Flanders High Temperature Rigid Filter PB1003, Precisionaire PrecisionCell HT Specification Sheet

Page 1

PrecisionCell HT

High Temperature Rigid Filters

Bulletin PB1003-1106

General

PrecisionCell HT filters are designed for high temperature applications up to 900

same rugged construction as the Gas Turbine

PrecisionCell. The HT version is manufactured of

specially selected components to meet high temperature requirements.

They are ideal for paint drying ovens or any application requiring high efficiency filtration at high temperatures. PrecisionCell HT filters are offered in two

high temperature operating ranges; 750

F and efficiency ranges of 65%, 85% and 95% per

ASHRAE Standard 52.1. Offered as a MERV 11-14

according to ASHRAE 52.2.

o

F. They feature the

ºF and 900º

Construction

The enclosing frame is manufactured of aluminized

steel, which is designed to eliminate spalling of corrosion inhibitors @ elevated temperatures.

The media pack is stabilized by a media pack

retaining bar and captured by faceguards upstream

and downstream. Grid strap bracing on the air

entering and leaving sides maintain the rigidity and

integrity of the PrecisionCell HT.

The media is designed for operation in high temperature applications and manufactured from one

continuous sheet of wet-laid micro-fine fiberglass,

which provides the required tensile strength and

operating pressure drop for these stringent applications.

