FitLinxx UWM02 Users Manual

SUBJECT:

A&D MEDICAL DIGITAL BLOOD

PRESSURE MONITOR ASSEMBLY

TEST SPECIFICATION

910-00059-01

DOCUMENT NUMBER:

910-00059-01

UMW02

ASSEMBLY

&

REVISION:

08

PAGE:

1of 18

Copyright © 2003-2004 FitSense Technology

Proprietary Information

Revision History

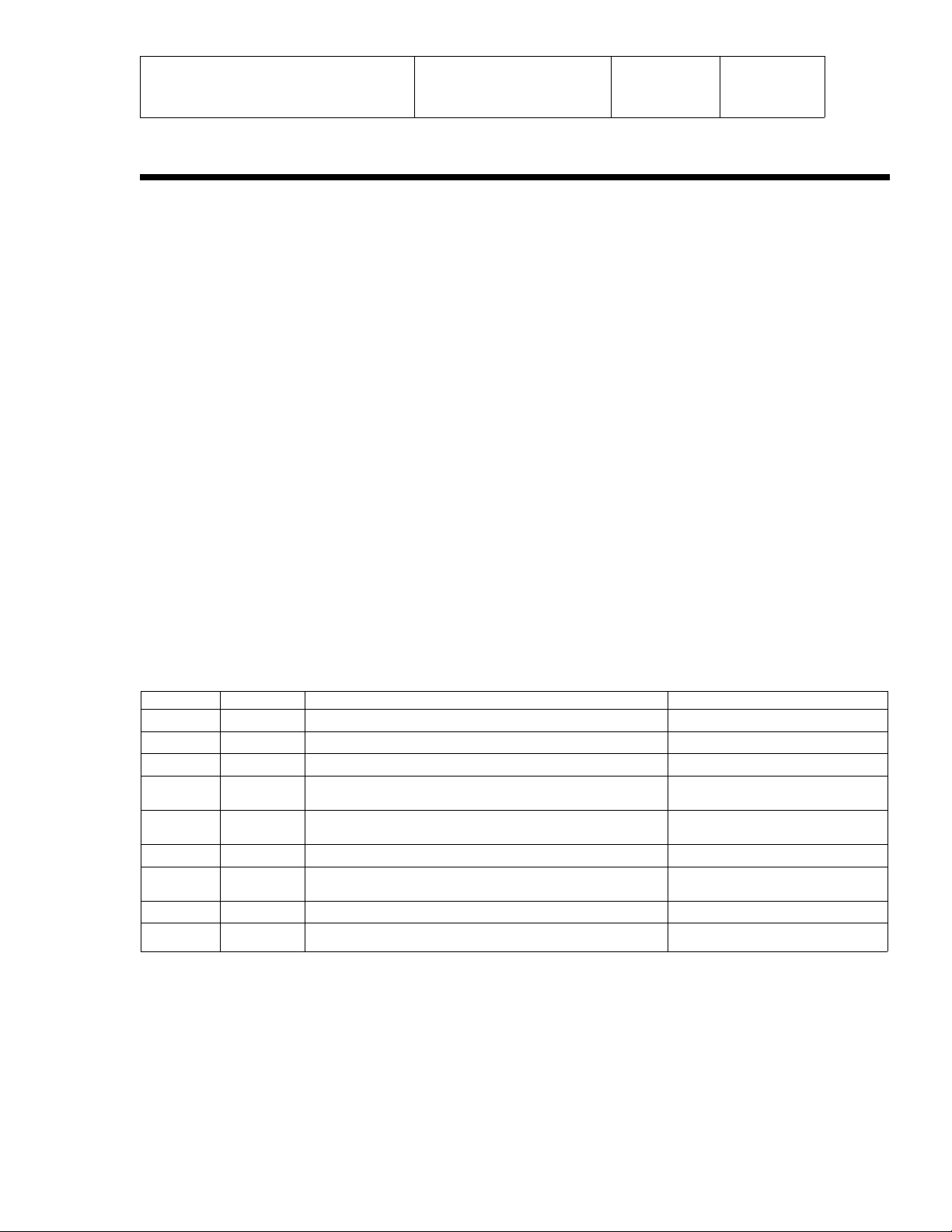

DATE VERSION DESCRIPTION AUTHOR

05/21/08 01 Initial release of document David W Smith

05/22/08 02 Added details to Functional Verification process David W Smith

06/09/08 03 Added FCC labeling details David W Smith

06/24/08 04 Updated rework instructions to reflect UWM in

location of best performance

7/16/08 05 Added details of test application, setup and test

process.

