★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

★

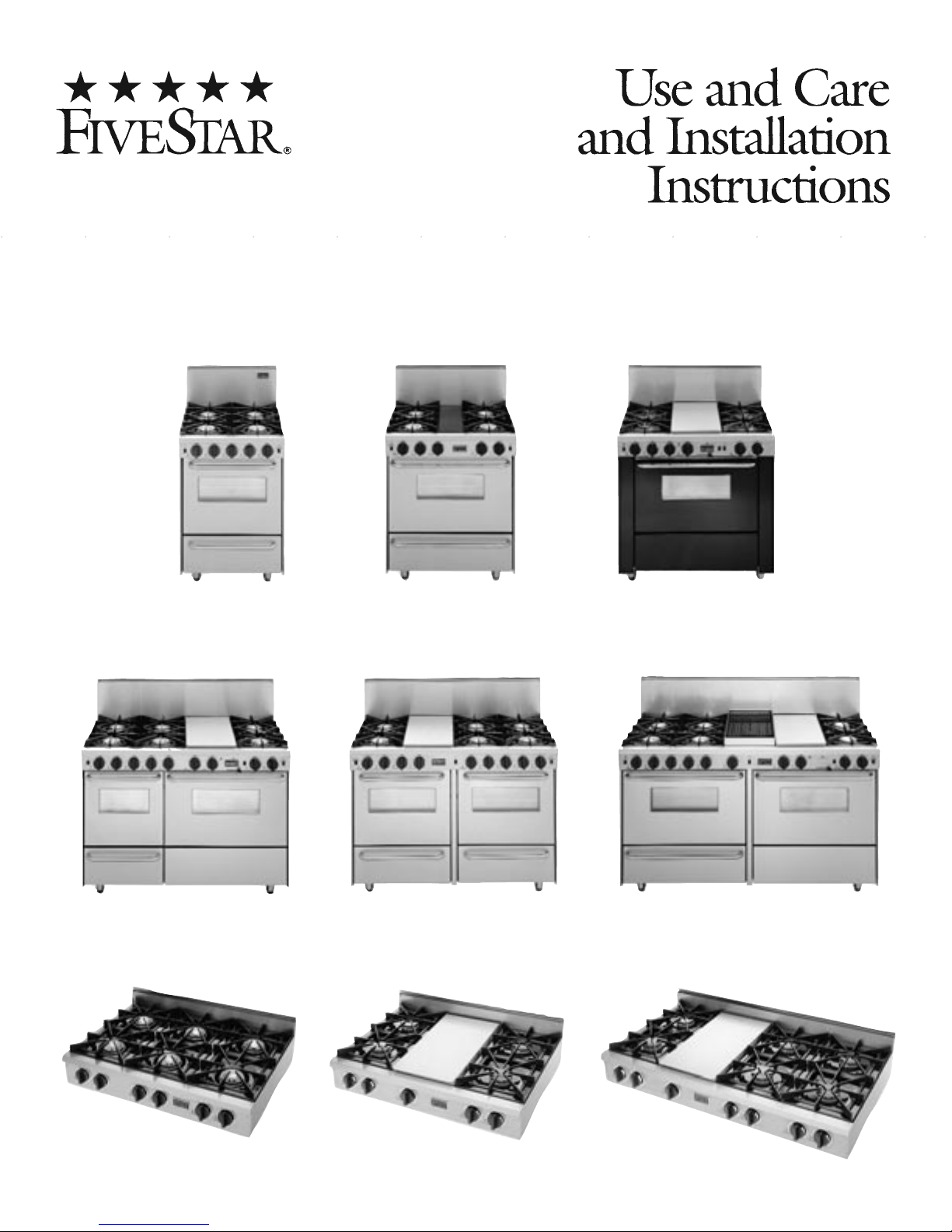

24”, 30” and 36” Range Models

48” and 60” Range Models

36” and 48” Cooktop Models

Your exact model may not be pictured.

INSTALLER: PLEASE LEAVE THIS MANUAL WITH THE RANGE FOR INSPECTION AND SERVICE USE.

CONSUMER: PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Before using your range or cooktop,

read this book carefully.

• It is intended to help you operate

and maintain your new range or

cooktop properly.

• Keep it handy for answers to your

questions.

• If you don’t understand something

or need more help, write (include

your phone number):

• FiveStar Division

Brown Stove Works, Inc.

P.O. Box 2490

Cleveland, TN 37320

(423) 476-6544

Accessories . . . . . . . . . . . 29, 30, 31, 32

Adjustments . . . . . . . . . . . . . . . . . . 6, 7

Aluminum Foil . . . . . . . . . . . . . . . . . 12

Backguard Assembly . . . . . . . . . . . . . 6

Baking. . . . . . . . . . . . . . . 12, 17, 18, 19

Broiler Assembly Removal. . . . . . . . 13

Broiling . . . . . . . . . . . . . . . . . 12, 19, 20

Burners (Oven & Griddle) . . . . . . . . 13

Cleaning Your Range . . . . . . . . . 14, 15

Convection Oven Cooking . . 17, 18, 19

Electric Ignition. . . . . . . . . . . . . . 14, 33

Energy–Saving tips. . . . . . . . . . . . . . 10

Final Preparation–Stainless. . . . . . . . 11

FiveStar Division address . . . . . . . . . . 2

Gas and Electric Connections . . . 3, 4, 5

General Information . . . . . . . . . . 10, 14

Griddle . . . . . . . . . . . . . . . . . . . . . . . 11

Griddle, Portable. . . . . . . . . . . . . . . . 29

Grill Use and Care . . . . . . . . . . . . . . 31

Initial Ignition of Range . . . . . . . 10, 12

Installation Instructions. . . . . . . . . . 3, 6

Lift-Off Oven Doors . . . . . . . . . . . . . 16

Model Identification . . . . . . . . . . 22, 23

Moisture . . . . . . . . . . . . . . . . . . . 12, 33

Operation of Range. . . . . . . . . . . . . . 11

Oven Racks. . . . . . . . . . . . . . . . . . . . 13

Oven Safety Tips. . . . . . . . . . . . . . . 8, 9

Oven Use . . . . . . . . . . . . . . . . . . . . . 12

Positioning/Leveling . . . . . . . . . . . . . . 6

Power Outage

Light Oven Pilot . . . . . . . . . . . . . 13

Power Outage

Light Top Burner . . . . . . . . . . . . . 14

Repair Parts. . . . . . . . . . . . . . . . . . . . 16

Safety Instructions. . . . . . . . . . . . . . 8, 9

Self-Cleaning Instructions. . . . . . 21, 22

Service . . . . . . . . . . . . . . . . . . . . . . . 16

Surface Cooking Tips . . . . . . . . . . 9, 10

Top Burners. . . . . . . . . . . . . . . . . 10, 11

Trouble Shooting Guide . . . . . . . 32, 33

Unpacking. . . . . . . . . . . . . . . . . . . . . . 3

Wall Clearances . . . . . . . . . . . . . . . . . 4

Warranty. . . . . . . . . . . . . . . Back Cover

Wiring Diagram . . . . 24, 25, 26, 27, 28

Record the model and serial

numbers.

You’ll find them on a label under the

cooking surface.

Model Number

Manufacturing Type Number

Serial Number

Use these numbers in any

correspondence or service calls

concerning your range.

If you received a damaged range. . .

Immediately contact the dealer (or

builder) that sold you the range.

CONTENTS

– Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

– WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas

supplier, call the fire department.

– Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

WARNING: If the information in

this manual is not followed exactly,

a fire or explosion may result

causing property damage, personal

injury or death.

WARNING: If not installed, operated and

maintained in accordance with the manufacturer’s

instructions, this product could expose you to

substances in fuel or from fuel combustion which

can cause death or serious illness and which are

know to cause cancer, birth defects or other

reproductive harm.

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

injury or property damage. Refer to this manual.

For assistance or additional information consult a

qualified installer, service agency, manufacturer

(dealer) or the gas supplier.

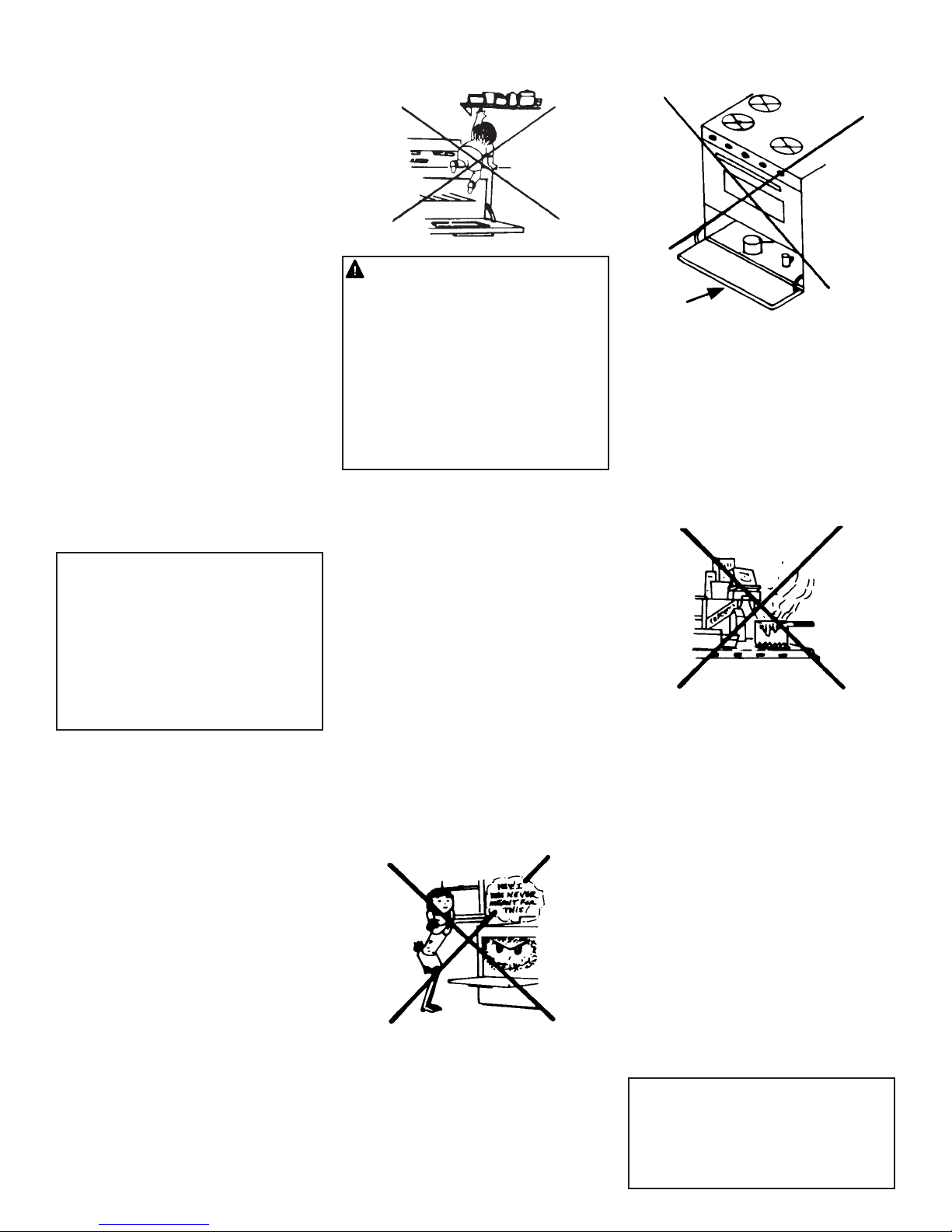

WARNING • ALL RANGES CAN TIP

• INJURY COULD RESULT

• INSTALL ANTI-TIP DEVICE

packed with range

• SEE INSTRUCTIONS . . .

