Page 1

INSTALLATION INSTRUCTIONS PUSH BUTTON START SYSTEM

INSTALLATION INSTRUCTIONS PUSH BUTTON START SYSTEM

SYSTEM OVERVIEW

CONTENTS:

INSTALLATION - WIRING OVERVIEW

PART NUMBER FR60003

Revised 7/28/10

CONTENTS:

Before beginning the installation, please review the most recent instructions at:

http://aftermarket.strattec.com. For questions concerning installation or performance,

please call 1-800-648-8022.

SYSTEM OVERVIEW

The PUSH BUTTON START SYSTEM supplements a standard automotive ignition switch with

a radio controlled secure start system. The driver is able to control the ACC, IGN, and STR

functions by use of an illuminated push button.

The system is designed to be wired in parallel to the existing ignition switch.

The switching functions of the ignition switch, which in a standard automotive system are

used to switch battery power to accessory, ignition, and starter circuits, are replaced by

3 relays controlled by the PUSH BUTTON START SYSTEM. The individual relays are used to

provide the system power to the accessory, ignition, and starter circuits.

Push Button Switch

Remote Keyless Entry (RKE) System

Docking Station Face Plate

Near Reader Module

Push Button Switch Harness

FOB

Relay Harness

Relays

Instruction Sheet

Main Were Harness

Docking Station

Docking Station Mounting Hardware

INSTALLATION - WIRING OVERVIEW

Notes to the Installer:

1. If this is the first time you have installed the FLAMING RIVER PUSH BUTTON START SYSTEM into a vehicle, it is recommended that the complete system should be temporarily

powered up and tested outside of the vehicle prior to final installation and hard wiring into the vehicle. Either a standard 12 volt battery or a 12 VDC power supply is adequate to

power the system. Fuses should be inserted as needed into the supply circuit. This bench-top testing of the system will allow the installer to become familiar with the operation of

the system as well as the wiring, fusing, and load requirements.

2. Follow good automotive wiring practice for installation of the system.

3. All wires on the switch harness, main harness, and relay harness are printed to show the connection to/from information. In addition, a wire chart is included in the instructions to

show the wiring information.

4. The system uses the Deutsch DTM type connectors for connection to the main and antenna harnesses. All connectors are keyed with different unique housing configurations. The

Deutsch connectors may be disconnected and reconnected as needed to route the harness and antenna wires as needed. Do not remove the individual wires from the Deutsch

housing shells unless the wires are damaged and require repair.

FLAMING RIVER INDUSTRIES, INC

©2010 FLAMING RIVER INDUSTRIES, INC. ALL RIGHTS RESERVED.

800 POERTNER DRIVE

1

BEREA, OHIO 44017

800.648.8022

Page 2

3

INSTALLATION - WIRING OVERVIEW (Overview Continued)

WARNING: The Push Button Entry System must be installed by a trained professional.

5. Arc welding on the frame or the body of the vehicle may generate or induce high voltages on the frame used for grounding or within individual electronic modules. When any electric

arc type (for example MIG, TIG, PLASMA) welding is required on the vehicle, take the following precautions to protect the Push Button Start System:

a. Disconnect the positive and negative terminals from the primary battery.

b. Disconnect both of the Deutsch wiring harness connectors from the Near Reader control unit module. The harness and module may be left in place if the welding operation is well

away from the control module.

c. If welding near any of the modules, remove the modules from the vicinity of the welding operation. It is not necessary to remove the wiring harness from the area as the harness

does not contain any sensitive electronic components.

