FlaktWoods ECONOVENT – PUM Technical Handbook

ECONOVENT®– PUM

Rotary heat exchanger

Technical Handbook

Fläkt Woods 3099 US 03.02 2 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

CONTENTS

Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3,4

Design – Description – Accessories

. . . . . . . . . . . . . . . . . . .5,6

The process in the psychrometric chart

. . . . . . . . . . . . .7,8,9

Rotor selection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Selection of heat exchanger type and size

. . . . . . . . . . . . .11

Efficiency

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Design chart

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13

Project design advice

. . . . . . . . . . . . . . . . . . . . . . . .14,15,16,17

Control Systems

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17,18,19

Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20,21

Dimensions and weights

. . . . . . . . . . . . . . . . . . . . . . . . . . .22,23

Ordering key

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24,25

Sample specification

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26,27

Fläkt Woods 3099 US 03.02 3 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Design

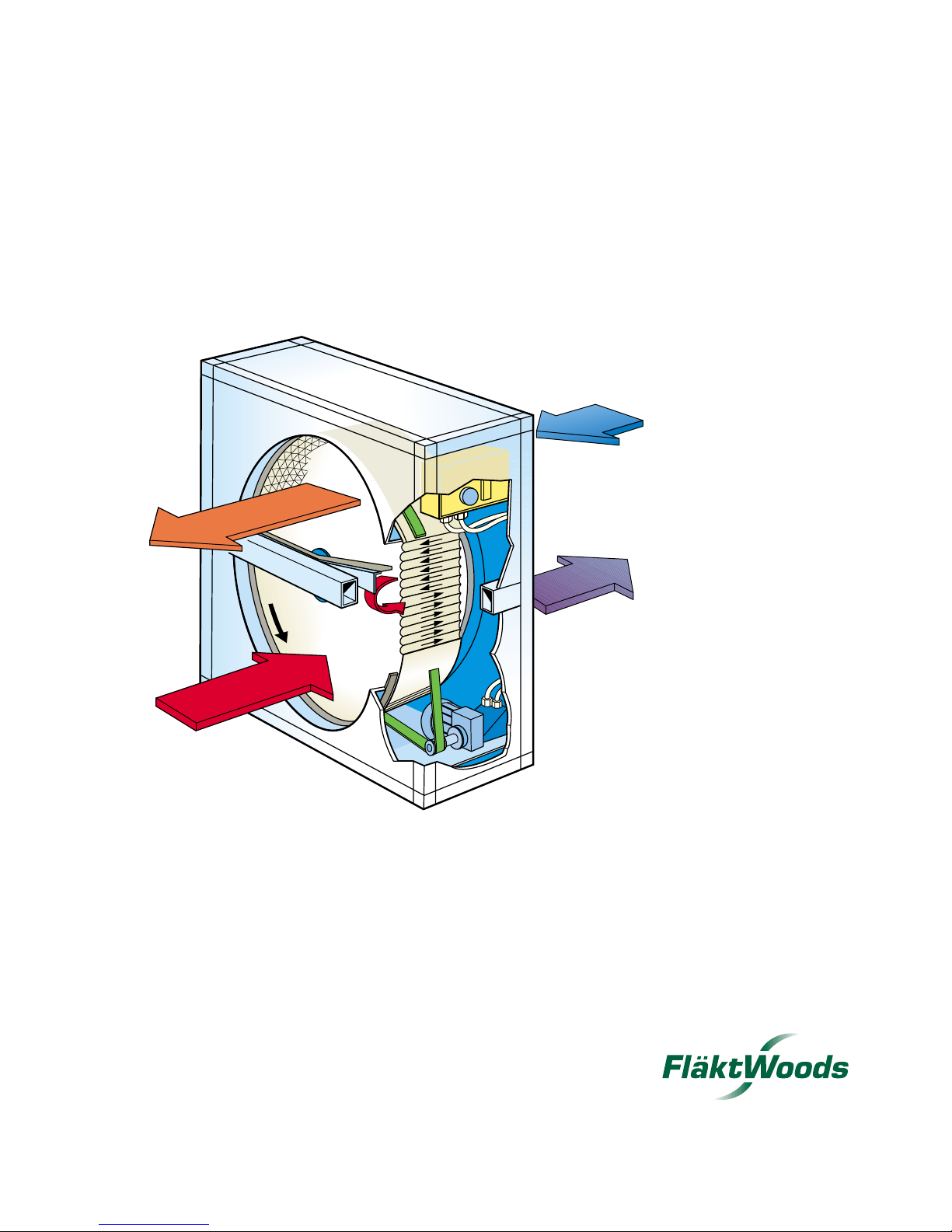

The ECONOVENT unit is a regenerative heat

exchanger comprising a rotor which transfers heat and

moisture from the exhaust air to the supply air as it

rotates.

The supply air flows through one half of the heat

exchanger, and the exhaust air flows in counterflow

through the other half. Supply air and exhaust air thus

flow alternately through small passages in the rotor in

opposite directions.

Most important benefits:

Reduced heat demand which, in turn, reduces the size

and thus also the investment cost for the boiler station

or the connection charge for tariff-linked heat, such as

electric power and heat from the district heating system.

In addition, the sizes and thus the investment costs for

air heaters, pipes and pumps are reduced.

Reduced heat energy demand, which reduces the

operating costs, i.e. the oil consumption or the con-

umption charge for electrical energy or heat from the

district heating system.

Reduced energy consumption for humidification

(hygroscopic rotors) of the air, since moisture is also

recovered.

Reduced cooling power demand (hygroscopic rotors)

which reduces the size and thus also the investment

cost for the refrigeration system (compressor, cooling

tower, etc.), air coolers, pumps and pipes.

Reduced energy consumption for refrigeration

(hygroscopic rotors).

General reduction in environmental pollutants.

ECONOVENT is a complete product range of rotary

heat exchangers for air handling systems in various types

of environments and plants. ECONOVENT is available

with six different materials for the rotor, and the right

material can therefore always be specified to suit most

environments.