packed with anti-tip bracket

IF RANGE IS RELOCATED, ANCHOR BRACKET MUST BE

REMOVED AND REINSTALLED IN NEW LOCATION.

2

WARNING: To reduce the risk of tipping the

appliance by abnormal usage or improper

door loading, the appliance must be secured

by properly installing the anti-tip device

packed with the appliance. To check the

installation remove the right top burner grates

and pan and verify that the anti-tip device is

engaged in the backguard slot.

FIVESTAR

INSTALLATION INSTRUCTIONS

Please read these instructions

before attempting to install this

range

Unpacking

Check the range carton for visible

damage. If there is damage or even

creases in the carton contact the

carrier, request an inspection, and file

the appropriate freight claim. Do not

refuse shipment. Responsibility for

shipping damage is with the carrier

and the dealer or end user. Cut the

shipping straps then carefully lift the

carton up from the range. This will

help eliminate possible damage to the

backguard that is packed in the top of

the range carton.

Remove, unwrap, and temporarily lay

aside any parts that are not attached

to the range. Make sure no parts are

left in the carton for accidental

disposal. Carefully inspect the range

for damage.

The standard top (not sealed) burners

are held in place with a screw to

protect them while in transit. These

shipping screws are to be removed to

give proper top burner operation and

allow easy removal.

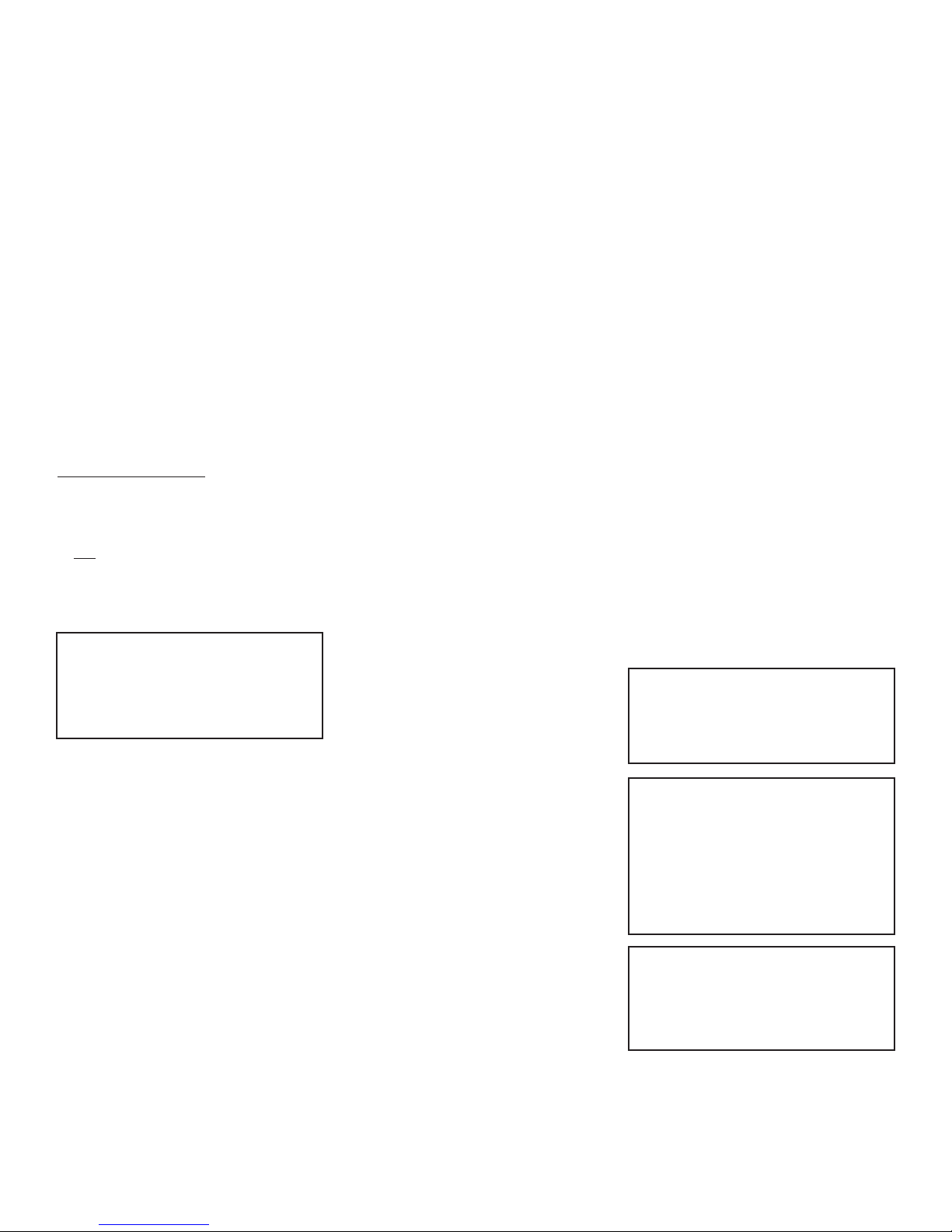

INSTALLATION OF ANTI-TIP BRACKET

ON 24”, 30” AND 36” MODELS

1) PLACE RANGE IN PROPER LOCATION WITH BACK OF RANGE AGAINST REAR WALL.

2) ADJUST LEG LEVELERS TO MATCH COUNTER HEIGHT.

3) REMOVE RANGE AND INSTALL ANTI-TIP BRACKET TO WALL, SEE NOTE, FIG. 2.

4) REINSTALL RANGE. ANTI-TIP BRACKET FLANGE MUST

ENTER SLOT IN BACK TO

PREVENT TIPPING.

3

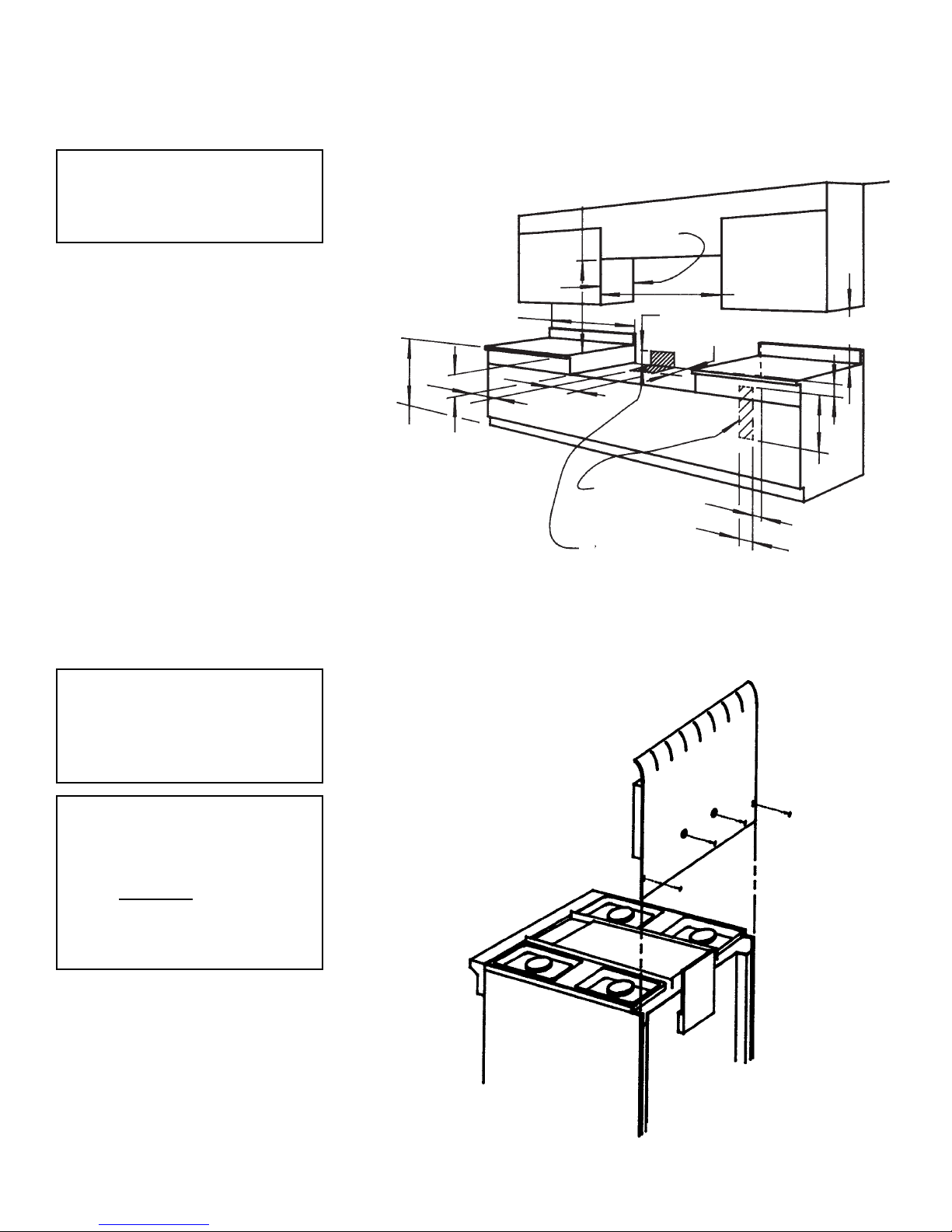

40” MINIMUM

6”

MINIMUM

13”

MAXIMUM

WIDTH OF

RANGE

18” MINIMUM

110V ELECTRICAL

CONNECTION AREA

SURFACE

MOUNT

CABINET CUT-OUT

24” RANGE = 24 3/16” 48” RANGE = 48 3/16”

30” RANGE = 30 3/16” 60” RANGE = 60 3/16”

36” RANGE = 36 3/16”

FIG. 1 WALL CLEARANCES

240V DUAL FUEL

MODELS ONLY

ANTI-TIP

BRACKET

NOTE:

ADD TO VERTICAL DIMENSION

DISTANCE BETWEEN CABINET

BOTTOM & FLOOR SURFACE

C SLOT IN

BACK

FIG. 2

BOTTOM OF

SIDE PANEL

FLOOR

UP

DOWN

3 1/2”

28 7/8”

EXHAUST

VENTILATION

*NOTE:

FOR HARD PIPING

SEE PAGE 5.