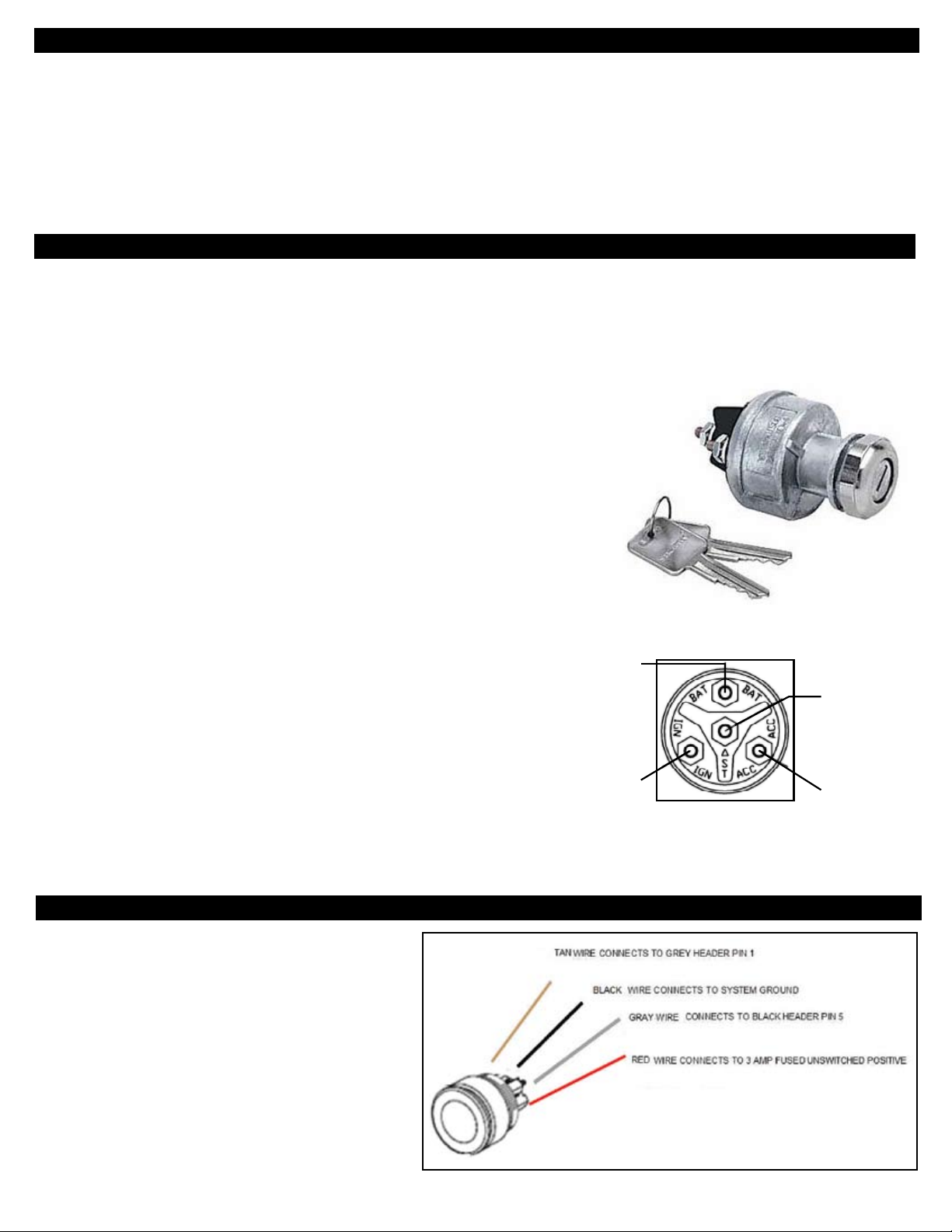

STEP 1

1. The PUSH BUTTON START SYSTEM is designed to be installed into a vehicle that utilizes a standard 4 position and 4 terminal 12 VDC automotive rated ignition switch, such as the

Flaming River Ignition Switch part number FRIGN1. For reference, the 4 switch positions utilized by turning the key clockwise are:

t Accessory (Accessory terminal has 12V in this position)

t Locked / Off (Key may be removed in this position, no power to any terminals in this position)

t Ignition / Accessory (Ignition and Accessory terminals have 12V in this position)

t Start (momentary position only, Ignition and Start terminals have 12V in this position)

The 4 terminals are

t Battery (direct to battery circuit, always powered)

t Accessory (lights, radio, other power options)

t Ignition (ignition power to coil assembly)

t Start (provides power to started circuit, connect to neutral safety switch or starter solenoid)

It is highly recommended that standard ignition switch and wiring should be kept intact to be used as a back-up

system to the push button start system.

The PUSH BUTTON START SYSTEM will require access to the battery, accessory, ignition, and starter circuits.

It is also recommended that a battery kill or similar switch should be installed to allow the system to be powered down

if the vehicle is stored for an extended length of time, as the system draws a small amount of power while the vehicle

is turned off. The system will not be damaged by repeated power up/ power down cycles and will return to a “ready”

state each time it is powered up.

2. Locate and identify the circuit terminals on the back of the ignition switch assembly.

ACC – Accessory Terminal

IGN – Ignition Terminal

ST – Starter Terminal

BAT – Battery Terminal

3. Dedicated Circuit required for System Power:

The system requires a dedicated unswitched (constant hot) 3 amp fused circuit to power the near reader control module, and provide power to the switch LED. The

dedicated unswitched (constant hot) 3 amp fused circuit should not be used for other functions, as if the power to this circuit is interrupted while the system is on and the vehicle

is running, it will cause the system to lose power which will turn off relays and the associated circuits that the relays are operating.

BATTERY

Flaming River Part Number FRIGN1

IGN.