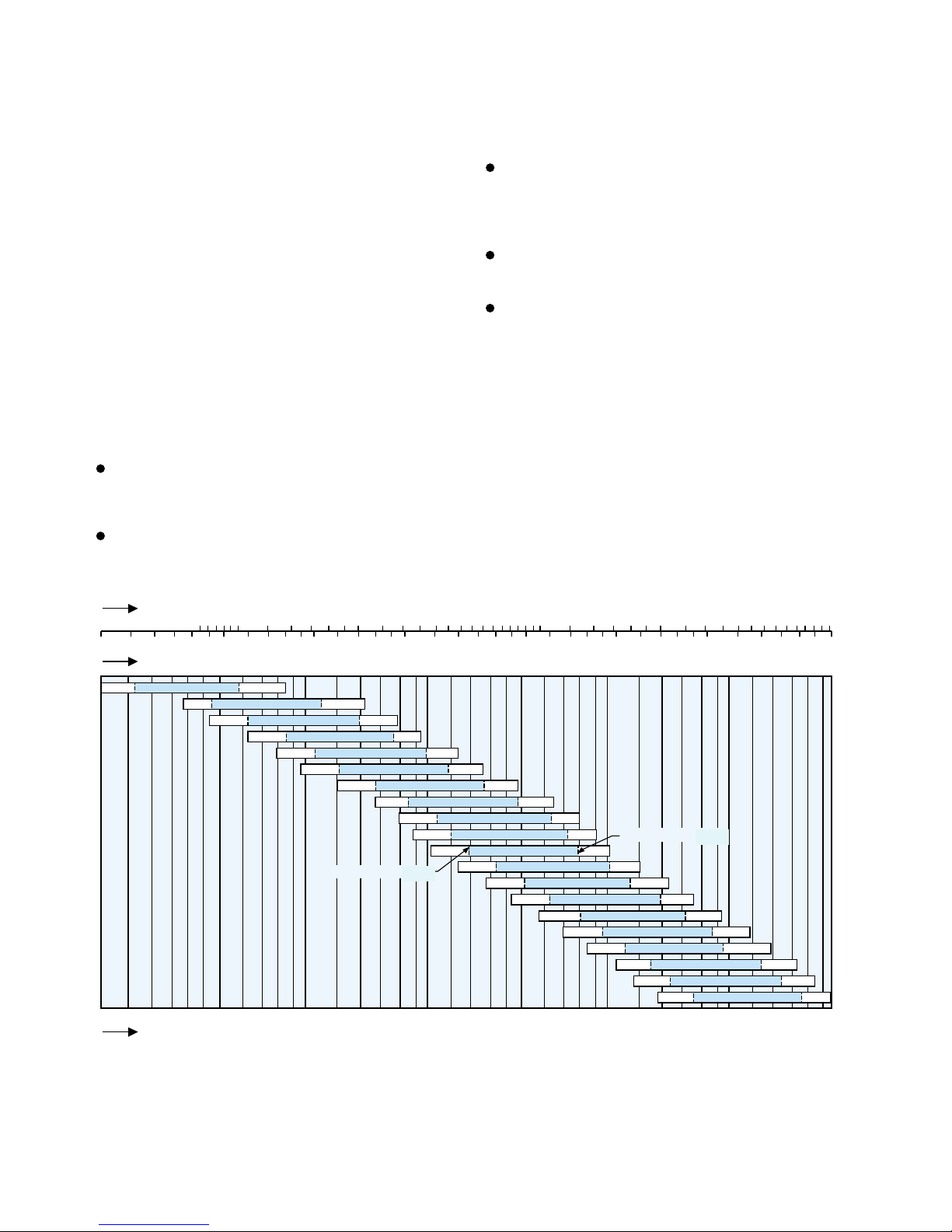

2000 3000 4000 5000 10 000 20 000 30 000 50 000

Air flow, m

3

/h

Air flow, m

3

/s

100 000 150 000

0.4 0.5 1 2 3 4 5 10 20 30 40 500.30.2

Air flow, CFM

500 1000 2000 3000 4000 5000 10 000 20 000 30 000 50 000 100 000

060

080

095

110

135

150

170

190

200

215

240

265

290

320

350

380

420

460

500

120

Size

Air velocity 400 FTM

Air velocity 900 FTM

FPM

FPM

Fläkt Woods 3099 US 03.02 4 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Design

General

The heat exchanger consists of a casing, a rotor of hygroscopic or non-hygroscopic type, and a rotor drive unit.

Adjustable seals are fitted between the casing and the

rotor on both sides, in order to minimize the leakage of

air. The heat exchanger can be ordered either with or

without purging sector.

The purging sector is adjustable and prevents the carryover of exhaust air to the supply air.