Physical Data

Frame: 24 ga. aluminized steel

Media: Dual layer microfine fiberglass

Separators: Hemmed-edge corrugated aluminum

Header Frame: 7/8” wide aluminized steel

Faceguards: Aluminized steel expanded

Cross Bracing: 1/2” “T” strap downstream and

horizontal strap upstream

Important Features

• Continuous duty up to 900ºF

• Aluminized steel construction

• 65%, 85%, 95% efficiencies

• Faceguards and grid straps

• MERV 11 to 14

Flanders Filters - Foremost in Air Filtration

Toll Free: 1-800-637-2803

Page 2

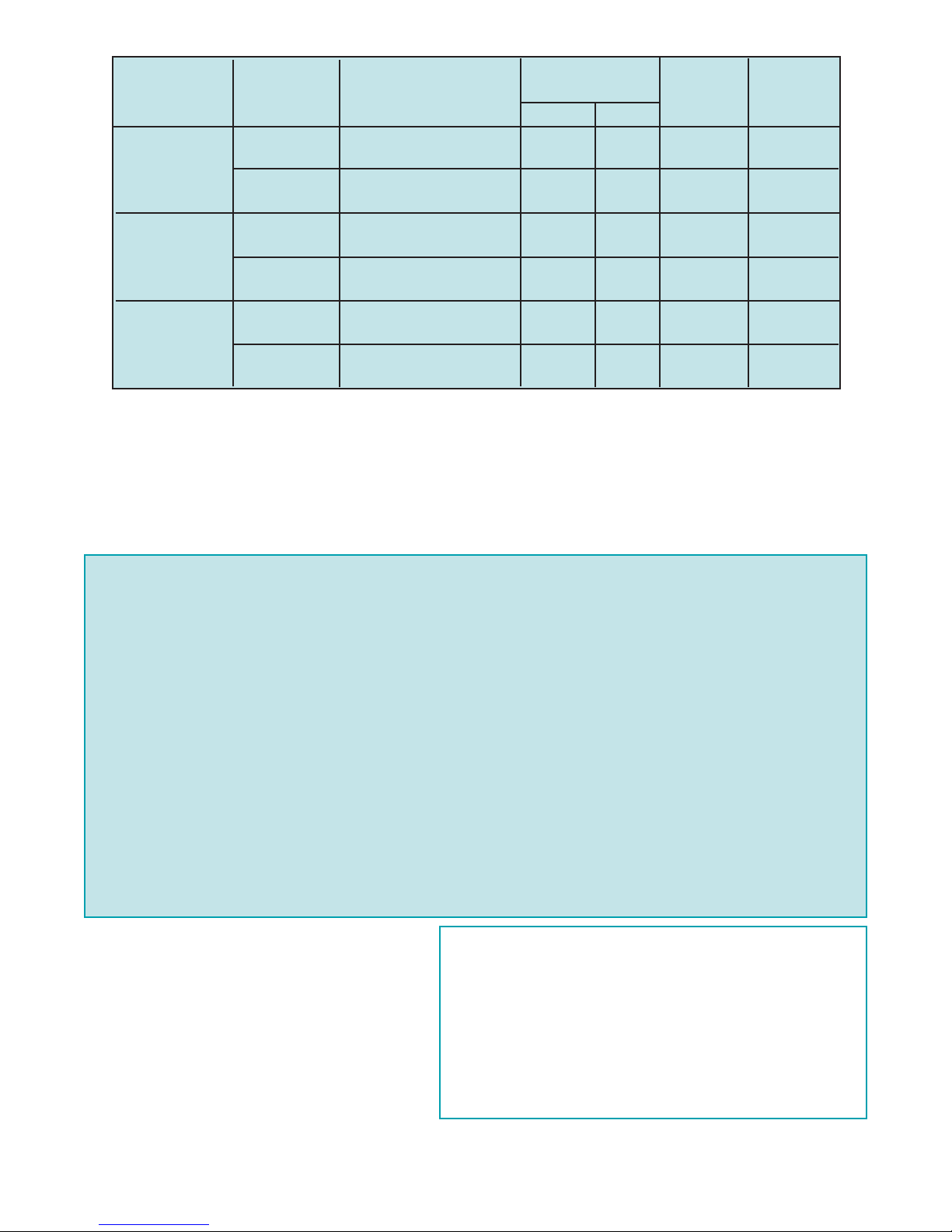

Operating

Efficiency Limit ºF

Nominal Size

H x W x D (inch)

500 fpm

Rating

Media Weight

Area Each

cfm pd (sq. ft.) (lbs)

60-65%

750

900

24 x 24 x 12 2000

.45

24 x 12 x 12 1000 69 21

24 x 24 x 12 2000

.50

140 26

175 28

24 x 12 x 12 1000 90 22

80-85%

750

900

24 x 24 x 12 2000

.55

24 x 12 x 12 1000 69 21

24 x 24 x 12 2000

.60

140 26

175 28

24 x 12 x 12 1000 90 22

90-95%

750

900

24 x 24 x 12 2000

.65

24 x 12 x 12 1000 69 21

24 x 24 x 12 2000

.70

140 26

175 28

24 x 12 x 12 1000 90 22

Notes:

1. PD represents clean pressure drop in inches w.g. The recommended final pressure drop is 2.5 inch w.g.

2. Operation down to zero velocity is satisfactory for all models.

3. Efficiencies are average and are based on ASHRAE Standard 52.1 and 52.2 dust spot test methods.

Performance values stated may be averages typical of the products listed. Contact factory for actual performance test reports on specific products.

4. Perfmormance values shown in this publication may be averages or estimates intended to generally represent

product styles. Always contact factory for latest actual test data on specific Flanders Precisionaire models.

Guide Specifications

1.0 General

1.1 High temperature rigid filters shall be

PrecisionCell HT separator type as manufactured

by Flanders.

1.2 Filter sizes and temperature ranges shall be as

scheduled on the drawings.

2.0 Filter Construction

2.1 Filters shall be constructed by pleating a continuous sheet of wet-laid micro-fine glass media

into closely spaced pleats with hemmed-edge

corrugated aluminum separators.

2.2 The filter pack shall be sealed into a 24 ga.

aluminized steel frame with fire-retardant

sealant.

Flanders - PrecisionAire

Foremost in Air Filtration

Toll Free: 1-800-637-2803

2.3 Expanded metal aluminized steel faceguards

shall be installed on the air entering and air leaving sides.

2.4 A 1/2” “T” strap shall be installed on the downstream side and 1/2” horizontal strap on the air

entering side.

3.0 Performance

3.1 Initial and final resistance shall not exceed the

scheduled values.

3.2 Media area shall equal that of the scheduled

high temperature filter.

3.3 The manufacturer shall guarantee performance

as outlined in section 7.4 of ARI Standard 800.

REPRESENTED BY:

Loading...

Loading...