Page 1

58-62 Impala

Rack & Pinion Cradle Kit

Page 2

58-62 Impala

Note: For safety disconnect battery cables and ensure that the vehicle is properly supported

by jack stands.

Before painting or powder coating of the cradle, we recommend that you pre-t the entire system

to ensure proper tment for your application.

Inventory pg 2

Electrical System Verication pg 4

Removal of Factory Steering pg 5-6

Installation of:

Rack and Cradle pg 7-8

Flaming River Tilt Column pg 9-10

Electrical System Notes pg 10

Universal Joint and Steering pg 11

Shaft Installation

Power Steering Pump Installation pg 12

Power Steering Bleeding Procedure pg 13

WARRANTY DISCLAIMER: Flaming River’s® Limited Warranty

Flaming River® warrants its products to be free from defects in material and workmanship for a period of one (1)

year aer the date of purchase, except that: All steering columns are warranted for a period of three (3) years from

the date of purchase. e Big Switch (part number FR1005) is warranted for a period of three (3) years from the date

of purchase, provided that it is not mounted with a steel bracket and provided further that it is adequately protected

from environmental conditions. All electrical products other than the Big Switch are warranted for a period of ninety (90) days from the date of purchase. Flaming River’s® warranty liability is limited to the replacement of defective

products. Flaming River® is not liable for any labor costs associated with any warranty claim, or for any incidental or

consequential damages. Improper installation, abuse, racing, and/or modication of the products voids this warranty. No warranty of merchantability or tness for a particular purpose is made by Flaming River® with respect to

any of its products. Warnings and Recommendations It is the customer’s responsibility to determine the suitability of

a given Flaming River® product for the customer’s uses. Likewise, it is the customer’s responsibility to install a Flaming River® product. Contact the vehicle manufacturer whenever installing a switch to conrm the appropriateness of

using such a switch and the recommended placement of the switch on the vehicle. Use qualied chassis specialists

for the installation of all steering related components. Be aware that the installation of certain Flaming River® products may adversely impact a manufacturer’s warranty with respect to certain vehicles and other manufactured goods.

Flaming River will repair or replace any product found to be defective in material or workmanship. Improper installation, abuse, racing and/or modication VOID WARRANTY. Flaming River® is not responsible for any labor costs

associated with any warranty.

Flaming River Industries

1

1-800-648-8022

FRxxxx Rev.A

12/15/10

Page 3

Part Number

Description

Qty

100759

Bolt -3/8-16x4.5”

FR1612/FR1613

FR1614

FR1715DD

FR1789P

FR1850-22

FR20098

FR20118

FRPMPSB-V

NYLOCK-3/8”-16

Assembly, Power Rack and Cradle

3/8”-16 Grade 8 Bolt 4.5” Long

Assembly, Power Steering Pump

Bracket. Small Block/Big Block

Power Steering Remote Reservoir

3/4”-36 x 3/4” DD Billet U-Joint

FR Power x 3/4” DD Billet Joint

22” 3/4” DD Shaft

58-64 Impala Floor Mount

Female Wiring Adapter

Power Steering Pump with V-Belt

Pulley

3/8”-16 Nylock Lock Nut Grade 8

1

5

1

1

1

1

1

1

1

1

5

WASH-3/8”

FR21011/FR21013

FR21012/FR21014

3/8” Flat Washer

Impala Floor Shift Tilt Column

OR (Depending on Kit Ordered)

