FLAMEN SIGMA Series, KAPPA Series, ALFA series, BETA series Installation And Operation Instructions For Fireplace Inserts

Installation and operation instructions for fireplace inserts

FLAMEN – SIGMA and KAPPA series

Certificate of warranty

During transport and manipulation of the fireplace inserts

SIGMA, the counterweight is locked in its upper position. The

lock needs to be released before installation, for the inspection

of the fire place insert and its putting into operation. Instructions for releasing the

lock are given in chapter Operation of the fireplace insert.

1

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Thank you for buying the fireplace insert made by FLAMEN. We believe that the

fireplace insert will bring you many pleasant moments. The fireplace inserts made by

FLAMEN - SIGMA and KAPPA series are equipped with:

- Corner bent glass or front decorated frameless glass screen

- Corner bent glass or front glass with design frame

- Vertical sliding and horizontal opening – SIGMA

- Horizontal opening – KAPPA

- Possibility of external air nozzle

- Modern simple design with stainless steel handle and the only control lever

- Elegant cladding from LacFire with a 4-year guarantee, heat accumulation for

efficient and clean wood burning

- Cover frame 4x45°

- Support and rectifying screws

- High quality maintenance-free and silent cable slide of the fire door

- With FLAMclean system for clean glass and low emissions

- Combustion chamber completely sealed

- With a grate and an ash pan

- Quality manufacturing

- 10-year guarantee on the fireplace body

- Certified according to ČSN EN 13229/A2 (Europe), 15a B-VG (Austria), BlmSchV

Stufe II (Germany)

- Accessories: Hot-air exchanger, electronic regulation Timpex and Plum

We would like to thank you for your purchase again and we wish you many pleasant

moments with the fireplace FLAMEN.

With passion for fire team of FLAMEN

2

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Table of contents

Technical description of the fireplace insert ................................................................................4

Description of the main parts ..................................................................................................4

Description of operating elements: .........................................................................................4

Main materials used ................................................................................................................4

Fireplace Accessories .............................................................................................................10

Spare parts .............................................................................................................................10

Technical parameters .................................................................................................................12

Table with technical parameters ............................................................................................13

Fireplace insert installation ........................................................................................................14

Installation .............................................................................................................................14

Chimney .................................................................................................................................15

Air supply for combustion ......................................................................................................16

Fireplace surround .................................................................................................................20

Combustible ceiling in the area of the surround ....................................................................23

Connection of hot-air distribution .........................................................................................23

Safety precautions .....................................................................................................................23

Fireplace insert operation ..........................................................................................................25

Releasing the counterweight lock ..........................................................................................25

Instructions for putting the fireplace insert into operation ...................................................25

Putting the fireplace insert into operation.............................................................................26

Adding fuel .............................................................................................................................28

Maintaining the fire in the fireplace ......................................................................................29

Adjusting the amount of air for combustion ..........................................................................29

Fireplace cleaning ..................................................................................................................29

Fuel ........................................................................................................................................33

Mechanical parts ....................................................................................................................33

Information ................................................................................................................................34

Waste disposal .......................................................................................................................34

Warranty terms and conditions .................................................................................................35

Certificate of warranty ...............................................................................................................37

List of repairs .........................................................................................................................38

3

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Technical description of the fireplace insert

Description of the main parts

The fireplace insert consists of a plinth which is fitted with rectifying screws to level

the fireplace insert into horizontal position. In the bottom part, there is an air-supply

box for combustion. This box enables to connect the air for combustion from another

room or exterior through flexible pipe. The bottom of the hearth serves for the

distribution of primary, secondary and tertiary air. In the bottom, there is also an ash

chamber with an ashpan. The hearth is lined with LacFire refractory concrete shaped

pieces. The hearth body is made from steel sheet, with the thickness of 3 or 4 mm. The

hearth area is closed by fireplace door which is made from heat-resistance ceramic

glass. The door is equipped with a seal. In the upper part of the hearth, there is a set of

deflectors for the regulation of the flue gas flow. These can also be used for the

regulation of draught with which flue gases are exhausted into the chimney. Flue gases

escape through a hub with the diameter of 160 mm which serves for the connection of

the flue pipe. The door, type SIGMA, enables horizontal movement. The door is led in

two rails and with four pairs of rollers. It is balanced with a counterweight connected

to the door with a stainless wire strand. After the door is arrested, it can also be

opened horizontally, e.g. for its cleaning.

Description of operating elements:

Operation of the fireplace insert is ensured by the following operating elements:

Handle – enables vertical movement of the door

Door stay – arrests the door for its horizontal opening or unhanging

Catch – enables horizontal opening of the door

Air-supply controller for burning – regulates the amount of air for burning and glass

rinsing.

The use of all operating elements is described in chapter Operation of the Fireplace

insert.

Main materials used

Fireplace inserts FLAMEN are made only from quality materials. The body of the

fireplace insert is made from steel sheet, with the thickness of 3 or 4 mm. The hearth,

including grate, is lined with a special accumulative refractory concrete LacFire.

