Page 1

Shut-off poppet valve,

Ň

designed to operate with gas detectors

2/2 way type ZB

Class

A - DN20¸DN65

klasa B

B - DN80 i DN100

Group 1

Diameters range DN

Media

threaded connection

Rp 3/4 ¸ Rp 2 1/2 (DN20 ¸ DN65) DN50 ¸ DN100

gas fuels (gases as per PN-EN 437)

FEATURES:

poppet valve

!

! simple design

! unidirectional, uniform flow

! triggered elecromagneticly

! available with two types of solenoid triggers:

WE (12V DC) or EZB-12,6G (230V AC)

! low weight (mass)

! bistable - in lack of voltage condition the valve could stay in one of stable

position: open or close.

Control voltage is necessary or valve closing only.

! opened only manualy (“memory” function)

! closed with electrical impulse

! has the option for manual closing with botton

! permanent strainer built-in

! adapted for external application

! conforms to

!

meets applicabe requirments of Regulation (UE) 2016/426 (GAR) from

PN-EN 161:2011+A3:2013

9 march 2016 y. and Directives UE:

2014/35/UE (LVD); 2014/30/UE (EMC)

APPLICATION:

in Gas Safety Systems installed: gas boiler rooms, industrial facilities,

!

public utility buidings, domestic installations (i.e.one family houses and

multi-family houses, farmsteads, private use recreational buildings),

reducing -measuring stations, biogas plants, etc. itp. - as an actuator

that surely and effectively cuts off the gas supply to faulty installations

when a gas presence is detected in supervised by System compartments

! in gas installations supplied in conformance with appropriate regulations

from low pressure gas grid

! additionally valve can be used as manual stopcock, however it can not act

as gas installation main stopcock

! together with gas detection system, valve can perform a function of lock-

up for devices that burn gas fuels and are intended for use inside the

buildings and utility compartments. Such a lock-up prevents from

accumulation of burning gas in mentioned buildings and compartments

TECHNICAL DATA

Valve

maximum operating pressure......... P = 0,25 bar

safe static pressure ........................ P = 5 bar

closing time ................................... < 1s

ambient and media temperature ... -25 C ¸ 60 C

pipe threaded connection .............. Rp - internal straight thread

pipe flanged connection ................

mounting direction ......................... any

Solenoid trigger

trigger type..................................... WE EZB-12,6G

control voltage....................... ........ 12V DC 230V AC

voltage tolerance ........................... -15%; +10%

power consumption........................ 26 W 46 VA

coil resistance ............................... 5,5 W 134 W

safety class ................................... III I (earthing)

impulse minimum time duration..... 0,2s -0,3s

(necessary for closing the valve)

operation type ............................... S1 continuous 100%

ambient temperature .................... -30 C ¸ 60 C

electrical connection ..................... tri-contact terminal block

degree of protection (acc. PN-EN 60529) IP65

design (integrated) ............................ resin-molded coil

MAX

S

o o

compliant with PN-EN 10226

keeps compatibility of flange

connection dimensions [PN16, 01, B]

in acc. with PN-EN 1092-1

o o

flanged connection

1015

Schematic symbol

A

P

ELECTRICAL TERMINATION

coil connection

12

plug-in socket

21

The plug can be fixed in 3

positions towards the socket

(each 90 )

AC

2

1

L

N

PE

max

3x1,5

Conductor wires polarization-indifferent (apart from PE);

recommended - as on figure

Connection wire size depends on the distance to

control module - see Service Manual of applied

control module.

