FlaktWoods EQKR ReCOOLER HP Maintenance Manual

AIR COMFORT

AIR COMFORT

AIR TREATMENT

9568 GB 2015.08.11

Heat-pump with heat recovery

EQKR ReCOOLER HP

» MAINTENANCE

Content Page

EQKR ReCOOLER HP

Heat-pump with heat recovery 1

Safety directions 2

Technical data 3

Product description 4

Description of the functions 5

Safety instructions 6

Operating and care 6

User interface 7

Maintenance 8

Maintenance

EQKR ReCOOLER HP

2

SAFETY DIRECTIONS

Important!

– The unit must NOT be used for purposes

other than as a reversible heat pump unit.

– The unit’s Operating & Maintenance

Instructions must be studied carefully

before starting/operating/servicing/

maintaining/scrapping the unit.

Keep these instructions in a safe place

for future reference!

– All service and maintenance must be

carried out by certified personnel.

Service/maintenance of the refrigerant

system must only be carried out by an

accredited company and certified

personnel wearing required protective

equipment (gloves and protective eye glasses).

– Lock and tag the heat pump prior to

performing service on the unit.

– Do NOT stand on the heat-pump unit!

– Use only genuine spare parts for

maintenance!

– Installation of units with split casing is

to be performed only by certified refri gerant technicians.

COMPULSORY DECLARATION AND RECURRING

INSPECTION

Compulsory declaration

This product contains refrigerant R410A which is a flourinated

greenhouse gas. The European Union is committed to reducing

emissions of such gases. Ensure that you are fully aware of

your local regulations and that they are complied with.

Recurring inspection

Recurring inspection, i.e. leakage inspection of the refrigerant

system must be carried out at least once annually by certified

personnel (normally a refrigeration service company), see

“Maintenance”.

Failure to comply with above terms and conditions can

result in serious injury and will void the warranty.

