FLC-BTM403 Series User Manual

FLC-BTM403 Series

User Manual

Document Type: Bluetooth Module User Manual

Document Number: FLC-BTM403-DS

Document Version: V1.0

Release Date: April 13, 2011

Copyright 2010 ~ 2011 by Flaircomm Technologies Inc., All Right Reserved

Without written permission from Flaircomm Technologies Inc., reproduction, transfer, distribution or

storage of part or all of the contents in this document in any form is prohibited

Flaircomm Technologies Confidential

-1-

FLC-BTM403 Series User Manual

FCC Regulations:

zThis device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

zThis device has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiated radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

-Reorient or relocate the receiving antenna.

-Increase the separation between the equipment and receiver.

-Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

-Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by the party responsible for compliance could void the user‘s authority

to operate the equipment.

4RF Exposure Information

This Modular Approval is limited to OEM installation for mobile and fixed applications only. The antenna installation

and operating configurations of this transmitter, including any applicable source-based time-averaging duty factor,

antenna gain and cable loss must satisfy MPE categorical Exclusion Requirements of §2.1091.

The end user has no manual instructions to remove or install the device and a separate approval is required for all other

operating configurations, including portable configurations with respect to 2.1093 and different antenna configurations.

Maximum antenna gain allowed for use with this device is 0.5 dBi.

When the module is installed in the host device, the FCC ID label must be visible through a window on the final device

or it must be visible when an access panel, door or cover is easily re-moved. If not, a second label must be placed on the

outside of the final device that contains the following text: “Contains FCC ID: TQ6BTM403”.

Flaircomm Technologies Confidential

-2-

FLC-BTM403 Series User Manual

CONTENT

1. INTRODUCTION.................................................................................................................................5

1.1 NAMING DECLARATION .......................................................................................................................5

1.2 FEATURES ............................................................................................................................................5

1.3 APPLICATIONS ..................................................................................................................................... 6

2. GENERAL SPECIFICATION ............................................................................................................7

3. PIN DEFINITION.................................................................................................................................8

3.1 PIN CONFIGURATION............................................................................................................................8

3.2 PIN DEFINITION....................................................................................................................................8

4. PHYSICAL INTERFACES ...............................................................................................................10

4.1 POWER SUPPLY ..................................................................................................................................10

4.2 RESET ................................................................................................................................................ 10

4.3 DIGITAL AUDIO INTERFACES ............................................................................................................. 11

4.3.1 PCM Interface Master/Slave .....................................................................................................11

4.3.2 Long Frame Sync ......................................................................................................................12

4.3.3 Short Frame Sync ...................................................................................................................... 13

4.3.4 Multi-slot Operation .................................................................................................................. 13

4.3.5 GCI Interface............................................................................................................................. 14

4.3.6 Slots and Sample Formats .........................................................................................................14

4.3.7 Additional Features ...................................................................................................................15

4.3.8 PCM Timing Information..........................................................................................................15

4.4 RF INTERFACE ...................................................................................................................................19

4.5 GENERAL PURPOSE ANALOGUE IO ....................................................................................................19

4.6 GENERAL PURPOSE DIGITAL IO......................................................................................................... 19

4.7 SERIAL INTERFACES ........................................................................................................................... 19

4.7.1 UART........................................................................................................................................ 19

4.7.2 USB........................................................................................................................................... 20

4.7.3 I2C .............................................................................................................................................22

4.7.4 SPI............................................................................................................................................. 22

5. ELECTRICAL CHARACTERISTIC...............................................................................................24

5.1 ABSOLUTE MAXIMUM RATING ..........................................................................................................24

5.2 RECOMMEND OPERATION CONDITIONS ..............................................................................................24

5.3 POWER CONSUMPTIONS...................................................................................................................... 24

5.4 INPUT/OUTPUT TERMINAL CHARACTERISTICS ................................................................................... 24

5.4.1 Digital Terminals....................................................................................................................... 24

5.4.2 USB........................................................................................................................................... 25

6. REFERENCE DESIGN......................................................................................................................26

7. MECHANICAL CHARACTERISTIC .............................................................................................27

8. RECOMMENDED PCB LAYOUT AND MOUNTING PATTERN..............................................28

9. RECOMMENDED REFLOW PROFILE........................................................................................29

10. ORDERING INFORMATION......................................................................................................30

10.1 PRODUCT PACKAGING INFORMATION ................................................................................................30

10.2 ORDERING INFORMATION................................................................................................................... 31

10.2.1 Product Revision .......................................................................................................................31

10.2.2 Shipping Package ......................................................................................................................31

10.2.3 Product Package ........................................................................................................................31

10.2.4 Product Grade............................................................................................................................31

Flaircomm Technologies Confidential

-3-

FLC-BTM403 Series User Manual

TABLE AND FIGURE

Table 1: Naming Declaration.......................................................................................................................... 5

Table 2: General Specification........................................................................................................................ 7

Table 3: Pin Definition.................................................................................................................................... 9

Table 4: Pin Status on Reset..........................................................................................................................11

Table 5: PCM Master Timing .......................................................................................................................16

Table 6: PCM Slave Timing..........................................................................................................................18

Table 7: Possible UART Settings..................................................................................................................20

Table 8: USB Interface Component Values .................................................................................................. 21

Table 9: Absolute Maximum Rating Recommended Operating Conditions................................................. 24

Table 10: Recommended Operating Conditions ........................................................................................... 24

Table 11: Power consumptions ..................................................................................................................... 24

Table 12: Digital Terminal............................................................................................................................ 25

Table 13: USB Terminal ...............................................................................................................................25

Table 14: Product Revision...........................................................................................................................31

Table 15: Shipping Package.......................................................................................................................... 31

Table 16: Product Package............................................................................................................................ 31

Table 17: Product Grade ...............................................................................................................................32

Figure 1: Pin Configuration.............................................................................................................................8

Figure 2: Configured PCM as a Master.........................................................................................................12

Figure 3: Configured PCM as a Slave........................................................................................................... 12

Figure 4: Long Frame Sync (Shown with 8-bit Companded Sample) ..........................................................13

Figure 5: Short Frame Sync (Shown with 16-bit Sample) ............................................................................13

Figure 6: Multi-Slot Operation with Two Slots and 8-bit Companded Samples........................................... 14

Figure 7: GCI Interface .................................................................................................................................14