4

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

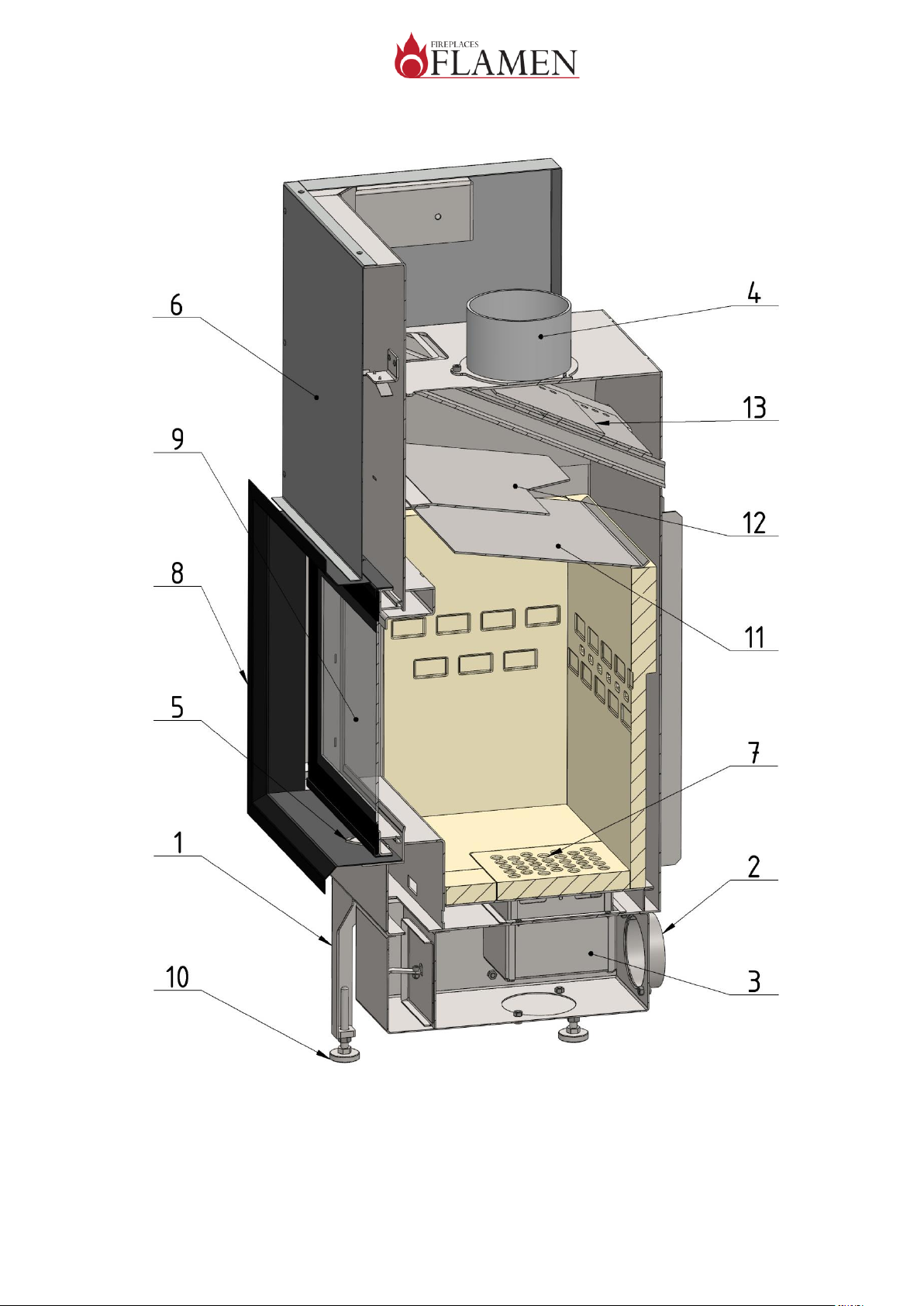

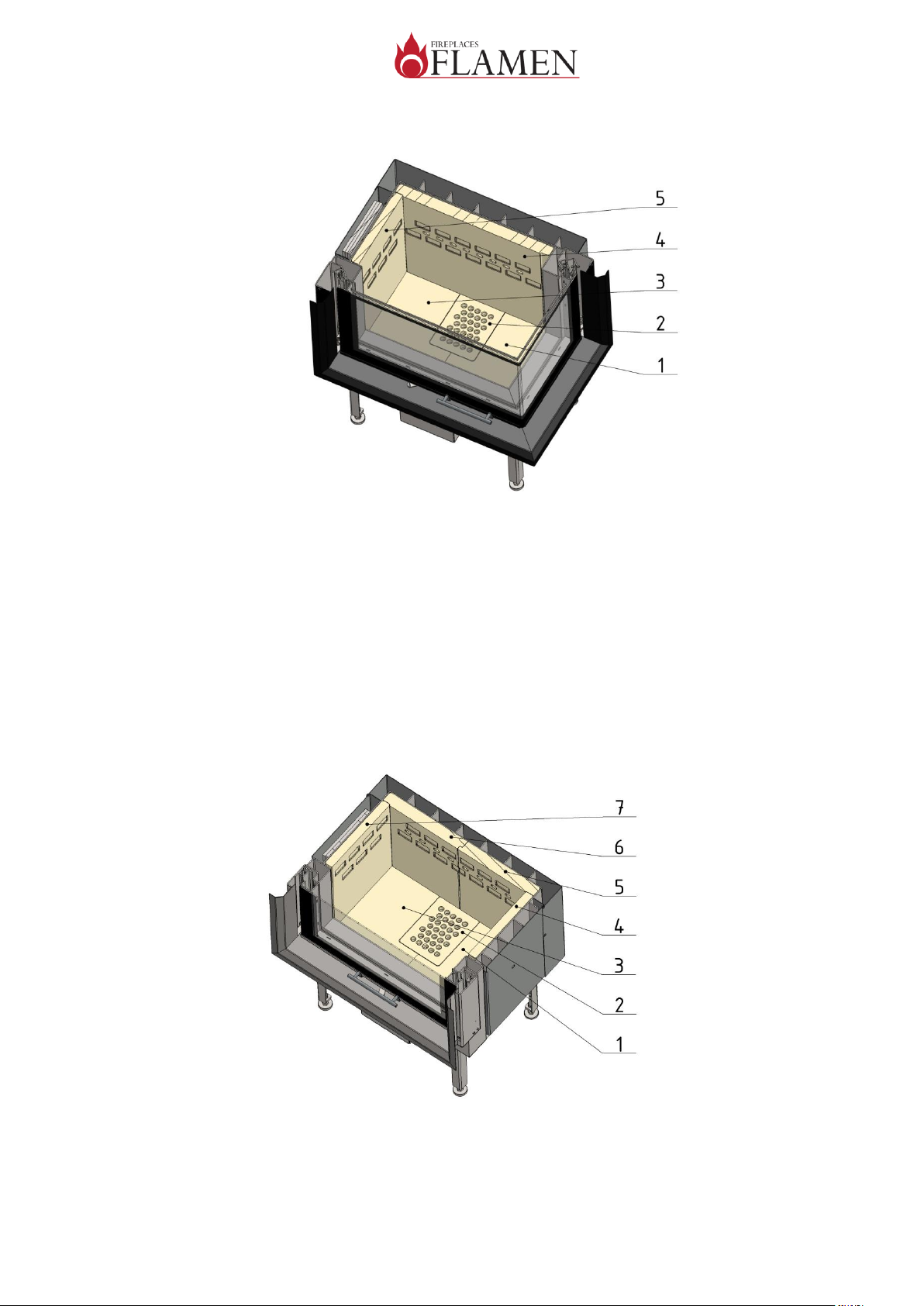

Picture No. 1. Cross-sectional view of the fireplace insert.

5

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Legend to picture No. 1:

