Page 1

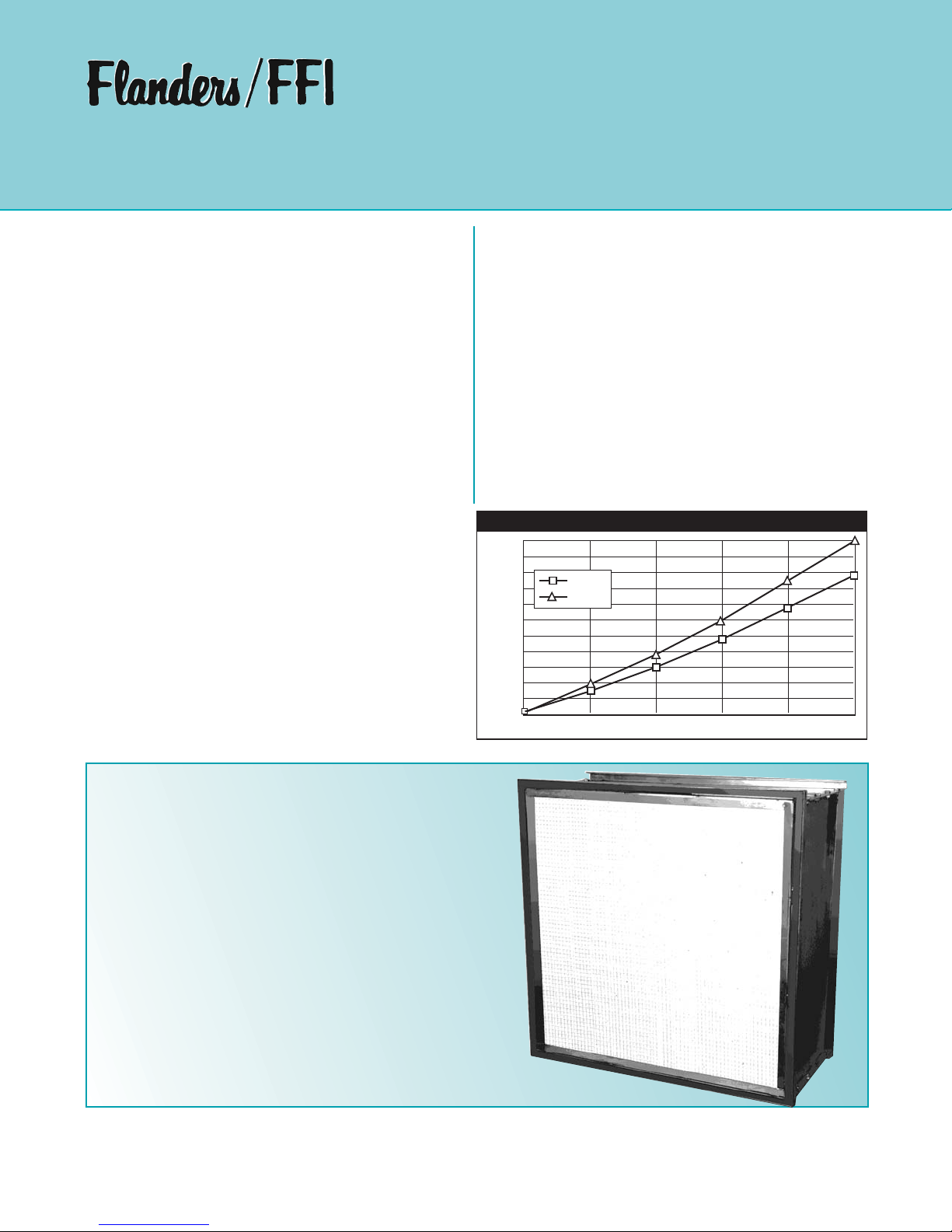

0 125 250 375 500 625

Air Velocity (fpm)

Pressure Drop (in. w.g.)