Figure 8: 16-Bit Slot Length and Sample Formats........................................................................................ 15

Figure 9: PCM Master Timing Long Frame Sync.........................................................................................17

Figure 10: PCM Master Timing Short Frame Sync ......................................................................................17

Figure 11: PCM Slave Timing Long Frame Sync......................................................................................... 18

Figure 12: PCM Master Timing Short Frame Sync ......................................................................................19

Figure 13: USB Connections for Self-Powered Mode ..................................................................................21

Figure 14: USB Connections for Bus-Powered Mode ..................................................................................22

Figure 15: Example EEPROM Connection with I2C Interface ..................................................................... 22

Figure 16: Design SPI for In-System Programming and Debug ...................................................................23

Figure 17: Reference Design......................................................................................................................... 26

Figure 18: Mechanical Characteristic............................................................................................................27

Figure 19: Leave 20mm Clearance Space from the Module chip Antenna................................................... 28

Figure 20: Recommended Reflow Profile..................................................................................................... 29

Figure 21: Product Packaging Information ...................................................................................................31

Figure 22: Ordering Information................................................................................................................... 31

Flaircomm Technologies Confidential

-4-

FLC-BTM403 Series User Manual

1. Introduction

FLC-BTM403/FLC-BTMDC748 is a small form factor and highly economic Bluetooth radio

module(class 1 or class 2) that allows OEM to add wireless capability to their products. The module

supports multiple interfaces that make it simple to design into fully certified embedded Bluetooth

solutions.

With FLC’s AT#™ programming interfaces, designers can easily customize their applications to

support different Bluetooth profiles, such as SPP, DUN, HDP, and etc. class1 module supports

Bluetooth® Enhanced Data Rate (EDR) and delivers up to 3 Mbps data rate for distances up to 300

meters with its integrated chip antenna, class 2 module supports 3Mbps data rate Transmission for

distances up to 10 meters with its integrated chip antenna.

The module is an appropriate product for designers who want to add wireless capability to their

products.

Note: According to the software divided into class1 and class2

1.1 Naming Declaration

New Naming Old Naming

FLC-BTM403A FLC-BTMDC748A(class1)

FLC-BTM403B FLC-BTMDC748B(class1)

FLC-BTM403C FLC-BTMDC748C(class2)

Table 1: Naming Declaration

1.2 Features

z Bluetooth v2.1+EDR

z UART and USB programming and data interfaces

z PCM digital audio interfaces

z 8MB on board flash

z Small form factor

z SMT pads for easy and reliable PCB mounting

z BQB/FCC/CE Certified

z RoHS compliant

Flaircomm Technologies Confidential

-5-

FLC-BTM403 Series User Manual

1.3 Applications

z Cable replacement

z Bar code and RFID scanners

z Measurement and monitoring systems

z Industrial sensors and controls

z Medical devices

z Industrial PCs and laptops

Flaircomm Technologies Confidential

-6-

FLC-BTM403 Series User Manual

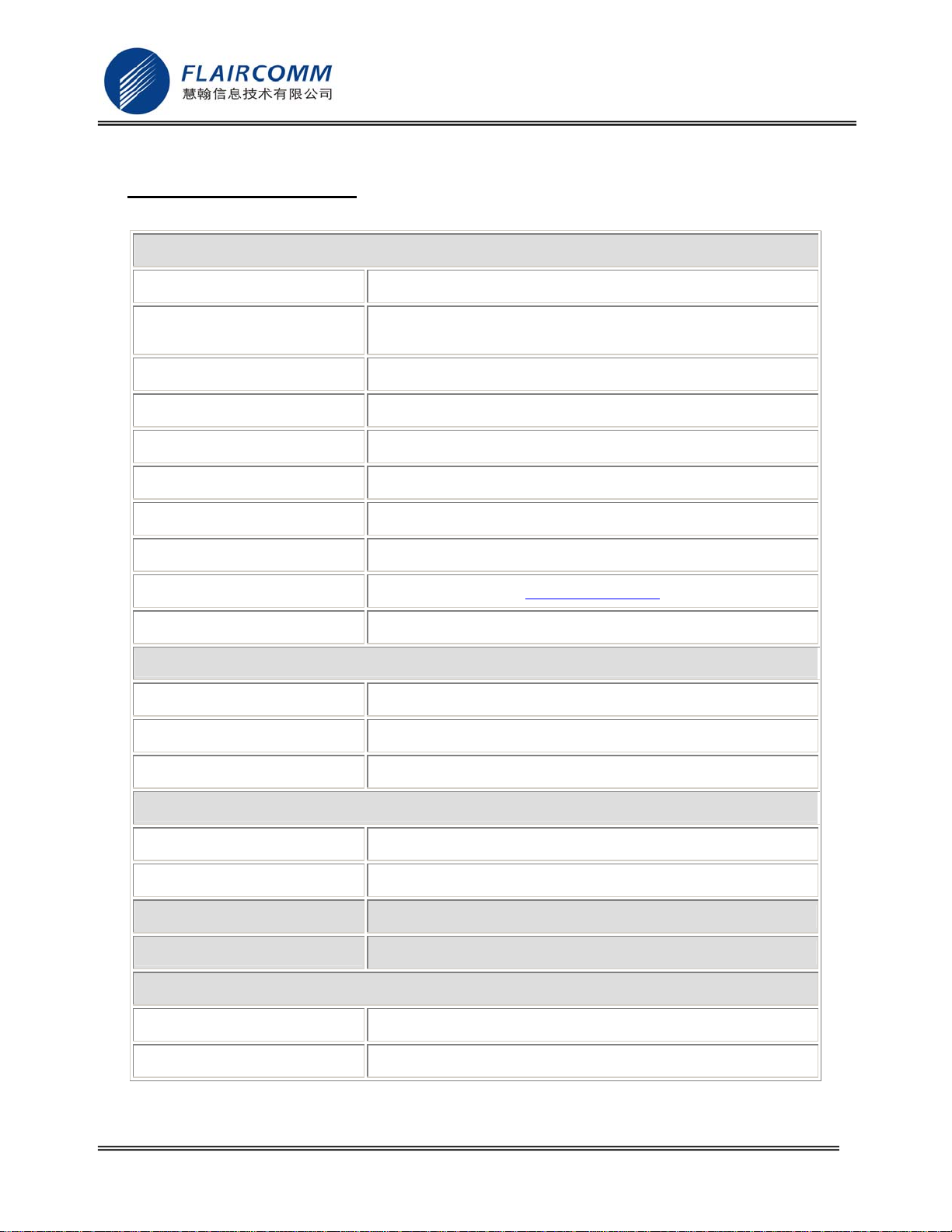

2. General Specification

Bluetooth Specification

Standard Bluetooth2.1+EDR

Profiles

Frequency Band 2.402G ~ 2.480G

Maximum Data Rate 3Mbps

Antenna Multilayer Ceramic Antenna or UFL port

RF Input Impedance 50 ohms

Baseband Crystal OSC 16MHz

Interface UART, PIO, AIO, USB, SPI, PCM

Sensitivity -84dBm@0.1%BER

RF TX Power +13dBm(class1) +4dbm(class2)