7/17/08 06 Define all distances in meters David W Smith

7/18/08 07 Clarify the use of System test on starting of test

application.

7/25/08 08 Added FCC statement on section 1.1 David W Smith

David W Smith

David W Smith

David W Smith

SUBJECT:

A&D MEDICAL DIGITAL BLOOD

PRESSURE MONITOR ASSEMBLY

DOCUMENT NUMBER:

910-00059-01

REVISION:

Table of Contents

1 INTRODUCTION.............................................................3

2 INCOMING INSPECTION................................................4

3 INCOMING TEST............................................................4

08

PAGE:

2of 18

4 BP MONITOR REWORK INSTRUCTIONS...................10

5 FUNCTIONAL TEST.....................................................11

6 PACKAGING.................................................................18

SUBJECT:

A&D MEDICAL DIGITAL BLOOD

PRESSURE MONITOR ASSEMBLY

1 INTRODUCTION

1.1 Purpose of this document

The purpose of this document is to specify the assembly and functional test

requirements for the A & D Medical Digital Blood Pressure Monitor with the Universal

Wireless Module (UWM).

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) this device may not

cause harmful interference and (2) this device must accept any

interference received, including interference that may cause undesired operation.

DOCUMENT NUMBER:

910-00059-01

REVISION:

08

PAGE:

3of 18

In adherence to FCC regulations any changes or modifications

not expressly approved by FitSense/FitLinxx could void the

user’s authority to operate the device.

1.2 Document Overview

This document in divided into the following section for organizational purposes.

Incoming Inspection; Describes UWM PCB packaging to be received by A&D

Medical.

Incoming Test; Describes the equipment, setup, and process for incoming test of the

UWM PCB.

Rework Instructions; Describes the wiring and mounting of the UWM PCB in the

Digital Blood Pressure Monitor.

Functional Test; Describes the equipment, setup, and process to Functionally Test

the wireless Blood Pressure Monitor containing the UWM PCB.