STARTER

ACC

STEP 2

1. Connect Push Button Switch Harness Connectors to the Push Button

Switch Terminals (See Figure 1).

2. Mount the Push Button Switch to an interior location in the vehicle.

The switch has been designed to mount into a 7/8 inch diameter hole.

3. NOTE: The tan and gray wires are connected to the mating wires

on the main wire harness. All wires are printed to show the connection

information.

The red wire is connected to the unswitched dedicated hot 3 amp

fuse circuit.

The black wire is connected to the vehicle ground; preferably a common

ground point should be used for all of the system ground wires.

3 4

A

B

Figure 1

2

Page 3

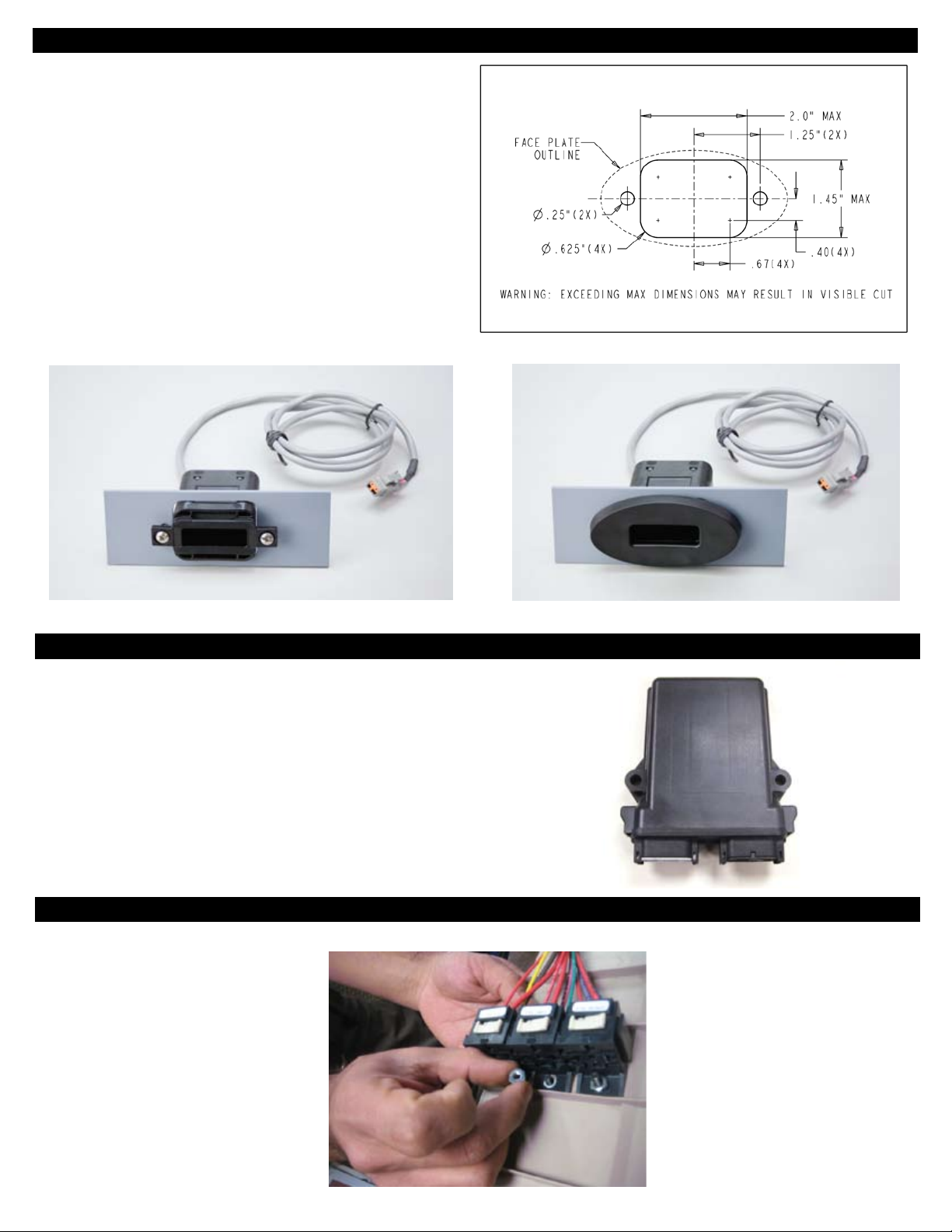

STEP 3

1. Mount the Docking Station in desired location.

a. Drill and Cut openings according to Figure 2 (Use enclosed template)

b. Route docking station cable through center opening

c. Slide docking station into opening and secure with provided bolts and lock nuts

2. Assemble the Docking Station Face Plate

a. Toe in top tab on docking station face plate

b. Rotate face to engage lower tab

c. Push face plate until both tabs snap into place

Note: If Docking Station Face Plate removal is required insert a large, flat blade screw

driver on tab and gently pry until the tab disengages. Pull Face from docking station.