detailed profiles depends on the firmware

SPP, DUN, HDP,

Power

Supply Voltage 3 ~ 3.6V DC

Working Current Depends on profiles, 22mA typical

Standby Current(Connected) <2mA

Operating Environment

Temperature -20ºC to +55ºC

Humidity 10%~90% Non-Condensing

Certifications

Environmental

BQB/FCC/CE

RoHS Compliant

Dimension and Weight

Dimension 35.30mm×14.00mm×2.50mm

Weight 2.00g

Table 2: General Specification

Flaircomm Technologies Confidential

-7-

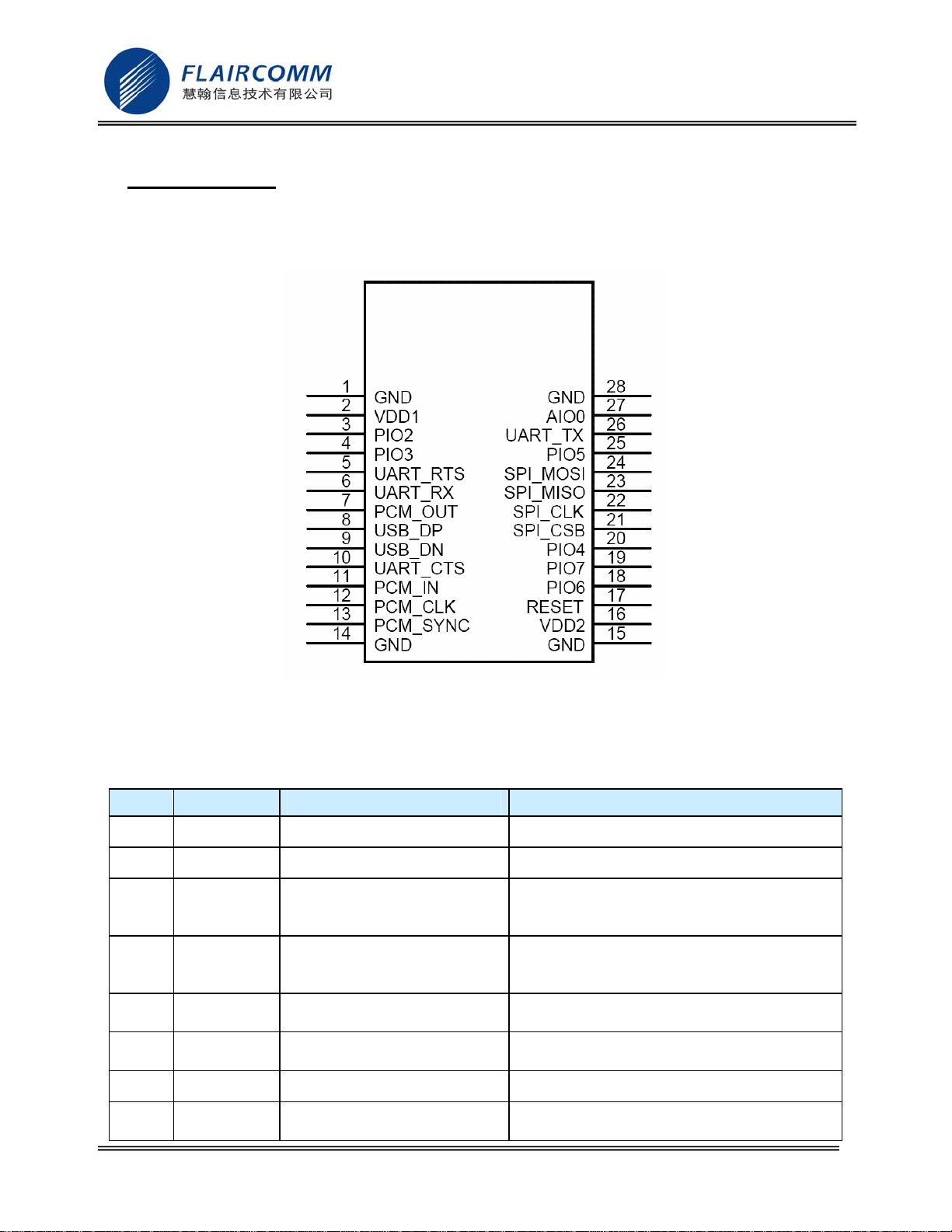

3. Pin Definition

3.1 Pin Configuration

FLC-BTM403 Series User Manual

Figure 1: Pin Configuration

3.2 Pin Definition

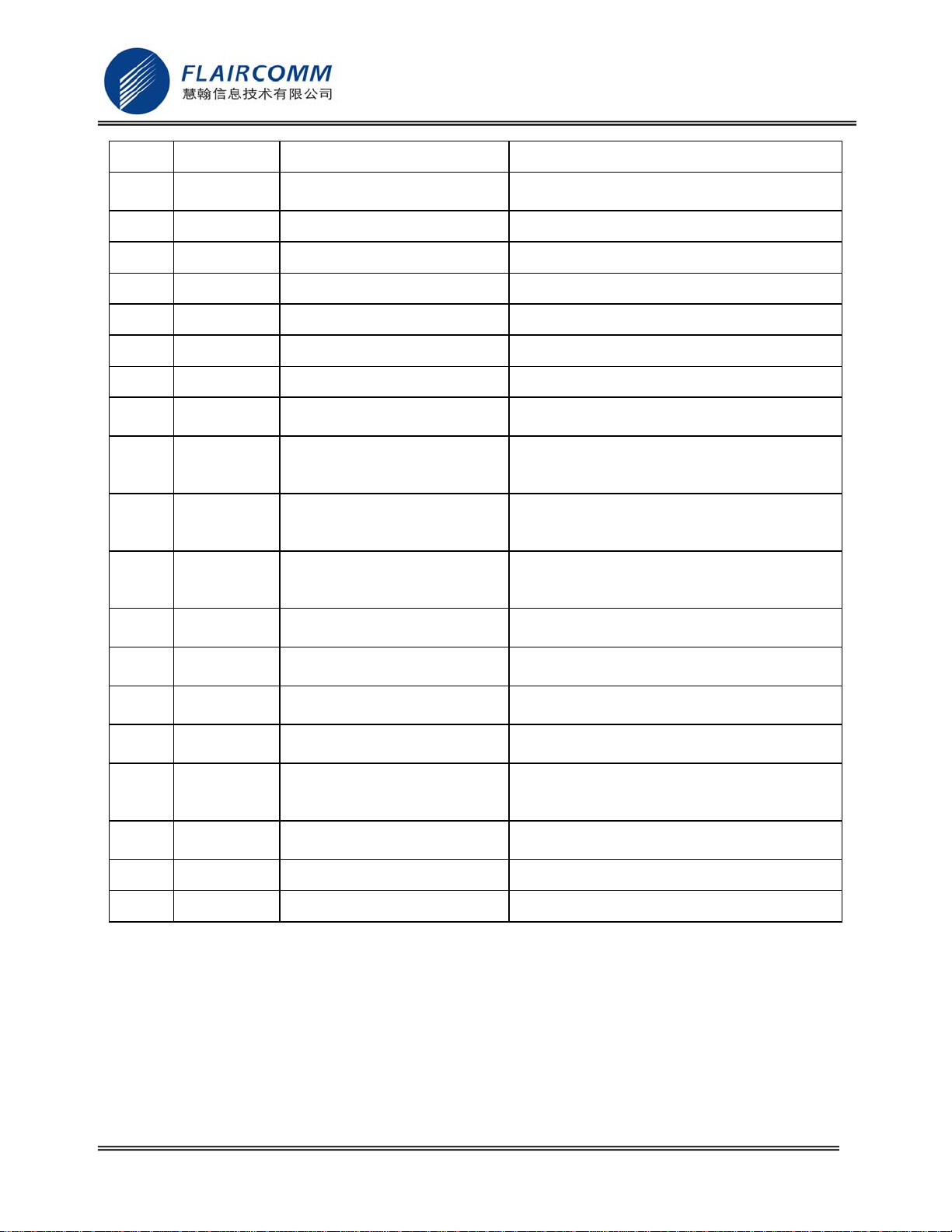

Pin Symbol I/O Type Description

1 GND Ground Ground

2 VDD 3V3 power input 3V3 power input

Bi-directional with

3 PIO2

4 PIO3

5 UART_RTS

6 UART_RX

7 PCM_OUT Bi-directional Synchronous Data Output

8 USB_DP Bi-directional

programmable strength internal

pull-up/down

Bi-directional with

programmable strength internal

pull-up/down

CMOS output, tri-state, with

weak internal pull-up

CMOS input with weak internal

pull-down

USB data plus with selectable internal 1.5Kohm

Programmable input/output line

Programmable input/output line

UART request to send active low

UART data input

pull-up resistor

Flaircomm Technologies Confidential

-8-

FLC-BTM403 Series User Manual

9 USB_DN Bi-directional USB data minus

10 UART_CTS

CMOS output, tri-state, with

weak internal pull-down

UART clear to send active low

11 PCM_IN CMOS Input Synchronous Data Input

12 PCM_CLK Bi-directional Synchronous Data Clock

13 PCM_SYNC Bi-directional Synchronous Data Sync

14 GND Ground Ground

15 GND Ground Ground

16 VDD 3.3V power input 3.3V power input

17 RESET

CMOS input with weak internal

pull-down

Reset if high. Input debounced so must be high

for >5ms to cause a reset

Bi-directional with

18 PIO6

programmable strength internal

Programmable input/output line

pull-up/down

Bi-directional with

19 PIO7

programmable strength internal

Programmable input/output line

pull-up/down