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

Maintenance

EQKR ReCOOLER HP

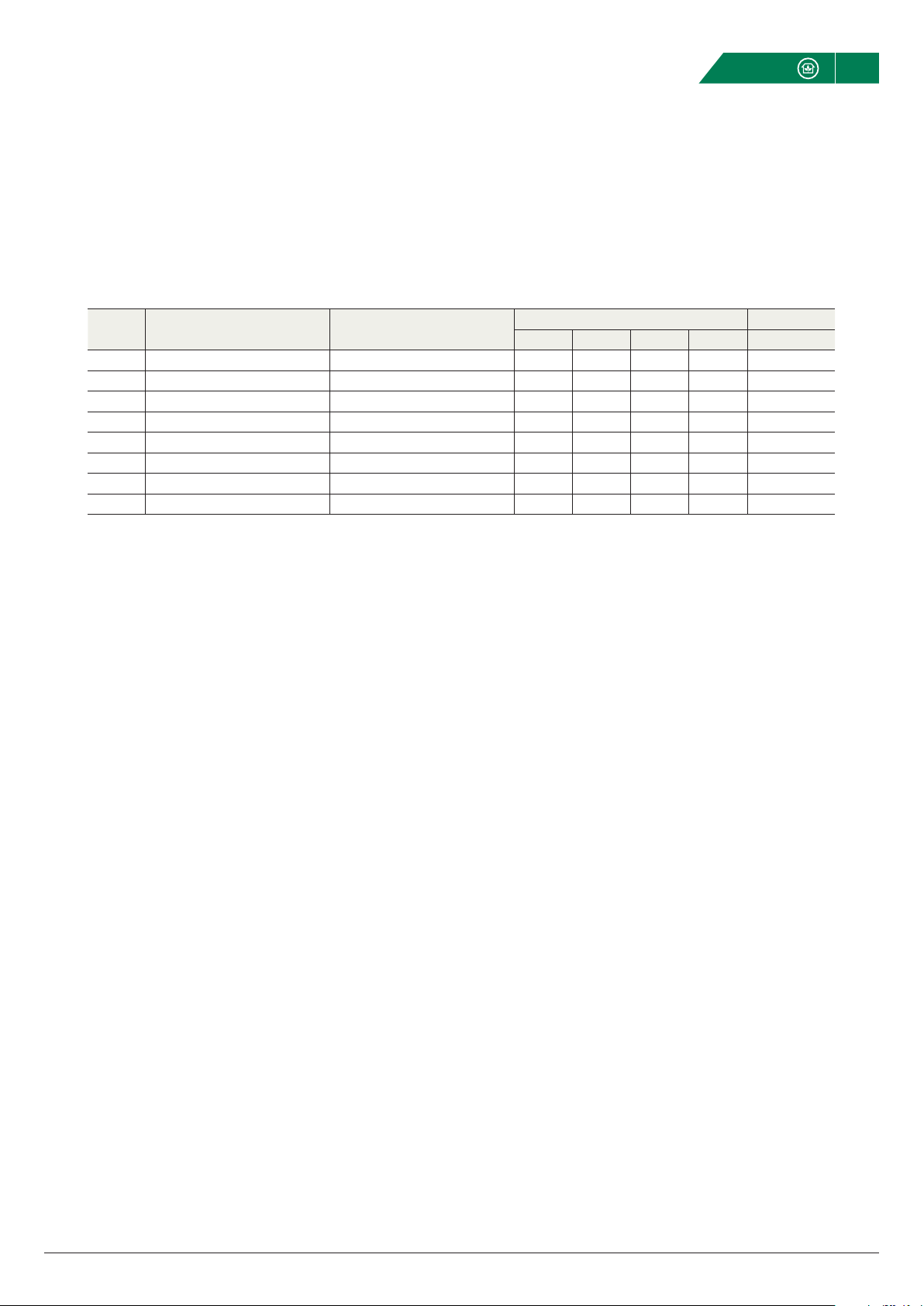

TECHNICAL DATA EQKR ReCOOLER HP

3

eQ size

11 14,3 18,7 6,9 6,9 1,9

18 17,1 26,2 9,8 9,8 1,9

23 20,9 32,4 16,4 16,4 1,9

32 21,1 39,9 21,5 21,5 1,9

41 33,8 53,7 13 13 26 1,9

50 41,7 65,4 14,3 19,5 33,8 1,9

72 61,8 93 13,5 13,5 13,5 44,5 1,9

Table above shows data for current ratings and refrigerant quantities for ReCooler HP delivered with eQ Master.

3x400 VAC Operating current (A)

(without electric heater)

8 22,1 22,1 4,9 4,9 0,9

3x400 VAC Operating current (A)

(with electric coil)

Circuit 1 Circuit 2 Circuit 3 Total (l)