Impala Column Shift Tilt Column

10

1

1

2

Flaming River Industries

1-800-648-8022

FRxxxx Rev.A

12/15/10

Page 4

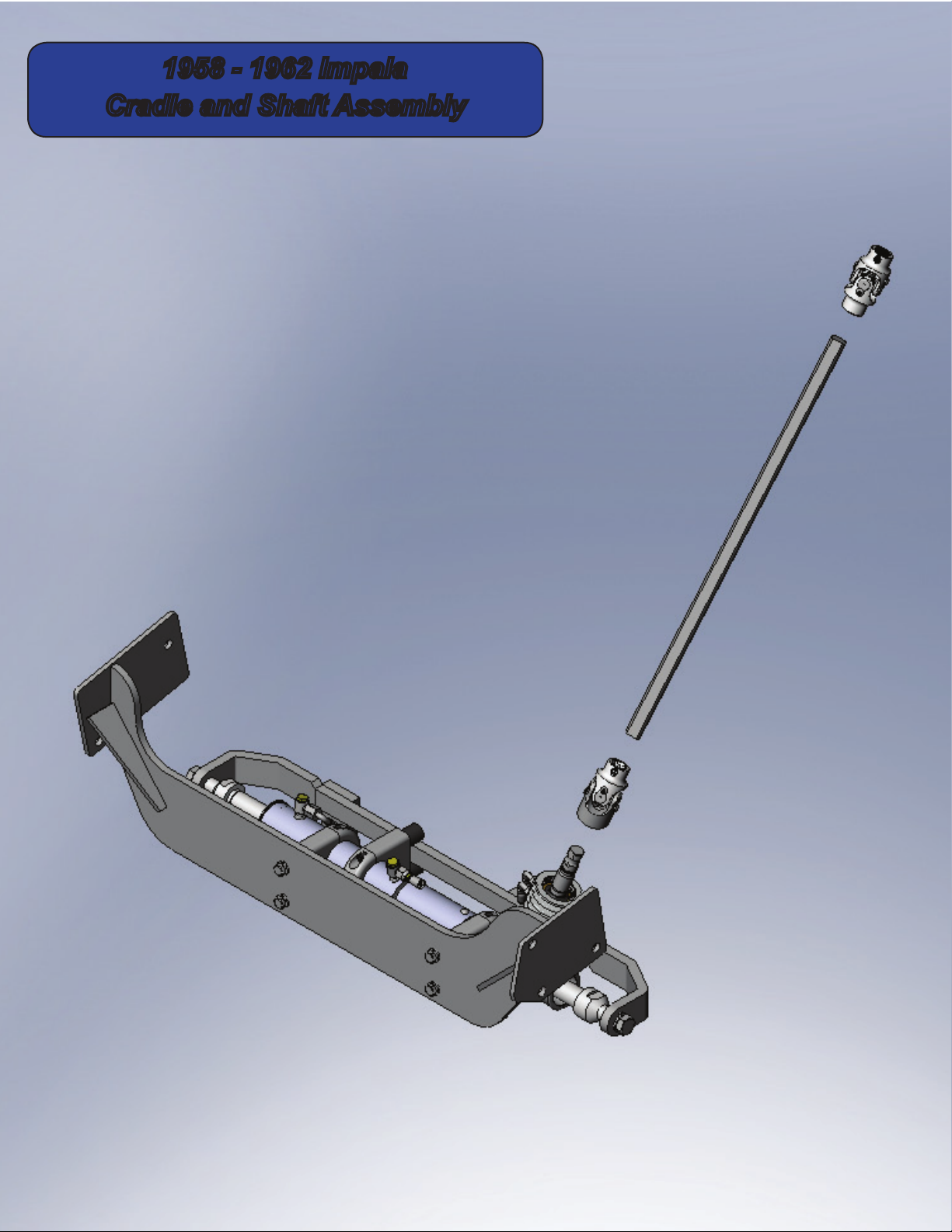

1958 - 1962 Impala

Cradle and Shaft Assembly

3

Flaming River Industries

1-800-648-8022

FRxxxx Rev.A

12/15/10

Page 5

Color Verication To Be Completed Before Disassembly

Before disconnecting the turn signal connector, verify the factory wiring colors and turn signal operation.

The use of a wiring diagram is recommended. This will be used when connecting the new Flaming River

Steering Column.

• Brake Light Switch

• Right Rear Turn Signal

• Left Rear Turn Signal

• Turn Signal Power

• Hazard Power

• Right Front Turn Signal

• Left Front Turn Signal

• Horn

Original System Removal

1) For safety, disconnect your battery.