Bi-directional with

20 PIO4

programmable strength internal

Programmable input/output line

pull-up/down

21 SPI_CSB

CMOS input with weak internal

22 SPI_CLK

23 SPI_MISO

24 SPI_MOSI

pull-up

input with weak internal pull-

down

CMOS output, tri-state, with

weak internal pull-down

CMOS input, with weak

internal pull-down

Chip select for Synchronous Serial Interface

active low

Serial Peripheral Interface clock

Serial Peripheral Interface output

Serial Peripheral Interface input

Bi-directional with

25 PIO5

programmable strength internal

Programmable input/output line

pull-up/down

26 UART_TX

CMOS input with weak internal

pull-down

UART data output

27 AIO0 Bi-directional Programmable input/output line

28 GND Ground Ground

Table 3: Pin Definition

Flaircomm Technologies Confidential

-9-

FLC-BTM403 Series User Manual

4. Physical Interfaces

4.1 Power Supply

The transient response of the regulator is important. If the power rails of the module are supplied

from an external voltage source, the transient response of any regulator used should be 20μs or less.

It is essential that the power rail recovers quickly.

4.2 Reset

The module may be reset from several sources: RESET pin, power-on reset, a UART break

character or via a software configured watchdog timer.

The RESET pin is an active high reset and is internally filtered using the internal low frequency

clock oscillator. A reset will be performed between 1.5 and 4.0ms following RESET being active. It

is recommended that RESET be applied for a period greater than 5ms.

The module has an internal reset circuitry, which keeps reset pin active until supply voltage has

reached stability in the start up. This ensures that supply for the flash memory inside the module will

reach stability before BC4 chip fetches instructions from it. Pull-up or pull-down

not be connected to the reset pin to ensure proper star up of

module

.

resistor

should

At reset the digital I/O pins are set to inputs for bi-directional pins and outputs are tri-state. The PIOs

have weak pull-downs.