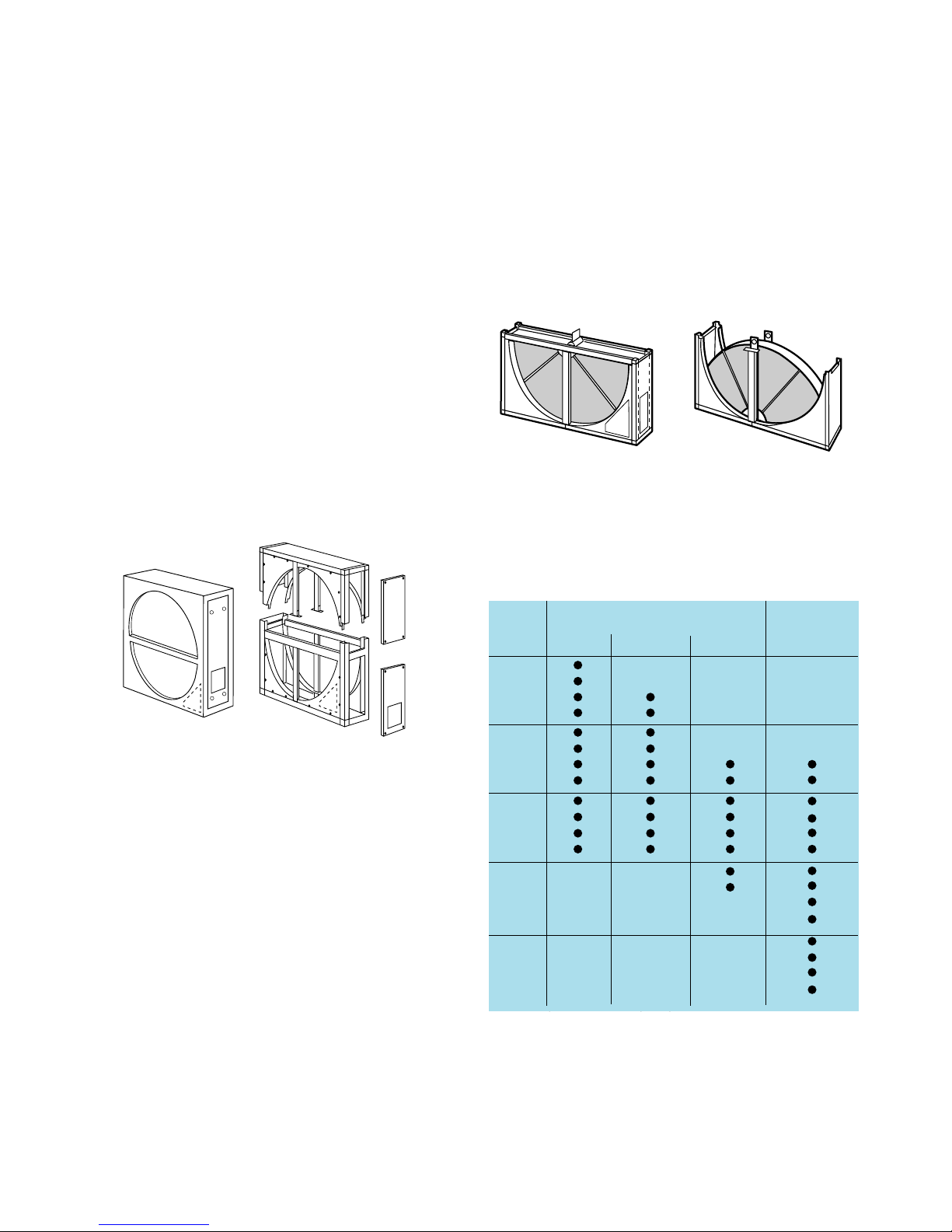

Casing for sizes 060–240

The casing is of single-skin design and is made as one

unit. An inspection panel (2 panels for size 190 and larger sizes) is located on the end wall or front (optional) of

the casing as shown in Fig. 1. The drive motor and speed

controller (for a variable speed unit) are fitted and tested

at the factory. Note that a split casing as shown in Fig. 2

is available for size 150 and larger sizes.

Casing for sizes 265–500

The casing is of single-skin design and is delivered split,

as shown in Fig. 3. Size 265 and 290 units can also be

ordered assembled at the factory. Inspection panels are

located on the front or on the end wall (optional) of the

heat exchanger as shown in Fig. 3. The drive motor is

installed on the inside of the inspection panel. Access

panels are provided on the front of the casing for installation of the rotor sector.

Fig. 1

Fig. 2

Inspection panel

standard

Inspection panel, optional

Inspection panel

standard

Inspection panel, optional

Fig. 3.

Delivery

The ECONOVENT PUM(A-F) Heat exchanger is delivered as shown in Table 1.

● Standard. 1) A composite rotor (PUMF) is always sectorized.

One factory-assembled unit Split casing

Split casing ( 2 units)

Size One-piece Sectorized Sectorized Sectorized

bbb rotor

1)

rotor rotor rotor

060

080

095 ●

110

120 ●

135

150

170

190

200

215

240 ●

265

290

320

350

380

420

460

500

Delivery form in split version.

Fläkt Woods 3099 US 03.02 5 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Design - Description - Accessories

Drive system

The drive system consists of an electric motor (constant

speed or variable speed) with reduction gear, driving the

rotor by means of a jointed V-belt. The V-belt is kept

automatically tensioned by the spring-mounted motor

bracket.

Temperature limit

The heat exchanger is suitable for use at temperatures up

to +165°F.

The temperature in the motor compartment must not

exceed +100°F. If the supply or exhaust air temperature

exceeds +100°F, see further under Temperature limit on

page 19.