1 Plinth

2 Flange for connecting outside air

3 Ashpan

4 Hub for flue gas outlet

5 Air-supply regulation

6 Slide cover

7 Grate

8 Cover frame

9 Glass

10 Height-adjustable leg

11 Bottom deflector

12 Upper deflector

13 Exchanger deflector

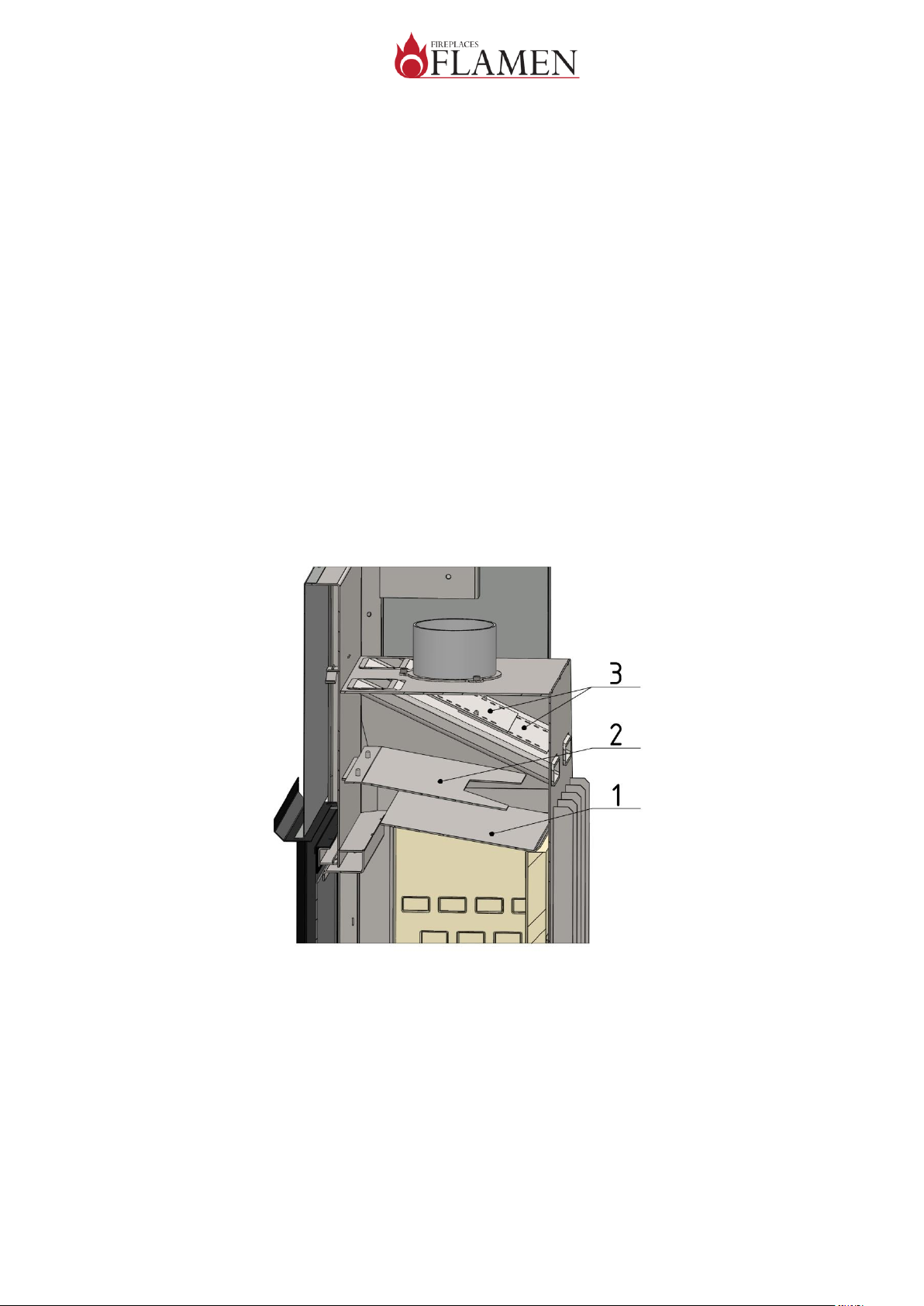

Picture No. 2. View of the set of deflectors.

Legend to picture No. 2:

1 Bottom deflector

2 Upper deflector

3 Exchanger deflectors

6

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

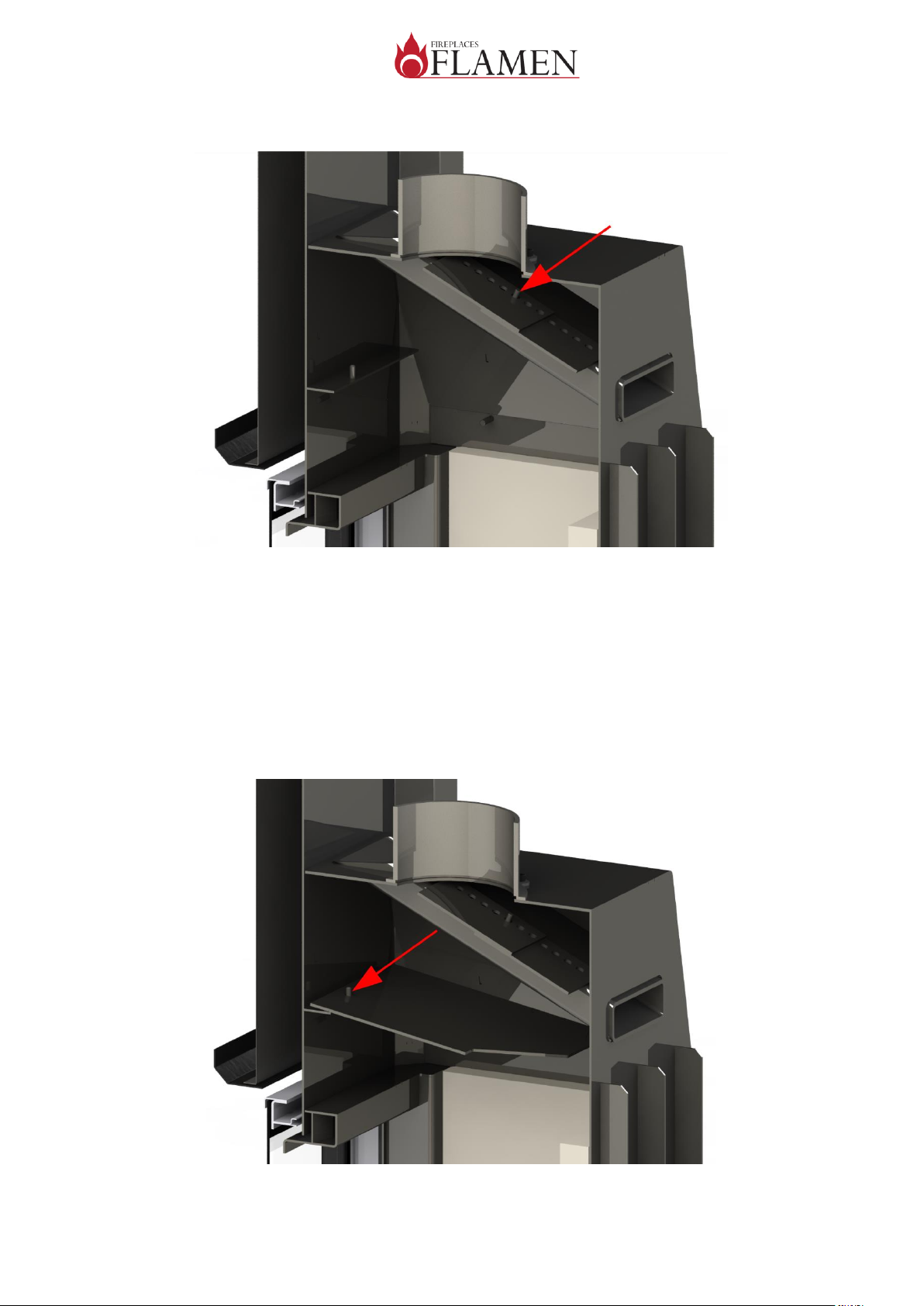

Picture No. 2A. Assembly of the Exchanger deflectors.

Firstly install the exchanger deflectors. Install these deflectors before connection to

the flue line! Place the deflectors on the top of the hot-air exchangers (rectangular

tubes). Position is secured by bolts (see pic. 2A) which fit to the holes at the sides of

the deflector. Positions of these deflectors can regulate the chimney draught. The

position can be either fully closed or slightly open. If necessary, this deflector can be

disassembled to increase the chimney draught (leads to a slight loss of efficiency).

Picture No. 2B. Assembly of the Upper deflector.

7

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Now assemble the upper deflector – see pic. 2B. This deflector has got two holes which

has to be put onto two bolts placed at the front side of the insert.