Refrigerant charge (kg) Oil / Circuit

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

Maintenance

EQKR ReCOOLER HP

4

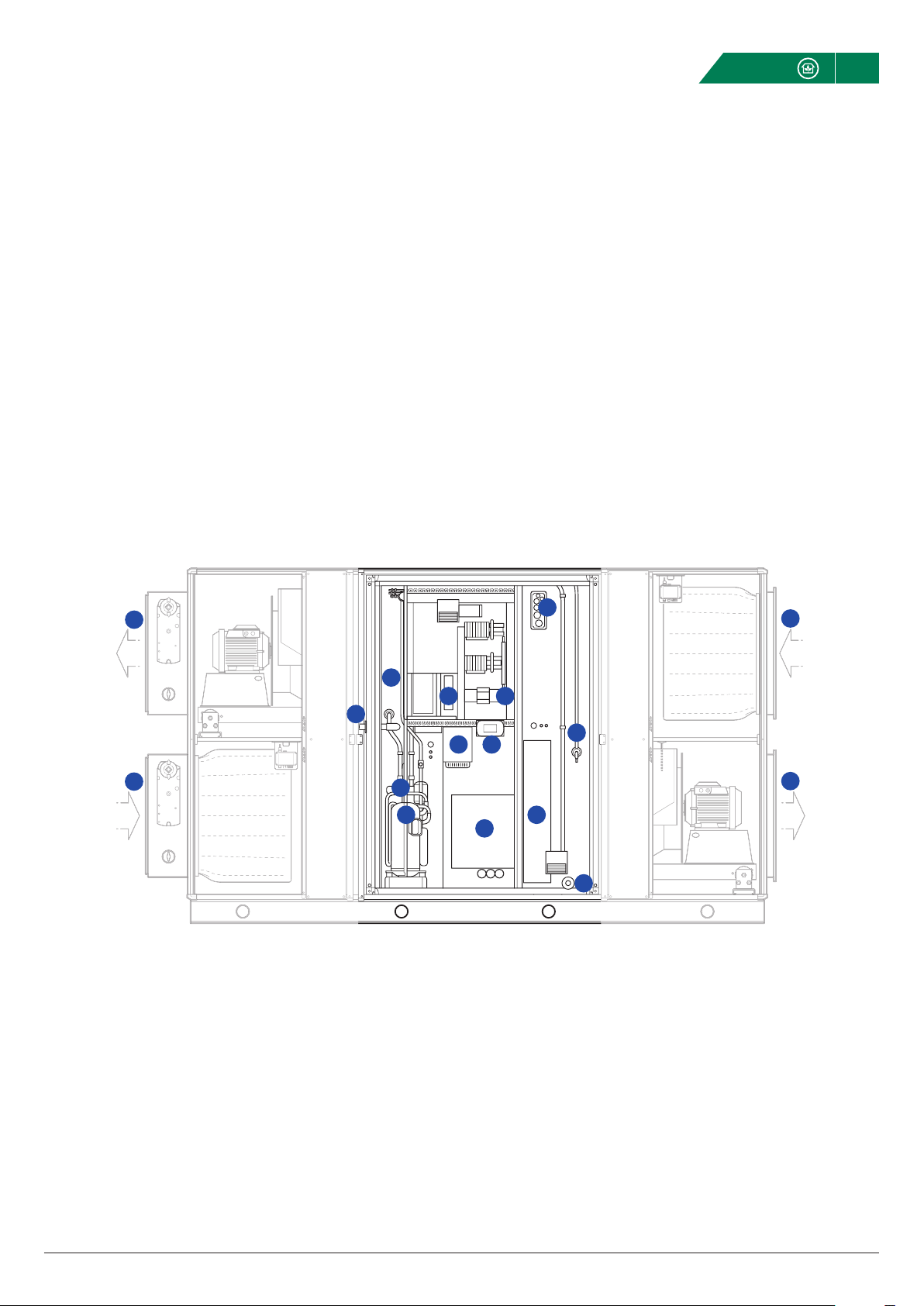

PRODUCT DESCRIPTION

The EQKR ReCooler is an integrated reversible heat pump

providing both heating and cooling. It consists of a rotary heat

exchanger and a Heat-pump unit. The ReCooler Heat-pump

has an independent control unit with heating-, cooling- and

thermal wheel demand supplied via an external control

source.

REFRIGERATION SYSTEM

The Reversible Heat-pump unit in the ReCooler is designed for

external air temperatures:

• Cooling+20to+40°C

• Heating,withelectricalheater+20to-20°C

• Heatingwithoutelectricalheater+20to-15°C

2

14

8

ROTOR UNIT

The rotor unit in the ReCooler is designed for heating and cooling air by utilising the temperature differences in the outdoor

air and extract air. The rotor operates to recover energy from

the extract air in combination with the heat pump unit.

OPTIONAL ELECTRIC DEFROSTING COIL

The defrost electrical heater is mainly used to shorten defrost

cycle time. It’s also used as an additional heater when evaporationtemperatureislow(<-21°C).Theelectricalheaterincludes two thermal protectors:

• Anautoreset

• Amanualreset

13

9

11

15

7

14

1

3

1. Outdoor air

2. Supply air

3. Extract air

4. Exhaust air

5. Rotary heat exchanger - service hatch

6. Compressor

7. Frequency inverter for compressor

8. Drainage

10

4

6

5

12

8

9. Control system for the ReCooler

10. 4-way valve in wrong position

11. Main switch disconnector

12. Optional – Electrical heater

13. Cable glands

14. Electronic expansion valves

15. Handheld terminal for the ReCooler

Fläkt Woods 9568 GB 2015.08.11 Specifications are subject to change without further notice

Loading...

Loading...