ST 3

ST 4

DR 1

DR 2

DR 3

DR 4

A0 A1><

+7 V +7 V

FlashCut CNC Section 11 Appendix

56

Axis Plug-In Interface

DIR1

DIR2

DIR3

ST 1

ST 2

ST 3

ST 4

DR 1

DR 2

DR 3

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

22 OH M

RP5 5

ST P1

ST P2

ST P3

ST P4

ST PX & D IRX FROM CPL D

HV-P WR HV-P WR

HV -GN DHV -GN D

EA RTH

DR 1

DR 2

DR 3

DR 4

EN A

CS1

CS2

CS3

CS4

SM 0

SM 1

HV -P W RMA KO-1

MA KO-2

MA KO-3

MA KO-4

STAT US 4

STAT US 3

STAT US 2

STAT US 1

+5 V

FR OM M CU

TO M CU

FAULT 4

FAULT 3

FAULT 2

FAULT 1

ST 1

ST 2

ST 3

ST 4

SCO M1

SCO M2

SCO M3

SCO M4

Rx D2

TxD 2

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

171918

20

SKT 10X2

JP71

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

171918

20

SKT 10X2

JP73

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

171918

20

SKT 10X2

JP72

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

171918

20

SKT 10X2

JP74

DR 5

CS5

MA KO-5

STAT US 5

FAULT 5

ST 5

SCO M5

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

171918

20

SKT 10X2

JP75

OE

1

LE

48

D147Q1

2

D246Q2

3

D344Q3

5

D443Q4

6

D541Q5

8

D640Q6

9

D738Q7

11

D837Q8

12

74AC T16 373DLU52A

SM 0

SM 1

CS1

CS2

CS3

CS4

SCO M1

SCO M2

SCO M3

SCO M4

CS5

SCO M5

ST P5 ST 5

SCOM-STB

ILCS -ST B

OE

1

LE

48

D147Q1

2

D246Q2

3

D344Q3

5

D443Q4

6

D541Q5

8

D640Q6

9

D738Q7

11

D837Q8

12

74AC T16 373DLU51A

DATA 0

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

OE

24

LE

25

D136Q1

13

D235Q2

14

D333Q3

16

D432Q4

17

D530Q5

19

D629Q6

20

D727Q7

22

D826Q8

23

74AC T16 373DLU51B

DATA 0

DATA 1

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

22 OH M

RP5 2

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

22 OH M

RP5 3

FALLIN G ED GE OF I L-CSX IS

LATC H F OR SM0:1 O N M AKO-X

+5 V

+5 V

+5 V

+5 V

ST P-E NA

DIR4

EN AB LE

DR 4

EN A

DIR5

DR 5

LED -DR 4

LED -DR 5

OE

24

LE

25

D136Q1

13

D235Q2

14

D333Q3

16

D432Q4

17

D530Q5

19

D629Q6

20

D727Q7

22

D826Q8

23

74AC T16 373DLU52B

DIR1

DIR2

DIR3

DIR4

DIR5

LED -DR 1

LED -DR 2

LED -DR 3

ST P-E NA

IN 8

IN 9

IN 11

IN 12

IN 13

IN 14

IN 15

IN 16

IN 17

<

<

<

<

<

<

<

<

<

<

CS6

22R5 1

22R5 2

22R5 3

IN 10

10K

R5 6

+5 V S W

+5 V S W

FlashCut CNC Section 12 Internal Connections

57

12. Internal Connections

FlashCut CNC Section 12 Internal Connections

58

Connection Schematic

8 Amp Microstepping Drive 8 Amp Microstepping Drive 8 Amp Microstepping Drive

JP83

JP33

JP50

JP40

JP71

JP72

JP73

JP74

JP75

JP85

JP84

JP30

JP31

JP32

JP80

JP81

JP82

JP23

TB40

TB80

Signal Generator

P203

P108

P204

P103

P201

P101

C101

LED's

Power Board

Switch

Voltage

Selector

1

1A

1B

1A

1

2

2

2A

2A

2B

GND

N

L

AC

Inlet

To Fan

1

2

3

4

6

5

1

2

3

4

6

5

1

2

3

4

6

5

Axis 1

Axis 2

Axis 3

Axis 1

Axis 2 Axis 3

JP53

Relay

Output

FlashCut CNC Section 12 Internal Connections

1

Revision History

Revision

Date

Description of Revision

A

2/26/10

Initial write up

B

5/3/10

1st Edit

C

5/7/10

1st Revision

D

8/17/10

2

nd

Revision

E

11/03/10

3rd Revision

Loading...

Loading...