Picture No. 2C. Assembly of the Bottom deflector.

Put this deflecor into the insert. The rear bent edge of the deflector has to be put on

the top side of the rear cladding – see pic. 2C. Lift the front side of the deflector up and

insert the delivered tubes on to the bolts placed on the left and right side. After

inserting the tube put the defletor down, the defletor will be supported by the tubes.

Herewith, the assembly of deflectors is fully finished.

8

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

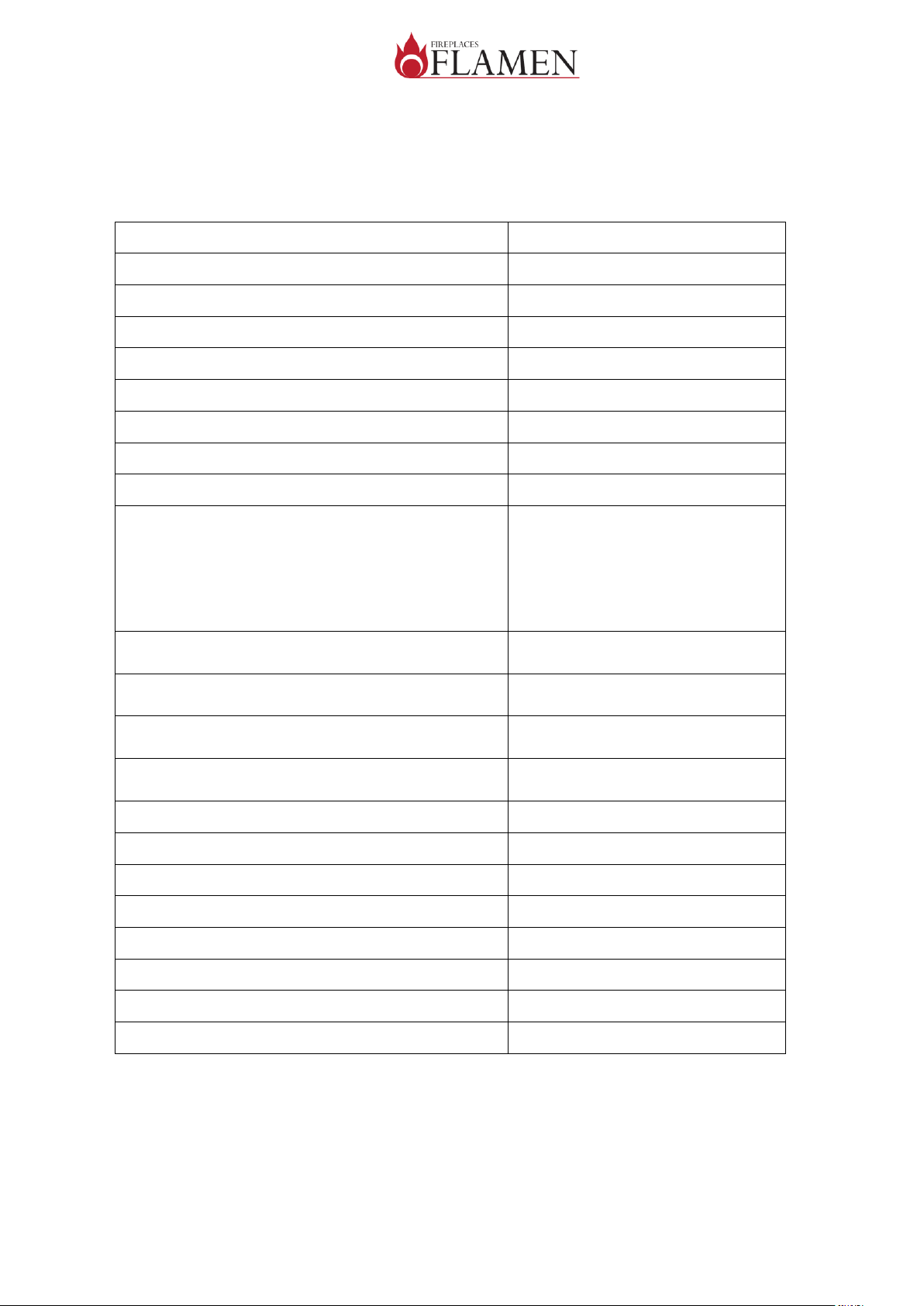

Picture No. 3A. View of the set of cladding – corner type.

Legend to picture No. 3A:

1 Right bottom

2 Grate

3 Left bottom

4 Back block

5 Side block

Picture No. 3B. View of the set of cladding – front type.

9

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Legend to picture No. 3B:

1 Right bottom

2 Grate

3 Left bottom

4 Right side block

5 Right back block

6 Left back block

7 Left side block

Surface finishing of metal parts, excluding the handle, with special colour which is

resistant up to 600°C; however it does not guarantee corrosion resistance in the

exterior environment with direct atmospheric effects or interior humid environment.

Surface finishing is suitable for interior, dry environment.

Fireplace Accessories

You can order following accessories for your fireplace insert:

- Electronic regulation Timpex and Plum

- Hot-air exchanger

- Walling cornice

- Glass cleaner

- Safety gloves

- Fire lighters

- All material necessary for fireplace surrounds, the complete offer of which can

be found on www.flamen.cz.

Spare parts

You can order following spare parts for you fireplace insert:

- Complete sealing set

- Refractory concrete blocks, see picture No. 3

- Grate, see picture No. 3

- Deflectors, see picture No. 2

- Flat glass (models F)

- Bent glass (models R, L)

10

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

- Metal bars for glass mounting

Use only original spare parts recommended by the manufacturer. For the identification

of spare parts use pictures No. 1.-3.

11

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Technical parameters

SIGMA F S frameless front glass screen with printing, horizontal and vertical

opening

SIGMA R S frameless right corner glass screen with printing, horizontal and

vertical opening

SIGMA L S frameless left corner glass with printing, horizontal and vertical

opening

SIGMA C S frameless three-side glass screen with printing, horizontal and

vertical opening

KAPPA F S frameless front glass screen with printing, horizontal opening

KAPPA R S frameless right corner glass screen with printing, horizontal

opening

KAPPA L S frameless left corner glass screen with printing, horizontal opening

KAPPA C S frameless three-side glass screen with printing, horizontal opening

SIGMA F frame front glass screen without printing, horizontal and vertical

opening

SIGMA R frame right corner glass screen without printing, horizontal and

vertical opening

SIGMA L frame left corner glass screen without printing, horizontal and

vertical opening

SIGMA C frame three-side glass screen without printing, horizontal and

vertical opening

KAPPA F frame front glass screen without printing, horizontal opening

KAPPA R frame right corner glass screen without printing, horizontal

opening

KAPPA L frame left corner glass screen without printing, horizontal opening

KAPPA C frame three-side glass screen without printing, horizontal opening

12

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Nominal heat output

9,50 kW

Efficiency

85%

Fuel

Wood, wooden briquettes

Moisture content in wood

Max. 20%

Fuel consumption (min. | nom. | max.)