2 INCOMING INSPECTION

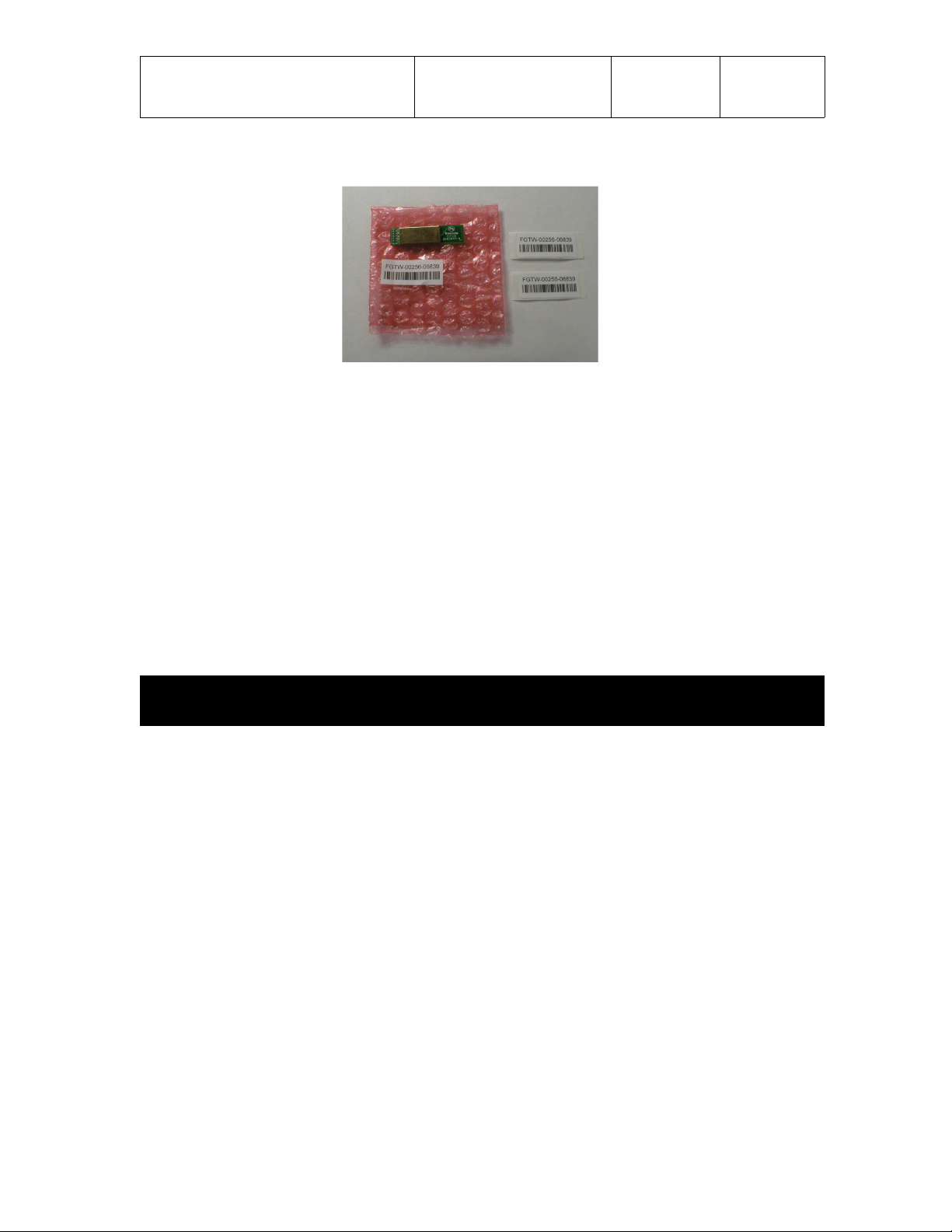

The UWM (P/N 710-00041-01) will be received in an ESD bubble bag with two bar

coded serial number labels and an FCC label as shown below .

SUBJECT:

A&D MEDICAL DIGITAL BLOOD

PRESSURE MONITOR ASSEMBLY

A ID Number label along with the FCC label is to be adhered to the blood pressure

monitor as described in the BP Monitor Rework Instructions. The second ID Number

label can be used on the product carton, packaging or as the manufacturer deems

appropriate.

The bar coded serial number label contains alpha and numerical characters. The

alpha characters represent the Device ID type as a BP monitor. The numerical

characters represents the Device ID Number plus a checksum. The bar code format is

UPC128.

DOCUMENT NUMBER:

910-00059-01

REVISION:

08

PAGE:

4of 18

The UWM PCB can be functionally verified and the corresponding labeling checked

utilizing the Incoming Test process described below. The UWM can be sample tested

per the MIL 105E Level ll Acceptance Plan.

3 INCOMING TEST

3.1 Test Equipment

The following test equipment is required for Incoming Test of the UWM PCB.

● USB based Personal Computer or laptop with Windows XP/2000 O.S. (provided by

A & D Medical)

● Custom Incoming Test Fixture (provided by FitSense)

● 3.30vdc power source for the UWM PCB Test Fixture (provided by A & D Medical)

● Digital Multimeter

● Known good ActiLink (provided by FitSense)

● ActiBPMfgTest test application (provided by FitSense)

3.2 UWM Test application

The System Test portion of the ActiBPMfgTest Manufacturing Test application

should be used for Incoming Test of the UWM PCB. When the application is started,

Select the tab for System Test.

The application (ActiBPMfgTest.exe) is installed in the C:\Program Files\ActiBP

Manufacturing Test. The application can be setup as a shortcut on the desktop.

SUBJECT:

