Flare Metro, Tuscany Standard Installation Manual

Flare Outdoor fire

Installation Guide

Metro or Tuscany Standard

Please read thoroughly before commencing installation

Manufacturers’ Notes

• Sika fix or a similar Anchor fix product is used in the assembly of this fireplace. Please read

the manufacturers’ instructions carefully.

• Bear in mind Anchor fix has a pot life, so make sure you have everything ready before you

start.

• Use OSH approved lifting equipment and avoid at all times working under suspended panels.

• It is important that this fireplace is not run as an open fire until both the fire bricks and heat

shields have been installed.

• Allow Anchor fix 48 hrs to cure before running the fire place.

• Both the fire bricks and concrete modules will have moisture in them as a result of the

manufacturing process. This needs to dissipated slowly otherwise they will crack as the

moisture expands and turns to steam. The only way this can be done is with six or eight

small fires where the heat intensity slowly increases. Starting with a fire that brings the fire

bricks up to warm to touch temperature and then progress with the following fires until the

concrete modules are at a warm to touch temperature.

Every care has been taken to ensure that this product has been constructed to the designer’s

specifications. Prior to shipping the fire place has been assembled & disassembled and a

comprehensive check of the kit set was completed to ensure that all parts were present.

Tools & product required

• spade or shovel

• level

• tape measure

• vise grips

• rubber mallet

• sash cramp

• caulking gun

• ladder

• wheel barrow

• two swift lift devises & chains

• 10 X 20kg bags of handy crete 17MPA

If fitting fire bricks

• concrete cutting blade on either a drop saw, angle grinder or power saw

Installation

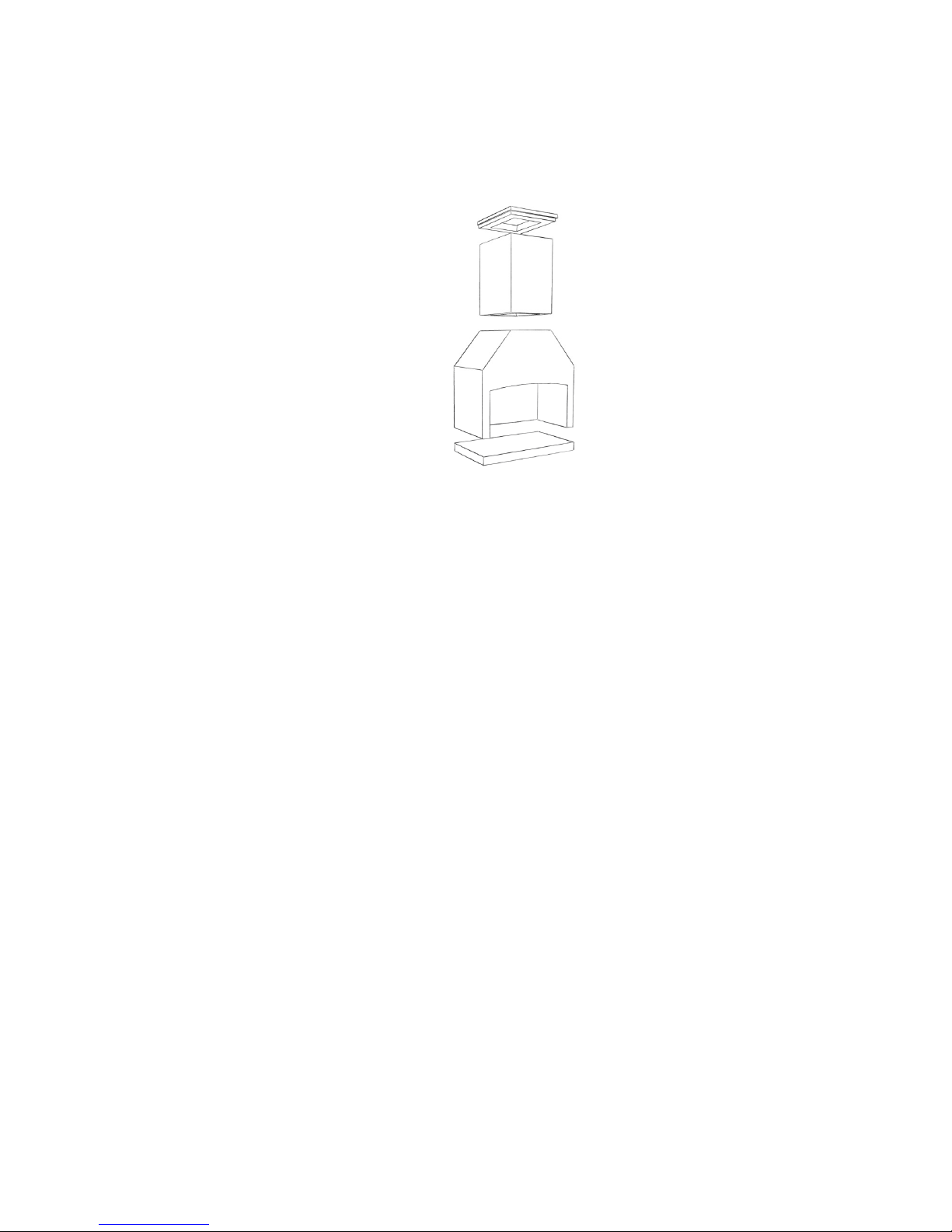

1. Start by lifting the fire box off the chimney and place it on some wooden bearers ready to lift

up at a later stage.

2. Now become familiar with each modules function and placement within the structure [See

plans]. Note: If there is water in the holes on the top of the modules this needs to be blown

out and allowed to dry before assembly

3. Ensure that the location for the fire place is level, free of top soil and has a stable building

base.

4. Mark out on the ground the footprint for the fire box module 1360mm x 720mm.

5. A footing hole needs to be dug on each corner. These need to be a minimum of 500 mm

deep and 300mm wide with an under cut at the base. Size will depend on site conditions.

[ See plans] Make the holes wide enough on the outside edge so that you can pour the

concrete into the footings with the fire box module in place. This footing system is designed

for “good ground” as defined in 3604.

6. Lift the fire box high enough to enable the four footing rods to be screwed into the four

threaded sockets on the underside corners & then tighten firmly.

7. Lower the fire box into position checking that the rods are central in the holes and that the

unit is level both ways. You need to spend time getting this part right.

8. Then fill the footing holes to the top with 17 MPA concrete.

9. Next pick up the chimney making sure that the B side is facing the back and that the holes on

top of the fire box are clean and dry.

10. Check that the chimney threaded rods are tight and clean and then fill each of the fire box

holes with Anchor fix and lower the chimney into place.

11. Check that the chimney is sitting down on the fire box and make sure that all surfaces line

up. A sash cramp and rubber mallet may be needed.

12. If bevels for the top are part of the order, apply eight generous globs of Anchor fix to the top

of the chimney and lift bevels into place and align the outside edges.

13. Installing the fire bricks.

Note: We encourage tight stacking and not mortar to hold the bricks in place. Over the years

we have found that it is inevitable that the mortar will crack and shrink and then result in lose

bricks. So take the time and cut them tight. If you want you can use a little anchor fix on the

bricks on the side walls.

Loading...

Loading...