Size and allowable lenght could be also

determined assuming as admissible10% voltage

drop on conductor (calculated from rated voltage

12 V)

PG11

O

AC, DC

1

DC

2

1

Mp

max

2

P

3x1,5

page 1/4ZB - data sheet release 02/2019/KK

Page 2

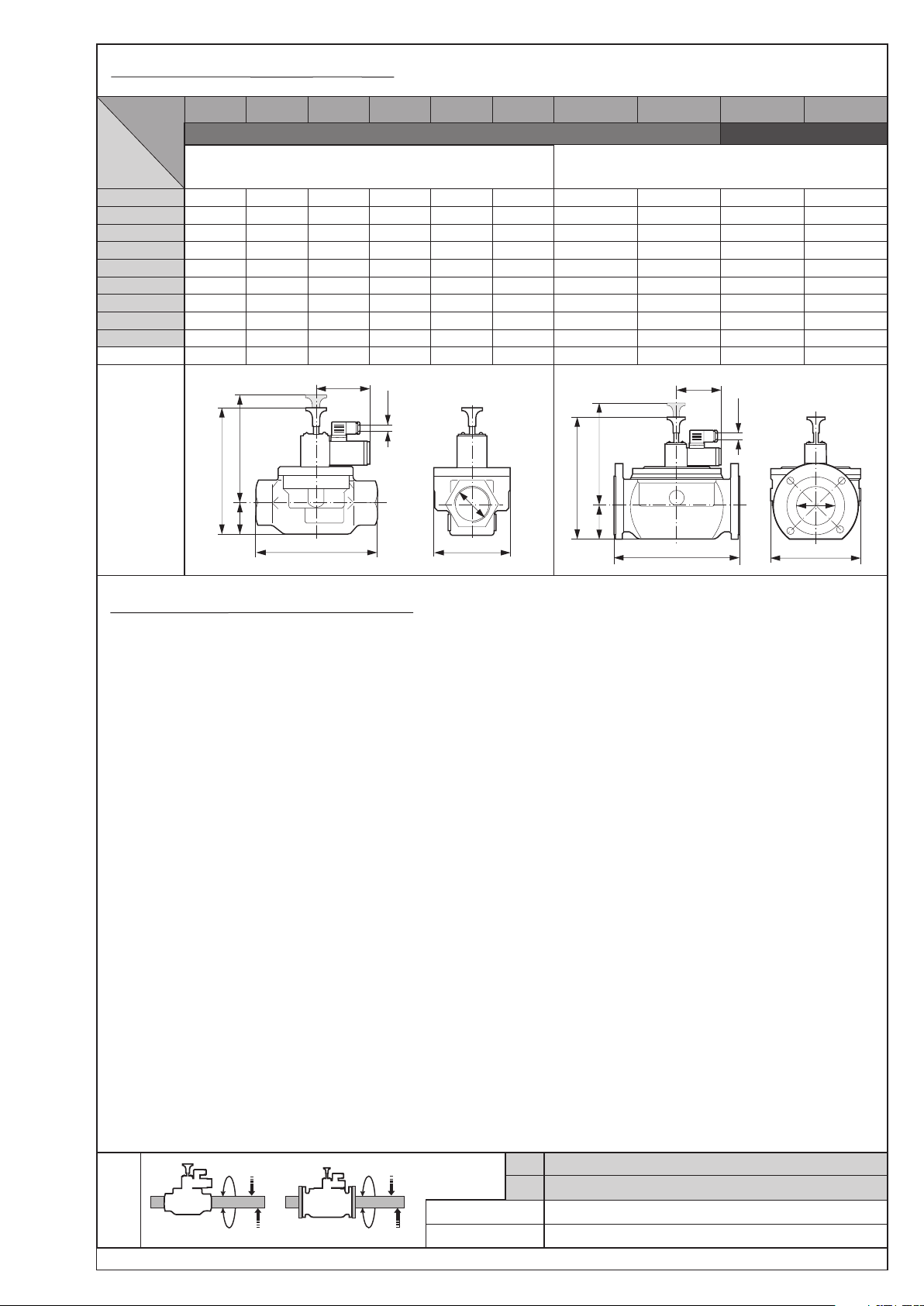

OVERALL DIMENSIONS (mm), WEIGHT (kg)

DN

Rp

A

B

(1)

C

E

L

P

Pg

Weight

ZB-20Type

ZB-25 ZB-32 ZB-40 ZB-50 ZB-65 ZB-50k ZB-65k ZB-80k ZB-100k

valves with threaded connection

(internal straight thread in acc. with PN-EN 10226)

20

3/4

127

22

112

77

105

92

11

1,20

A

25 32 40 50 65 50 65 80 100

1 1 1/4 1 1/2 2 2 1/2

137 155 180 188 218 225 243 307 318

28 37 48 40 61 78 83 94 103

116 126 143 158 170 157 171 231 239

79 100 112 142 170 165 185 200 222

115 144 178 193 240 230 270 310 350

92 92 92 92 92

11 11 11 11 11 11

1,35 1,96 2,62 3,18 4,81

P

Pg

C

B

L

valve class A

Rp

E

valve class B

valves with flanged connection [PN16, 01, B]

(conforms to PN-EN 1092-1)

92 92 95 95

11 11 11

4,06 5,82 9,80 11,82

P

Pg

C

A

DN

B

L

E

INSTALLATION - basic assembly requirments:

! valve can be installed:

Ř outside the buildings - in the junction box protecting

against direct influence of atmospheric factors

Attention! Valve is not waterproof!!!

It should be installed in such a box and in such a

way that it is completely protected against

dripping water during rain and snowfall.

Ř inside the buildings

! install downstream the main tap, upstream or downstream

the gas meter (according to the gas flow arrow on the valve)

! it is necessary to anticipate and take into account the

pressure surplus that may occure at the valve inlet in case of

failure to components in the system located upstream the

valve

! mounting position - any

! direct contact of the valve with wall, ground, etc. is

unacceptable; keep the minimum distance - about 1 cm

! location of the valve should be selected so as to ensure free

access needed to its operation (for persons authorized to do

so)

! attention should be paid so that after valve installation there

is enough space left (maneuvering area) for ease coil

replacemet

! ensure proper rigidity of the installation in the place where

the valve is installed (Group 1 valve).