2 | 2,6 |3,7 kg/h

Heated area

105-333 m

3

Minimal chimney diameter

160 mm

Minimal operating chimney draught

12 Pa

Recommended log length

33 cm

Weight

SIGMA F 236 kg

SIGMA R/L 240 kg

SIGMA C 230 kg

KAPPA F 216 kg

KAPPA R/L 220 kg

KAPPA C 210 kg

Total height

SIGMA 1444 (+80) mm

KAPPA 1326 (+80) mm

Total width without cover frame

782 mm corner type

734 mm front type

Total width

844 mm corner type

774 mm front type

Total depth without cover frame

543 mm corner type

543 mm front type

Total depth

605 mm

Body material

Steel

Cladding material

Refractory concrete LacFire

CO content at 13% O

2

0,09%

Dust concentration calculated at 13 % O2

24 mg.Nm

-3

Mean flue gas temperature behind smoke socket

209 °C

Flue gas mass flow

7,4 g.s

-1

Cladding type

With grate and ashpan

Table with technical parameters

(applicable to all SIGMA and KAPPA types):

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

13

www.flamen.cz

Fireplace insert installation

Read these instructions before installing the fireplace insert.

During transport and manipulation of the fireplace inserts

SIGMA, the counterweight is locked in its upper position. The

lock needs to be released before installation, for the inspection

of the fire place insert and its putting into operation. Instructions for releasing the

lock are given in chapter Operation of the fireplace insert.

Caution: All local regulations, including those that refer to

national and European standards for this type of appliances,

shall be complied with when installing the product.

Installation

We recommend installation by qualified personnel who carry out the installation and

connection to the chimney. Before the first use, the installation shall be inspected by a

professional chimney sweep who issues a written inspection report.

When you receive the fireplace insert, inspect it for obvious

defects – defects in glass, function of travels, door stays and

opening, scope of delivery.

Prior to the realisation of the surrounding, it is necessary to test the operation of the

fireplace insert. During the test operation (firing up), the paint will burn out (ventilate

intensively during the burning of paint because exhaust fumes will occur!). During this

test, please also check all mechanisms and verify their functionality!

The fireplace inserts FLAMEN are designed for the surround in the interior. Their

installation and surround are very important for the function of the fireplace insert.

The installation and surround of the fireplace insert are subject to local regulations

which are to be complied with for a safe, functional and proper operation. The

fireplace inserts are approved for operation by accredited testing and certification

organisation in the Czech Republic. The fireplace insert requires a separate chimney;

the connection shall be according to your local regulations.

According to the applicable law, the proper connection of the

fireplace insert to the chimney shall be supervised by the

authorised person, professional chimney sweep. The appliance

shall be used in normal environment.

14

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

In the event of change of this environment where temporary fire or explosion hazard

can occur (e.g. when gluing the linoleum, PVC, when working with coating

compositions etc.), the appliance shall be taken out of operation before danger can

occur. When the fireplace is installed on floor from flammable materials, it is necessary

to put the fireplace insert on inflammable heat insulating pad, exceeding the fireplace

insert edge by 300 mm in the heat-emission direction and by 100 cm in other

directions.

The fireplace insert shall be connected to the chimney according to your local

regulations. Such connection ensures adequate exhaust of flue gas. The connection

shall be approved by a professional chimney sweep. Flue pipes according of high

quality shall be used for the connection. The connection shall be tight and

mechanically firm. The flue pipe in the flue socket of the fireplace insert shall be

mechanically secured with a lock or split cotter pin. When connecting to the chimney

flue, the extension joint is to be sealed. When the flue pipe is running through

flammable construction parts, your local regulations shall be complied with.

Hot-air fireplaces cannot be installed:

- in rooms with the surface smaller than 12 m

2

.

- in corridors (pass through rooms and production areas).

- in places, where flash fuels or explosive materials are manipulated.

- in flats with other appliances working with open fire (e.g. gas water heaters,

cookers), where these appliances are not placed in a separate room.

- in rooms with hot-air heating with forced air circulation (uderpressure arises),

with extractor hood.

In these cases it is necessary to consult the professionals.

Chimney

Before connecting the fireplace insert to the chimney, the chimney shall be inspected

by a professional chimney sweep service which inspects the state of the chimney and

confirms its suitability for the connection of fireplace insert.

The choice of chimney is influenced by several aspects. Particularly important is the

cross-section of the chimney (the minimal diameter for fireplace inserts SIGMA and

KAPPA is 160 mm, the cross-section of square chimneys shall be 150 mm x 150 mm)

and its height - minimal height is 5 m (length from the edge of the chimney flu to the

chimney outlet). The fireplace insert shall be connected to a separate chimney with a

separate flue pipe under the angle of 45°, 90° or with a vertical flue pipe with the

maximal length of 1,5 m. The connection shall comply with your local regulations. Any

15

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

other connection can result in improper function of the flue liner as a result of

insufficient chimney draught. The necessary draught in the chimney for the proper

operation of the fireplace insert is minimally 12 Pa. When the draught is bigger than 15

Pa and there is a need to reduce it, it is recommended to install a flue gas flap. We

recommend to realise the connection in such a way that the flue gas condensates or

rainfall do not leak into the flue pipe and in the fireplace insert (this does not apply to

vertical connection to the chimney).

Caution: The cross-section of the flue vent shall not be bigger than the cross-section of

the chimney vent and shall not get smaller in the direction to the chimney. If the

calculation demonstrates that the cross-section of the flue vent and the cross-section

of the chimney vent can be smaller than the cross-section of the flue neck of the

appliance, the cross-section of the flue pipe directly behind the flue neck of the

appliance shall be reduced by short gathering or with step change in cross-section.

Air supply for combustion

It is necessary to ensure sufficient air supply for combustion for the operation of the

fireplace insert. Fireplace inserts SIGMA and KAPPA enable supply of air for

combustion from the exterior or from the next room, where the climate in the room

where the fireplace is installed is not influenced. In this case there shall be the

minimum number of branches and bends and you shall take into consideration the

barriers to air circulation. Another possibility how to secure the sufficient amount of

air for combustion is ventilation or connection of the room to another area with a

sufficient amount of air. Exhaust hoods or ventilation and air-conditioning equipments

placed in the same area as the fireplace insert can be source of problems as they can

change the draught conditions.

The most suitable connection of external air suction for combustion is the connection

to a system chimney which has an air vent, e.g. CIKO.

Pictures No 4. and 5. show possible installations of fireplace insert with air supply for

combustion from exterior, respectively interior.

16

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Picture No 4. Cross-section of a typical surround.

17

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Picture No 5. Cross-section of a typical surround – installation, including hot-air

exchanger.

18

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Legend to pictures No. 4 and 5:

1. Chimney vent

2. Wall of the building

3. Ventilation of insulation area

4. Insulation area above the chamber

5. Ceiling of the hot-air chamber

6. Air gap (ventilated)

7. Thermal insulation layer

8. Flue pipe

9. Hot-air chamber in the fireplace insert

10. System of deflectors and partitions

11. Fireplace insert body

12. Refractory concrete

13. Hearth of the fireplace insert

14. External air supply

15. Non-combustible floor in front of the fireplace

16. Air supply from the room

17. Bottom part of the fireplace insert

18. Regulation of air supply for the combustion

19. Cover frame

20. Walling cornice

21. Thermal insulation layer

22. Wall of the hot-air chamber

23. Hot-air nozzle

24. Ventilation of the hot-air chamber

25. Room ceiling

26. Grid

27. Insulated air flue with the diameter of 150 mm

28. Air flue with the diameter of 150 mm

29. Passage of air flu into the next room

The outlet grids shall be permanently open when using the fireplace insert!