FLUSH

MOUNT

36”

2”

1 1/2”

26”

5”

5”

1”

34”

24”

5”

2”

*SEE NOTE

Wall Clearances

All units must be installed in

accordance with minimum side wall

clearances and clearances extended

vertically above the cooking top. See

Figs. 1 & 6 for illustration. This unit

may not be installed directly adjacent

to sidewalls, tall cabinets, tall

appliances, or other side vertical

surfaces above the 36” cooking

surface height. There must be a

minimum of 6” vertical side clearance

to either side of the appliance

extending from the cooking surface to

18” above to a maximum wall cabinet

depth of 13”, see Figs. 1 & 6.

Comb

ustible surfaces above the unit

must be a minimum of 40” above the

unit’s top cooking surface for the full

width of the appliance if a range hood

is not

used. If a hood is used we

recommend 30” to the bottom of the

hood above the top cooking surface

(Top of hood 7’ from floor).

FiveStar hoods may be installed from

24” to 36” above the cooking surface.

A minimum of 28” is required when a

FiveStar backsplash with warming

shelves is used.

ANY OPENINGS IN THE WALL

BEHIND THE UNIT AND IN

THE FLOOR UNDER THE

RANGE MUST BE SEALED.

BEFORE PLACING THE

RANGE IN OPERATION

CHECK FOR GAS LEAKS

WITH A SOAPY WATER

SOLUTION. DO NOT USE AN

OPEN FLAME TO CHECK

FOR LEAKS.

INSTALLER: INFORM THE

CONSUMER OF THE

LOCATION OF THE GAS

SHUT-OFF VALVE.

NOTE: THESE INSTALLATION

INSTRUCTIONS SHOULD

REMAIN WITH THE UNIT

FOR FUTURE REFERENCE.

Gas and Electric

Connections

Plug in the electric power supply cord

and make certain that the gas stub-out

is prepared properly for the gas

connection prior to moving the range

into place. The gas supply line must

be at least the same size or greater

than the inlet line of the range. All

FiveStar ranges use a

1

/

2” NPT inlet.

Check any installer-supplied intake

pipes and fittings visually and blow

them out with compressed air to clear

any dirt particles, threading chips, or

other foreign matter before installing

in a service line.

The Unit should be connected to a

supply line with

1

/2 inch black iron

pipe or a certified flexible connector,

(See Figure 3,4 & 5). For U.S.A.

installations, flexible connectors must

comply with ANSI Z21.69 (latest

edition) or for Canadian installation

CAN/CGA-6.16 (latest edition

revision) with suitable strain reliefs.

Manifold pressure should be checked

with a manometer. For natural gas 4”

wcp is required. For LP gas 10” wcp

is required. The incoming line

pressure must be at least 1” wcp

higher (but no more than 14” wcp)

than the manifold pressure.

(a) The appliance and its individual

shutoff valve must be disconnected

from the gas supply piping system

during any pressure testing of that

system at test pressures in excess of

1

/2 psig (3.5 kPa).

(b) The appliance must be isolated

from the gas supply piping system by

closing its individual manual shutoff

valve during any pressure testing of

the gas supply piping system at test

pressures equal to or less than

1

/2 psig

(3.5 kPa).

We suggest that you have the dealer

where you purchased your new unit

install it or have him arrange with a

local plumber to make the

installation. Installation must conform

with local codes. In the absence of

local codes, the installation must

conform with the National Fuel Gas

Code, ANSI Z223.1 Latest Edition in

the U.S.A. Canadian installations

must conform with CAN 1-B149.1 or

.2. To prevent gas leaks, use an

approved sealing compound, which is

resistant to liquefied petroleum gases,

on all threaded connections.

All gas models come equipped with a

three-wire (two conductor with ground)

supply cord. Dual-fuel ranges are not

supplied with a range connection

cord. The unit must be electrically

grounded and installed in accordance

with local codes. In the absence of

local codes the installation must

comply with ANSI/NFPA 70 (latest

edition) in the U.S.A. or for Canadian

installations C22.1 (latest edition).

WALL CLEARANCES

GAS AND ELECTRIC CONNECTIONS

4

Connecting the Range to Gas

Shut off the main gas supply valve

before disconnecting the old range

and leave it off until new hook-up has

been completed. Don’t forget to

relight the pilot on other gas

appliances when you turn the gas

back on.

Because hard piping restricts

movement of the range, the use of an

A.G.A.-certified flexible metal

appliance connector is recommended

unless local codes require a hardpiped connection.

When codes require hard piping,

piping must be recessed into or enter

through the rear wall, See Fig. 1.

Openings are provided in the back

cover for through the wall piping.

On sealed b

urner models the nipple

provided, See Fig. 4, must be

removed and replaced with piping as

illustrated in Fig. 5.

Never use an old connector when

installing a new range. If the hard

CAUTION: DO NOT USE A FLAME

TO CHECK FOR GAS LEAKS.

piping method is used, you must

carefully align the pipe; the range

cannot be moved after the connection

is made.

To prevent gas leaks, put pipe joint

compound on, or wrap pipe thread

with Teflon* tape all around male

(external) pipe threads.

1. Install a manual gas shut-off valve

in the gas line in an easily accessed

location outside of the range. Make

sure everyone operating the range

knows where and how to shut off the

gas supply to the range.

2. Install male 1/2” flare union

adapter to the 1/2” NPT internal

thread at inlet of the regulator. Use a

backup wrench on the regulator fitting

to avoid damage.

3. Install male 1/2” or 3/4” flare

union adapter to the NPT internal

thread of the manual shut-off valve,

taking care to back-up the shut-off

valve to keep if from turning.

4. Connect flexible metal appliance

When using test pressures greater

than 1/2 psig to pressure test the gas

supply system of the residence,

disconnect the range and individual

shut-off valve from the gas supply

piping. When using test pressures of

1/2 psig or less to test the gas supply

system, simply isolate the range from

the gas supply system by closing the

individual shuf-off valve.

connector to the adapter on the range.

Position range to permit connection at

the shut-off valve or vise versa.

5. When all connections have been

made, make sure all range controls

are in the off position and turn on the

main gas supply valve. Use a liquid

leak detector at all joints and

connections to check for leaks in the

system.

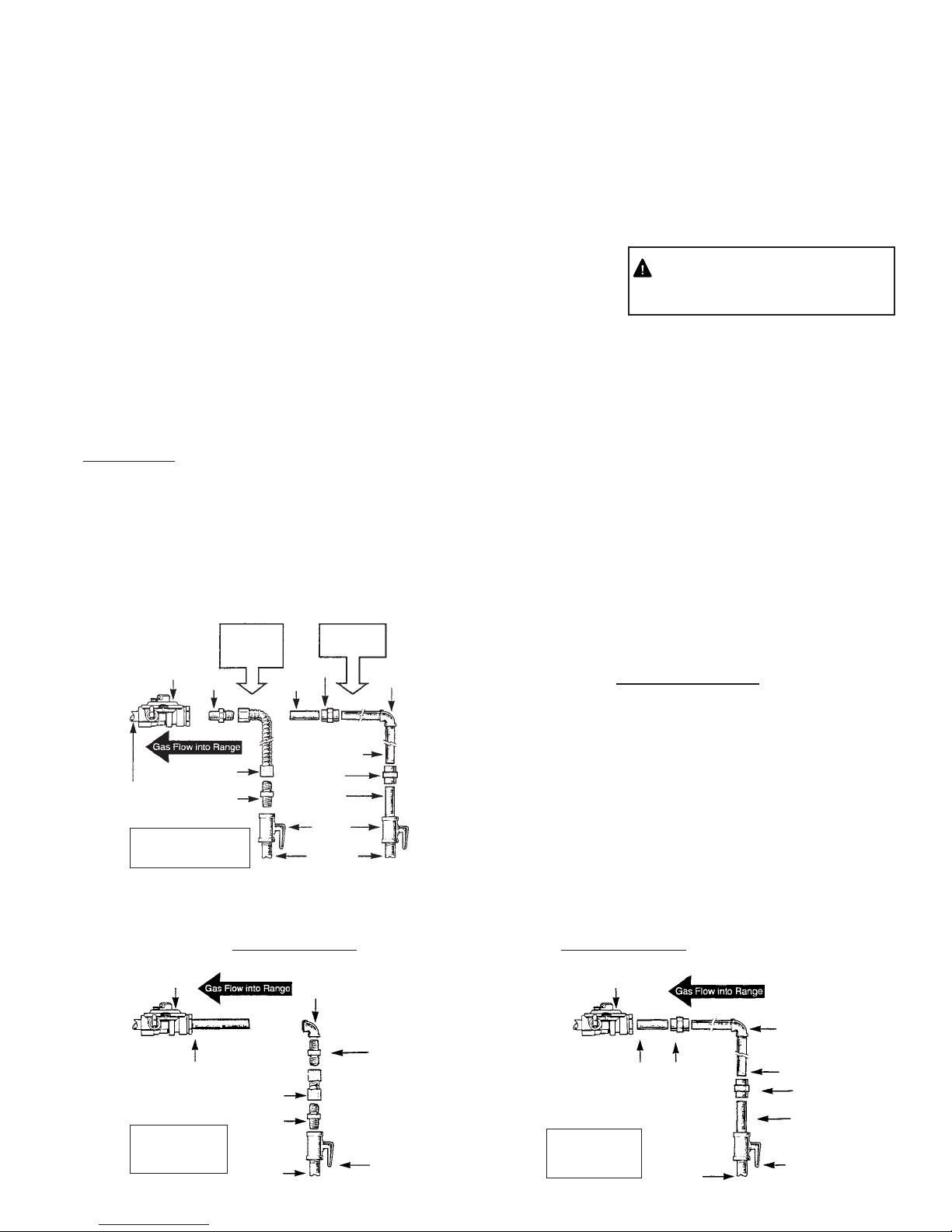

FIG. 3

FIG. 5FIG. 4

Flexible Connector and Rigid Pipe Hookups for

Models Equipped with Standar

d Bur

ners

Flexible Connector Hookup for Models

Equipped with Sealed Bur

ners

Rigid Pipe Hookup for Models Equipped

with Sealed Bur

ners

Installer: Inform the

consumer of the location

of the gas shut-off valve.