This can be achieved by using rigid supports to the bending

and torsional stress exerted by the piping system in the

installation (eg due to the lack of alignment of the of the

pipeline at the inlet and outlet of the valve)

! maximum moments: turning T and bending M

cannot exceed the values given in TABLE 1

MAX MAX

! ensure that valve is mounted rigidly so as to avoid any

vibration

in valves with threaded connections pipe should be screw in

!

that way so that 10 second torque not exceed values of

T given in TABLE 1

MAX

use appropriate thread sealant to esure tightness of the

!

connections

! tighten the flange screws crosswise Attention: maximum

torque of 50 Nm (~5 kGm)

! a strainer which protects from mechanical impurities should

be fitted upstream the valve in the gas installation.

Maximum dimension of strainer openings should not

exceed 0,2 mm

! valve’s assembly should be finalized with carrying out an

leaktightness test of installation including ZB valve using

compressed air or inert gas (oxygen use is forbidden)

Test pressure cannot exceed P = 5 bar

! during operation valve

S

- cannot be exposed to dilatation nor dynamic forces

- need to have ensured correct operating temperature

(ambient and media)

- should be protected against strong dustiness and

water flooding

TABLE 1

DN

20

25

32

40

50

65

80

400

780

100

400

950

page 2/4ZB - data sheet release 02/2019/KK

M

MAX

M

T

MAX

MAX

M

MAX

Rp

3/4

T

MAX

M

T

MAX

MAX

M

MAX

Ł

[Nm] t 10s

[Nm] t Ł10s

85

90

1

125

160

1 1/4

160

260

1 1/2

200

350

2

250

520

2 1/2

325

630

Page 3

CONSTRUCTION

valve manual open hand grip

1.

pilot sleeve

2.

3.

poppet pin

4.

slide rings

5.

pull spring

6.

sealing ring (o-ring)

7.

bonnet

8.

sealing ring (o-ring)

9.

pressing spring

10.

filter

11.

poppet

12.

poppet gasket

13.

valve seat

14.

valve body

15.

fastening screw

16.

plug-in socket

17.

impedance coil Pg11

18.

power supply socket

19.

trigger movable core

20.

valve manual close button

21.

solenoid trigger

22.

interlock ball

23.

seating stud

24.

plug G1/8 lub G1/4

25.

limit switch for example K01/1type from DUNGS

26.

impedance coil Pg11

27.

obique bush

28.

limit switch push rod

29.

pushing ball

1

2

3

4

5

6

7

8

9

10

15

16

17

18

19

20

21

22

23

PP A

11

12

13

14

Valve head* position sensor

(valve closing)

Switchning function

25 26 27 28 29 3

1

24

3

2

F

Constructional materials

valve body aluminium alloy

poppet pin stainless steel

pilot sleeve aluminium alloy

springs galvanized or

stainless steel

poppet body aluminium alloy

poppet gasket NBR (nitrile-butadiene rubber)

valve seat aluminium alloy

sealings NBR (nitrile-butadiene rubber)

slide rings PTFE

filter stainless steel - filter gauze

solenoid coil copper

(*) - valve head: movable part of valve which shuts-off gas fow

page 3/4ZB - data sheet release 02/2019/KK

Page 4

Dp

FLOW CHARACTERISTIC

[mbar]

80

60

2 3 4 10865 20 30 40

1

2 3 4 10865

Base conditions

O

+15 C

1,013 bar

dry

ZB - 20

ZB - 25

ZB - 32

ZB - 40

20 30 40 100806050 200 300 400 800600

air dv =1

ZB - 50

ZB - 65

ZB - 80

ZB - 100

Q [m /h]

3

3 4 865

2 3 4 10865 20 30 40 100806050 200 300 400 600

10

20 30 40 100806050

natural gas (methane) dv =0,65

propane-butane dv =1,56

200 300 400 800600

ACCESSORIES - options (available upon request)

! plugs G1/8 or G1/4 (position 24) with gaskets

Note that standard version does not have holes for

above plugs.

! counterflages with connector pipe (for valves with flanged

connection)

! stub pipe for inlet and/or outlet pressure measurment

(Ć 9, G1/8 lub G1/4 together with gaskets)

- used alternatively with plugs

! gas pressure sensor (at the inlet anr/or outlet of a valve)

Pressure sensors are assembled as marked on figure,

position 24

! valve head position sensor (position 25) from DUNGS type

K01/1

! plug with voltage presence indicator

! colour

ORDERING

Necessary information for ZEG valve order:

! valve type

! control voltage

! possible option and accessories

Example:

ZB-32/12V DC

it means:valve with threaded connection DN32

control voltage DC 12V

standard design

3

Q [m /h]

3

Q [m /h]

FLAMA-GAZ ELEKTROZAWORY S.C.

43-418 Pogwizdów k/Cieszyna, ul. Szkolna 3

phone +48 33 856-85-70, fax +48 33 856-85-62, www.flamagaz.com, e-mail: firma@flamagaz.com

release 02/2019/KK

Modification without prior notice of technical specification reserved

page 4/4ZB - data sheet

Loading...

Loading...