Figure 2

STEP 4

1. Mount the module to a flat surface using 1/4" or equivalent screws (not included). During installation

the wiring harnesses can be removed temporarily from the control modules. The wire harness

connectors (Deutsch) are keyed to insure correct orientation when reattached to the control modules.

STEP 5

1. Mount and position in a convenient orientation the three (3) relay pack assembly to a flat surface.

3

Page 4

5

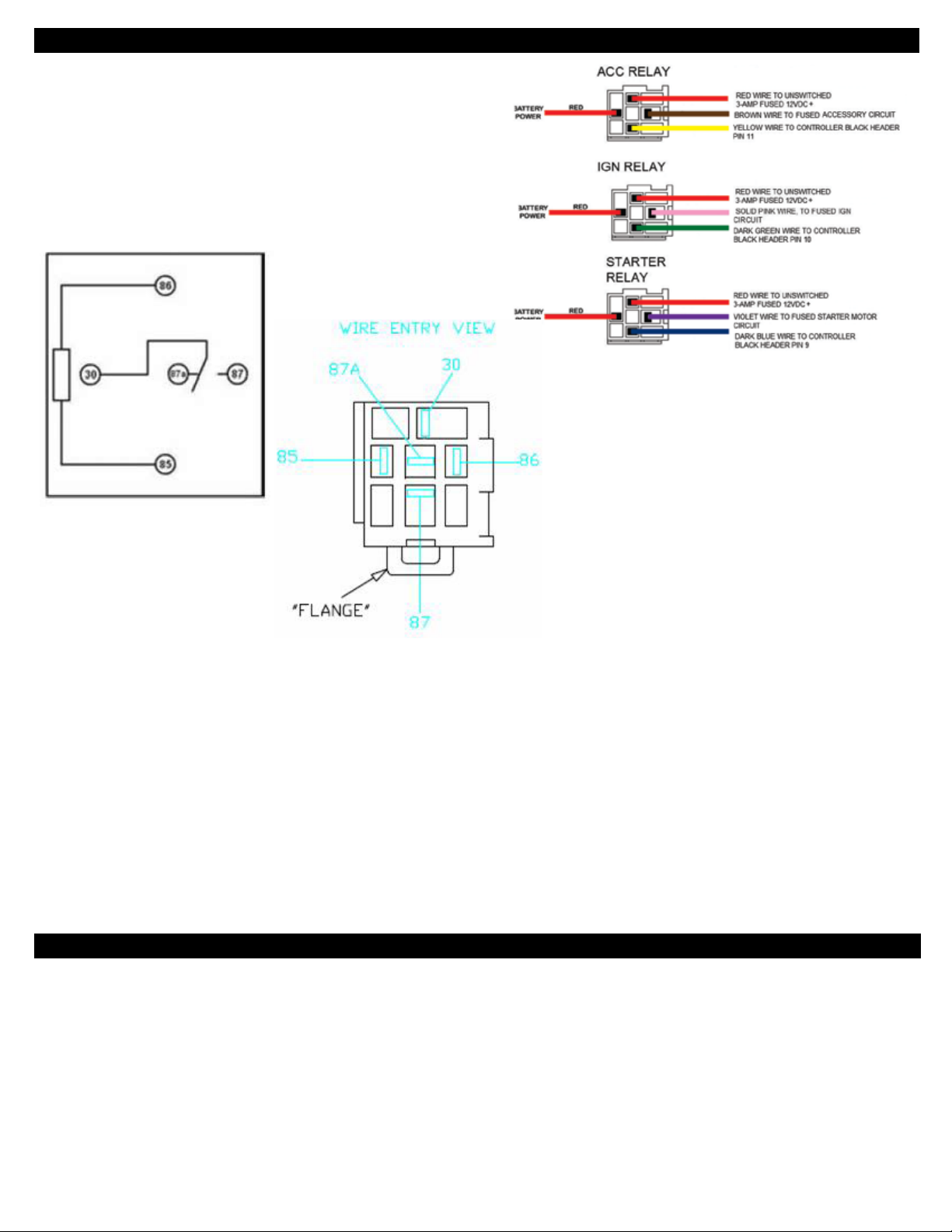

STEP 6

Relay pack wiring (please refer to the relay pack wiring diagram).

1. Operation: The system uses standard automotive rated Form C relays to

switch the high current loads. A schematic of the relay is shown along with the

pinouts as viewed from the wire entry side. The relay part number, pinouts, and

load ratings (40 amps for the N.O. pin) are printed on the sides of the relays. The

relays do not use internal diode or resistor snubbers.

