Page 1

1960-1965 Comet

Page 2

Note: For safety disconnect battery cables and ensure that the vehicle is properly supported by jack

stands.

Before painting or powder coating of the cradle, we recommend that you pre-fit the entire system to ensure proper fitment for your application.

Inventory pg 2

Removal of Factory Steering pg 4 - 5

Installation of:

Flaming River Tilt Column pg 6

Electrical System Notes pg 7

Rack and Cradle pg 8

Universal Joint and Steering pg 9

Shaft Installation

Power Steering Pump Installation pg 10

Power Steering Bleeding Procedure pg 11

WARRANTY DISCLAIMER: Flaming River’s® Limited Warranty

Flaming River® warrants its products to be free from defects in material and workmanship for a

period of one (1) year after the date of purchase, except that: All steering columns are warranted for

a period of three (3) years from the date of purchase. The Big Switch (part number FR1005) is warranted for a period of three (3) years from the date of purchase, provided that it is not mounted with

a steel bracket and provided further that it is adequately protected from environmental conditions.

All electrical products other than the Big Switch are warranted for a period of ninety (90) days from

the date of purchase. Flaming River’s® warranty liability is limited to the replacement of defective

products. Flaming River® is not liable for any labor costs associated with any warranty claim, or for

any incidental or consequential damages. Improper installation, abuse, racing, and/or modification of

the products voids this warranty. No warranty of merchantability or fitness for a particular purpose is

made by Flaming River® with respect to any of its products. Warnings and Recommendations It is the

customer’s responsibility to determine the suitability of a given Flaming River® product for the customer’s uses. Likewise, it is the customer’s responsibility to install a Flaming River® product. Contact

the vehicle manufacturer whenever installing a switch to confirm the appropriateness of using such a

switch and the recommended placement of the switch on the vehicle. Use qualified chassis specialists

for the installation of all steering related components. Be aware that the installation of certain Flaming River® products may adversely impact a manufacturer’s warranty with respect to certain vehicles

and other manufactured goods. Flaming River will repair or replace any product found to be defective

in material or workmanship. Improper installation, abuse, racing and/or modification VOID WARRANTY.

Flaming River® is not responsible for any labor costs associated with any warranty.

Page 3

Part No. DescriPtioN Qty Notes

100954 Mounting Hardware Kit 1

100956 Power Rack & Pinion Cradle Assembly 1

FR1614 Remote Power Steering Fluid Reservoir 1

FR1934 1”DD x 3/4”DD Universal Joint 1

FR1969 3/4”DD x FR Power Universal Joint 1

FR20010RK Billet Aluminum Shift Linkage 1 Column Shift Kit Only

FR20059 Adjustable Shift Arm 1 Column Shift Kit Only

FR20097 Aluminum Floor Mount 1

FR20118-1 Wiring Connector w/Hazards 1

FR21017 Tilt Column Shift Steering Column 1 Column Shift Kit Only

FRXXXXX Tilt Floor Shift Steering Column 1 Floor Shift kit Only

FRHRN2 Horn Relay 1

FRMBPW1 Power Steering Pump Bracket 1

FRPMPSB-V Power Steering Pump w/ V-Belt Pulley 1

2

Flaming River Industries

1-800-648-8022

081511

Page 4

3

Flaming River Industries

1-800-648-8022

081511

Page 5

Original System Removal

1. If your vehicle has a column shift style

steering column, disconnect the

transmission shift linkage from the

steering column.

2. Remove the horn button by pushing down

on the horn button and turning counter

clockwise. Next remove the steering

wheel retaining nut and then using a

wheel puller remove the steering wheel

from column.

3. Remove the two nuts from the column

support bracket from under the dash.

Next unplug the electrical connector that

connects the steering column to the

vehicle harness.

Flaming River Industries

1-800-648-8022

4. Remove the upper alignment bushing

that is located at the center of the turn

signal switch. Next remove the column

tube by sliding it off of the column shaft.

4

081511

Page 6

Original System Removal

Pitman Arm

Idler Arm

Outer Tie Rod Ends

5. Remove the pitman arm from the steering box using a pitman arm puller.

Note: If the vehicle is equipped with power steering remove any power steering lines connected to

valve and drain the system.

6. Remove the two (2) bolts that retain the idler arm to chassis.

7. Remove the cotter pins and the castle nuts from the outer tie rod ends, using a pickle fork remove

the tie rod ends from the spindle arms and then remove the steering linkage from the vehicle.

8. Remove the three (3) bolts that hold the

steering to chassis and remove the

steering box from the car.

5

Flaming River Industries

1-800-648-8022

081511

Page 7

Installation of Flaming River Tilt Column

A B

1. Slide new swivel fl oor mount over the column tube (Picture A) so the swivel portion of the fl oor

mount is at the end of he column tube (Picture B). Next place the column through the fi rewall and

loosley mount the fl oor mount to hold the column in place.