Materials and finish

Frame Sizes 060–240: galvanized sheet metal

Sizes 265–500: rotor support steel beams

primed with anti-corrosion

paint.

Cover panels, inspection panels and purging sector: galvanized sheet metal.

Hub (one-piece rotor): aluminum

Hub (sectorized rotor): steel, primed with anti-

corrosion paint.

Rotor material

ALUMINUM ROTORS (A, C and E rotors) are nonhygroscopic, i.e. they recover only sensible heat, as long

as condensation does not occur.

ALUMINUM ROTORS (B and D rotors) are hygroscopic and recover both sensible heat and latent heat

(on changing moisture content).

COMPOSITE ROTORS (F) rotors are hygroscopic, i.e.

they recover both sensible heat and latent heat. The composite material is incombustible and contains no metals,

which means that the material cannot corrode.

The material is treated with silica gel-based substances.

GENERAL SURVEY OF ROTORS

ECONOVENT

Material Property

Max temperature -

rotor designation

range, °F

A Aluminum Non-hygroscopic 165

B Aluminum Hygroscopic 165

C Edge-reinforced aluminum Non-hygroscopic 165

D Edge-reinforced aluminum Hygroscopic 165

E Epoxy-coated aluminum Non-hygroscopic 165

F

Composite Hygroscopic 165

1)

Heating and cooling energy recovery in air handling systems

- without moisture transfer.

Heating and cooling energy recovery in air handling systems

- with moisture transfer.

Heating and cooling energy recovery in air handling systems

- without moisture transfer in a corrosive environment.

Heating and cooling energy recovery in air handling systems

- with moisture transfer in a corrosive environment.

Heating and cooling energy recovery in air handling systems

- without moisture transfer in corrosive environment.

Heating and cooling energy recovery in air handling systems

- with moisture transfer in corrosive, city, marine and

coastal environments.

Application

1) Available for a max. temp. of 275°F. Get in touch with Munters International Inc.

Fläkt Woods 3099 US 03.02 6 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

Design - Description - Accessories

Accessories

PUMZ-17 Duct connection frames

Slip joint connection, made of galvanized sheet metal and

fitted to the heat exchanger at the factory.

PUMZ-20 Speed detector

Used for continuous monitoring of the rotor speed, with

automatic alarm if the rotor should stop when heat recovery is needed.

An alarm relay and sensor unit are needed for a constantspeed exchanger. Only the sensor unit is needed for a

variable-speed exchanger.

PUMZ-21 Differential thermostat

In cooling energy recovery, used for switching the heat

exchanger to maximum speed when the outdoor temperature is higher than the exhaust air temperature. Two sensors are included for fitting in the outdoor air and

exhaust air ducts upstream of the heat exchanger.

PUMZ-27 Cleaning equipment

For automatic purging of the air passages in the rotor.

With compressed air nozzle which is moved by means of

a pneumatically actuated cylinder in a radial direction

along the face of the rotor. Nozzle, cylinder and control

unit are included.

For assistance in selecting the variant and locating the

equipment, please get in touch with Munters

International Inc. representative.

PUMZ-28 Condensate tray

For collecting and disposal of the condensate from the

rotor.

Fläkt Woods 3099 US 03.02 7 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