Installer: Inform the

consumer of the

location of the gas

shut-off valve.

Installer: Inform the

consumer of the

location of the gas

shut-off valve.

5

*Teflon: Registered trademark of Dupont.

Pressure

Regulator

Pressure

Regulator

Pressure

Regulator

Adapter

Adapter

Adapter

Nipple

Union

90˚

Elbow

90˚ Elbow

90˚

Elbow

Flexible

Connector

Hookup

Rigid Pipe

Hookup

Black Iron Pipe

Black

Iron Pipe

Union

Nipple

Union

Nipple

Union

Nipple

Nipple (provided)

Gas

Shut-off

Valve

Gas

Shut-off

Valve

Gas

Shut-off

Valve

1/2” or 3/4”

Gas Pipe

1/2” or 3/4”

Gas Pipe

1/2” or 3/4”

Gas Pipe

Adapter

Manifold Pipe

Flex Connector

(6 ft. max.)

Flex Connector

(6 ft. max.)

Backguard Assembly

The backguard, located in the “top

pack” of the range, must be installed

prior to placing the range in position

for gas hookup. See Figure 7.

Positioning/Leveling

To position the range use a lift jack or

enough manpower to lift the range

completely. Avoid sliding, pushing, or

pulling the range because this

increases the possibility of bending

the legs or the coupling connectors

and could also result in damage to the

floor covering.

Ranges and built-in cooktops must be

level to obtain proper cooking results.

Ranges adjust from 35

7

/8” to 37 7/8” or

2” max. All units must be level frontto-back and side-to-side. See Fig. 2.

Built-in cooktops must be installed in

a cut-out and on a level surface, as

illustrated in Fig. 6.

NEVER BLOCK THE FLOW

OF AIR FOR COMBUSTION

OR VENTILATION. SEE

INSTRUCTION FIG. 2.

Adjustments

Appliances will either be set for use

with Natural gas or Propane (LP) gas.

The factory orifice setting is indicated

by a second alpha prefix letter in the

model number. The letter “T”

indicates a natural gas setting. The

letter “P” indicates a propane (LP)

setting.

ALL ADJUSTMENTS AND/OR

CONVERSIONS MUST BE

MADE BY THE INSTALLER

OR SERVICING UTILITY

DURING INSTALLATION.

SEALED TOP BURNER

MODELS ARE FACTORY SET

FOR THE GAS FOR WHICH

THEY ARE TO BE USED.

THEY CANNO

T BE CHANGED

FROM ONE GAS TO

ANOTHER WITHOUT

FACTORY AUTHORIZATION.

FIG. 6 COOKTOP INSTALLATION CLEARANCES

FIG. 7 BACKGUARD INSTALLATION

NOTE: COOKTOPS DO NOT HAVE LEVELING LEGS.

CABINET SUPPORT MUST BE LEVEL.

6

40” MINIMUM

13”

MAXIMUM

WIDTH OF

RANGE

6” MINIMUM

18” MINIMUM

2”

2”

2”

1 1/2”

36”

6 3/16”

2”

12”

2 1/2”

5 1/2”

CUT-OUT WIDTH

48” COOKTOP = 48 3/16”

36” COOKTOP = 36 3/16”

CUT-OUT HEIGHT

6 3/16” including

countertop thickness

24” DEEP BASE CABINETS

SUGGESTED

NOTE:

FASTENERS ARE

PROVIDED AND MUST

BE REMOVED

AND RE-USED

AMOUNT PROVIDED:

30” - 4

36” - 4

48” - 5

60” - 6

ELECTRICAL

CONNECTION

AREA

GAS CONNECTION

AREA

FIG. 13

FIG. 12 VARI-FLAME™

CENTER SIMMER BURNER

FIG. 10 STANDARD BURNER

CONVERSION

LP GAS SETTING

Tighten orifice hoods for surface and

oven burners approximately two

complete turns and adjust air

shutters. The gas pressure regulator

must be set to the LP gas setting to

provide 10 inches water column

pressure.

NAT. GAS SETTING

Unscrew orifice hoods for surface

and oven burners approximately two

complete turns and adjust air

shutters. The gas pressure regulator

must be set to the NAT. setting to

provide 4 inches water column

pressure.

FIG. 9 PRESSURE REGULATOR

CONVERSION

Oven/Griddle Control

(Thermostat)

The oven pilot gas selector screw is

located on this control. To change

oven pilot gas setting: (A) Remove

oven control knob by pulling straight

out. The oven gas selector screw is

found in the lower left hand corner

indicating “LP” or “N”. (B) These

letters will appear upside down

reading “N” and “LP”. (C) Rotate the

adjustment screw tab to the proper

setting. See Figure 8.

LP

N

All ranges are equipped with a gas

pressure regulator for controlling and

maintaining a uniform gas pressure in

the gas manifold of the range. The

burner orifices are sized for the gas

pressure delivered by the regulator

supplied. The pressure regulator

must not be removed. To convert the

regulator from one gas to another

remove convertor cap by inserting a

coin into slot in top an twisting, turn

cap over and re-install. See Fig. 9.

Standard top burners . . . Be sure

the shipping screws have been

removed from the burners. The

correct positioning should place the

top of the burner head approximately

3/8” below the cooking surface. See

Fig. 11.

Top burners have LOW, MEDIUM,

and HIGH positions. Adjust gas and

air mixture in the HIGH position. To

adjust LOW turn knob to LOW,

remove knob and while holding the

valve stem in the LOW setting with a

pair of pliers turn the adjusting screw

until a flame of approximately

1

/8” is

obtained.

High flames on surface burners are

inefficient and unsafe. The flame

should always be adjusted so that it

is no larger than the bottom of the

pan.

Pilot is out when control dial

is “OFF.” Spark electrode is

directly above “CHUTE.”

Vari-Flame™ . . . FiveStar

Standard front burners are equipped

with a true center-simmer feature that

is factory set. The burner orifice hoods

are black for NAT. gas and brass for

LP. gas. If the range is to be converted

from NAT. gas to LP. or vice versa call

800-251-7224 for proper orifices and

instructions.

Oven and Griddle Burners

These burners are supplied gas by

automatic safety valves. The safety

valve orifice must be set for the gas

being used. See Figure 10. This valve

is located at the base of the oven

burner in the broiler compartment and

at the base of the griddle burner in the

burner box under the griddle assembly.

Flame Height

Improper flame height is inefficient

and unsafe. The flame on these burners

should be blue in color and

approximately 1

1

/4” in height. See

Figure 13.

FIG. 8 PILOT GAS SELECTOR KEY

FIG. 11 TOP BURNER LOCATION

NEVER USE THE OVEN FOR

STORAGE

7

Front View

Harper-Wyman

Regulator

1”

3 / 8

1 1/4” OVEN BURNER

FLAME HEIGHT

1 1/4” GRIDDLE BURNER

FLAME HEIGHT

BURNER PAN

LPG

NAT

Converter

Cap

Pointer

Oven pilot selector key

switches from LP to NAT

(vice versa).

BEFORE PERFORMING ANY

SERVICE, DISCONNECT THE

RANGE POWER SUPPLY AT

THE HOUSEHOLD

DISTRIBUTION PANEL BY

REMOVING THE FUSE OR

SWITCHING OFF THE

CIRCUIT BREAKER.

EACH HOUSEHOLD SHOULD

HAVE AN APPROPRIATE

FIRE EXTINGUISHER FOR

USE IN THE EVENT OF A

HOUSE FIRE.

CAUTION: ITEMS OF

INTEREST OF CHILDREN

SHOULD NOT BE STORED IN

CABINETS ABOVE A RANGE.

THE RISK CAN BE REDUCED

BY INSTALLING A RANGE

HOOD THAT PROJECTS

HORIZONTALLY A MIN. OF 5

INCHES BEYOND THE

BOTTOM OF THE CABINETS.

SAFETY INSTRUCTIONS

• Read all instructions before using

this appliance.

Statistics show many accidents

occur in the home. Most of these

could be prevented with care and

judgment. Use this appliance only

for its intended use as described in

this manual. When using appliances,

basic safety precautions should be

observed, including the following:

• Be sure your appliance is properly

installed and grounded by a

qualified technician in accordance

with the provided installation

instructions.

• Don’t attempt to repair or replace

any part of your range unless it is

specifically recommended in the

book. All other servicing should be

referred to a qualified technician.

• WARNING - All ranges can tip

and injury could result. To prevent

accidental tipping of the range,

attach it to the wall or floor. See

Figure 2.

• Never wear loose-fitting or

hanging garments while using the

appliance. Flammable material

could be ignited if brought in

contact with hot surfaces or open

flames and may cause severe burns.

• Use only dry pot holders . . . moist

or damp pot holders on hot surfaces

may result in burns from steam. Do

not let pot holders touch hot surfaces

of the range. Do not use a towel or

other bulky cloth as a pot holder.