2. Place the rubber spacer into the factory

under dash mount and trim away excess.

Next, making sure the column is straight, fi t

the under dash mount to the new Flaming

River steering column and then mount the

steering column in the factory original

position.

New Flaming River steering

column installed.

6

Flaming River Industries

1-800-648-8022

081511

Page 8

Connecting the Electrical System

Function FR Column Location Vehicle Wiring

Horn

Lt Front Turn Signal

Rt Front Turn Signal

Hazard

Turn Signal - Power

Lt Rear Turn Signal

Rt Rear Turn Signal

Brake Light

Note: The hazard power wire goes to a 12v power source from the vehicle’s fuse panel. This feature will

add 4-Way Emergency flasher to the car.

Column Plug

Black

Light Blue

Blue

Brown

Purple

Yellow

Green

White

G

H

J

K

L

M

N

P

Brown (Horn Relay)

Green/White

White/Black

See Note

Blue

Green/Orange

Orange/Blue

Green

Female Wiring Connector

Horn Relay

1. Connect the Yellow and Blue wires on the horn relay to the Yellow wire on the vehicle harness.

2. The Red wire on the horn relay connects to the Yellow wire with a stripe on the vehicle harness.

3. The Brown wire on the horn relay connects to the Black wire on the steering column harness

terminal G.

Note: The Black wire on the horn relay is not used.

7

Flaming River Industries

1-800-648-8022

081511

Page 9

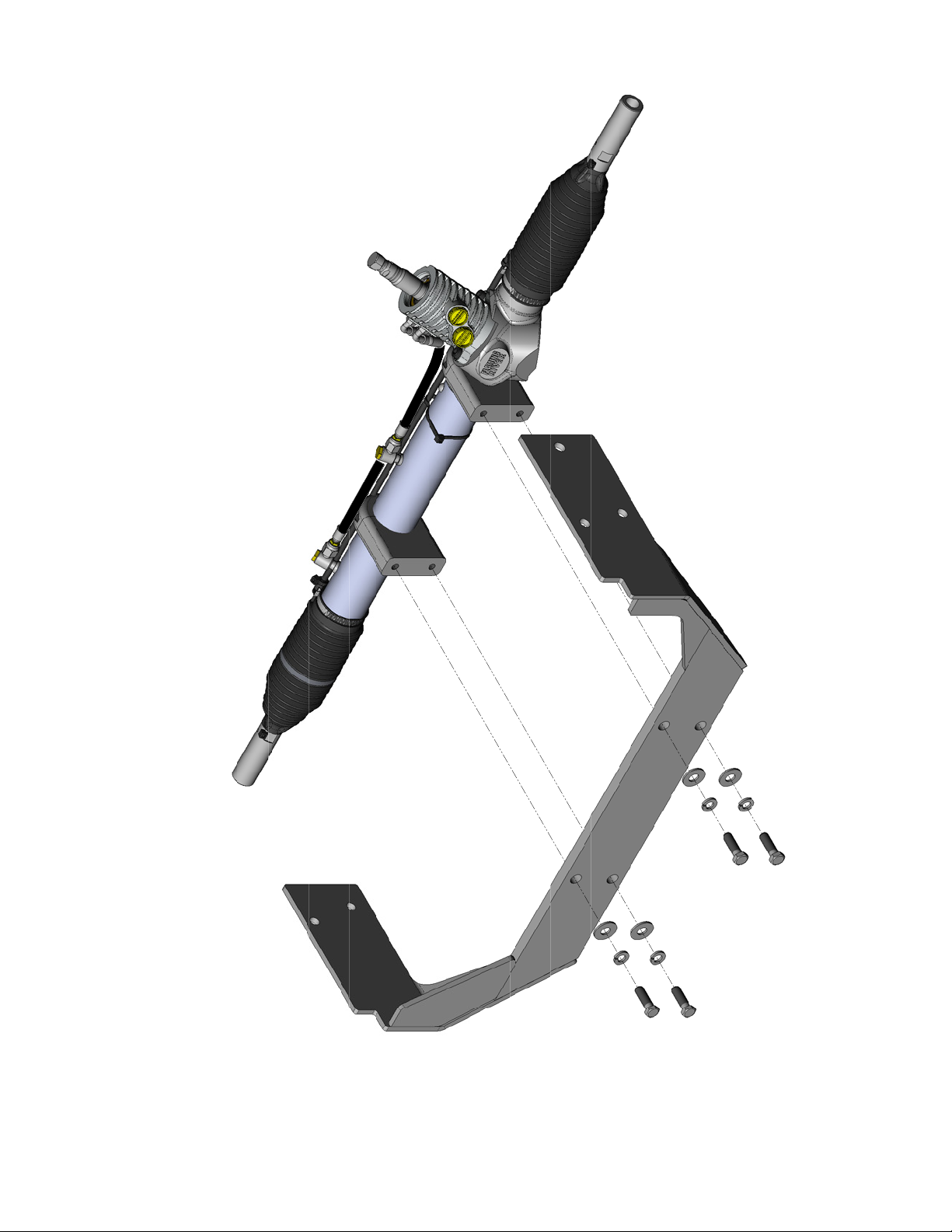

Installation of Flaming River Rack & Cradle System

The rack mounting cradle is only shown

here to show the mounting bolts.