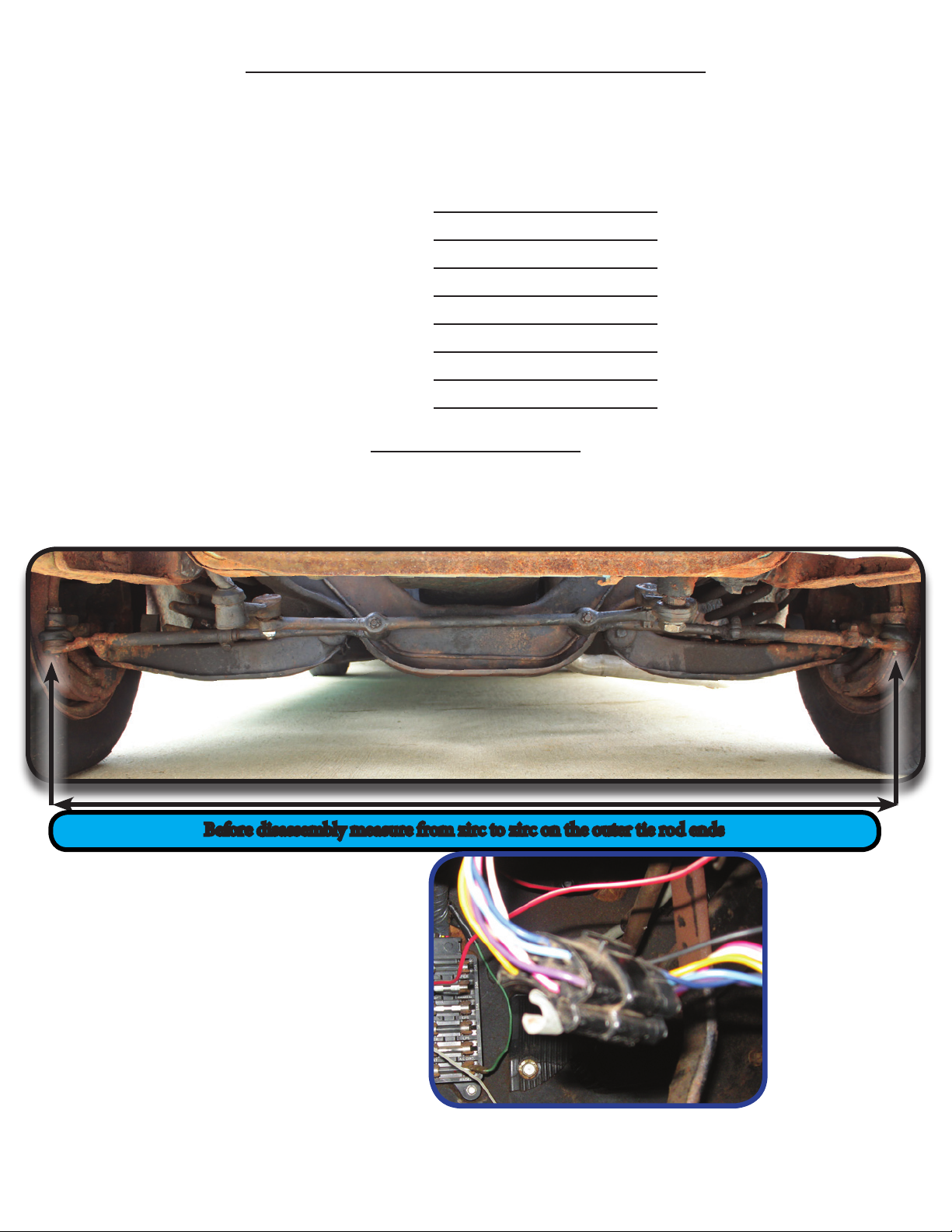

2) Before disassembly measure from zirc to zirc on the outer tie rod ends. Write this dimension down

for future reference.