Alpha 2000 Pressure Drop vs. Air Velocity

2.20

2.00

1.80

1.60

1.40

1.20

1.00

0.80

0.60

0.40

0.20

0.00

HEPA

ULPA

®

Alpha 2000

FOREMOST IN AIR FILTRATION

High Capacity Design

The Alpha 2000 High Capacity HEPA filter is available in a nominal 12” depth configuration. It is

designed for optimum performance and low operating costs in both new and replacement systems.

The Alpha 2000 saves space, energy, and material

and labor costs with 40% more media area than the

standard capacity Alpha Cell filter.

Save Space

Alpha 2000 HEPA filters operate at 500 fpm (2000

cfm for a 24” x 24” size) at 1.35 inch w.g. clean

pressure drop versus conventional Alpha Cell filters

that operate at 250 fpm and .80 inch w.g. clean

pressure drop.

Construction

A popular construction option consists of 16 ga.

galvaneal frames and moisture-resistant microfine

wet-laid fiberglass media folded over hemmededge low amplitude corrugated aluminum separators. The filter pack is bonded to the frame by a fireretardant urethane elastomer to provide a rigid

leak-free assembly.

High Capacity HEPA Filters

Bulletin PB1402-0107

ed at conventional 250 fpm velocities during the life

of the filters. The Alpha 2000 99.97% and 99.99%

high capacity 24” X 24” X 11.5” filter has a clean

pressure drop of 1.0 inch w.g. at 1500 cfm, compared to standard Alpha Cell filters with a clean

pressure drop of 1.50 inch w.g. at the same air flow.

Save Replacement Material and Labor

Costs

Savings are significant with high capacity Alpha

2000 filters. They operate at lower velocities and

provide life cycles up to three times the life of standard capacity filters. Savings are achieved in

replacement materials and labor costs as a result of

fewer filters.

Save Energy

Alpha 2000 filters in a conventional HEPA filter

bank impose a lighter load on the fan when operat-

Important Features

• Efficiencies are 99.97% and 99.99% on 0.30

and 99.9995% on 0.12 micrometer particles.

• High capacity Alpha 2000 filters can reduce the

filter bank size

• Corrugated aluminum separators stabilize the

moisture-resistant media pack (separator

style)

• Available as a separatorless media filter with a

self-supporting media pack (*Pureform)

• Available in a variety of frame materials in

gasket or fluid seal design.