• On a cold morning you might be

tempted to use the range as a

kitchen heater – DON’T! Use of

the range in this manner may be

hazardous. Oven controls and other

valve components are not designed

for heating use. Never use your range

for warming or heating the room.

• When preparing your meals a

great deal of heat is generated,

consequently some parts of the

range will become HOT. Consider

this in choosing the location for

your range. Don’t leave children

unattended near the range when it’s

in use or while the surfaces are still

hot from use. They should never be

allowed to sit or stand on any part

of the appliance.

• Never allow children to play with

the range controls. Teach them that

the range and pans on it can be hot.

Don’t allow anyone to climb about

the range or use it or the doors for

stepping, leaning, or sitting.

Possible hazards or injuries may

result. It’s recommended that

practices of storing items above the

stove be discontinued.

• Due to potential hazard don’t use

the oven or broiler space for

storage. The top of the range should

never be used for storage either.

Flammable items can catch fire and

plastic items may ignite or melt.

• Keep hood and grease filters clean

to maintain good venting and to

avoid grease fires.

• Do not let cooking grease or other

flammable materials accumulate

in or near the range.

• Do not use water on grease fires.

Never pick up a flaming pan.

Smother flaming pan on surface unit

by covering pan completely with

well-fitting lid, cookie sheet or flat

tray. Flaming grease outside a pan

can be put out by covering with

baking soda or, if available, a multipurpose dry chemical or foam type

fire extinguisher.

8

Do not

use gas

broiler for

storage.

9

• DO NOT TOUCH BURNERS,

BURNER GRATES, OR

INTERIOR SURFACE OF

OVEN. These surfaces may be hot

enough to burn even though they

appear to be cool. During and

immediately after use do not touch,

or let clothing or other flammable

materials contact any hot surfaces or

any interior area of the oven; allow

sufficient time for cooling.

Potentially hot surfaces include the

cooking surface and areas facing the

cooking surface, oven vent opening

and surfaces near the opening, and

crevices around the oven door.

Remember: The inside surface of

the oven may be hot when the door

is opened.

• Don’t heat unopened food

containers in the oven. Pressure

could build up and the container

could burst causing an injury.

• Place oven rack in desired

position while oven is cool. If rack

must be handled when hot use a pot

holder. Pulling out the oven rack to

the stop position is a convenience in

lifting heavy foods. It is also a

precaution against burns from

touching hot surfaces of the door or

oven walls.

• When using cooking or roasting

bags in oven, follow the

manufacturer’s directions.

• Do not use your oven to dry

newspapers.

Surface Cooking

• Use proper pan size. Select

utensils having flat bottoms large

enough to cover the burner. The

use of undersized utensils in which

the flame comes up the side of the

utensil does not heat the contents

faster, it only scorches the outside

of the utensil making clean up

harder. Adjust the top burner knob

to select a flame size to cover just

the bottom of the pan or pot.

• Surface areas near burners may

become hot enough to cause

burns. During and immediately

after use, do not touch areas near

burners until they have had

sufficient time to cool.

• Never leave top burners

unattended at high heat settings.

Boilover causes smoking and greasy

spillovers may catch on fire.

• Don’t use aluminum foil to line

burner pans or anywhere in the

oven except as described in this

book. Misuse could result in fire

hazard or damage to the range. Only

certain types of glass, glass/ceramic,

earthenware, or other glazed

containers are suitable for range-top

service; others may break because

of the sudden change in

temperature.

Oven

• Don’t bake in a gas oven unless

the broiler pan is in position and

free of grease. Be careful when

handling the pan, especially when

hot. Grease left in the pan can catch

fire if the oven is used without

removing the grease from the

broiler pan. Keep oven free from

grease buildup.

• Never use ammonia in an oven

that is warmer than room

temperature and always have

direct ventilation.

• Stand away from range when

opening oven door. Hot air or

steam which escapes can cause

burns to hands, face, and/or eyes.

• When replacing an oven light

bulb, be sure the oven is cool,

disconnect power to the range,

and use a dry cloth to handle the

bulb.

• Is the protruding handle of a

utensil on the range an attraction

to curious little hands? YOU BET

IT IS. Always turn utensil handles to

the side or back of the range. It’s

also possible for an adult to hit the

handle accidentally.

• Always turn surface burner to

OFF before removing cookware.

Keep an eye on foods being fried at

HIGH or MEDIUM temperatures.

• To avoid the possibility of a burn

always be certain that the controls

for all top burners are at OFF

position and all burner pans are

cool before attempting to remove

the burner pan or burner.

• Don’t put removable surface

burners in a dishwasher.

• Foods for frying should be as dry

as possible. Frost on frozen foods

or moisture on fresh foods can

cause hot fat to bubble up and over

sides of pan.

• Use only enough fat for effective

shallow or deep-fat frying. Filling

the pan too full of fat can cause

spillovers when food is added. If a

combination of oils or fats will be

used in frying, stir together before

heating, or as fats melt. Always heat

fat slowly, and watch as it heats.

• Use deep fat thermometer

whenever possible to prevent

overheating fat beyond the

smoking point.

ENERGY-SAVING TIPS

Surface Cooking

Cook fresh vegetables with a

minimum amount of water in a

covered pan.

Watch foods when bringing them

quickly to cooking temperatures at

high heat. When food reaches

cooking temperature, reduce heat

immediately to lowest setting that

will keep it cooking.

When boiling water for tea or coffee,

heat only amount needed. It is not

economical to boil a container full of

water for one or two cups.

Use correct heat for cooking task:

HI–to start cooking (if time allows,

do not use high heat to start).

MEDIUM–quick browning.

LOW–finish cooking most quantities,

double-boiler heat, and for small

quantities.

VARI-FLAME

TM

FRONT BURNERS

SIM–to maintain serving temperature

of most foods.

Oven Cooking

Preheat oven only when necessary.

Most foods will cook satisfactorily

without preheating. If you find

preheating is necessary, preheat for 10

to 12 minutes.

Always turn oven OFF before

removing food.

During baking, avoid frequent door

openings. Keep door open as short a

time as possible.

Cook complete oven meals instead of

just one food item. potatoes, other

vegetables, and some desserts will

cook together with a main-dish

casserole, meat loaf, chicken, or roast.

Choose foods that cook at the same

temperature and in approximately the

same time.

Use residual heat in the oven

whenever possible to finish cooking

casseroles, oven meals, etc. Also add

rolls or precooked desserts to warm

oven, using residual heat to warm

them.

GENERAL INFORMATION

• Range may be installed directly

against rear walls and side base

cabinets. It may not be installed

directly against side tall cabinets,

sidewalls, or tall appliances. See

“Wall Clearances” Figure 1 & 6.

• Electrical requirements: 120 volts,

60 Hz, 15 amps. Dual-fuel ranges

120/240 volts, 60 Hz, 20 amps.

• Natural gas: 4.0” WC, propane

10.0” WC.

• Residential exhaust vent hoods

may be installed above the range.

Provide properly sized exhaust

fans for efficient operation, no

sprinklers are required.

• If this range is removed for any

reason, service or cleaning, etc., it

must be replaced as outlined in

the installation instructions before

placing the range back in operation.

Field Adjustments

All ranges are tested before leaving the

factory. Field adjustments are necessary

for proper operation. The range must be

installed and adjusted by a qualified

technician. Final adjustments and/or

conversions from one gas to another

are not covered under the warranty.

Contact your dealer for the name of

their authorized Service Agency. If

none is available, contact the corporate

office for the nearest authorized

Service Agency in your area. Phone

(800) 251-7485.

Top Burners

All burners have electronic ignition.

Standard top burners have “manual”

ignitors. Sealed top burners (if

equipped), oven burners, griddle and

grill burners have flame-sensing

ignitors.

To light the top burners, push the knob

in and turn counter-clockwise to the

“LITE” position. As soon as the knob

reaches the “LITE” position, you’ll

hear a “clicking” sound. The knob

operates both a gas valve and an

electric switch. If you don’t hear a

clicking sound, turn the knob off and

check the electric connection, fuse or

circuit breaker if necessary. After

ignition, on standard burner models,

rotate the knob slightly clockwise out

of the “LITE” position. This turns off

the electricity to the electrodes and the

clicking will stop. DON’T LEAVE

THE KNOB IN THE “LITE”:

POSITION . . . it will shorten the life

10

WARNING!!!

DUAL-FUEL MODELS ARE

NOT SUPPLIED WITH A

CONNECTION CORD. IF NOT

PROPERLY GROUNDED,

SEVERE SHOCK CAN OCCUR.

PUSH IN

TURN COUNTER

CLOCKWISE

ONLY

OFF

WARNING!!!

ALL GAS MODELS ARE

EQUIPPED WITH A POWER

CORD WITH A THREE PRONG

GROUNDING PLUG FOR

YOUR PROTECTION. DO NOT

CUT OR REMOVE THE

GROUNDING PRONG FROM

THIS PLUG.

CAUTION!!!

ALL CONTROLS ROTATE

COUNTER-CLOCKWISE TO

OPERATE. NEVER ROTATE

CONTROLS CLOCK-WISE

FROM THE "OFF" POSITION.

THIS WILL DAMAGE

CONTROLS AND

VOID WARRANTY

CLAIMS.

11

of the electronic system.

On sealed burner models, if equipped

with flame sensing ignitors, the

clicking sound stops after ignition.

Each time a knob is placed in the

“LITE” position all electrodes will

spark. There are electrodes under the

top for each pair of burners and one

for the griddle. There is one electrode

in each broiling section for the oven

burner. In the event of a power failure

you may light the top burners with a

match. Hold lighted match near the

surface burner and turn knob counterclockwise to the “LITE” position. See

Oven and Griddle Burners section

for instructions to light the oven

burner in the event of a power failure.

Page 14.

Final Preparation

Stainless Steel

New units are wiped clean with

solvents at the factory to remove any

visible signs of dirt, oil, grease, etc.

remaining from the manufacturing

process, then coated with a thin film of

mineral oil. Some stainless steel parts

may have a plastic protective wrapper

which must be peeled off. The range

should be washed thoroughly with hot,

soapy water to remove these film

residues and any installation dust or

debris before being used for food

preparation, then rinsed and wiped dry.

Solutions stronger than soap and water

are rarely required. All stainless steel

body parts should be wiped regularly

with hot, soapy water and with a liquid

cleaner designed for this material. If

buildup occurs, do not use steel wool,

abrasive cloths, cleansers, or powders!

