Page 1

®

Flaming River Industries, Inc.® 800 Poertner Dr. Berea,Ohio 44017

440-826-4488 • Fax 440-826-0780 • Toll Free 1-800-648-8022

www.flamingriverhd.com

BATTERY CONTROL SAFETY SYSTEMS

5

0

0

A

M

P

K

I

L

L

S

W

I

T

C

H

TheThe

Page 2

2

Flaming River Industries 1-800-648-8022

P/N 102606 • Rev A • 06/06/17

500 Amp Battery Disconnect Switch:

FR1046 The Big Switch 500 with Lock-Out Bracket

FR1046LED The Big Switch 500

with Lock-Out Bracket & LED Indicator

FR1047 The Big Switch 500 Lock-Out Hole

with Lever Handle w/ Retrot Diamond Bracket

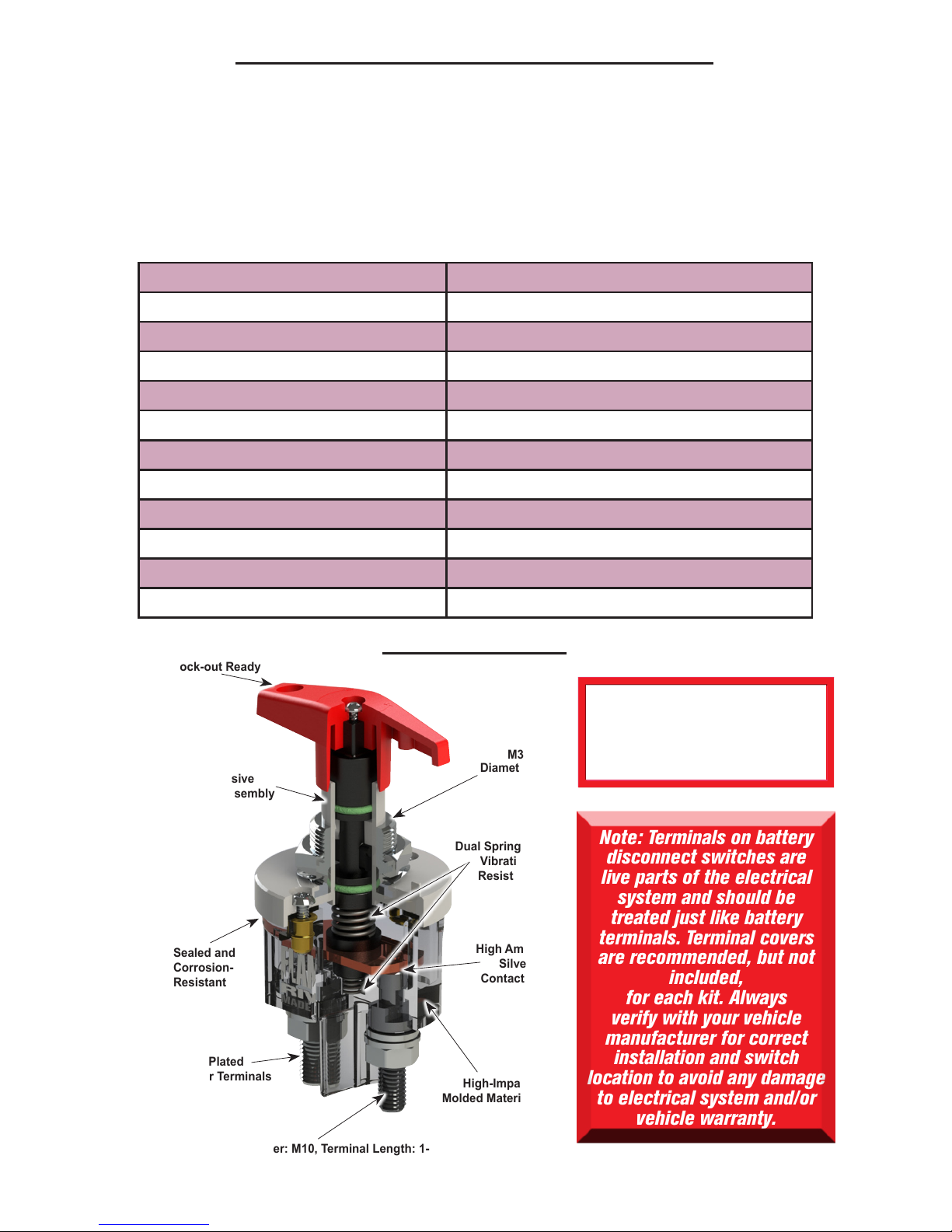

Voltage 12V/24V

Max Continuous Current 500 Amps

Environmental Protection Rating IP65

Corrosion Resistant Yes

Operating Temperature -40°F to + 176°F (-40°C to +80°C)