FOR ALL RELAYS: Pins 30 and 86 are connected to B+, 12VDC. Pin 85 is pulled

low by the system to power the coil; pin 87 is the high current output which is

enabled when the coil is powered. Pin 87A is not used.

Form C Relay

Relay Pinouts

2. Prior to any connection to the main harness, the individual relay circuits may be tested by momentarily switching the yellow, green, or blue wires to ground, this will activate the

relay coils , and enable the relay load circuits on pin 87 of the relays.

The yellow, green, or blue wires (from relay coil pin 85) are then connected to the same color and marking of wires from the main harness. Wire lengths may be shortened or

lengthened as needed.

3. IMPORTANT: A test lamp or other method should be used to verify proper operation and sequencing of the relays with the system prior to hard-wiring the relays to the ACC, IGN, and

STARTER circuits. It is important to run this test to ensure that any neutral transmission safety interlocks and clutch interlocks are completely functional, and that the relays will

function correctly when the yellow, green, or blue wires are switched to ground.

4. All of the red wires (to 12VDC) from the relay pack may be spliced together to a larger gage single battery wire. This circuit should contain a fuse or circuit breaker with adequate

capacity to handle the combined ACC / IGN / STR loads.

Alternatively, the 3 red relay coil wires (these are the smaller 18 gauge wires at pin 86 of the relay packs) may be connected to the dedicated low power circuit, with the combined

ACC / IGN / STR red wires connected to a high current fused or circuit breaker protected circuit.

STEP 7

1. Wire the main harness.

a. The red wire from the main harness should be terminated to the dedicated 3 amp constant hot fused circuit.

b. The black wire should be terminated to an adequate ground point.

c. The blue, green and yellow wires are connected to the mating wires on the relay harness. These wires are switched by the control unit to ground in order to switch the

corresponding relays. The wires should never be tied directly to 12 volts without a load, as this will short the output transistors and damage the unit.

d. The docking station cable should be routed and connected at this time.

4

Page 5

STEP 8 - VERIFY PUSH BUTTON START SYSTEM OPERATION:

1. Ensure the FOB is located within the docking station.

2. Pressing the push button switch for one half second or pressing and holding will advance to the next mode every 0.5 seconds. All push-button presses will trigger the push button

switch to blink and cause the system to advance to the next state.

a. From OFF state: This will advance unit to ACC mode. The push-button will blink slowly.

b. From ACC mode: This will advance unit to IGN mode. The push-button will blink quickly indicating that the starter motor has not yet engaged.

c. From IGN mode: This will advance unit to CRANK mode for as long as button is pressed. Unit will go back to IGN mode when released. The push-button will stay illuminated,

indicating starter motor has been engaged.

d. From IGN mode: After a CRANK has been initiated this will advance unit to OFF state and push-button will no longer be illuminated and the sequence may be repeated.

e. From OFF state: Holding continuously will advance through to CRANK.

3. Pressing the push button for less than one half second prior to an engine CRANK will bring unit to OFF state.

STEP 9 - FOB PROGRAMMING

1. Locate a programmed FOB in the docking station. Activate the ACC mode and then Switch OFF within 20 seconds.

a. If the FOB is removed from the docking station before ACC is switched OFF then programming mode will not be entered.

b. Programming mode is identified by the Blue indicator flashing once per second.

c. Programming mode will extinguish in 30 seconds if left unattended.

2. Within 30 seconds, remove the programmed FOB from the docking station and install the FOB to be learned.

3. Press and release the Start/Stop switch (<1 sec). A valid read is identified by a steady blue indicator after which system operation transfers to ACC mode (i.e. “Ignition Switch

Sequence”).

4. Additional FOBs are added by repeating step 1 and 2.

5. A maximum of four FOBs can be stored in the system.

STEP 10 - FOB REMOVAL

1. Locate a programmed FOB in the docking station. Activate the ACC mode and then Switch OFF within 20 seconds.

a. If the FOB is removed from the docking station before ACC is switched OFF then programming mode will not be entered.

b. Programming mode is identified by the Blue indicator flashing once per second.

c. Programming mode will extinguish in 30 seconds if left unattended.

2. Press and hold the Start/Stop switch for >30 sec. After 30 seconds has expired, a steady blue indicator will indicate that all FOBs have been removed except the one used to

initiate programming mode.