A&D MEDICAL DIGITAL BLOOD

PRESSURE MONITOR ASSEMBLY

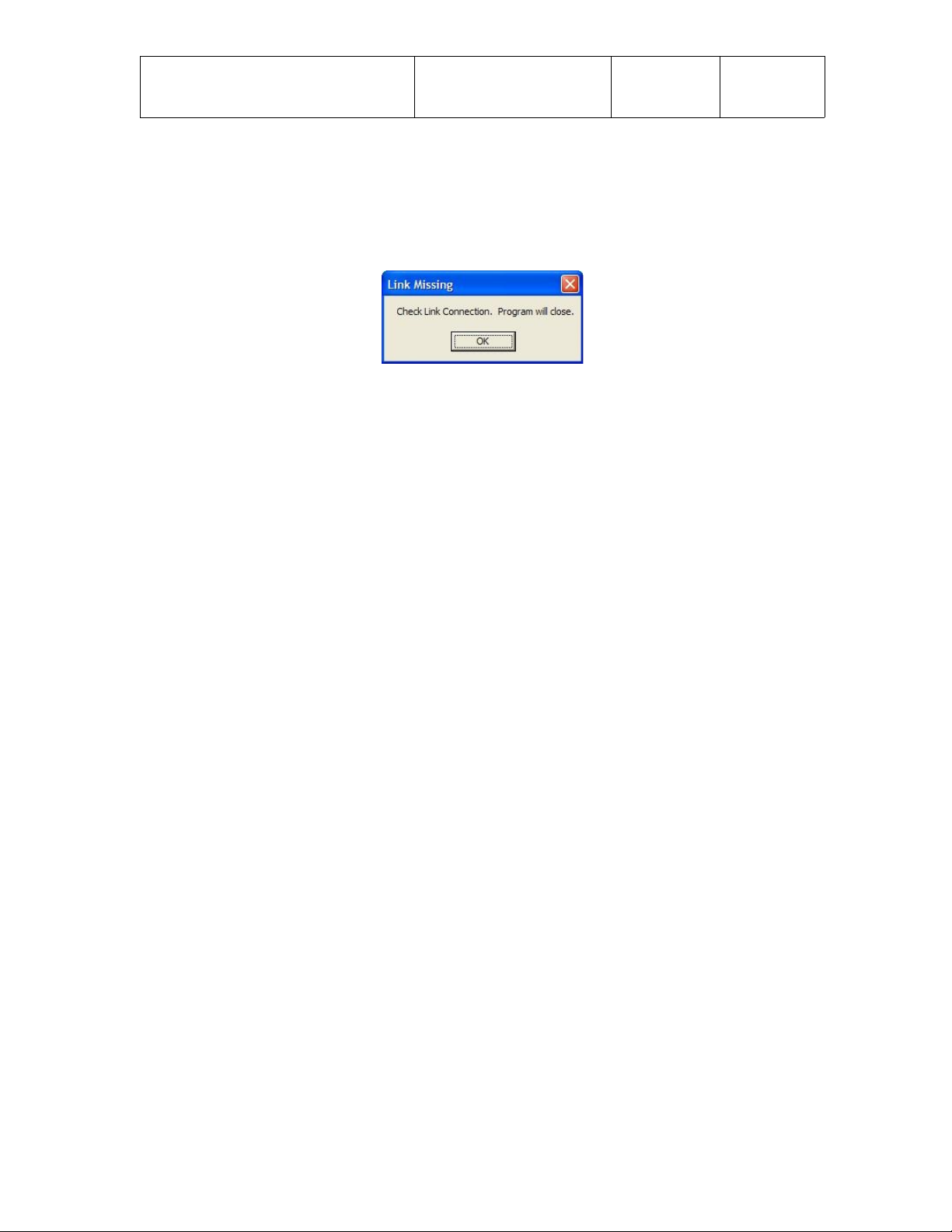

A known good ActiLink must be installed in the USB port of the test PC prior to starting

the application. If no ActiLink is present, or the ActiLink is not functioning properly, an

error message “Check Link Connection, Program will close” will be displayed

and the program will exit when the operator clicks on the “OK” tab as shown below.