Switch Body Material Glass-filled nylon

Internal Contacts AgSnO2 (Silver Tin Oxide) Plated Copper

Contact Terminals AgSnO2 (Silver Tin Oxide) Contacts

Stud Diameter M10

Available Stud Length 1.18 in (1-3/16 in)

Contact Hardware Nickel-plated brass

M10 Tightening Torque 11-13 ft·lbs

Note: Terminals on battery

disconnect switches are

live parts of the electrical

system and should be

treated just like battery

terminals. Terminal covers

are recommended, but not

included,

for each kit. Always

verify with your vehicle

manufacturer for correct

installation and switch

location to avoid any damage

to electrical system and/or

vehicle warranty.

Note: Terminals on battery

disconnect switches are

live parts of the electrical

system and should be

treated just like battery

terminals. Terminal covers

are recommended, but not

included,

for each kit. Always

verify with your vehicle

manufacturer for correct

installation and switch

location to avoid any damage

to electrical system and/or

vehicle warranty.

Non-Corrosive

Plunger Assembly

High Amp

Silver

Contacts

Lock-out Ready

Sealed and

Corrosion-

Resistant

Dual Springs/

Vibration

Resistant

M30

Diameter

High-Impact

Molded Material

Silver-Plated

Copper Terminals

Terminal Diameter: M10, Terminal Length: 1-3/16”

Switch Features

(Lock

not Included)

To activate switch,

push handle down

while turning

Page 3

3

Flaming River Industries 1-800-648-8022

P/N 102606 • Rev A • 06/06/17

Item No. Description Qty

1.................... Switch Assembly ........................................................................... 1

2.................... Switch Bracket ................................................................................ 1

3.................... Switch Handle/Screw ...................................................................... 1

4.................... Off/On Logo Tag .............................................................................. 1

5.................... Wave Washer .................................................................................. 1

6.................... M30 Hex Nut ................................................................................... 1

7.................... 1/4”-20 x 7/8” Hex Cap Screw ....................................................... 2

8.................... 1/4” Flat Washer ............................................................................. 2

9.................... 1/4”-20 Nylock Nut ......................................................................... 2

10.................. Hex Nut for Terminal Stud .............................................................. 2

11 .................. Lock Washer for Terminal Stud ..................................................... 2

12.................. Flat Washer for Terminal Stud ...................................................... 2

1

3

4

8

7

11

6

9

2

5

12

10

FR1046

FR1047

FR1046

FR1047

FR1046LED

(Lock

not Included)

Kit Contents (Varies based on part number)