For the proper function of the fireplace insert and to prevent its overheating during

the operation, the grid in the upper part of the surround or any other hole for the heat

outlet shall be open during the operation. The minimum surface of this hole is 1550

cm2. In the bottom part, there also needs to be a grid for the air supply under the

surround. The minimum surface of this grid is 1450 cm2. These grids must not be

covered. When installing the fireplace surround, it is necessary to leave an inspection

19

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

opening that enables the access to the surround for the purpose of cleaning the

chimney, flue pipe and fireplace insert.

All local regulations shall be complied with when installing the appliance!

Fireplace surround

The realisation of the surround depends on the individual design requirements. The

construction of fireplace is specified in your local regulations. When building the

fireplace surround, several important principles shall be complied with:

- When installing the surround, use only materials designed for this purpose

which are resistant to high temperatures, temperature changes, do not release

substances dangerous to health or dust. As an example, we can recommend

e.g. insulating material Silca and heat-accumulating material APK.

- Individual parts of such a surround shall be connected only with mortars and

cements which are designed for this purpose.

- For the plastering, use furnace gauze and furnace plastering, e.g. Silaterm.

- Always obey instructions and recommendation from the manufacturers of

these products.

- Potential combustible parts of the surround shall be properly insulated from

the fireplace insert. There shall be no direct connection e.g. of wood and

fireplace insert anywhere.

- To enable dilatation, it is necessary to leave an expansion gap of 3 mm between

the surround and the front part of the fireplace insert. This expansion gap is

covered by a frame which is part of the fireplace insert delivery. There shall be

no direct contact between the fireplace mantle and the surround.

Cross-section of a typical support is showed in pictures No 4 and 5.

The fireplace insert is to be placed on non-combustible floor or pad (e.g. concrete

base). The floor shall have an appropriate load capacity. After installing the fireplace

insert at its place, it is necessary to bring the fireplace insert with the help of rectifying

screws into level position.

20

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Picture No. 6 Rectifying screw

Legend to picture No 6:

1 Baseplate sheet

2 Rectifying screw

3 Levelling nut

Non-combustible floor or floor shall exceed the edge of the

surround by at least 800 mm in the direction of heating of the

front of the insert and by 400 mm in the direction parallel with

this side, as showed in picture 7. We recommend insulating the walls and ceiling

from the surround area with plates Silca or with similar product with the minimum

thickness of 100 mm.

21

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Picture No 7. Necessary overhangs of the non-combustible floor for the installation of

the fireplace insert.

Legend to picture No 7:

1 Surround

2 Fireplace insert

3 Floor

4 S Distance in parallel direction (400 mm)

5 H Distance in heating direction (800 mm)

Cold air is supplied to the fireplace surround through the bottom grid; when the air

moves up, it is heated by the insert walls, and it rises and gets out through the upper

grid from beneath of the fireplace surround. The area over the chamber with the insert

body is separated from the ceiling (insulation of combustible ceiling) and this area is

ventilated through the grid.

If the heated air is distributed from the air-hot exchanger (accessories), its distribution

is usually made with flexible Al-hopes with the diameter of 150 mm to the grids. Alhopes shall be fixed to the exchanger or to the grid with self-tapping screws, rivets or

clips.

The surrounds of fireplace inserts with vertical sliding doors –

SIGMA series – shall be made in such a manner that access to

the sliding door mechanism for eventual maintenance and

repair is ensured. The surround shall enable the demounting of the cover frame –

position No 8 in picture No 1.

The safe distance from the door frame linings and similar placed building constructions

from combustible substances and from the installation of pipe, including its insulation

22

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

is minimally 200 mm. From other parts of constructions from combustible substances

minimally 400 mm. This applies to construction substances with flammability class B,

C1 and C2 according to ČSN EN 13501-1:2007.

Combustible ceiling in the area of the surround

Such ceilings need to be separated from the area of the fireplace surround with plates

Silca or with similar products with the minimum thickness of 100 mm. Right above the

edge of the upper flue pipe, there shall be a ceiling barrier of the area of the surround

from this material, which leads to ceiling insulation. This barrier shall be equipped with

a grid that enables the air exchange in the created area.

The recommended minimum dimensions of the heat insulation of walls and ceilings

from materials Silca:

- for non-combustible walls up to 11,5 cm and outer walls: 100 mm

- for non-combustible walls from 11,5 cm and outer walls: 60 mm

- in combustible walls we recommend their thermal surround, e.g. from gassilicat

on the entire surface of the enclosure and their insulation with materials Silca

with the sickness of 100 mm.

The minimum gap between the fireplace insert and the heat insulation of the surround

or non-combustible wall is 70 mm in all walls; the recommended value for the optimal

function of the fireplace insert is 80 mm. If the insert is equipped with an air-hot

exchanger (accessories), the recommended gap between the wall and the exchanger is

30 mm.

Connection of hot-air distribution

When the fireplace insert is equipped with a hot-air exchanger, hot-air distribution is

installed. Flexible Al hope is usually used for the hot-air distribution, in case of

distribution for longer distances with insulation. The hope shall be mounted onto the

exchanger flange or grid and fixed with the help of clip, self-tapping screw or rivet. The

grids can be equipped with blinds that can regulate the direction of air circulation. At

least one grid needs to be always open – it is the grid in the room where the fireplace

insert is installed. The total length of the hot-air distribution shall not exceed 12 m; the

length of individual branches shall not exceed 4 m. The distribution shall be as even as

possible, without sharp transitions, always with gradual upward direction. The outlet

of the distribution in the room shall not be in the downward direction (e.g. from the

ceiling).

Safety precautions

For reasons of fire safety, when building the surround of the insert, it is necessary to

ensure sufficient access for cleaning the appliance, the flu pipe and the chimney.

23

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

When installing and using the fireplace insert, provisions of

your local regulations shall be complied with.

Any changes to fireplace insert are not admissible. Only spare parts provided by the

manufactures shall be used for the repairs. In the event of failure or when the fireplace

insert does not work properly, stop the heating immediately.

Follow the provisions of your local regulations when installing the fire place insert.

Keep the minimum safety distances from any flammable objects defined in the

regulation. The safety distance from the flammable substances with the flammability

class C2 is according to the regulation 200 mm. The distances are to be doubled for the

flammability class C3 or when not proving the flammability class according to ČSN EN

13501-1+A1.

Chimneys and flue pipes to which the fireplace insert is connected shall be swept by a

chimney sweep in the intervals defined in your local regulations. Neglected sweeping

can result in ignition of smoke black or tar in the chimney. In case of ignition do not

use water for extinction. Close the air-supply for the combustion. If possible, close the

chimney flap. Contact the chimney sweep to inspect the chimney body and the

manufacturer of the fireplace insert to inspect the insert.

24

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Fireplace insert operation

Releasing the counterweight lock

The lock needs to be released before inspecting the

completeness of the delivery, before inspecting the fireplace

insert and before installing a fireplace surround. To release the

lock, fully unscrew the screw in the position 1 according to picture No 8.