Driver Side Passenger Side

1. Install the rack and pinion cradle by sliding it into place between the frame rails. Using the

new hardware, install the three (3) 7/16” bolts on the drivers side using the original holes from the

steering gear box. On the passenger side use the two (2) 3/8” bolts were the idler arm was

mounted. Tighten the 7/16” bolts and nuts to 50-65 ft lbs. and the 3/8” bolts and nuts to

40-45 ft lbs..

Rack & Cradle Shown Installed.

8

Flaming River Industries

1-800-648-8022

081511

Page 10

Installation of Universal Joints & Shafting

View from Top

View from bottom

1. Using a 3/4” wooden dowel rod, mock

up the steering shaft to obtain the correct

shaft lengths and u-joint angle.

2. Once the correct shaft lengths are obtained,

install shafts and u-joints snugging down each

set screw so that it leaves a mark in the shaft.

3. Remove the shafts and using a 1/4” drill

bit, dimple each mark left by the set screws.

4. Re-install the shafts and u-joints using a red

thread locker on the set screw threads. Tighten

each set screw to 25 ft lbs. and then tighten all

jam nuts securely.

** We recommend that you regulary inspect the

u-joint set screws for tightness.**

9

Flaming River Industries

1-800-648-8022

081511

Page 11

Water Pump

Power Steering

Pump Bracket

Installation of Power Steering Pump

Power Steering

Fluid Reservior

Power Steering Pump

1. Install the power steering pump bracket to the water pump as shown in the picture.

2. Mount the power steering pump to the bracket. Only snug the mounting bolts, the mounting bolts will

be tightened once the belt is installed and the pulley is adjusted.

3. Install the power steering fl uid reservior, the reservior must be mounted higher than the pump for

correct fl uid fl ow to the pump.

Flaming River Synthetic Power Steering Fluid

Formulated for High Performance Steering Systems! This

newly developed line of Synthetic Power Steering Fluid

is a natural addition to Flaming River’s Power Rack and

Pinions and Power Steering Accessory product lines.

Available in a 1 quart bottle, this Power Steering Fluid

reduces operating temperatures and fl uid expansion,

resists foaming, and also increases the life of power

steering systems by reducing internal wear and tear.

Flaming River’s Synthetic Power Steering Fluid is recommended for all power steering applications. Simply

purge the vehicle of its current power steering fl uid and

replace with Flaming River’s unique blend that easily

mixes with any trace amounts of other steering fl uid left

behind.

FR41001 – Flaming River Synthetic Power Steering Fluid

10

Flaming River Industries

1-800-648-8022

081511

Page 12

Power Steering Bleeding Procedure

1. Raise the front wheels off the ground

and support the vehicle on jack stands.

2. Turn the steering wheel to the left lock

and fi ll the reservoir and let the vehicle sit

for 2 minutes.

3. WITH THE ENGINE OFF - Rotate the

steering wheel lock to lock 20-25 times,

while rotating the wheel have someone

monitor the fl uid level and fi ll as necessary.

4. Top off fl uid

5. WITH THE ENGINE RUNNING - Rotate

the steering wheel lock to lock 20-25

times, while rotating the wheel have

someone monitor the fl uid level and fi ll as

necessary.

6. Lower the vehicle

7. Top off fl uid

8. WITH THE ENGINE RUNNING - Rotate

the steering wheel lock to lock 20-25

times, while rotating the wheel have

someone monitor the fl uid level and fi ll as

necessary.

Install your power steering lines to the

correct pressure or return ports.

If using a stainless steel line kit, follow the instructions provided with

your kit.

FR1610 Stainless Steel Line Kit is available Seperatley.

Note: If using the original power steering pump, you must fi rst fl ush the pump of any power

steering fl uid. Contaminated power steering fl uid may cause damage to the new rack and pinion.

Note: If the power steering fl uid is foamy, let the vehicle sit for 10 minutes and then repeat the

bleeding procedure.

Note: Trapped air in the system will cause a milky appearance in the fl uid. Trapped air will also cause

the fl uid level to rise in the reservoir when the engine is not running.

11

Flaming River Industries

1-800-648-8022

081511

Loading...

Loading...