Before disassembly measure from zirc to zirc on the outer tie rod ends

3) Disconnect the wiring at the steering

column under the dash.

4

Flaming River Industries

1-800-648-8022

FRxxxx Rev.A

12/15/10

Page 6

Original System Removal

4) Remove the bolts retaining the column dash mounting bracket and oor mounting plate.

Dash Mounting Bracket

Floor Mounting Bracket

5) Remove the bolt that retains the coupler

to the factory intermediate shaft. Spread

the ange and then slide the column off of

the shaft and remove the column from the

car.

6) Remove the bolt that retains the rag joint

to the factory steering box. Spread the

ange and then slide the shaft off of the

steering box and remove the shaft from the

car.

5

Flaming River Industries

1-800-648-8022

FRxxxx Rev.A

12/15/10

Page 7

7) Remove the bolts that hold the steering

box to the frame, and then remove the box from

the car.

8) Remove the bolts that hold the idler

arm bracket to the frame, the outer

tie rod ends from the spindle arms,

then remove the steering linkage

from the car.

9) Grind down lip on the driver’s side chassis

so it is completely smooth. This will allow

the cradle to mount ush onto the

car chassis

Before

**Lip is located on the inside of

the driver’s side frame rail**

Flaming River Industries

1-800-648-8022

FRxxxx Rev.A

12/15/10

6

Aer

Page 8

Flaming River Rack and Pinion Installation

1) Install the rack and pinion cradle by sliding it into place between the frame rails. Using the new

hardware, install the three (3) 3/8” bolts on the drivers side using the original holes from the

steering gear box. On the passenger side use the bottom idler arm bolt and hole just to the rear of

the idler arm and use the (2) 3/8” bolts and tighten all the bolts and nuts to 40-45 ft. lbs..

Driver Side Mounting

Passenger Side Mounting

2) To install the Flaming River rack and travel bar system, position the rack into place and install and

the rack to the cradle using the mounting brackets provided. Note: The locking set screw in the

center of the rack mounts can be loosened to adjust the pinion angle which will aid in u-joint

alignment.

Driver Side Mounting

Rack & Pinion Mounting

Brackets

7

Flaming River Industries

1-800-648-8022

FRxxxx Rev.A

12/15/10

Passenger Side Mounting

Page 9

Flaming River Rack and Pinion Installation

3) Install the OEM inner tie rod end into the Flaming River Travel Bar. Note: If using the original parts

some adjustment of the tie rod assembly may be required when connecting the to the spindle arm

and the travel bar.

OEM Inner Tie Rod End

4) To install the outer tie rod end into the

spindles you must load the front sus-

pension. Securely place jack stands un

der the lower control arms and lowering

the car onto the jack stands. Make

sure that your wheels are centered,

then install the outer tie rod into the

spindle arms and tighten the

castle nuts to 30-40ft lbs. Make sure to

install the cotter pins through the castle

nut and tie rod end and bend the

tabs over.

Rack & Cradle Installed

In Car

Travel Bar

8

Flaming River Industries

1-800-648-8022

FRxxxx Rev.A

12/15/10

Page 10

Flaming River Tilt Column Installation

1) Install the original column

mounting bracket onto the new

Flaming River Tilt Column.

OEM Column

Dash Mount

2) Slide new tilt column through the split ring of

the new aluminum oor mount.

Split Ring

Column Tube

9

Flaming River Industries

1-800-648-8022

FRxxxx Rev.A

12/15/10

Page 11

Flaming River Tilt Column Installation

4) Place the column through the rewall

and under the dash, tighten the

mounting screws under the dash and

using the new hardware provided fasten

the oor mount to the rewall.

5) Replace the factory dash bezel using the

screws that were removed earlier.

Factory dash bezel mounted

to Flaming River Tilt Column

Wiring Circuit

Brake Light Switch

Right Rear Turn Signal

Le Rear Turn Signal

Turn Signal Power

Hazard Power

Right Front Turn

Signal

Le Front Turn Signal

Horn

Connecting the Electric System

Pin Location

Vehicle Wiring

P

Reference Color

Verication from

column disassembly.