Flanders Filters - Foremost in Air Filtration

Toll Free: 1-800-637-2803

1

Page 2

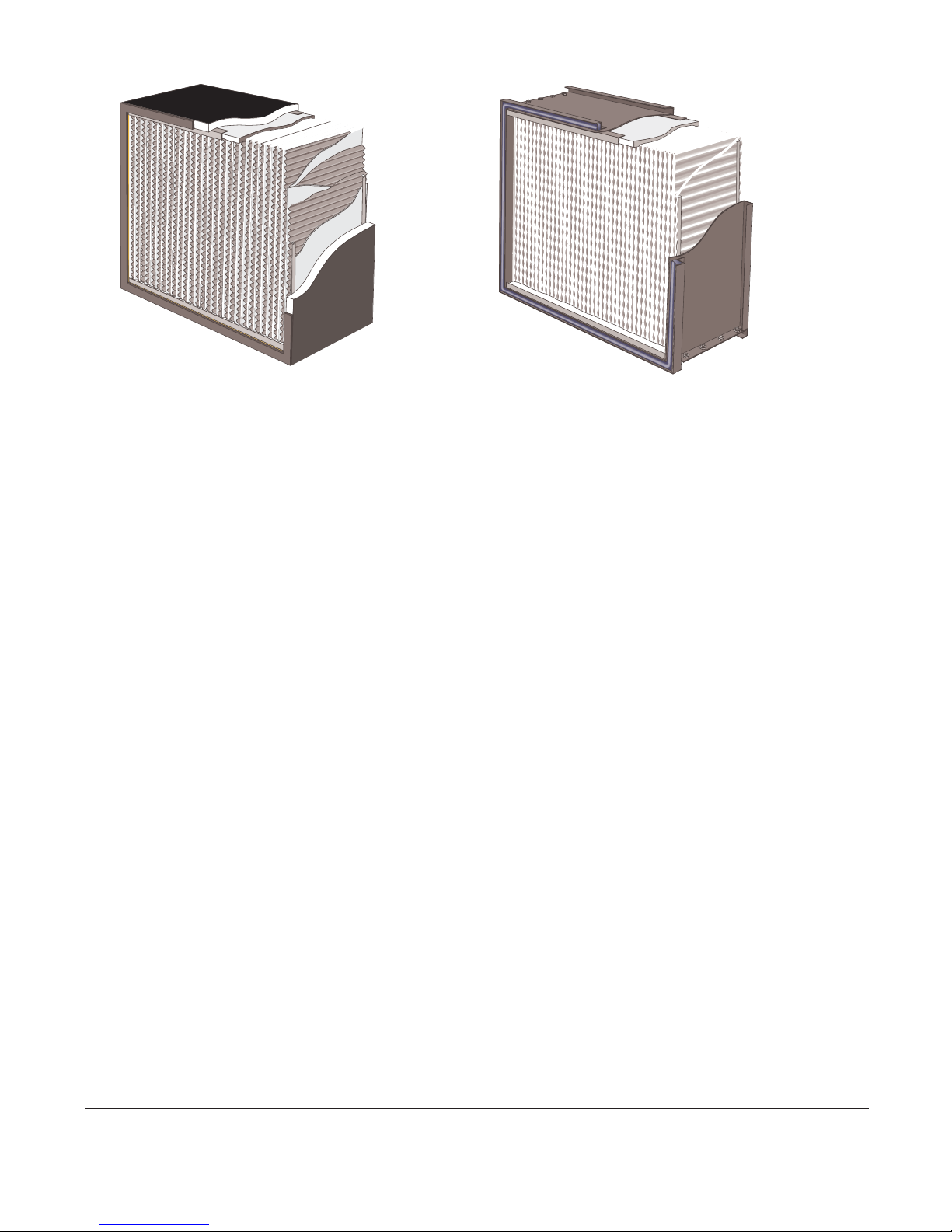

Alpha 2000 with

Separator Style

Media Pack

Alpha 2000 with

Pureform Media

Pack

Separator or Separatorless

Flanders manufactures both conventional Separator Style and Pureform Separatorless HEPA

Filters. To make a Separator Style filter, the media is folded over corrugated aluminum separators with hemmed edges to separate the pleats in the filter pack. Flanders manufactures its own

filter media, enabling it to develop a unique manufacturing process for the production of Pureform

Separatorless HEPA Filters. In one manufacturing operation, Flanders produces a self-supporting and self-separating Pureform Media Pack.

The Pureform Filter offers many advantages over conventional Separator Style HEPA Filters:

• More usable media area for longer service life because of higher dust holding capacity

• Reduced cost of ownership because of longer service life

• Maximum utilization of the media

• Can handle some harsh environments which may attack aluminum separators

• Media pack can be incinerated

• Media is 28 mils thick, which is significantly thicker than conventional 15 mil media used

in Separator Style HEPA Filters

2

Flanders Filters - Foremost in Air Filtration

Toll Free: 1-800-637-2803

Page 3

Frame Materials: Alpha 2000 Filters are available in a variety of wood and metal frame materials such as particle board, plywood, galvanized steel and stainless steel.

Gasket and Fluid Seal: The standard gasket seal is 0.75” x 0.25” neoprene for installation on either the

upstream, downstream or both sides of the filter. The standard Fluid Seal is Flanders Blu-Jel® Seal which is a

two - part silicone material suitable for temperatures up to 390°F.

Faceguards (Optional): Faceguards are used to protect the filter media from mechanical damage. The typical

faceguard material is expanded aluminized steel. Galvanized 4 x 4 mesh welded wire and Type 304 stainless steel are also available.

Underwriters Laboratories Qualification: Alpha 2000 Filters are either UL900 Class 1 or Class 2 listed depending

on materials of construction.

UL 900 Class 1 — Flanders HEPA Filters are UL 900 Class 1 rated except those filters manufactured with nonfire-retardant wood frames. Upon request, the filter will have a stamp indicating compliance with UL 900 Class

1.