Pin Name / Group Pin Status on Reset

USB_DP Input with PD

USB_DN Input with PD

UART_RX Input with PD

UART_CTS Input with PD

UART_TX Tri-state output with PU

UART_RTS Tri-state output with PU

SPI_MOSI Input with PD

SPI_CLK Input with PD

SPI_CSB Input with PU

SPI_MISO Tri-state output with PD

PCM_CLK Input with PD

PCM_SYNC Input with PD

PCM_IN Input with PD

PCM_OUT Tri-state with PD

RESETB Input with PU

PIOs Input with weak PD

AIOs Output, driving low

Flaircomm Technologies Confidential

-10-

FLC-BTM403 Series User Manual

RF-IN High impedance

Table 4: Pin Status on Reset

Note: Pull-up (PU) and pull-down (PD) default to weak values unless specified otherwise.

4.3 Digital Audio Interfaces

The module has offered PCM digital audio interface.

PCM is a standard method used to digitize audio (particularly voice) for transmission over digital

communication channels. Through its PCM interface, the module has hardware support for continual

transmission and reception of PCM data, thus reducing processor overhead for applications. The

module offers a bi-directional digital audio interface that routes directly into the baseband layer of

the on-chip firmware. It does not pass through the HCI protocol layer.

Hardware on the module allows the data to be sent to and received from a SCO connection. Up to

three SCO connections can be supported by the PCM interface at any one time.

The module can operate as the PCM interface master generating an output clock of 128, 256 or

512kHz. When configured as PCM interface slave, it can operate with an input clock up to 2048kHz.

The module is compatible with a variety of clock formats, including Long Frame Sync, Short Frame

Sync and GCI timing environments.

It supports 13-bit or 16-bit linear, 8-bit µ-law or A-law companded sample formats at 8k samples/s

and can receive and transmit on any selection of three of the first four slots following PCM_SYNC.

The module interfaces directly to PCM audio devices including the following:

z Qualcomm MSM 3000 series and MSM 5000 series CDMA baseband devices

z OKI MSM7705 four channels A-law and µ-law CODEC

z Motorola MC145481 8 -bit A-law and µ-law CODEC

z Motorola MC145483 13 -bit linear CODEC

z STW 5093 and 5094 14 -bit linear CODECs

The module is also compatible with the Motorola SSI™ interface.

4.3.1 PCM Interface Master/Slave

When PCM is configured as a master, the module generates PCM_CLK and PCM_SYNC.

Flaircomm Technologies Confidential

-11-

FLC-BTM403 Series User Manual

Figure 2: Configured PCM as a Master

When PCM is configured as the slave, the module accepts PCM_CLK rates up to 2048kHz.

Figure 3: Configured PCM as a Slave

4.3.2 Long Frame Sync

Long Frame Sync is the name given to a clocking format that controls the transfer of PCM data

words or samples. In Long Frame Sync, the rising edge of PCM_SYNC indicates the start of the

PCM word. When the module is configured as PCM master, generating PCM_SYNC and

PCM_CLK, then PCM_SYNC is 8-bits long. When the module is configured as PCM Slave,

PCM_SYNC may be from two consecutive falling edges of PCM_CLK to half the PCM_SYNC rate,

i.e., 62.5µs long.

Flaircomm Technologies Confidential

-12-

FLC-BTM403 Series User Manual

Figure 4: Long Frame Sync (Shown with 8-bit Companded Sample)

4.3.3 Short Frame Sync

In Short Frame Sync, the falling edge of PCM_SYNC indicates the start of the PCM word.

PCM_SYNC is always one clock cycle long.

Figure 5: Short Frame Sync (Shown with 16-bit Sample)

As with Long Frame Sync, the module samples PCM_IN on the falling edge of PCM_CLK and

transmits PCM_OUT on the rising edge. PCM_OUT may be configured to be high impedance on the

falling edge of PCM_CLK in the LSB position or on the rising edge.

4.3.4 Multi-slot Operation

More than one SCO connection over the PCM interface is supported using multiple slots. Up to three

SCO connections can be carried over any of the first four slots.

Flaircomm Technologies Confidential

-13-

FLC-BTM403 Series User Manual

Figure 6: Multi-Slot Operation with Two Slots and 8-bit Companded Samples

4.3.5 GCI Interface

The module is compatible with the General Circuit Interface (GCI), a standard synchronous 2B+D

ISDN timing interface. The two 64Kbps B channels can be accessed when this mode is configured.

Figure 7: GCI Interface

The start of a frame is indicated by the rising edge of PCM_SYNC and runs at 8kHz. With the

module in slave mode, the frequency of PCM_CLK can be up to 4.096MHz.

4.3.6 Slots and Sample Formats

The module can receive and transmit on any selection of the first four slots following each sync

pulse. Slot durations can be either 8 or 16 clock cycles. Durations of 8 clock cycles may only be

used with 8-bit sample formats. Durations of 16 clocks may be used with 8-bit, 13-bit or 16-bit

sample formats. The module supports 13-bit linear, 16-bit linear and 8-bit µ-law or A-law sample

formats. The sample rate is 8k samples/s. The bit order may be little or big endian. When 16-bit slots

are used, the 3 or 8 unused bits in each slot may be filled with sign extension, padded with zeros or a

programmable 3-bit audio attenuation compatible with some Motorola CODECs.

Flaircomm Technologies Confidential

-14-

FLC-BTM403 Series User Manual

Figure 8: 16-Bit Slot Length and Sample Formats

4.3.7 Additional Features

The module has a mute facility that forces PCM_OUT to be 0. In master mode, PCM_SYNC may

also be forced to 0 while keeping PCM_CLK running which some CODECS use to control power

down.

4.3.8 PCM Timing Information

Symbol Parameter Min Typical Max Unit

fmclk

PCL_CLK

Frequency

4MHz DDS generation.

Selection of frequency

is programmable.

128

-

256

512

- kHz

Flaircomm Technologies Confidential

-15-

- PCM_SYNC frequency - 8 kHz

tmclkh

tmclkl

-

tdmclksynch

tdmclkpout

tdmclklsyncl

tdmclkhsyncl

tdmclklpoutz

tdmclkhpoutz

tsupinclkl

thpinclkl

FLC-BTM403 Series User Manual

48MHz DDS

generation. Selection of

frequency is

2.9 - kHz

programmable.