N

M

L

K

J

H

G

Column Wiring

White

Green

Yel l ow

Purple

Brown

Blue

Light Blue

Black

10

Flaming River Industries

1-800-648-8022

FRxxxx Rev.A

12/15/10

Page 12

Universal Joint Installation

1) Using a 3/4” wooden dowel rod, mock

up the steering shaft to obtain the correct

shaft lengths and u-joint angle.

2) Once the correct shaft lengths are

obtained, install shafts and u-joints

snugging down each set screw so that it

leaves a mark in the shaft.

3) Remove the shafts and using a 1/4” drill

bit, dimple each mark left by the set

screws.

4) Re-install the shafts and u-joints using

a red thread locker on the set screw

threads. Tighten each set screw to

25 ft. lbs. and then tighten all jam nuts

securely.

** We recommend that you regularly inspect the

u-joint set screws for tightness.**

Dimple

11

Flaming River Industries

1-800-648-8022

FRxxxx Rev.A

12/15/10

Page 13

Power Steering Pump Bracket

Power Steering Lines (FR1610 Not included in Kit)

Included in the FR1610 kit is a ½” feed line that connects from the remote reservoir to the power steering pump. is is

attached using the 2 stainless steel hose clamps. e 3/8” Double Crimped Pressure Line will attach the pressure port of

the powersteering pump and to the pressure side of your steering gear. AN ttings with o-rings are included to complete

the installation. e single crimped 3/8” line is used for the return line from the steering gear to the reservoir. is will

attach to the steering gear to the reservoir using a AN Fitting and the ¼”NPT barbed tting with a stainless steel hose

clamp. Custom length hose kits can be ordered from Flaming River by providing a drawing with dimensions.

When cutting the stainless steel hose it is easier to use a chop saw or cut o wheel. Wrap the hose in black electrical tape

and cutting through the tape to help avoid fraying. You may need to use a side cutter to trim any frayed stainless steel

line. e lines can be installed to the 90 degree ttings loose until to ensure proper line routing. To tighten, hold the line

itself and tighten the ttings to 10-12 lbs.

Note: Over crimping or kinking the line my cause damage

to the Teon liner and voids warranty.

Note: If you are not using

FR1610 P/S Line Kit you must

order FRM14x6AN & FRM16x6AN

AN Fittings for the rack.

12

Flaming River Industries

1-800-648-8022

FRxxxx Rev.A

12/15/10

Page 14

Power Steering Bleeding Procedure

1) Raise the front wheels off the ground and

support the vehicle on jack stands.

2) Turn the steering wheel to the left lock

and ll the reservoir and let the vehicle sit

for 2 minutes.

3) WITH THE ENGINE OFF - Rotate the

steering wheel lock to lock 20-25 times,

while rotating the wheel have someone

monitor the uid level and ll as

necessary.

4) Top off uid

5) WITH THE ENGINE RUNNING - Rotate

the steering wheel lock to lock 20-25

times, while rotating the wheel

have someone monitor the uid level and

ll as necessary.

6) Lower the vehicle

7) Top off uid

8) WITH THE ENGINE RUNNING - Rotate

the steering wheel lock to lock 20-25

times, while rotating the wheel

Install your power steering lines to the correct

pressure or return ports.

have someone monitor the uid level and

ll as necessary.

If using a stainless steel line kit, follow the instructions provided with your kit.

FR1610 Stainless Steel Line Kit is available Separately.

Note: If using the original power steering pump, you must rst ush the pump of any power steering uid.

Contaminated power steering uid may cause damage to the new rack and pinion.

Note: If the power steering uid is foamy, let the vehicle sit for 10 minutes and then repeat the bleeding procedure.

Note: Trapped air in the system will cause a milky appearance in the uid. Trapped air will also cause the uid level

to rise in the reservoir when the engine is not running.

13

Flaming River Industries

1-800-648-8022

FRxxxx Rev.A

12/15/10

Loading...

Loading...