Picture No 8. Releasing the counterweight lock

The counterweight lock is released by releasing (fully unscrewing) the lock screw in the

position 1. The door shall be in its bottom position when doing this operation.

Instructions for putting the fireplace insert into operation

Before putting the fireplace insert into operation, control if it contains all the parts:

hearth cladding, door, including glass, ashpan, set of deflectors, grate – see pictures No

1.-3.

The fireplace insert can be operated only by adults! Do not

leave children near a lit fireplace (also during the sufficient

time after its operation) unattended by adults! The surface of

25

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

the fireplace insert is hot and can cause severe burns. When using the fireplace

insert, it needs to be operated and supervised. For safety operation of the fireplace

insert use safety gloves.

Caution: During the first operating hours, the pint gets cured and the paint can get soft

causing inproper dood closing and opening. During those first operating hours keep

the door ajar in order to prevent the adhesion of the door to the body and inproper

closing and opening. During operation of the fireplace insert, the door of the fireplace

insert should be closed except when reloading fuel.

Outdoor temperature above 15°C, wet and rainy days, strong wind can result in a

deterioration of chimney draught (exhaust of flue gas from the fireplace), and the flue

gas is not properly exhausted.

Never suddenly close or open the air supply, as the accumulated gases could explode.

- When you first fire the fireplace insert, operate it only at a moderate output.

- When you first fire the fireplace insert, the surface finishing undergoes a

hardening process which is connected with unpleasant smell. Therefore you

should ventilate when first fire the fireplace. The surface finishing needs to be

burned gradually and therefore you should increase the performance up to the

full intensity gradually.

- For the firing use only firelighters intended for this purpose.

- Use only recommended fuels in the fireplace insert – wood, wooden briquettes,

never heat with plastic materials, paper, waste etc.

- Except of firing the fireplace insert and reloading fuel, the door of the fireplace

shall be closed to prevent flue gas outlet into the room.

- The surface of the fireplace insert is heated during the operation and therefore

you should use safety gloves.

Use this fireplace insert in finished interiors where there is no high dust formation and

humidity. Do not use the fireplace insert for heating in unfinished buildings as it could

lead to its overheating. The manufacturer is no liable for potential damages as a result

of overheating the fireplace insert.

This fireplace insert is intended for a short-time operation and it is necessary to

periodically reload fuel dependant on the operation intensity of the fire place insert,

usually after one or several hours (in case, when hard wood is used, e.g. beech wood).

Putting the fireplace insert into operation

- If you have a flue gas valve installed, bring it into open position.

26

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

- If you have an air supply valve for the combustion installed, bring it into open

position.

- Open the door of the fireplace insert (in models SIGMA in vertical movement, in

models KAPPA in horizontal movement), see pictures No 9. and 10.

- Put a firelighter designed for this purpose and wood cut into small pieces into

the hearth and form a pyramid of woods.

- Adjust the air supply for the combustion in the fireplace insert into fully open

position, see picture No 11.

- Light the fire-lighter and leave the door slightly open until the wood starts

burning. The operation of the fireplace insert shall be under permanent

supervision during this time.

- When the fire starts burning, add 2-3 smaller logs and adjust the air-supply to

the required burning intensity.

- If you use a flue gas valve, close it.

Picture No 9. Opening of the door SIGMA.

27

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Picture No 10. Opening of the door KAPPA.

Picture No 11. Positions of the control.

Legend to picture No 11:

Position 1 – the smallest air volume for combustion - closed

Position 2 – medium air volume for combustion

Position 3 – the biggest air volume for combustion – fully open

Adding fuel

- If you have a flue gas valve installed, bring it into open position.

- Open the fireplace door and wait for 15-20 seconds until the pressure in the

fireplace insert is equilibrated and the smoke is discharged, then close the

door.

- Now add fuel, usually 3 logs.

- Close the door.

28

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

- After ca. 20 seconds, adjust the flue gas valve into closed position (if you have it

installed).

Maintaining the fire in the fireplace

- There shall be a layer of hot embers with the height of ca. 2-3 cm.

- Add only logs of recommended size.

- To maintain the fire adjust the air-supply for combustion into ca. 1/3. However,

do not decrease the air amount a lot, you prevent potential glass soiling.

Adjusting the amount of air for combustion

The fireplace insert has a single control panel to regulate the air supply for the

combustion. If you adjust it into the maximum right position, then the maximum air for

the combustion is supplied into the fireplace insert – picture No 11. Air supply: The

primary pre-heated air is supplied under the grate, the secondary pre-heated air from

the back side of the hearth and the tertiary pre-heated air through the rinsing liner

onto the glass. If you adjust the control into the maximum left position, the minimum

air is supplied into the fireplace insert, see picture No 11. The individual air proportions

are fixly adjusted by the manufacturer. The precise adjusting of the combustion

process with the fireplace insert control cannot be defined precisely, it is always

necessary to take into consideration the actual humidity and fuel type, climatic

conditions and chimney draught.

Fireplace cleaning

Do not clean the fireplace insert until it is completely cold. Bear

in mind that apparently cooled ash can include hot embers

which can cause fire.

The chimney and the flue pipes shall be cleaned by a professional chimney sweep. The

chimney and flue pipes to which the fireplace insert is connected need to be swept by

a chimney sweep in the periods defined in the governmental regulation No. 91/2010

Sb. If the chimney sweep is neglected, there is a risk of ignition of accumulated smoke

black and tar in the chimney. In case of ignition in the chimney, do not use water to

extinguish it. Close the air supply for the combustion. If possible, close the chimney

flap. Contact the chimney sweep to inspect the chimney body and the manufacturer of

the fireplace insert to inspect the fireplace insert.

Note that the accumulated ash shall reach only up to half of the height of the

ashpan; otherwise there is a risk of damage of air supply flap. If necessary remove the

ash from the bottom of the hearth and clear the ashpan. To remove the ashpan firstly

remove the grate, sweep the ash into the ahs pan, then take and remove the ashpan,

see picture No 13. Spill the ash preferably into a metal container. Put the ashpan back

into the ash chamber and put the grate back.

29

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Picture No 12. Horizontal opening of the door, SIGMA series.

OPEN CLOSED

Arrest the door in its position according to picture No. 15. To open the door, use the

key which is part of the delivery. You can also open the door with a flat wrench of 12

mm. After inserting the wrench, move it upwards to release the door lock; to lock the

door again, push the door into its position and secure it by moving the wrench

downwards.

Picture No 13. Removing the ashpan.

30

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Legend to picture No 13:

1 – ash pan handle

2 – ash pan body

For the proper cleaning of the fireplace, you can use a special vacuum ash cleaner

designed for this purpose. Clean the fireplace insert according to the intensity and

frequency of use, the general cleaning of the fireplace insert shall, however, be done at

least once a year. When cleaning the fireplace insert, remove also the set of deflectors.

Firstly, remove the deflector from the position No 1, then 2 and at last from the

position 3. The position of deflectors is showed in picture No 14. When you finish the

cleaning of the insert, flue pipes and the chimney, return the deflectors in the reverse

order.

Picture No 14. Position of deflectors.

Legend to picture No 14.