(a)

(a)

PCM_CLK

high

4MHz DDS generation 980 - - ns

PCM_CLK low 4MHz DDS generation 730 - ns

PCM_CLK

jitter

Delay time from PCM_CLK high to

PCM_SYNC high

Delay time from PCM_CLK high to valid

PCM_OUT

Delay time from PCM_CLK low to

PCM_SYNC low (Long Frame Sync only)

Delay time from PCM_CLK high to

PCM_SYNC low

Delay time from PCM_CLK low to

PCM_OUT high impedance

Delay time from PCM_CLK high to

PCM_OUT high impedance

Set-up time for PCM_IN valid to

PCM_CLK low

Hold time for PCM_CLK low to PCM_IN

invalid

48MHz DDS

generation

21 ns pk-pk

- - 20 ns

- - 20 ns

- - 20 ns

- - 20 ns

- - 20 ns

- - 20 ns

30 - - ns

10 - - ns

Table 5: PCM Master Timing

Flaircomm Technologies Confidential

-16-

FLC-BTM403 Series User Manual

Figure 9: PCM Master Timing Long Frame Sync

Figure 10: PCM Master Timing Short Frame Sync

Symbol Parameter Min Typical Max Unit

fsclk PCM clock frequency (Slave mode: input) 64 - 2048 kHz

fsclk PCM clock frequency (GCI mode) 128 - 4096 kHz

Flaircomm Technologies Confidential

-17-

thsclksynch

tsusclksynch

tdsclkhpout

tsupinsclkl

thpinsclkl

FLC-BTM403 Series User Manual

tsclkl PCM_CLK low time 200 - - ns

tsclkh PCM_CLK high time 200 - - ns

tdpout

tdpoutz

Hold time from PCM_CLK low to

PCM_SYNC high

Set-up time for PCM_SYNC high to

PCM_CLK low

Delay time from PCM_SYNC or

PCM_CLK whichever is later, to valid

PCM_OUT data (Long Frame Sync only)

Delay time from CLK high to PCM_OUT

valid data

Delay time from PCM_SYNC or

PCM_CLK low, whichever is later, to

PCM_OUT data line high impedance

Set-up time for PCM_IN valid to CLK

low

Hold time for PCM_CLK low to

PCM_IN invalid

Table 6: PCM Slave Timing

30 - - ns

30 - - ns

- -

- -

- -

20

20

20

ns

ns

ns

30 - - ns

30 - - ns

Figure 11: PCM Slave Timing Long Frame Sync

Flaircomm Technologies Confidential

-18-

FLC-BTM403 Series User Manual

Figure 12: PCM Master Timing Short Frame Sync

4.4 RF Interface

The module integrates a balun filter. The user can connect a 50ohms antenna directly to the RF port.

4.5 General Purpose Analogue IO

The general purpose analogue IO can be configured as ADC inputs by software. Do not connect

them if not use.

4.6 General Purpose Digital IO

The general purpose digital IO can be configured by software to have various functions such as

button, LED or interrupt signals to host controller. Do not connect them if not use.

4.7 Serial Interfaces

4.7.1 UART

This is a standard Universal Asynchronous Receiver Transmitter (UART) interface for

communicating with other serial devices. Four signals UART_TX, UART_RX, UART_CTS, and

UART_RTS are used to implement the UART function, UART_CTS, UART_RTS can be used to

implement hardware flow control. PIO2 and PIO3 can be configured as DTR and RTS.

Flaircomm Technologies Confidential

-19-

FLC-BTM403 Series User Manual

Parameter Possible Values

Baud Rate Minimum

Maximum 3M baud (≤1%Error)

Flow Control RTS/CTS or None

Parity None, Odd or Even

Number of Stop Bits 1 or 2

Bits per Byte 8

Table 7: Possible UART Settings

1200 baud (≤2%Error)

9600 baud (≤1%Error)

4.7.2 USB

There is a full speed (12M bits/s) USB interface for communicating with other compatible digital

devices. The module acts as a USB peripheral, responding to request from a master host controller,

such as a PC.

The module features an internal USB pull-up resistor. This pulls the USB_DP pin weakly high when

module is ready to enumerate. It signals to the USB master that it is a full speed (12Mbit/s) USB

device. The USB internal pull-up is implemented as a current source, and is compliant with section

7.1.5 of the USB specification v1.2. The internal pull-up pulls USB_DP high to at least 2.8V when

loaded with a 15kΩ ±5% pull-down resistor (in the hub/host) when VDD =3.1V. This presents a

Thevenin resistance to the host of at least 900Ω. Alternatively, an external 1.5kΩ pull-up resistor can

be placed between a PIO line and DP on the USB cable.

4.7.2.1 Self-Powered Mode

In self-powered mode, the module is powered from its own power supply and not from the VBUS

(5V) line of the USB cable. It draws only a small leakage current (below 0.5mA) from VBUS on the

USB cable. This is the easier mode for which to design, as the design is not limited by the power that

can be drawn from the USB hub or root port. However, it requires that VBUS be connected to

module via a resistor network (Rvb1 and Rvb2), so the module can detect when VBUS is powered

up. The module will not pull USB_DP high when VBUS is off.

Self-powered USB designs (powered from a battery or LDO) must ensure that a PIO line is allocated

for USB pull-up purposes. A 1.5KΩ 5% pull-up resistor between USB_DP and the selected PIO line

should be fitted to the design. Failure to fit this resistor may result in the design failing to be USB

compliant in self-powered mode. The internal pull-up in the module is only suitable for bus-powered

USB devices, e.g., dongles.

Flaircomm Technologies Confidential

-20-

Note:

FLC-BTM403 Series User Manual

Figure 13: USB Connections for Self-Powered Mode

USB_ON is shared with the module PIO terminals.

Identifier Value Function

R

s

Rvb1 22kΩ 5% VBUS ON sense divider

Rvb2 47kΩ 5% VBUS ON sense divider

Table 8: USB Interface Component Values

27Ω Nominal Impedance matching to USB cable

4.7.2.2 Bus-Powered Mode

In bus-powered mode, the application circuit draws its current from the 5V VBUS supply on the

USB cable. The module negotiates with the PC during the USB enumeration stage about how much

current it is allowed to consume. For Class 2 Bluetooth applications, FLC recommends that the

regulator used to derive 3.3V from VBUS is rated at 100mA average current and should be able to

handle peaks of 120mA without foldback or limiting. In bus-powered mode, the module requests

100mA during enumeration. For Class 1 Bluetooth applications, the USB power descriptor should be

altered to reflect the amount of power required. This is higher than for a Class 2 application due to

the extra current drawn by the Transmit RF PA. When selecting a regulator, be aware that VBUS

may go as low as 4.4V. The inrush current (when charging reservoir and supply decoupling

capacitors) is limited by the USB specification. See USB Specification v1.1, section 7.2.4.1. Some

applications may require soft start circuitry to limit inrush current if more than 10µF is present

between VBUS and GND.