5

Page 6

7

MAIN HARNESS WIRE TABLE

12 POSITION DEUTSCH

CONNECTOR COLOR

4 COLORS WITH 4 UNIQUE

KEYWAYS

http://www.laddinc.com/shared/pdf/DTM06-12S-%20%20%20RevNC.pdf

GREY 1 TAN 18 GXL

GREY 2 NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

GREY 3 NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

GREY 4 NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

GREY 5 NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

GREY 6 NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

GREY 7 NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

GREY 8 NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

GREY 9

GREY 10 RED- NEAR ANT CABLE CABLE 18 PVC CABLE NOT MARKED

GREY 11 BLACK 18 GXL GREY SOCKET PIN11 TO GND GROUND

GREY 12 RED 18 GXL

BLACK 1 NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

BLACK 2 NOT POPUL ATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

BLACK 3 NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

BLACK 4 NOT POPUL ATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

BLACK 5 GREY 18 GXL

BLACK 6 NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

BLACK 7 NOT POPULATED NOT POPUL ATED NOT POPULATED RESERVED FOR IGN3 SIGNAL

BLACK 8 NOT POPULATED NOT POPULATED NOT POPULATED RESERVED FOR IGN2 SIGNAL

BLACK 9 BLUE 18 GXL

BLACK 10 GREEN 18 GXL

BLACK 11 YELLOW 18 GXL

BLACK 12 NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED NOT POPULATED

PIN WIRE COLOR

BLACK - NEAR ANT

CABLE

GAUGE AND

INSULATION

CABLE 18 PVC CABLE NOT MARKED

WIRE MARKING FINAL CONNECTION TO NOTE

GREY SOCKET PIN 1 TO SWITCH

TERM 3

12V POWER TO GREY SOCKET

PIN12

BLACK SOCKET PIN 5 TO SWITCH

TERM A

BK SOCKET PIN9 TO STR

RELAY PIN85

BK SOCKET PIN10 TO IGN1

RELAY PIN85

BK SOCKET PIN11 TO ACC

RELAY PIN85

SWITCH TERMINAL 3

NEAR READER ANTENNA

BLACK WIRE

NEAR READER ANTENNA

RED WIRE

12 VOLT 3 AMP FUSED

CONSTANT HOT

SWITCH TERMINAL A SWITCH TERM A =LED NEGATIVE

STR RELAY PIN85 COIL IS PULLED LOW TO ACTIVATE

IGN1 RELAY PIN85 COIL IS PULLED LOW TO ACTIVATE

ACC RELAY PIN85 COIL IS PULLED LOW TO ACTIVATE

SWITCH TERMINAL 3 & 4 = NORM OPEN

TERMINALS

ANTENNA LEADS ARE NOT POLARIZED

ANTENNA LEADS ARE NOT POLARIZED

MODULE GROUND, COMBINE WITH OTHER

CONTROL MODULE

USE DEDICATED CIRCUIT COMBINED WITH

OTHER CONTROL MODULE

IGN2 AND IGN3 SIGNALS ARE OFF DURING

CRANK AND ON DURING RUN, RESERVED

FOR FUTURE BUILDS

IGN2 AND IGN3 SIGNALS ARE OFF DURING

CRANK AND ON DURING RUN, RESERVED

FOR FUTURE BUILDS

RELAY HARNESS WIRE TABLE

RELAY BLOCK

LABEL

ACC RLY 30 RED 12 GXL ACC 12V FEED PIN 30 12 VDC HIGH CURRENT 12 VDC HIGH CURRENT FEED CAN BE COMBINED WITH OTHER HIGH CURRENT RELAY FEEDS WITH PROPER FUSE OR CIRCUIT BREAKER

ACC RLY 85 YELLOW 18 GXL BLK SCKT PIN 11 TO ACC RELAY PIN 85 BLACK 12 POSITION DEUTSCH CONNECTOR PIN 11 COIL IS PULLED LOW TO ACTIVATE

ACC RLY 86 RED 18 GXL ACC RELAY COIL FEED PIN 86 12 VDC 12 VDC LOW CURRENT FEED CAN BE COMBINED WITH OTHER LOW CURRENT RELAY FEEDS WITH PROPER FUSE OR CIRCUIT BREAKER

ACC RLY 87 BROWN 12 GXL ACC HIGH CURRENT OUTPUT PIN 87 ACCESSORY LOAD PROVIDES 12V POWER TO LOAD, OLDER GM COLOR CODE

IGN1RLY 30 RED 12 GXL IGN1 12V FEED PIN 30 12 VDC HIGH CURRENT 12 VDC HIGH CURRENT FEED CAN BE COMBINED WITH OTHER HIGH CURRENT RELAY FEEDS WITH PROPER FUSE OR CIRCUIT BREAKER

IGN1RLY 85 GREEN 18 GXL BK SCKT PIN 10 TO IGN1 RELAY PIN 85 BLACK 12 POSITION DEUTSCH CONNECTOR PIN 10 COIL IS PULLED LOW TO ACTIVATE