1 – bottom deflector

2 – middle deflector

3 – upper deflector

When removing the deflectors, proceed in reverse order as described in chapter

Description of the parts.

When cleaning the door of fireplace inserts SIGMA, the door

shall be arrested to prevent its potential movement upwards.

Arrest the door with putting out the handle which is placed in

the upper left side of the door frame, see picture 15.

31

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Picture No. 15 Arresting the door.

Legend to picture No 15.

Position A – the door frame is secured against its moving upwards

Position B – the door frame is unsecured

Deposits are built up on the glass during operation of the fireplace insert. Clean the

glass regularly in order to prevent the build up of a rather thick layer of deposits. To

clean the glass, use only products intended for this purpose.

The dismounting of the door or its frame shall be performed by a professional firm or

by the manufacturer. The manufacturer is not liable for potential malfunction as a

result of unprofessional treatment.

This arrestment of models SIGMA is necessary also when you

want to unhang the door. If you do not arrest the door, the

counterweight falls out of the chamber and takes down the

wire and the movable door mechanism. To put the mechanisms again into operation

it will be necessary to access the fireplace surround.

When the fireplace insert is not in operation for a longer time, inspect if the chimney,

fuel pipe and regulation elements are not stuck.

32

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Fuel

The fireplace insert is intended for the operation only with the fuel defined by the

manufacturer – wood or wooden briquettes. Operate the fireplace insert at nominal

output, add the given amount of wood and do not burn any other materials. All types

of wood have essentially the same heating capacity in the relation to their weight (ca 4

kW.kg-1). To fire the fireplace, use rather soft wood which is burning easier. For

ordinary burning, however, use rather hard wood, from leafy trees, e.g. oak,

hornbeam, beech. The wood used for the combustion in the fireplace insert shall not

be fresh or have a high content of resin. Use solely dry wood with the maximum

moisture of 20%. It is ideal to let the fresh wood dry under a good ventilated shed for

two years at least. You remove the surface moisture from the wood when you bring it

home at least one day before its use.

Mechanical parts

The abrasive surfaces of the door hinges and of the door latch mechanism need to be

treated with carbon grease (molybdensulfit lubricant) or with lubricant for high

temperatures.

33

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Information

Waste disposal

Wooden palettes – to be broken and burned in the fireplace, eventually landfill for

inert waste

Plastic tape, shrink-wrap, polystyrene, glass, sealing tape – municipal waste (sorted

waste)

Refractory concrete – landfill for inert waste

Steel – salvage point

34

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Warranty terms and conditions

1. The manufacturer grants a warranty for this product for a period of 24 months which

commences on the date when the product was collected from the seller. If not stated

otherwise in these warranty terms and conditions, the manufacturer grants an extended

warranty period of 120 months beginning from the date of installation of the product on

metal part of the fireplace insert body, if the fireplace insert is installed by a certified

seller; the list of certified sellers is attached to this certificate of warranty (hereinafter

referred to as „extended warranty“). If the product is not installed by a certified seller,

the extension of the warranty period to 120 months will not apply. The installation of the

product shall be approved by a certified seller in the certificate of warranty.

In the event that the manufactures has provided an extended warranty under these

warranty terms and conditions, this warranty is limited to certain parts of the product. In

the case of an extended warranty, the manufacturer grants a warranty period of 48

months for the cladding from refractory concrete and a warranty period of 24 months for

parts under thermal pressure which are subject to wear: ashpan, removable deflectors.

Door seals wear out, depending on the intensity of use of the product, and its normal

wear is not a reason for complaint. Defects of door frame glass (ceramic glass) must be

applied no later than after three periods of heating and no later than after three months

from the installation of the insert at the consumer.

The installation shall be certified by the seller or by a person who installed the product in

the certificate of warranty. The warranty period begins on the date when the product was

collected from the seller or on the date when the product was put into operation

(installation) by a certified seller; however, always not later than 4 weeks from the date,

on which the product was collected from the seller. The warranty is provided only for the

first user, unless otherwise agreed in writing with the manufacturer.

2. The warranty applies to all defects in the manufacture and defects in material that

occurred or will occur during the warranty period.

3. The warranty does not apply to ordinary wear and tear of the product or its parts

resulting from normal use (e.g. sealing wear, color change of the tiles and their

mechanical damage).

4. The warranty does not apply to following cases:

- defects caused as a result of mechanical damage or use of inadmissible chemical

substances;

- damages caused during transport unless the product is transported by the

manufacturer

35

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

- when the information in the type label is different from the information in the

instructions;

- defects caused by unprofessional, respectively inadequate operation, by not

following the terms and conditions for use and operation of this products which are

defined in these instructions;

- in case, when the fireplace insert is connected to a chimney with too low or too

high draught;

- defects caused by improper storage in humid or uncovered places;

- defects caused by the use of inappropriate fuel – defected or wet wood

- defects caused by the use of considerably higher or lower amount of fuel

compared to the information in these instructions;

- by not complying with the relevant technical regulations and applicable building

regulations;

- defects caused as a result of additional modification of the product, e.g. additional

changes of the hearth or exhaust of flue gases etc.;

- unavoidable situation;

- typical acoustic manifestations when heating and cooling the insert of the product.

5. The manufacturer compensates the appropriate and effectively incurred costs for

wrapping and delivery of the claimed products if the claim is justified.

6. The client can lodge the claim at the certified seller from whom he bought the product

or directly at the manufacturer. If the product was bought from a different person than

person defined in the previous sentence, the client is obliged to lodge the claim at a

person from whom he bought the product, respectively who delivered him the product.

7. All rights arising from product liability according to these warranty terms and

conditions expire unless they were claimed by the client within the warranty period

defined by the manufacturer in this certificate of warranty, respectively in these warranty

terms and conditions.

8. The manufacturer reserves the right to charge work associated with service activities,

provided they are made within the unrecognized claim.

36

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Model:

Serial number:

Date of removal from storage:

Date, Store manager´s signature

Date of sale:

Date, Seller's identification (Ident.- No., address), Seller´s signature

Date of installation:

Date, Installer´s identification (Ident. -No., address), Installer´s signature

The customer was informed about the use and operation of the product.

Date, Customer´s signature

Note:

Certificate of warranty

Hot-air fireplace insert

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

37

www.flamen.cz

Date of

notification

of defect

Date of

repair

Description of defects and repairs

Signature

of Service

Technician

List of repairs

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

38

www.flamen.cz

CE marking attached in accordance to ČSN EN 13 229/A2

MANUFACTURER:

Producing plant:

FLAMEN, s.r.o.

Svitavská 500/7

CZ-678 01 Blansko, Czech republic

Registered Office:

FLAMEN, s.r.o.

Holušická 2221/3

CZ-148 00 Praha 4, Czech republic

VAT Id. No. CZ29413036S

Registration in the Trade Register: Municipal Court in Prague, section C, insert 204599

www.flamen.cz

39

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

40

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

41

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

42

FLAMEN, s.r.o., Correspondence address: Svitavská 500/7, CZ-678 01 Blansko, Id No: 294 13 036, VAT Id No: CZ29413036

Seat: Holušická 2221/3, CZ-148 00 Praha 4, Entry in companies´ register: City court in Praha, section C, insert 204599

www.flamen.cz

Loading...

Loading...