Flaircomm Technologies Confidential

-21-

4.7.3 I2C

FLC-BTM403 Series User Manual

Figure 14: USB Connections for Bus-Powered Mode

PIO5, PIO7 and PIO6 can be used to form a master I2C interface. The interface is formed using

software to drive these lines. It is suited only to relatively slow functions such as driving a LCD,

Keyboard, scanner or EEPROM. In the case, PIO lines need to be pulled up through 2.2Kohm

resistors.

Figure 15: Example EEPROM Connection with I

2

C Interface

4.7.4 SPI

he synchronous serial port interface (SPI) can be used for system debugging. It can also be used for

in-system programming for the flash memory within the module. SPI interface uses the SPI_MOSI,

SPI_MISO, SPI_CSB and SPI_CLK pins. Testing points for the SPI interface are reserved on board

in case that the firmware shall be updated during manufacture.

The module operates as a slave and thus SPI_MISO is an output of the module. SPI_MISO is not in

high-impedance state when SPI_CSB is pulled high. Instead, the module outputs 0 if the processor is

running and 1 if it is stopped. Thus the module should NOT be connected in a multi-slave

Flaircomm Technologies Confidential

-22-

FLC-BTM403 Series User Manual

arrangement by simple parallel connection of slave SPI_MISO lines. The SPI interface is needed

when debugging the Bluetooth functions so please leave test points/pads as shown in Figure 16 on

PCB.

VDD

PC

The Module

SPI-CSB

SPI-MISO

SPI-MOSI

SPI-CLK

GND

System

Mainboard

Download Cable &

Adaptor by Flaircomm

Pad or

Connector

Figure 16: Design SPI for In-System Programming and Debug

Flaircomm Technologies Confidential

-23-

FLC-BTM403 Series User Manual

5. Electrical Characteristic

5.1 Absolute Maximum Rating

Rating Min Max Unit

Storage Temperature -40 +120 °C

Operating Temperature -40 +85 °C

PIO/AIO Voltage -0.4 +3.6 V

VDD Voltage -0.4 +3.7 V

USB_DP/USB_DN Voltage -0.4 +3.6 V

Other Terminal Voltages except RF -0.4 VDD+0.4 V

Table 9: Absolute Maximum Rating Recommended Operating Conditions

5.2 Recommend operation conditions

Operating Condition Min Typical Max Unit

Storage Temperature -40 -- +85 °C

Operating Temperature Range -20 -- +70 °C

VDD Voltage +3 +3.3 +3.6 V

Table 10: Recommended Operating Conditions

5.3 Power consumptions

Operating Condition Min Typical Max Unit

Radio On*(Discovery)

Radio On*( Inquiry window time)

Connected Idle (No Sniff)

Connected with data transfer

Table 11: Power consumptions

*If in SLAVE mode there are bursts of radio ON time which vary with the windows. Depending on how you set the

windows that determines your average current.

23 mA

73 mA

20 mA

6 10 25 mA

5.4 Input/output Terminal Characteristics

5.4.1 Digital Terminals

Supply Voltage Levels Min Typical Max Unit

Input Voltage Levels

Flaircomm Technologies Confidential

-24-

FLC-BTM403 Series User Manual

V

input logic level low -0.4

IL

-

+0.8 V

VIH input logic level high 0.7VDD - VDD+0.4 V

Output Voltage Levels

VOL output logic level low, lOL = 4.0mA - - 0.4 V

VOH output logic level high, lOH = -4.0mA VDD-0.2 - - V

Input and Tri-state Current

With strong pull-up -100 -40 -10 μA

With strong pull-down 10 40 100 μA

With weak pull-up -5 -1.0 -0.2 μA

With weak pull-down -0.2 +1.0 5.0 μA

I/O pad leakage current -1 0 +1 μA

CI Input Capacitance 1.0 - 5.0 pF

Table 12: Digital Terminal

5.4.2 USB

USB Terminals Min Typical Max Unit

Input Threshold

VIL input logic level low - - 0.3VDD V

VIH input logic level high 0.7VDD - - V

Input Leakage Current

GND < VIN < VDD

CI Input capacitance 2.5 - 10.0 pF

Output Voltage Levels to Correctly Terminated USB Cable

V

output logic level low 0.0 - 0.2 V

IL

VIH output logic level high 2.8 - VDD V

(a)

-1 1 5 μA

Table 13: USB Terminal

(a) Internal USB pull-up disabled

Flaircomm Technologies Confidential

-25-

6. Reference Design

FLC-BTM403 Series User Manual

Figure 17: Reference Design

Flaircomm Technologies Confidential

-26-

FLC-BTM403 Series User Manual

7. Mechanical Characteristic

Figure 18: Mechanical Characteristic

Flaircomm Technologies Confidential

-27-

FLC-BTM403 Series User Manual

8. Recommended PCB Layout and Mounting Pattern

A very important factor in achieving maximum Bluetooth performance is the placement of a module

with on-board antenna designs onto the carrier board and corresponding PCB layout. There should

be no any trace, ground and vias in the area of the carrier board underneath the module’s on-board

antenna section as indicated in Figure 19. Antenna portion of the module must be placed at least

20mm away from any metal part and the antenna should not be covered by any piece of metal. The

antenna of the module MUST be kept as far from potential noise sources as possible and special care

must also be taken with placing the module in proximity to circuitry that can emit heat. The RF part

of the module is very sensitive to temperature and sudden changes can have an adverse impact on

performance.

Figure 19: Leave 20mm Clearance Space from the Module chip Antenna

Flaircomm Technologies Confidential

-28-

FLC-BTM403 Series User Manual

9. Recommended Reflow Profile

The soldering profile depends on various parameters necessitating a set up for each application. The

data here is given only for guidance on solder reflow.

℃

250

217

210

25

A

0

1 2

B C D

3 4 5 6

Figure 20: Recommended Reflow Profile

E

min

Pre-heat zone (A) — This zone raises the temperature at a controlled rate, typically 0.5 – 2 °C/s.