IGN1RLY 86 RED 18 GXL IGN1 RELAY COIL FEED PIN 86 12 VDC 12 VDC LOW CURRENT FEED CAN BE COMBINED WITH OTHER LOW CURRENT RELAY FEEDS WITH PROPER FUSE OR CIRCUIT BREAKER

IGN1RLY 87 PINK 12 GXL IGN1 HIGH CURRENT OUTPUT PIN 87 IGN1 LOAD PROVIDES 12V POWER TO LOAD, OLDER GM COLOR CODE

STRTR RLY 30 RED 12 GXL STR 12V FEED PIN 30 12 VDC HIGH CURRENT 12 VDC HIGH CURRENT FEED CAN BE COMBINED WITH OTHER HIGH CURRENT RELAY FEEDS WITH PROPER FUSE OR CIRCUIT BREAKER

STRTR RLY 85 BLUE 18 GXL BLK SOCKT PIN 9 TO STR RELAY PIN 85 BLACK 12 POSITION DEUTSCH CONNECTOR PIN 9 COIL IS PULLED LOW TO ACTIVATE

STRTR RLY 86 RED 18 GXL STR RELAY COIL FEED PIN 86 12 VDC 12 VDC LOW CURRENT FEED CAN BE COMBINED WITH OTHER LOW CURRENT RELAY FEEDS WITH PROPER FUSE OR CIRCUIT BREAKER

STRTR RLY 87 VIOLET 12 GXL STR HIGH CURRENT OUTPUT PIN 87 STARTER SOLENOID LOAD PROVIDES 12V POWER TO LOAD, OLDER GM COLOR CODE

SWITCH HARNESS WIRE TABLE

WIRE

COLOR

TAN 18 GXL

GREY 18 GXL

RED 18 GXL 12V POWER TO SWITCH TERMB

BLACK 18 GXL GND TO SWITCH TERM 4 GND

RELAY PIN WIRE COLOR GAUGE AND INSULATION WIRE MARKING FINAL CONNECTION TO NOTE

GAUGE AND

INSULA-

TION

WIRE MARKING FINAL CONNECTION TO NOTE

GREY SOCKET PIN 1 TO SWITCH

TERM 3

BLACK SOCKET PIN 5 TO SWITCH

TERM A

GREY 12 POSITION DEUTSCH

CONNECTOR PIN 1

BLACK 12 POSITION DEUTSCH

CONNECTOR PIN 5

12 VOLT 3 AMP FUSED

CONSTANT HOT

SWITCH TERMINAL 3 & 4 = NORM OPEN

SWITCH TERMINAL 3 & 4 = NORM OPEN

TERMINALS

SWITCH TERM A =LED NEGATIVE

SWITCH TERM B = LED POSITIVE

TERMINALS

6

Page 7

Central Locking System User’s Manual

Functions

1. Arm

Press button on the FOB, the doors will lock automatically and the engine will be immobilised. The LED light will turn on and flash twice every 2 seconds.

2. Disarm

Press button on the FOB, the doors will unlock automatically. The LED light will turn off.

3. Emergency override

When the FOB is lost or has failed, to override the system while the car is armed,

a. Open the door with the key

b. Press the override button 3 times

c. Hold down the button for 2 seconds on the 3rd press.

The system will then be overridden and the LED light will turn on/off slowly.

4. Transmitter programming

Press the override button for 2 seconds, the LED light will turn on, press FOB button once, the LED light will flash twice to indicate the successful programming of this FOB;

press FOB button of another FOB once, the LED light will flash twice to indicate the successful programming of this FOB. Only two FOBs are functional for this system.

Technical parameter

Working voltage: 9 V~15 V

Static current: <10 mA (in arming mode)

Working current: <30A

Frequency: 433.92 MHz

INSTALLATION DIAGRAM (4-door, 1-master)

7

Page 8

9

Installation Instruction For Remote Keyless Entry (RKE) System

A. COMPONENTS & PARTS ILLUSTRATIONS:

Main Control Lock

(ML)

Support Board

(SB)

Sub-Control Lock

(SL)

Control Rod

(CR)

Central Control Box

Rod Fixing Block

Components & Parts Specification List

Model No. Name Specifications Quantity Usage

ML Main Control Lock 5 pins 1 For driver's Side Front Door

SL Sub-Control Lock 2 pins 3 For Other Three Doors

CL Central Control Box - 1 -

SB Support Board - 4

For Fixing Main Control Lock And

Sub-Control Lock

(CL)

(BR)

CR Control Rod - 4 BR Rod Fixing Block - 4 -

Ssl

Bns

Sub-Control Lock

Fixing Screws

Support Board

Bolt-Nut Sets

TS MS*8 8 -

M5*8 8 -

Control Wires UL Qualified 1 -

B. INSTALLATION PROCEDURES:

1. Installation of all control locks:

a. Unfasten the internal decoration board of the doors.

b. Be sure to position the control lock to the correct direction shown in fig. 1 (make sure the main shaft in the control lock is moving in parallel to the moving direction of the door-

lock knob snap-slot).