Page 4

4

Flaming River Industries 1-800-648-8022

P/N 102606 • Rev A • 06/06/17

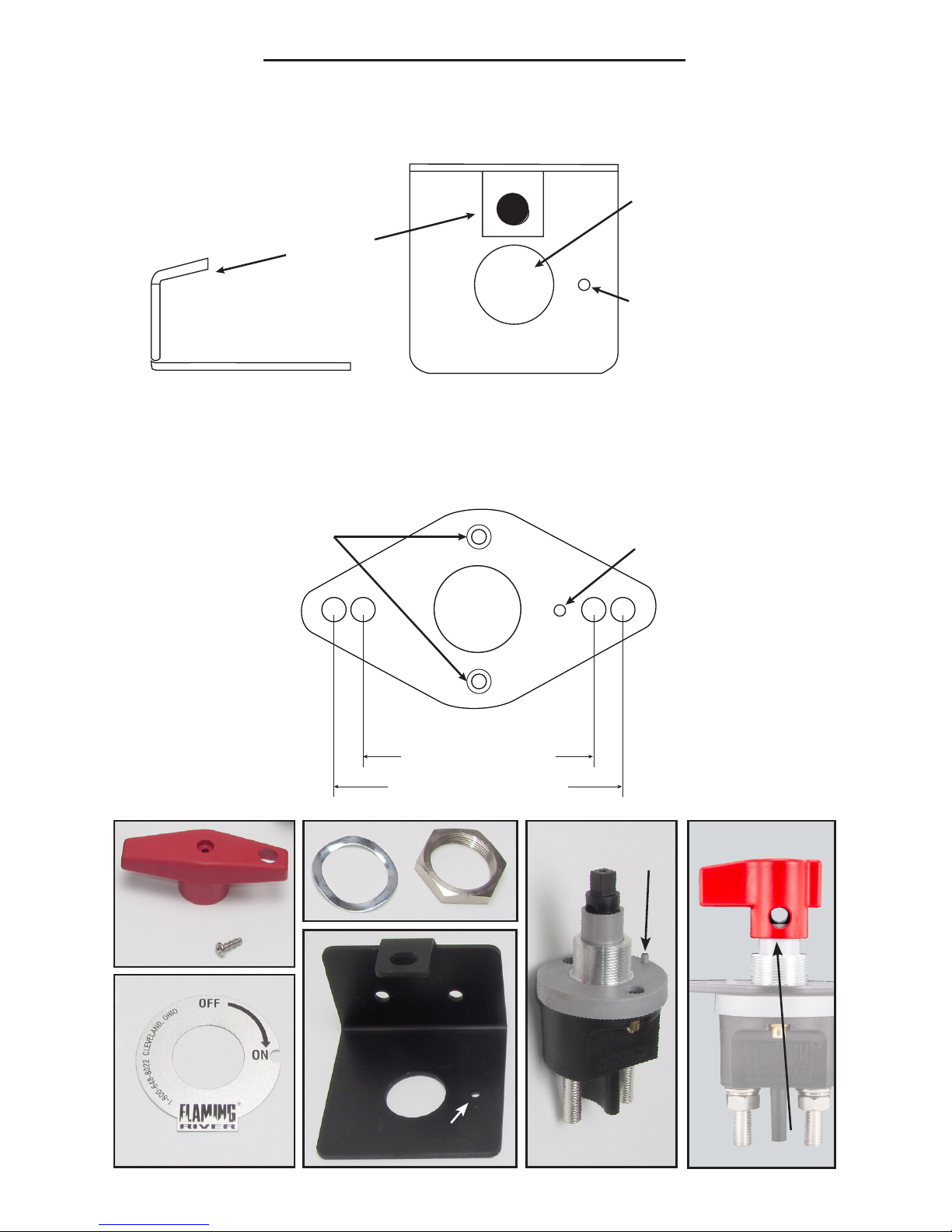

Switch and Bracket Assembly

(Refer to diagrams on following page)

FR1046/FR1046LED

1. Place the red T-handle (A) on top of the switch (F) and turn

clockwise to turn the switch ON and remove the T-handle.

2. Remove the M30 hex nut (C) and wave washer (B) from the

packaging.

3. Insert the neck of the switch (F) into the mounting bracket hole

(E) and slide on the ON/OFF plate (D), wave washer (B), and

M30 hex nut (C).

4. Tighten the hex nut (C) until the wave washer (B) is completely

at. Do not tighten the nut more than 7-10 ft.·lbs. Make sure the

tab on the gray switch (F) top ts into the small alignment hole.

The top of the gray switch (F) should be ush against the bottom

of the bracket (E).

5. Install the T-handle (A) on the shaft of the switch. Insert and

tighten the Phillips head screw into the handle. Rotate the switch

to the OFF position by turning the handle counter-clockwise.

FR1047

1. Diamond bracket is already properly installed on your FR1047

Battery Disconnect Switch.

2. Using the information in gure 2, determine the desired

mounting hole width: either 3.15” (80 mm) or 3.94” (100 mm)

spacing.

3. Install the switch in the vehicle and the lever style handle (G)

onto the top of the switch shaft with the supplied phillips head

screw.

A

D

Figure 1 (Lock-Out Bracket)

Lockout

Bracket

Switch

Mounting Hole

Locating Tab Hole

Top View

Figure 2 (Diamond Bracket)

Switch

Mounting Hole

Switch

Mounting Holes

Locating Tab Hole

Mounting Holes:

3.15” (80 mm)

3.94” (100 mm)

Page 5

5

Flaming River Industries 1-800-648-8022

P/N 102606 • Rev A • 06/06/17

A

B

C

D

E

F

Alignment Hole

Alignment Tab

Figure 1 (Lock-Out Bracket)

Lockout

Bracket

Switch

Mounting Hole

Locating Tab Hole

Top View

Figure 2 (Diamond Bracket)

Switch

Mounting Hole

Switch

Mounting Holes

Locating Tab Hole

Mounting Holes:

3.15” (80 mm)

3.94” (100 mm)

Switch and Bracket Assembly (cont.)

G

Page 6

6

Flaming River Industries 1-800-648-8022

P/N 102606 • Rev A • 06/06/17

Electrical Connections

Make sure you have properly mounted the switch with the included

attachment hardware before installing cables, wiring, or making

electrical connections. Remove the positive and negative cables

connected to the battery before proceeding. This is for the installer’s

safety. No part of the vehicle should be energized while installing the

switch. The Big Switch 500 Series battery disconnect switches can

be used to disconnect either the positive or negative terminals of the

battery. Verify installation and wiring with the vehicle’s manual

and follow all vehicle manufacturer instructions.