If it is necessary to scrape stainless

steel to remove encrusted materials,

soak with hot, wet cloths to loosen the

material, then use a wood or nylon

scraper. Do not use a metal knife,

spatula, or any other metal tool to

scrape stainless steel! Scratches are

almost impossible to remove.

A light coat of oil such as Johnson’s

Baby Oil may be applied periodically

to the stainless steel surfaces. This

will help prevent moisture from

penetrating the stainless surfaces.

Once the unit is installed as outlined in

the Installation Instructions (pages 3-6)

it is important that the air supply to the

unit remains open. The oven air supply

comes through the front floor area

under the range. The surface burners

get air from the area below the control

panel. THESE AREAS MUST

REMAIN OPEN. See Figure 2.

Operation of Ranges

Cooking Utensils

Most cooking utensils are suitable for

use on the FiveStar and it is not

necessary to replace your present

domestic utensils with commercial

cookware. This is a matter of personal

choice. Cookware should be in good

condition and free from excessive

dents or bulging on the bottom to

provide maximum performance and

convenience.

Before You Cook

Before staring to cook, clean the

range thoroughly with hot, soapy

water. Turn the oven to 400 degrees

for approximately one hour to burn

off the “binder” from the insulation.

There will be a slight odor.

Griddle

The griddle is coated with a thin film

of oil. The first “burn in” of the new

griddle should include a gradual

seasoning. The griddle is a heavyduty machined steel plate and for

efficient use must be seasoned as

follows:

Clean the griddle surface thoroughly

with hot, soapy water to remove the

protective oil coating.

Rinse with a mixture of

1

/4 cup white

vinegar to one quart water.

Spread unsalted shortening or liquid

vegetable oil evenly over the entire

griddle surface.

Turn the control to 350 degrees and

wait until the shortening just begins

to smoke then turn the control off.

Rub the melted shortening into the

griddle surface with burlap or other

rough material, moving in the direction

of the griddle surface grain, making

sure to cover the entire surface.

Let the griddle cool and wipe it clean

with a dry cloth. “Season” it again.

When the griddle is cool after the

second seasoning, wipe it clean once

again and wipe with a thin film of

shortening or vegetable oil. A well

seasoned griddle will become dark

brown with age.

Griddle Cooking

• Preheat griddle at 450˚ for 12

minutes, then turn to selected

temperature.

• Use liquid cooking oil, cooking

sprays, or butter for eggs, pancakes,

French toast, fish, and sandwiches.

This will help to reduce sticking.

Meats usually have enough natural

oils

• Remove food particles with a metal

spatula during cooking to make the

clean up easier and to avoid

including those particles in the

cooked food. Be sure to keep the

spatula flat. The corners can scratch.

• Direct the flow of grease to the

center of the grease well.

• Do not over-heat the griddle. Turn it

off when not in use, or lower heat

between cooking loads.

Griddle Knob Settings

Food Built-In Portable

Eggs 250-300° Low

Bacon 325-350° Med

French Toast,

Pancakes 375-400° Med

Fish fillets 350° Med

Hamburgers 350° Med

Steaks 350° Med

Griddle Clean Up

Cooked-off grease will drain from the

griddle toward the front of the range

and accumulate in the grease well.

Direct the flow of grease to the center

of the grease well with a spatula.

After using the griddle, always

remove the grease well in front of the

griddle. Portable griddle does not

have removable grease well. Pour or

spoon off grease in the well cup and

wash it in hot, soapy water. Use a dry

cloth to wipe up any accumulation of

grease in the recessed section of the

griddle under the removable grease

well. The grease well needs to be

cleaned after each use of the griddle.

if grease is permitted to accumulate, a

fire hazard could occur, since the

griddle burner is near the grease well.

Rub the surface of a warm griddle

with unsalted solid shortening or

vegetable oil. Wipe it with burlap or

another rough cloth to remove any

residue. Stubborn spots may be

removed by rubbing the surface with

a rough-grained nylon scrubbing pad

with cooking oil.

walls. Correct pan placement allows

air circulation for proper baking and

browning.

• Do not place pans in the oven

directly over each other. Stagger the

pans so that air flow will not be

inhibited. See Figure 14.

• Always keep oven vent ducts

unobstructed.

moderate baking range is 350 degrees

to 425 degrees.

Baking

When baking, follow the recipe

instructions. Use correct ingredients,

measure them carefully, and use the

correct type and size utensil suggested

in the recipe. Remember to preheat

properly, if needed. Avoid frequent

opening of the oven during preheating

and baking, as this causes heat loss

and the temperature to vary.

When baking cakes in glass baking

dishes, lower the oven temperature 25

degrees to prevent browning of the

bottom and sides before the top

becomes brown.

Also when using glass bakeware it

would be better to increase the preheat

time to have exact stabilization of the

oven’s temperature. To do so, allow 20

minutes time for temperatures up to

350 degrees and 30 minutes for

temperatures up to 425 degrees. Avoid

opening the door as much as possible.

Don’t be concerned if condensation

occurs on the oven window. This is

normal and usually disappears after the

oven has operated for a short time.

Broiling

No definite time can be given for

broiling meats because of varying

thickness, amount of fat, and personal

taste. Be careful when handling hot

broiler pans; be careful of the hot

grease. Serious injury can result due to

spillage of hot grease. Never leave a

dirty broiler pan in place, always clean

it and return it to the broiler assembly.

Unauthorized broiler pan substitutes

should never be used. Excess fat

should be trimmed to eliminate the

possibility of flame up. The meat

could be ruined or fire could occur

causing loss of property and bodily

injury.

When broiling fatty meats, the lowest

broil position must be used. We

recommend the lowest positions at all

times.

Always broil with the oven door and

broiler door closed. When broiling is

completed, turn the dial to “OFF” and

If “cooked in” food spots can’t be

removed with the scrubbing pad you

may need to use a pumice grill stone

that is available from restaurant

supply houses. The Grillmaster Grill

Stone, by U.S. Pumice Company, is a

porous abrasive pumice block that

cleans a griddle with just the right

amount of abrasive action.

To use:

1. Pour liberal amount of cooking oil

on warm (not hot) grill plate.

2. Sprinkle grill plate with generous

amount of table salt.

3. Scour in one direction only until all

carbon and food are removed. Do

not over-scour as this removes the

“cure” and causes sticking.

4. Wipe clean with a dry cloth.

Do not use hot, soapy water to clean

the griddle. This will remove the

cooked-in seasoning of the griddle.

Never flood a hot griddle with cold

water! This can cause griddle plate

warping and/or cracking.

Use of Oven

• Preheat not more than ten to twelve

minutes.

• Allow at least one inch space

around oven pans and the oven

Aluminum Foil in

Oven and Broiler

Aluminum foil is a cause of many

range fires. Make certain that vents or

air openings aren’t covered by the

foil. If the vents located along the

sides of the oven bottom are blocked,

poor cooking and burner performance

will result. Never cover a rack with

aluminum foil.

Oven Temperature

Selection

It’s important to select a proper

temperature setting. Never set the dial

to a higher degree than needed with

the intention of lowering the setting at

a later time. This will not speed up

the action. It can cause the oven to

cycle slower and cause the

temperatures to vary so that cooking

results may be unsatisfactory. The

oven will maintain a more even

temperature if the oven control dial is

set directly from “OFF” to the

desired temperature and not turned

back toward “OFF”. Imagine that the

control has three sections: 1. Low

Temp. 2. Bake 3. Broil. The “Low

Temp” has a temperature range of

140 degrees to 200 degrees. This

section is used to keep food at serving

temperature. The bake cycle is from

250 degrees to 550 degrees. This can

be termed as the very low range (250

degrees to 275 degrees) to extremely

hot (500 degrees to 525 degrees). The

WARNING!!!

ALWAYS ALLOW GRIDDLE TO

COOL PRIOR TO CLEAN UP

OR REMOVAL FOR STORAGE.

FIG. 14 PAN POSITIONING–TOP RACK

(LEFT), BOTTOM RACK (RIGHT)

12

CAUTION: IF THE

OVEN BURNER DOES NOT

IGNITE WITHIN 20 TO 60

SECONDS AFTER THE

PILOT IS LIGHTED, TURN

THE OVEN TEMP

CONTROL TO OFF AND

WAIT FOR POWER TO BE

RESTORED. DO NOT

ATTEMPT TO RELIGHT

THE PILOT AGAIN.

13

remove the broiler pan temporarily for

cleaning.

• Do not use the broiler area for

storage of utensils.

Oven Racks

The oven racks should be arranged

before the oven knob is turned to an

“ON” position. Place the racks so the

food is “centered” in the oven, not the

rack.

When more than one utensil is used,

be sure to stagger them allowing space

between each one. See Figure 14.

Don’t allow the utensils to touch any

part of the oven, especially the glass

window. It is best to use 2 racks and

place food so one utensil is not

directly over another. Convection oven

models have 3 racks.

Oven Rack Removal

Pull the oven rack forward and lift up

on the front of the rack so it will clear

the rack keeper.

To replace the oven rack, guide the

angled rear portion of the rack under

the rack keeper and slide the rack to

the rear.

Gas Broiler Assembly

Each gas oven has a gas broiler below

the oven. A broiler pan and grill are

held in place by a uniquely fashioned

broiler rack. See Figure 15. To open the

broiler, gently lift up and pull forward

on the “drop-down” broiler door. Use a

hot pad or “range mitten” to grasp the

broiler pan and gradually pull forward.

It will reach a temporary “stop.”

Continue to pull forward and the broiler

rack will pull out along with the broiler

pan and grill to expose the entire broiler

grill surface.

FIG. 15 BROILER ASSEMBLY

The pan and grill may be removed

from the broiler rack by lifting up on

the front of the broiler pan so it will

clear the “pan keeper,” then pull

forward slightly and using hot pads or

mittens, with both hands lift the

broiler pan and grill free of the broiler

rack. The “broiler rack” may be

removed from and returned to the

broiler section in the same manner as

removing an oven rack. To return the

pan and grill to the broiler rack, pull

the broiler rack out to the stop

position. Insert the pan and grill into

the recessed section of the broiler

rack making certain that the “pan

keeper” pins clear the front edge of

the broiler rack. Slide the pan and

grill in place under the pan retainers.