2 a. Either choose to apply the support board (SB) for installing the main control lock (ML) and the Sub-Control Lock (SL)

b. Or to drill two holes, with dia. 5-6mm, in the internal side of the car doors, then fasten the control locks with TS M5*14 screws (Ssl) directly

3. Assemble the control rod (CR) to the control lock (adjust to make both end-sections of the rod parallel to each other as shown in fig. 2).

4. Assemble the control rod (CR) and door-lock knob rod into the rod fixing block (BR) (as shown in fig. 3), be sure to adjust until adequate motion stroke is found, then fasten the rods

with the Hexahole cap bolts tightly (adjustment of stroke is shown in fig. 4).

8

Page 9

Cautions: 1. The installation of the Control Lock shall never obscure the mechanism and motion of car door and glass.

2. Make sure the motion direction of control lock mainshaft is in parallel to that of door-lock.

9

Page 10

11

2. CONTROL WIRE WIRING ILLUSTRATION

CAUTIONS: 1. Connect – Red wire and Black wire to battery Cathode and Anode respectively.

2. For protecting wires passing through door and car casing, please insert wires through flexible tubes for preventing moisture.

3. MECHANISM MOTION TEST:

a. Pull and push the door-lock snob repeatedly to see if the other three door lock moves in the same direction and at the same time. (When a reversed motion is found, please reverse

the connection of the Yellow and Green wires)

b. When the test is finished successfully, fasten the door internal decoration board properly.

10

Page 11

4. TROUBLESHOOTING

CONDITION RESOLUTION RECOMMENDED

1. Neither the main-control lock nor sub-control lock functions. A. Check the connection of power wire and the Fuse to see if they are in

normal conditions.

B. Check the plug of control box to see if it is normal.

C. Replace the Central Control Box when necessary.

2. Main control lock disfunctions. A. Check the matching color-code wires to see if they are correctly matched, or if

there is a short way.

B. Check the matching constructions to see if there are any loose parts.

C. Check and identify the correct moving stroke and installed parts directions.

D. Replace the main control lock, if necessary.

Sub-control lock disfunctions. A. Check the matching color-code wires to see if they are correctly matched, or if

there is a short way.

B. Check the matching constructions to see if there are any loose parts.

C. Check and identify the correct moving stroke and installed parts directions.

D. Replace the main control lock, if necessary.

Warranty Statement

The STRATTEC Push Button Start System is guaranteed to be free from defects in material and/or workmanship and to perform as advertised when properly installed, used and

maintained in accordance with the installation instructions. Failure to adhere to and/or comply with the installation instructions will void all associated warranty obligations. Should

any part(s) prove defective within 6 months from date of purchase, it (they) will be replaced F.O.B. our factory without charge provided the defective part(s) is returned to our

factory transportation charges prepaid.

STRATTEC Security Corporation will not be responsible for labor charges, loss or consequential damage of any kind or character caused by defected parts or charges incurred in the

replacement or repair of defective parts by the Purchaser. Careless handling, including that by freight companies, and improper installation or use may void all warranties.

FCC WARNING:

Note: Changes not expressly approved by the party

responsible for compliance could void the user’s

authority to operate the equipment.

FCC Interference Statement (Part 15.105 (b))

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one of the following measures:

• Reorientorrelocatethereceivingantenna.

• Increasetheseparationbetweentheequipmentandreceiver.

• Connecttheequipmentintoanoutletonacircuitdifferentfromthattowhichthereceiverisconnected.

• Consultthedealeroranexperiencedradio/TVtechnicianforhelp.

FCC - Radio Frequency Devices

This device complies with part 15 of the FCC Rules. Operation

is subject to the following two conditions: (1) This device may

not cause harmful interference, and (2) this device must accept

any interference received, including interference that may

cause undesired operation.

Cahiers des charges sur les normes radioélectriques du Canada

L’utilisation de ce dispositif est autorisée seulement aux

deux conditions suivantes: (1) il ne doit pas produire de

brouiliage, et (2) l’utilisateur du dispositif doit être prêt

à accepter tout brouilage radioélectrique reçu, méme

si ce brouiliage est susceptible de compromettre le

fonctionnement du dispositif.

11

Loading...

Loading...