1. Select two battery cables of required length for the installation.

Cable gauge size will be at the installer’s discretion depending

on vehicle requirements and specications. If the installer

wishes to cut and reuse the original battery cable, make sure

that there is enough cable to reach the switch without stressing

the cable or the battery disconnect switch.

2. Attach the two cable ends to the switch terminals as shown in

below. Tighten the M10 nuts until the lock washers atten, but

no tighter than 11-13 ft.·lbs.

3. Once the cables are installed and tightened, terminals covers

(recommended, but not included) should be applied to the

switch terminals.

4. Make sure the The Big Switch 500 is turned to the OFF position.

Connect the load-side cable to the required point on your

vehicle FIRST. Hook up the cable that connects directly to the

battery terminals SECOND. See below for clarication.

5. Turn ON The Big Switch 500 and make sure your vehicle is

powered.

FR1003TM Terminal Covers

Sold in sets of two. Can be used to

cover cables on all Battery Disconnect

Switches. Sold separately from switch.

Page 7

7

Flaming River Industries 1-800-648-8022

P/N 102606 • Rev A • 06/06/17

Connection of the LED indicator should be completed at the time

the switch is mounted but before battery cables are connected

to the switch. Do not install the switch or LED indicator while the

vehicle battery is connected to the vehicle. Make sure that the area

of the chassis where the bracket is mounted has a good connection

to ground and is not insulated by plastic or paint. If this is not

possible, an additional wire should be run directly to the WHITE

ground wire to complete the circuit.

1. Make sure that the switch is installed in the bracket and mount

the switch in the desired location. Only screw on ONE of the

lock nuts.

2. Take the WHITE wire with the smaller eyelet and slide it over

the right screw. Tighten down the right lock nut so that the eyelet

is pressed rmly against the vehicle chassis for a proper ground

connection.

3. Take the BLACK wire with the large eyelet and slide it over the

screw terminal that is connected to the VEHICLE LOAD.

4. Before proceeding, make sure the battery disconnect switch is

in the OFF position.

5. Connect the vehicle load side battery cable, followed by the

battery side battery cable, and secure these connections with

the provided M10 washers, lock washers, and nuts.

6. Connect your battery cables to the positive and negative battery

terminals and test your newly installed switch.

LED Indicator Wiring Instructions (FR1046LED Only)

DO NOT ATTEMPT TO OVER

TIGHTEN THE BASE TO THE

HOUSING (7-10 FT. LBS Max..)

THIS WILL VOID WARRANTY

Battery

Cable

Positive or Negative

Terminal

Cable

Figure 3

Nickel-Plated Brass Fasteners

Connect

First

Connect

Second

To Vehicle

Load

LED Only

To

Bracket

White (neg.)

Black (pos.)

Page 8

Flaming River Ind.

800 Poertner Dr

Berea, OH 44017

800-648-8022

WARRANTY DISCLAIMER: Flaming River’s® Limited Warranty

Flaming River® warrants its products to be free from defects in material

and workmanship for a period of one (1) year after the date of purchase,

except that: The Big Switch (part number FR1046/FR1047) is warranted

for a period of three (3) years from the date of purchase, provided that it is

not mounted with a steel bracket and provided further that it is adequately

protected from environmental conditions. All electrical products other

than the Big Switch are warranted for a period of ninety (90) days from

the date of purchase. Flaming River’s® warranty liability is limited to the

replacement of defective products. Flaming River® is not liable for any

labor costs associated with any warranty claim, or for any incidental or

consequential damages.

Improper installation, abuse, racing, and/or modication of the products

voids this warranty. No warranty of merchantability or tness for a particular

purpose is made by Flaming River® with respect to any of its products.

Warnings and Recommendations

It is the customer’s responsibility to determine the suitability of a given

Flaming River® product for the customer’s uses. Likewise, it is the

customer’s responsibility to install a Flaming River® product. Contact

the vehicle manufacturer whenever installing a switch to conrm the

appropriateness of using such a switch and the recommended placement

of the switch on the vehicle.

Use qualied chassis specialists for the installation of all steering related

components. Be aware that the installation of certain Flaming River®

products may adversely impact a manufacturer’s warranty with respect to

certain vehicles and other manufactured goods. Flaming River will repair

or replace any product found to be defective in material or workmanship.

Improper installation, abuse, racing and/or modication VOID WARRANTY.

Flaming River® is not responsible for any labor costs associated with any

warranty.

Loading...

Loading...