UL 586 — UL 586 is typically required for Nuclear Grade HEPA Filters. Many of the Flanders non-Nuclear HEPA

Filters meet the requirements of UL 586. To be listed under UL 586, filters must be submitted to Underwriters

Laboratories for extensive testing including spot flame and environmental exposure to heated air. Upon request,

a numbered UL 586 label certifying that the filter meets Standard 586 can be applied to the filter (maximum size

is 24” x 30”).

Banks: Alpha Frames are designed for Alpha 2000 filters in built-up filter banks. Each filter is secured in the

frame with four bolt-type fasteners that either compress the gasket or press the knife edge into the gel in the filter channel to maintain a leak-tight seal.

Surelock HEPA Filter Housings are recommended for side-access applications. The filters are sealed in place

with either spring-loaded swing arm assemblies or a locking mechanism. The swing arm assemblies or locking

mechanism either compress the gasket or press the knife edge into the gel in the filter channel to maintain a

leak-tight seal.

3

Page 4

Alpha 2000 HEPA Filter Dimensions and Capacities

Filter Depth Filter Size and Frame Actual Face Size CFM Capacity at Clean Weight

(inches) Depth Designator (Inches Pressure Drop, Inches w.g. (lbs)

.95 1.35 1.75

11-1/2 GG-F 24x24 1500 2000 2500 38

GC-F 24x12 650 920 1180 26

YY-F 23-3/8x23-3/8 1350 1900 2450 37

YUF 23-3/8x11-3/8 610 865 1150 25

GN-F 24x30 1750 2550 3250 45

CC-F` 12x12 290 430 550 14

NOTE: The pressure drop for fluid seal (Separator or Pureform) and scan tested Pureform

filters will be approximately 15% higher.

Guide Specifications

1.0 General

1.1 Alpha 2000 HEPA filters shall be extended media

(separator type) (Pureform separatorless type)

filters as manufactured by Flanders.

1.2 Filter sizes, capacities and construction options

shall be as scheduled on the drawings.

1.3 Filters shall be (UL 900 Class 1)(UL586 listed.

2.0 Filter Construction

2.1 The filter pack shall be constructed by pleating a

continuous sheet of non-woven water-resistant

fiberglass media around hemmed-edge corrugated aluminum separators. (or) The filter pack

shall be constructed by pleating a continuous

sheet of formed, corrugated medium so that the

pack is self-supporting without the use of spacers of any kind, including separators, tape

strings, adhesives or strips of media.

2.2 The filter pack shall be sealed into a (galvaneal)

409 stainless steel) (304 stainless steel) (particle board) (fire-retardant particleboard) (fireretardant plywood) frame with a fire

retardant(polyurethane foam) ( solid urethane)

sealant. (Steel frames shall be 16 ga.)(Wood

frames shall be 3/4” thick.)

2.3 (A 40-durometer closed-cell neoprene gasket)

(Silicone jel in a channel) shall be provided on

one or more sides to seal the filter in the mounting device.

3.0 Performance

3.1 Initial and final resistances shall not exceed the

scheduled values.

3.2 Alpha 2000 HEPA Filters shall have a minimum

efficiency of 99.97% on 0.30 micrometer particles when tested at rated capacity on a Q-107

Penetrometer in accordance with IEST-RP-CC-

001.3, Type A. Measure the upstream and down

stream concentration of these particles with a

light scattering photometer, determine the penetration and calculate the efficiency.

3.3 Alpha 2000 Scan Tested HEPA Filters shall have

a minimum efficiency of 99.99% on 0.30 micrometer particles in accordance with IEST-RP-CC-

001.3, Type C. The scan test shall consist of

challenging the filter with a high concentration of

an approved oil aerosol or PSL Spheres.

Utilizing a photometer or particle counter, the

media pack and the pack- to- frame seal shall be

scanned to insure that there are no leaks greater

than .01% of the upstream concentration at 100

fpm face velocity

®

Flanders Filters, Inc.

531 Flanders Filter Road

Washington, NC 27889

Phone: (252) 946-8081

Toll Free: (800) 637-2803

Fax: (252) 946-3425

Website: www.flanderscorp.com

REPRESENTED BY:

Loading...

Loading...