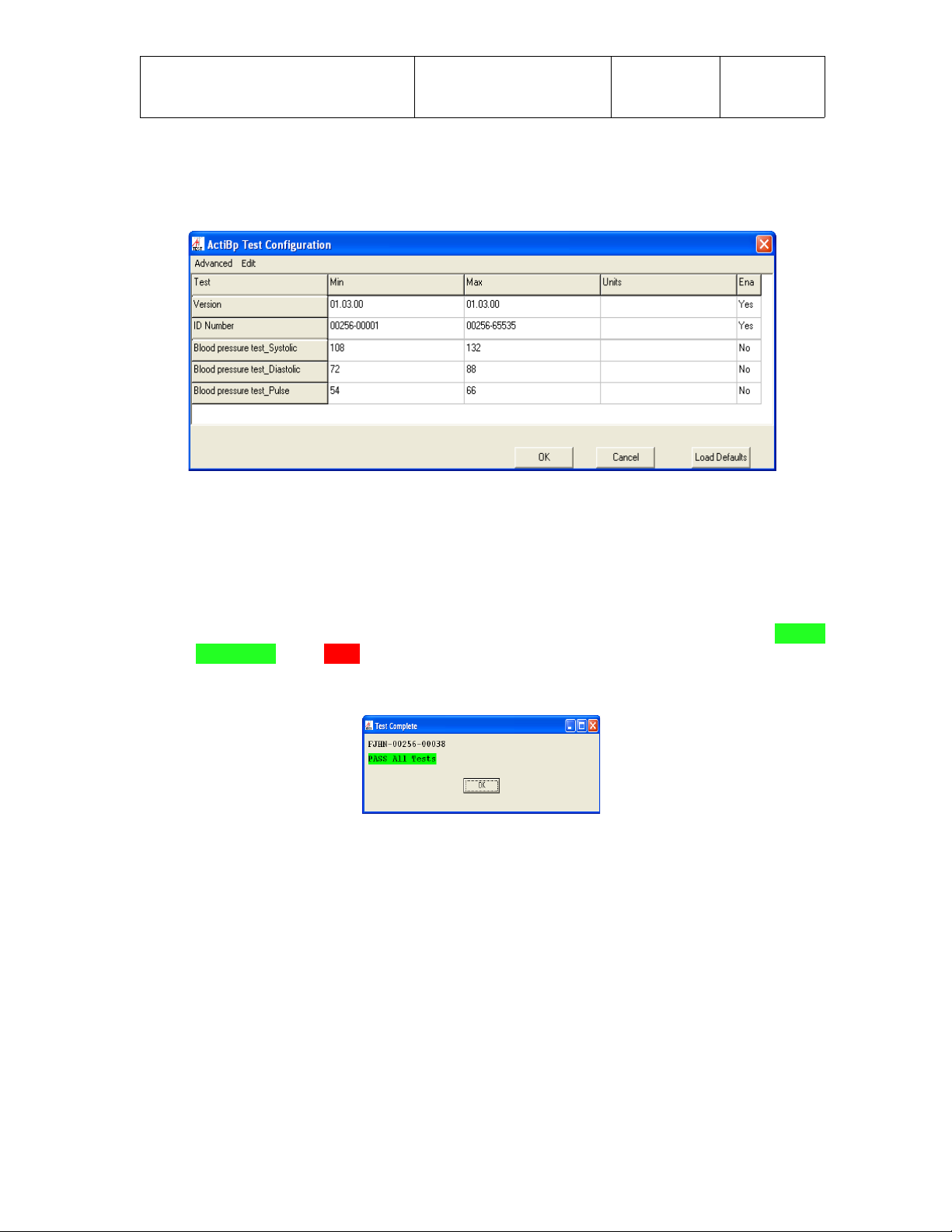

The application has a Test Configuration screen which allows manufacturing engineers

to enable/disable tests and set specific test parameters. Test configuration limits that

can be modified include firmware Version and ID Number. To access the Test

Configuration screen, the engineer would select “Edit”, then “Limits”, then enter the

password.

DOCUMENT NUMBER:

910-00059-01

REVISION:

08

PAGE:

5of 18

No password is set when the application is first installed. Select “OK” to access the

Test Configuration limits screen for the first time. To setup a password, select

“Edit”, then “Limits”. Select “Advanced”, then select “Password”. Enter the new

password and select “OK”. The new password is now required each time to access

the Test Configuration screen.

Once in the Test Configuration screen, the test “limits” should be set as follows for

Incoming Test of the UWM PCB;

● Version - Min and Max values should be set to reflect the latest revision of UWM

PCB firmware. The current firmware Version is 1.3.0

● ID Number - Min and Max values should be set to reflect the range of UWM PCB

ID Numbers for the BP monitor. The current ID Number range is from

00256-00001 through 00256-65535.

In the Test Configuration screen, each sub-test can be enabled or disabled as required

by entering Yes or No in the “Ena” column. For Incoming Test of the UWM PCB, the

tests should be enabled/disabled as follows and as shown in the screen capture below.

● Version - Enabled with a Yes in the Ena column.

● ID Number - Enabled with a Yes in the Ena column.

● Blood pressure test_Systolic - Disabled with a No in the Ena column.

● Blood pressure test_Diastolic - Disabled with a No in the Ena column.

SUBJECT:

A&D MEDICAL DIGITAL BLOOD

PRESSURE MONITOR ASSEMBLY

● Blood pressure test_Pulse - Disabled with a No in the Ena column.

DOCUMENT NUMBER:

910-00059-01

REVISION:

08

PAGE:

6of 18

Once the test limits have been correctly set as described above for Incoming Test of

the UWM PCB, select the “OK” tab. This will save the Test Configuration limit settings,

which will now be utilized each time the test application is started.

When the application has completed testing of a UWM PCB, a message with a PASS

ALL Tests or a FAIL status and the ID Number of the tested PCB will be displayed

across the top of the test screen, as shown below.

All results, pass or fail, are captured in a log file located in C:\Program Files\ActiBP

Manufacturing Test folder. The log file will also contain information regarding the Mfg.

Plant and test Station Number. To set the Plant and test Station Number, select

“Edit”, then “Location”, and enter the specific information. Select the “Ok” tab

when complete.

3.3 UWM Incoming Test Setup

A PC or laptop is required for Incoming Test of the UWM PCB. The PC or laptop

should be placed at one end of a non-metallic table top at a height of 36 inches (0.914

meters) from the floor. The ActiLink should be placed on the opposite side of the the

laptop or PC at a height of 36 inches (0.914 meters) from the floor using a USB

extension cable. Refer to photograph below.

Loading...

Loading...