Push the pan and rack to the rear of

the broiler compartment. Close the

broiler door.

Oven and Griddle Burners

These concealed burners use

automatic re-ignition flame-sensing

ignitors to ignite a gas pilot. You

don’t have to place the griddle control

or oven control dial in any special

“LITE” position – just use in the

same manner as a regular oven

control dial. When the control knob is

“ON” the sparking will start

immediately and stop automatically

as soon as the pilot lite is ignited. The

oven/griddle burner will then come on

within 20 seconds to 60 seconds after

the sparking has stopped. The main

burner is ignited by the pilot lite and

cycles on and off as heat is needed or

desired temperature is reached. The

pilot lite is turned off when the

control dial is turned to the OFF

position.

When either the oven control or

griddle control dial is turned on, all

electrodes will spark at a rate of

about 1

1

/

2 sparks per second. When

any top burner knob is placed in the

“LITE” position, all electrodes will

spark at a rate of about 2

1

/2 sparks

a second. This is normal.

To light oven pilot manually in the

event of a power failure: (You light

the pilot, not the burner.)

• 1. CAUTION: Make certain the

oven is cool when manually

lighting oven pilot.

• 2. Open broiler door. Oven pilot is

located on the left side of the oven

burner at the back of the burner. See

Figure 13.

• 3. Hold a lighted match and reach

through the broiler compartment to

the oven pilot.

• 4. While holding the lighted match

near the tip of the pilot assembly,

turn the oven control dial to an

“ON” position. Immediately remove

your hand from the broiler

compartment after the pilot gas

ignites. From 20 to 60 seconds after

the pilot ignites, gas will flow to the

oven burner and the burner will

ignite.

• 5. Close the broiler door.

• 6. Set desired temperature.

• 7. When cooking is finished, turn

the Oven Temp Control to “OFF”.

This will shut off all gas to the

oven.

NOTE: Whenever electrical power is

off, you will have to light the pilot

manually each time you want to use

the oven.

If the oven does not function properly

when the power is restored, or at any

other time, call a serviceman to

determine the source of the problem.

PAN RETAINER

PAN “KEEPER”

BROILER RACK

BROILER PAN AND GRILL

DO NOT ATTEMPT TO SERVICE

THE RANGE YOURSELF.

DO NOT ATTEMPT TO SERVICE

THE RANGE YOURSELF.

NOTE: THESE INSTALLATION

INSTRUCTIONS SHOULD

REMAIN WITH THE UNIT FOR

FUTURE REFERENCE.

Electronic Ignition

Ranges and built-in cooktops have top

igniter electrodes. When a top burner

knob is turned to the “LITE” position

electrodes will spark at a rate of

approximately 2

1

/2 pulses (sparks) per

second. On sealed burner models

equipped with “flame sensing” the

sparking will stop once the burner has

ignited. On standard burner models,

after ignition, rotate the knob slightly

clockwise to stop sparking.

In the event of a power failure you

may light the top burners with a match

by holding a lighted match near the

surface burner and turning the knob to

the “LITE” position.

Oven and griddle burners are

equipped with a spark ignition system

that has a “flame sensing” feature that

automatically stops the sparking once

the burner pilot gas is ignited. Turning

the control dial ON will activate an

electronic module and send pulses

(sparks) to all electrodes (including top

burners) at a rate of approximately 1

1

/

2

pulses (sparks) per second.

To light the oven or griddle burner

pilot manually in the event of a power

failure see page 14 and Figure 13 on

page 7.

Spark Modules

The heart of an electronic spark

system is the module that is located

either in the burner box, at the bottom

of the appliance, or behind the

“dummy panel” on self cleaning

models. Modules at the bottom

location can be reached through an

access panel under the range. There is

sufficient wiring to withdraw the

module assembly to check the

connections, make repairs or

replacement. If sparking does not

occur when the oven, griddle, or grill

control is turned ON see page 32.

Wiring Diagrams

Wiring diagrams are located in the Use

and Care manual. One is also located

behind the control panel near the

griddle knob or on the back of the false

panel under the self-cleaning oven.

NOTE: Burner rates specified on the

rating plate of your range apply for

elevations up to 2,000 feet above sea

level. For locations where altitudes are

higher than 2,000 feet above sea level

the b.t.u. rated input should be reduced

four percent for each 1,000 feet higher

than 2,000 feet above sea level. If this

adjustment is necessary, you should

contact a qualified serviceman.

CLEANING YOUR RANGE

Make certain all parts of the range are

cool before cleaning. Be sure to

replace the parts correctly.

Knobs

Pull forward to remove the knobs.

Wash in a water solution with a mild

detergent mix. Do not use an abrasive

cleaner or any abrasive action.

Abrasive action will scratch away the

knob markings.

If the knobs become loose on the

valve stem, spread the valve stem

slightly with a small screwdriver.

Stainless Steel

Stainless steel body parts should be

wiped regularly with hot, soapy

water. Use a liquid cleaner designed

for stainless steel when soapy water

will not do the job. Do not use steel

wool, abrasive cloths, cleansers, or

powder. If there are encrusted

materials, soak them with hot towels

to loosen the material, then use a

wooden or nylon spatula or scraper.

Do not use metal to scrape stainless

steel.

Do not allow citrus or tomato juice to

remain on a stainless steel surface.

Wipe spills immediately. Citric acid

will permanently discolor stainless

steel.

A light coat of oil such as Johnson’s

Baby Oil may be applied periodically

to the stainless steel surfaces. This

will help prevent moisture from

penetrating the stainless surfaces.

Spill-Over

Any spill-overs should be wiped up as

soon as possible and before it burns

in and cooks solid.

Lift off the top burner grates.

Lift up the front of the burner pan to

remove it.

Remove the burner and let it soak in

hot, sudsy water. Most stains will

then wipe off; if not, scrub with a

strong, but non-abrasive cleaning pad.

Rinse the burner thoroughly.

IT IS VERY IMPORTANT THAT

THE BURNER BE DRAINED AND

DRIED BEFORE REPLACING IT

IN THE RANGE. A wet burner will

not allow the gas to ignite properly.

This could result in a build-up of gas

which could result in an explosion or

fire.

If the spill has gone below the burner

pans, remove the drip trays and wash

them with hot, soapy water . . . rinse

clean. The burner box bottom may be

cleaned with a damp cloth.

Avoid Harsh Cleaners

Around Aluminum Parts

Do not use harsh cleaners or

degreasers on or around functional

parts (valves, controls, etc., or

aluminum tubing). This will damage

or drastically reduce the life of the

part.

Moisture

During the initial heat-up of your

range, the heat mixing with the cooler

air in the oven cavity may produce

fogging of the door glass or a

collection of water on the door. To

prevent this, open the oven door for

the first few seconds of initial oven

heat-up. This will allow the moist air

14

15

FIG. 16 BROILER DOOR

ADJUSTMENT/REMOVAL

Broiler Door

To adjust or remove broiler door, see

Fig. 16.

Gas Oven Bottom Removal

First remove racks from oven. The

oven bottom lifts from the rear. Grasp

each side of oven bottom and lift

upward from the rear until bottom is

clear – lift it to remove from the

front. See Figure 17. Electric bottoms

do not remove.

Fig. 17

Burner Drip Pans

Below each standard top burner is an

individual burner drip pan. Remove

the shipping screws holding the

burners in place. (One screw for each

burner at the burner support).

Remove the burner to get to the burner

drip pan. Be sure the burner is cool.

These individual porcelain drip pans

under each burner are dishwasher-safe

for easy cleaning.

within the oven to escape without the

forming of visible moisture on the

range. The amount of moisture will

depend upon the humidity of the air

and water content of the food being

cooked. Fogging and even dripping

water will usually occur in

geographic locations of high

humidity.

Oven Door Hinges

The oven door hinges are properly set

before leaving the factory. The

springs are adjusted to allow the door

to remain open when pulled 90

degrees forward and yet pull the door

tight against the oven front frame seal

when closed. The hinge and spring

assemblies are located in the door.

See Figure 18.

Lift-Off Doors

All models are equipped with lift-off

doors, see Fig. 18 for instructions.

FiveStar Sealed Burner Models

Top Burner Caps

When burner caps are removed for any

reason, they must be properly re-seated

for proper ignition and burner

performance.

Align notches in burner cap with

“pegs” in burner base and place burner

cap on burner base. Notch in burner

cap must also align with burner ignitor

as illustrated.

IGNITION

NOTCH AND

PORTS

BURNER

BASE “PEGS”

BURNER

IGNITOR

BURNER

BASE

BURNER

CAP

BROILER DOOR

BROILER DOOR

HINGE

Lift-Off Oven Door

(on some models)

FIG. 18

LIFT OFF DOOR

To remove oven door/s:

• Open door fully.

• Rotate the “hinge retainers” into

the locked position, as shown over

the hook located on the bottom side

of each hinge quadrant.

• Lift the door slightly, to clear

“hinge slots”, and pull straight out

to clear hinge mechanism from

main front opening.

To replace oven door/s:

• Insert hinges into front frame

opening locating “hinge slots” on

front frame as shown.

• Rotate “hinge retainers” back into

the “open” position.

• Rotate door to make sure it

functions properly.

TO CLEAN THE DOOR:

Inside of door:

• Soap and water will normally do

the job.

Heavy spattering or spillovers may

require cleaning with a mild

abrasive cleaner. Soapy, wet metal

pads may also be used. Do not

allow food spills with a high sugar

or acid content (such as milk,

tomatoes, sauerkraut, fruit juices or

pie filling) to remain on the surface.

They may cause a dull spot even

after cleaning.

• If necessary, you may use an

oven cleaner.

Follow package directions:

Outside of door:

• Use soap and water to thoroughly

clean the top, sides and front of the

oven. Rinse well.

• Spillage of marinades, fruit juices,

tomato sauces and basting materials

containing acids may cause

discoloration and should be wiped

up immediately. When surface is

cool, clean and rinse.

• Do not use oven cleaners, cleansing

powders or harsh abrasives on the

outside of the door.