The purpose of this zone is to preheat the PCB board and components to 120 ~ 150 °C. This stage is

required to distribute the heat uniformly to the PCB board and completely remove solvent to reduce

the heat shock to components.

Equilibrium Zone 1 (B) — In this stage the flux becomes soft and uniformly encapsulates solder

particles and spread over PCB board, preventing them from being re-oxidized. Also with elevation

of temperature and liquefaction of flux, each activator and rosin get activated and start eliminating

oxide film formed on the surface of each solder particle and PCB board. The temperature is

recommended to be 150° to 210° for 60 to 120 second for this zone.

Equilibrium Zone 2 (c) (optional) — In order to resolve the upright component issue, it is

recommended to keep the temperature in 210 – 217 ° for about 20 to 30 second.

Reflow Zone (D) — The profile in the figure is designed for Sn/Ag3.0/Cu0.5. It can be a reference

for other lead-free solder. The peak temperature should be high enough to achieve good wetting but

not so high as to cause component discoloration or damage. Excessive soldering time can lead to

intermetallic growth which can result in a brittle joint. The recommended peak temperature (Tp) is

230 ~ 250 °C. The soldering time should be 30 to 90 second when the temperature is above 217 °C.

Cooling Zone (E) — The cooling ate should be fast, to keep the solder grains small which will give

a longerlasting joint. Typical cooling rate should be 4 °C.

Flaircomm Technologies Confidential

-29-

FLC-BTM403 Series User Manual

10. Ordering Information

10.1 Product Packaging Information

Flaircomm Technologies Confidential

-30-

FLC-BTM403 Series User Manual

Figure 21: Product Packaging Information

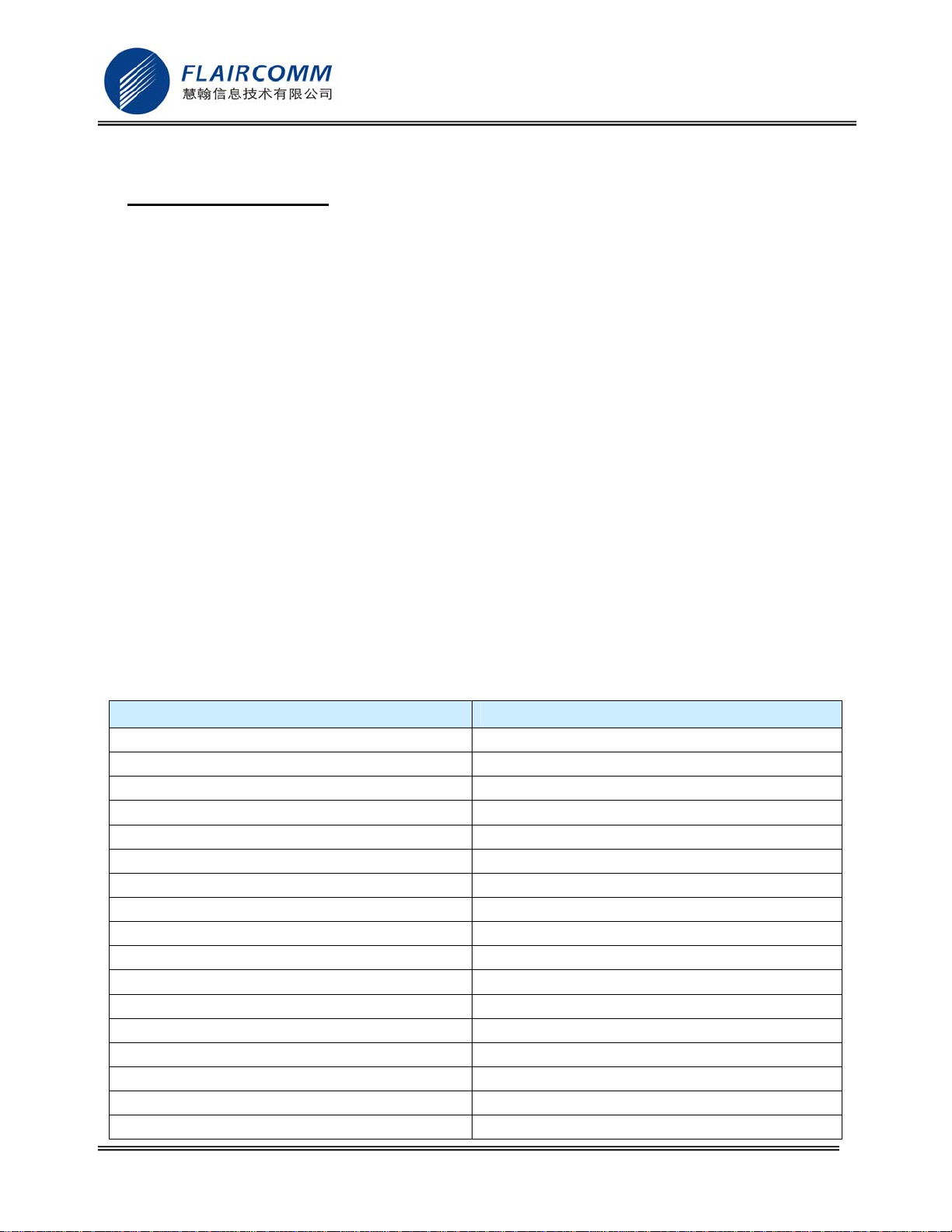

10.2 Ordering information

10.2.1 Product Revision

Figure 22: Ordering Information

Product Revision Description Availability

A Multilayer Ceramic Antenna ( Class 1) Yes

B UFL connector (Class 1) Yes

C Multilayer Ceramic Antenna ( Class 2) Yes

Table 14: Product Revision

10.2.2 Shipping Package

Shipping Package Description Quantity Availability

0 Spongy Cushion In Box — No

1 Plastic Tray In Box — No

2 Tape 800x5 =4000 Yes

Table 15: Shipping Package

10.2.3 Product Package

Product Package Description Availability

Q QFN Yes

L LGA No

B BGA No

C Connector No

Table 16: Product Package

10.2.4 Product Grade

Product Grade Description Availability

C Consumer No

I Industrial Yes

V Automobile After-Market Yes

A Automobile Before-Market No

Flaircomm Technologies Confidential

-31-

FLC-BTM403 Series User Manual

Table 17: Product Grade

Flaircomm Technologies Confidential

-32-

Loading...

Loading...