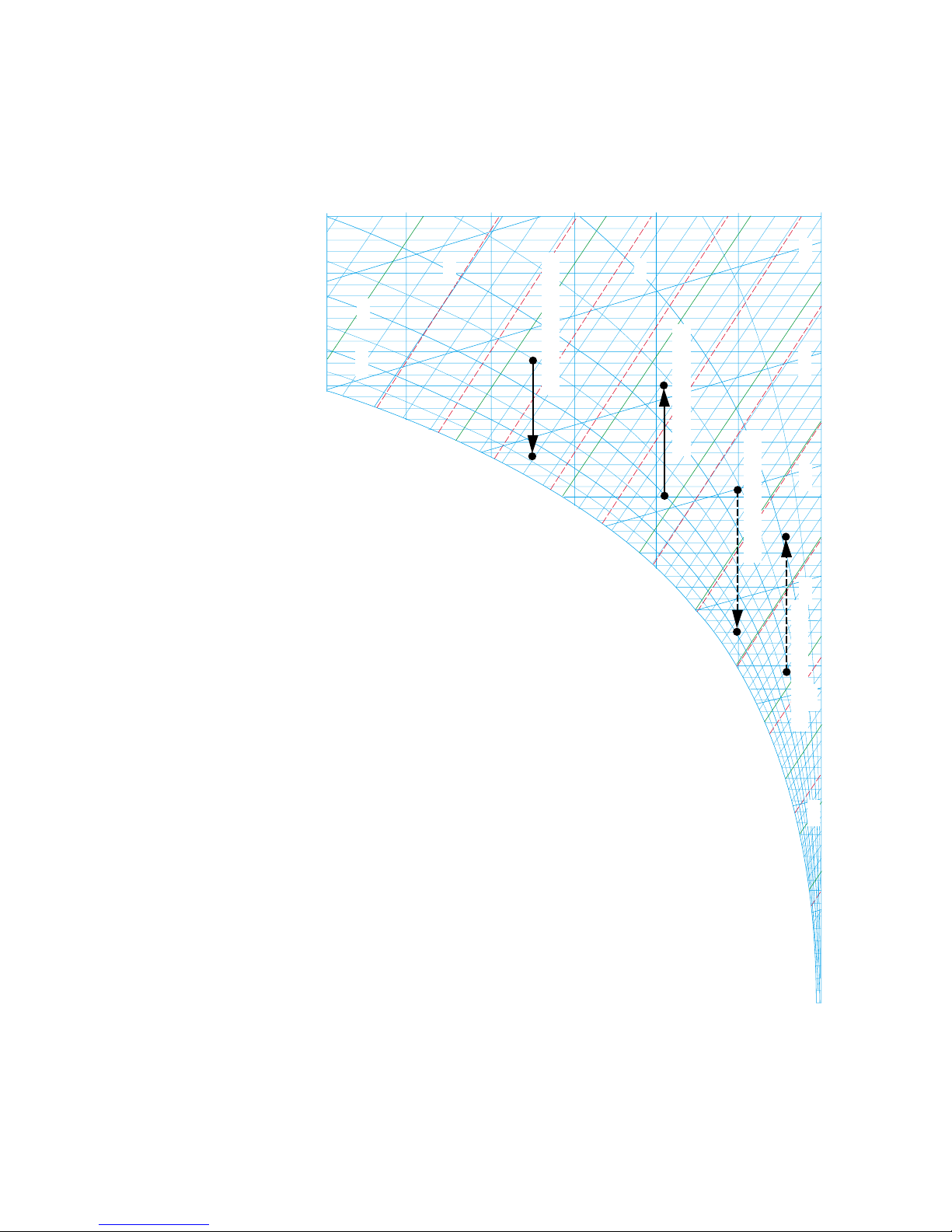

The process in the psychrometric chart

35

70

105

140

175

-20 -10 0 10 20 30 40 50 60 70 80 90

Dry Bulb Temperature°F

Humidity Ratio

grains/lb

100 110 120

0

5

10

15

20

25

30

35

40

45

50

20%

40%

60%

12.0

12.5

14.5

14.0

13.513.0

80%

Chart 1

Non-hygroscopic rotors - type A, C and E

In type A, C and E NON-HYGROSCOPIC rotors, only

sensible heat exchange takes place as long as there is no

condensation in the rotor. As soon as condensation

occurs, the condensate will evaporate in the supply air.

The graphic presentation of the process in the psychrometric chart when condensation takes place varies with

the operating conditions and can therefore not be specified generally.