16

HINGE

SLOT

HINGE RETAINER

“LOCKED”

REMOVAL

ACTION

HINGE RETAINER

“OPEN”

QUANDRANT

HOOK

HINGE

MECHANISM

17

CONVECTION OVEN MODELS

Convection oven ranges offer the

choice of “regular” radiant baking

and roasting or convection baking and

roasting. The benefits of convection

cooking are:

1. More even baking and roasting.

2. A general reduction in cooking

time for most baked foods; up to

30% faster.

3. Or the opportunity to reduce

cooking temperature and stay with

original recipe cooking time.

4. Convection cooking doesn’t dry out

foods.

OVEN INTERIOR

DUAL-FUEL VERSION SHOWN

(Gas convection ranges do not have elements in the oven.)

General Baking Recommendations

Convection Cooking on Multiple Racks

• When cooking foods for the first

time in your new oven, use recipe

cooking times and temperatures as a

guide only. Use tested recipes from

reliable sources.

• Preheat the oven only when

necessary. For baked foods that rise

and for richer browning, a preheated

oven is better. Casseroles can be

started in a cold oven. Preheating

takes from 6 to 8 minutes.

• Arrange oven racks before turning

on oven. Follow suggested rack

positions in the various baking

charts. (See “Oven Interior”

Illustration.)

• Allow about 1 to 1

1

/2 inches of

space between the oven side walls

and utensils for proper air

circulation.

• When baking foods in more than

one utensil, place them on opposite

corners of the rack. Stagger utensils

when baking on two racks so that

one utensil does not shield another

(See Fig. 14).

• To conserve energy, avoid frequent

or prolonged door openings. At the

end of cooking, turn oven off before

removing food.

• Always test for doneness (fingertip,

toothpick, sides pulling away from

the pan). Do not rely on time or

brownness as only indicators.

• Use good quality baking utensils

and the size recommended in the

recipe.

• Dull, dark, enameled or glass

utensils will generally produce a

brown, crisp crust. Shiny metal

utensils produce a light, golden

crust.

• Frozen pies in shiny aluminum pans

should be baked on a cookie sheet

on rack 1 or be removed to a dull or

glass pan prior to baking.

For best results, bake foods on one

rack at a time as described in this

manual. However, very good results

can be obtained when baking

quantities of foods on multiple racks,

using the “Turbo Air Flow”

convection system.

The convection oven is suggested for

multiple rack cooking, especially

three rack cooking. For two rack

cooking, the radiant bake oven

provides very good baking results

especially when pans can be

staggered.

Many foods can be prepared on three

racks at the same time. These are just

a few examples: cookies, cakes (layer

or sheet cakes), cupcakes, rolls,

biscuits, muffins, pies, frozen

convenience foods, pizzas, appetizers,

and snack foods.

To obtain the best results in multiple

rack cooking, follow these

suggestions:

• Use temperature and times in this

manual as a guide for best results.

• Rack positions are numbered from

bottom to top. (See “Oven

Interior” Illustration.)

• For two rack baking, rack positions

#2 and 4 are best for most baked

products but positions #1 and 3

also provide acceptable results.

• For three rack baking use positions

#2, 3 and 4.

• Stagger small utensils, such as

layer cake pans, in the oven.

• Jelly roll pans and cookie sheets

should be placed lengthwise, front

to back, in front of the fan for

more even browning.

BROIL

ELEMENT

CONVECTION

FAN

BAKE ELEMENT

FAN HOUSING

RACK POS. #4

RACK POS. #3

RACK POS. #2

RACK POS. #1

18

Baking Chart

* For Multiple Rack Baking, see page 17.

** The times given are based on specific brands of mixes or recipes tested.

Actural times will depend on the ones you bake.

*** Convection bake temperatures can be lowered approximately 25˚F on package mix or

recipes to achieve radiant bake time results.

Product and Type

Pan

Size

Rack*

Position

Temp. (˚F)

Preheated

Convection

Time**

Radiant

Bake

Time**

CAKE

Yellow-2 layers 9” 2 or 3 350˚ 22-26 30-35

White-2 layers 9” 2 or 3 350˚ 18-24 25-30

Chocolate-2 layers 9” 2 or 3 350˚ 22-26 30-35

Bundt tube 2 350˚ 30-34 35-45

Angel Food tube 2 375˚ 21-23 30-40

Pound Cake loaf 2 325˚ 30-37 40-50

Snacking Cake 8x8” 2 375˚ 19-22 30-35

Cupcakes 3 350˚ 12-15 15-20

Sheet Cake 15x10” 3 350˚ 16-19 20-25

PIES

Two Crust

Fruit, fresh 9” 2 400˚-425˚ 26-33 35-55

Fruit, frozen 9” 1 400˚-425˚ 33-41 45-60

One Crust

Custard, fresh 9” 3 350˚ 33-38 35-40

Custard, frozen 9” 1 375˚ 38 60-65

Pie Shell 9” 2 425˚-450˚ 8-12 8-12

COOKIES

Chocolate Chip 3 350˚-375˚ 6-9 8-12

Peanut Butter 3 350˚-375˚ 6-9 8-12

Sugar 3 350˚-375˚ 6-9 8-12

Brownies 8x8” 2 350˚ 22-30 30-40

BREADS, YEAST

Loaf loaf 2 375˚ 19-22 30-40

Rolls 3 375˚-400˚ 8-12 15-20

BREADS, QUICK

Loaf, Nut, Fruit loaf 2 350˚ 45-56 60-75

Gingerbread 9x9” 2 350˚ 30 40

Cornbread 8x8” 2 400˚-450˚ 12-30 15-30

Cornbread Muffins 3 400˚ 8-12 10-20

Biscuits 3 400˚-425˚ 8-15 10-20

Muffins 3 400˚ 12-22 15-25

19

Convection Baking of Frozen Convenience Foods

• Follow package recommendations

for oven temperature, foil covering

and use of cookie sheets. Baking

times will be similar. See chart

below for some examples.

• Center foods in the oven. If more

than one food item is being baked

or if foods are being baked on

multiple racks, stagger foods for

proper air circulation.

• Most foods are baked on rack

position #3., see page 17.

• For multiple rack baking, use rack #

2 and 4. However, pizzas should be

placed on cookie sheets and baked on

rack positions #3 and 4, see page 17.

Here are a few examples of times and temperatures:

Broiling (Dual-Fuel)

The electric broil element provides

flexibility for broiling foods. If you

have a FiveStar barbecue grill, we

recommend you use the grill for most

of your broiling.

To Broil (Dual-Fuel)

1. Place oven rack on the rack

position suggested in the chart.

Distance from broiling elements

depends on foods being prepared.

Rack position #4 is usually

recommended unless otherwise

stated, see page 17.

2. Turn the temperature control knob

counter-clockwise to BROIL. You

will reach what seems to be a

“stop,” but it is a “detent.” Gently

force the knob past the detent. This

“sets” the thermostat to the broil

mode. You then select the broil

temperature by turning the knob

clockwise to the desired

temperature.

Always broil with the oven door

closed. The oven thermostat will

maintain the termperature while

your food is broiled.

3. Place food on roasting/broiler pan

provided with oven. After top broil

element is red place food in oven.

Preheating takes a few minutes, or

until element glows a bright cherry

red.

4. TO RESET THE OVEN FOR

BAKING IT IS NECESSARY TO

TURN THE OVEN CONTROL

DIAL TO “OFF” AND THEN

BACK TO THE TEMEPRATURE

SETTING OF YOUR CHOICE.

Broiling Tips

• Tender cuts of meat or marinated

meats are best for broiling. For best

results, steaks should be at least 1”

thick. Thinner steaks should be pan

broiled.

• Do not cover broiler grid with foil

since this prevents fat drippings

from draining into bottom of pan.

• To make cleaning easier, spray pan

and grid with non-stick spray such

as Pam.

• Before broiling, remove excess fat

from meat and score edges of fat

(do not cut into meat) to prevent

meat from curling. Salt after

cooking.

•To prevent dry surface on fish or lean

meat, brush melted butter on top.

• Foods that require turning should be

turned only once during broiling.

• Cooking times given in the chart are

to be used only as a guide.

• The oven has a VARIABLE BROIL

FROZEN

CONVENIENCE

FOODS

Chicken, fried 3 25 375˚ 25-30 375˚

Donuts, glazed 3 5 300˚ 6 300˚

Fish, batter fried 3 20 425˚ 25-30 425˚

French fries 3 15 450˚ 15-20 450˚

Macaroni & Cheese 3 35 425˚ 30-35 425˚

Pot Pies 3 30 425˚ 30-40 425˚

Pizza 3 17 425˚ 15-17 425˚

Turkey, slices with

gravy (TV dinner) 3 50 425˚ 55-60 425˚

Minutes

Temp. ˚F

Minutes

Temp. ˚F

RACK

POSITION

CONVECTED OVEN

NOT PREHEATED

RADIANT BAKE

PREHEATED

FEATURE which means that the

broiling temperature can be varied

by selecting a lower temperature

setting on the TEMPERATURE

knob. Using a lower temperature

setting will cause the broil element

to cycle on and off. This feature can

be used for foods that need to cook

more slowly or need less radiant

heat. If foods are broiling too fast,

the control can be set at a lower

temperature to reduce the cooking

speed rather than moving the broiler

pan to a lower rack.

20

BEEF “BROIL” SETTING

Steak (1") 4

Rare 33

Medium 44

Well 55

Hamburgers (

3

/4") 4

Rare 3

Medium 4

Well 43

PORK TO “BROIL” AND BACK TO 500˚F

Bacon 4 5 (no turning)

Chops (

1

/2") 4 3 3

Chops (1") 4 9 8

Ham Steak 4 3 2

Sausage Links 4 5 3

Sausage Patties 4 5 1

LAMB TO “BROIL” AND BACK TO 500˚F

Chops (1") 4

Medium 53

Well 55

Patties (

3

/4") 4

Medium 43

Well 54

POULTRY TO “BROIL” AND BACK TO 500˚F

Breast Halves 4 7 4

SEAFOOD TO “BROIL” AND BACK TO 475˚F

Fish Fillets, Buttered (

1

/4") 4 4 (no turning)

Scrod, Buttered (

1

/2") 4 8 (no turning)

Cod (1") 4 12 (no turning)

Lobster Tail 4 9-12 (no turning)

MISCELLANEOUS “BROIL” SETTING

Hot Dogs 4 2 2

Toast 4 1 1

Rack

FOODS KNOB SETTING Position 1st Side 2nd Side