Outdoor air summer

Exhaust air summer

Exhaust air winter

Outdoor air winter

Fläkt Woods 3099 US 03.02 8 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

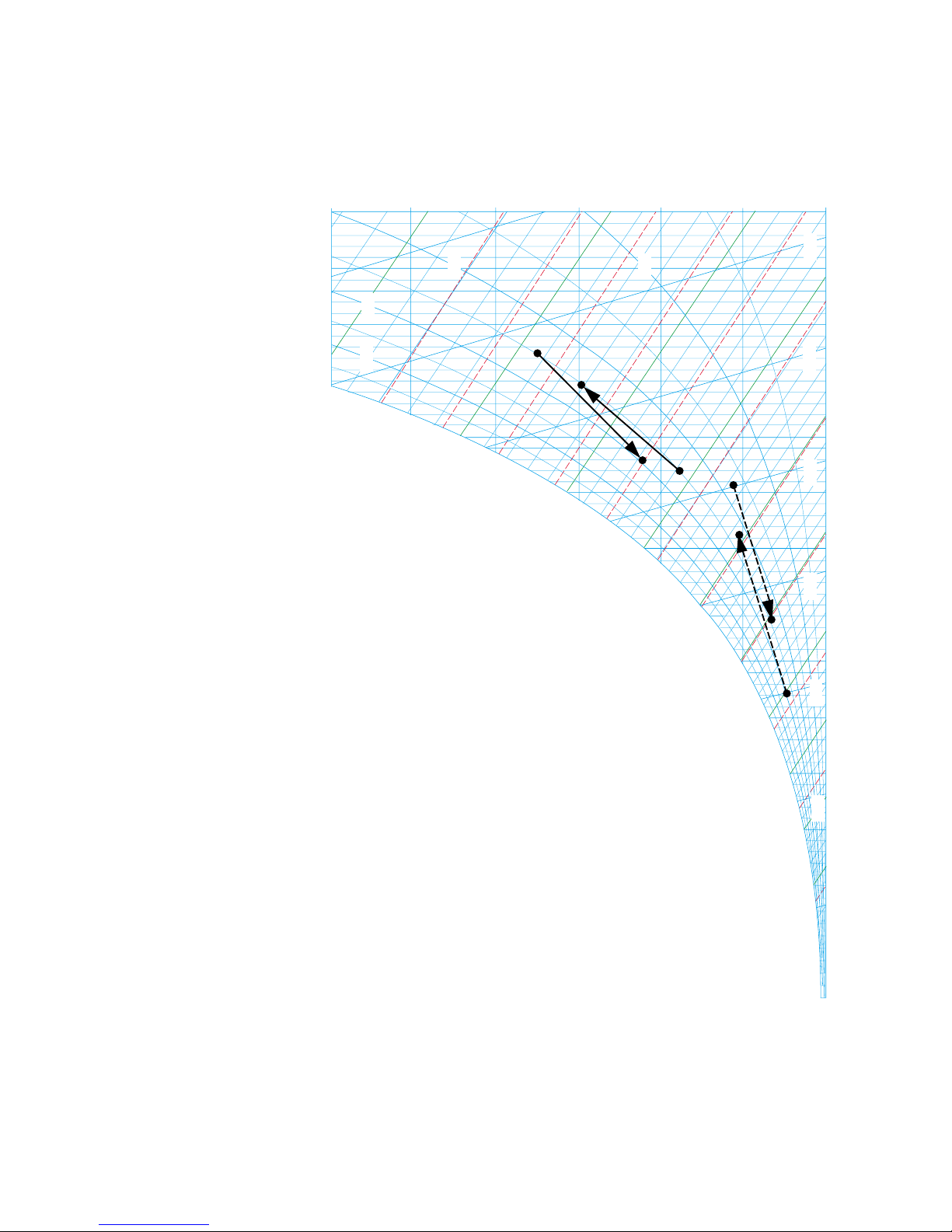

The Process in the psychrometric chart

35

70

105

140

175

-20 -10 0 10 20 30 40 50 60 70 80 90

Dry Bulb Temperature°F

Humidity Ratio

grains/lb

100 110 120

0

5

10

15

20

25

30

35

40

45

50

20%

40%

60%

12.0

12.5

14.5

14.0

13.513.0

80%

Chart 2

Hygroscopic rotors - type B, D and F

In type B, D and F HYGROSCOPIC ROTORS, the

moisture and temperature efficiencies at full speed are

equal. As a result, the process in the psychrometric chart

runs along the interconnecting line between the inlet

conditions for the supply and exhaust air

Outdoor air summer

Exhaust air summer

Exhaust air winter

Outdoor air winter

Fläkt Woods 3099 US 03.02 9 Specifications are subject to alteration without notice

PUMA (A–F) Rotary heat exchanger TECHNICAL HANDBOOK

The Process in the psychrometric chart

Summer operation

Charts 1 and 2 show summer conditions in which the outdoor air is warmer and more humid than the exhaust air.

The hygroscopic rotor (Chart 2) lowers both the moisture

content and the temperature to the vicinity of the exhaust

air conditions, and gives an enthalpy efficiency of 75%. The

nonhygroscopic exchanger (Chart 1) lowers the temperature

by the same amount, but does not change the moisture content. In this case the supply air enthalpy efficiency will be

only about 25%. The example illustrates the significance of

the high moisture efficiency of the hygroscopic rotor, above

all in humid, warm climates.

Winter operation

Charts 1 and 2 show a winter case with moderately low

outdoor temperatures. No condensation takes place in the

nonhygroscopic rotor, (Chart 1) which therefore does not

contribute to the moisture content of the supply air. On

the other hand, the hygroscopic rotor (Chart 2) raises the

moisture content of the supply air by almost 11 Gr/lb of

air, which usually offers welcome humidification of the

supply air. The nonhygroscopic rotor can operate without

risk of freezing even when condensation takes place at

temperatures below 32°F.

Frosting - Defrosting

Rotor temperatures below 32°F need not necessarily cause

frosting in the rotor. Moisture transfer then takes place by

the moisture, which has been deposited as frost on the

rotor surface, being evaporated on the supply air side. For

frosting to occur, there must also be excess water in the

rotor. This will take place if the supply air is not capable

of absorbing the moisture that has condensed out of the

exhaust air.

The frosting process, which causes an increase in pressure

drop across the rotor, normally takes many hours. The

frosting problem is therefore often relieved by the outdoor temperature varying over a 24 hour period, or

because the heat exchanger is in operation during only

part of the 24-hour period.

Frosting limit

Frosting will occur if excess water should occur, at the

same time as the supply air inlet temperature is below

14ºF. This temperature applies with relatively good accuracy at different airflow rates, full speed and typical

exhaust air temperatures occurring in comfort ventilation

systems.

Excess water will occur in the hygroscopic rotor as soon

as the interconnecting line between the inlet conditions

for the two air streams intersects the saturation line in the

psychometric chart (see Chart 3).

In the case of a nonhygroscopic rotor, excess water will

form when the interconnecting line between the supply

air condition and the exhaust air dewpoint plus approximately 7ºF, as shown in Chart 4, intersects the saturation

line in the psychometric chart.

Frosting time

As an example, it will take about 8 hours for the pressure

drop to increase by 50% if the saturation curve is intersected as shown in Chart 3, and about 4 hours if the saturation curve is intersected as shown in Chart 4.

Note that the frosting time will be as above if the temperature and moisture conditions are constant throughout

the frosting time. But since the temperature often varies,

the frosting time may be appreciably longer. As a result of

factors such as operating time and supply air temperature

variations, experience shows that a minor intersection of

the saturation curve is permissible without significant

frosting occurring, even if the design outdoor temperature is below 14°F.

Defrosting - avoidance of frosting

Frosting can be totally avoided by preheating the outdoor

air to a temperature so that the line connecting indoor

and outdoor conditions in the psychometric chart falls

below the saturation line. Heating to 14ºF is normally

adequate. The rotor can be defrosted, normally within

5–10 minutes, in several ways.

– By reducing the rotor speed to around 0.5 r/min (see

example 5 page 22).

– By preheating the incoming outdoor air to around

23°F.

– By bypassing a sufficient amount of supply air across

the rotor so that the outlet temperature on the

exhaust air side will be at least around 41°F. As an

example, the supply air flow rate would have to be

reduced to around half for defrosting to take place at

the normal exhaust air temperature, at a 75%

temperature efficiency and an outdoor temperature

of about –4°F.

All three methods can be used for a variable speed rotor

drive, while the last two can be used with constant speed

drive.around half for defrosting to take place at the normal exhaust air temperature, around 75% temperature

efficiency and an outdoor temperature of about –4°F.

All three methods can be used for a variable-speed rotor,

while the last two can be used at constant speed.

Loading...

Loading...