Page 1

FiTech

Fuel Injection

T

M

Instruction Manual

for the following Go EFI Systems

30003 - Go Street EFI System

Note:

These kits are not

legal for use on pollu-

tion controlled vehicles

This Quick Start Manual is designed to get you up and

running with the Go Street Kit and either the 40003 Fuel

Command Center or the 40005 Inline Fuel Delivery Kit.

The FiTech Go EFI System is the industry's most advanced throttle body EFI system and also the easiest to

install. It includes a very advanced Handheld Controller

but is also capable of being far more tunable than any

Warning:

uct involving fuel system parts or gas tank modificaitons.

Work in a well ventilated area with an approved fire extinguisher readily available. Eye goggles and other safety apparel

should be worn to protect against debris and sprayed gaso-

Caution must be oberved when installing any prod-

30003 Kit Contents

(1) 4-Injector Throttle Body - Die Cast Finish (30003) (1) Harness

"A" (Plug-in pigtail user harness)

(1) ECU (Mounted on Throttle Body)

(1) Set of four or eight injectors pre-installed

(1) Idle Air Control (Installed on Throttle Body)

(1) Throttle Position Sensor (Mounted on Throttle Body)

(1) Coolant Sensor

(1) Handheld Controller w/billet case

(1) Wide Band O2Sensor

(1) O2Sensor Bung Kit

competitive product that utilizes a Handheld Controller.

Please read the full instruction manual before beginning

your installation.

These instructions cover the Basic Kit installation and

setup as well as general instructions for both of the optional Fuel Delivery Kits. For technical assistance with

your Go EFI System, call 951-340-2624.

line. We recommend having this installation performed by an

experienced qualified automotive technician. The finished installation must be thoroughly checked for any fuel system

leaks. All safety precautions must be observed when working

with fuel. Note: Do not use solid core ignition wires.

(1) Fuel Pressure Regulator (Installed in Throttle Body)

(1) Gasket Kit

(2) -06 AN Inlet/Outlet Fittings (Installed on Throttle Body

(2) Inlet/Outlet Port Plugs (Installed on Throttle Body)

(1) Data Com Cable

(1) 8 gigabyte SD Card (Installed in Controller)

(1) 3/8-NPT Reducer

(1) 10mm Port Plug

(1) Instruction Booklet

Table of Contents for Instruction Manual:

Kit Contents................................................................................. 1

About your FiTech Go EFI System................................................2

Fuel Delivery Requirements......................................................2/ 3

Oxygen Sensor Installation.......................................................3/4

Throttle Body Installation.............................................................4

About your FiTech Go EFI System

The Fitech Go EFI System will bolt directly to any 4-BBL

intake manifold. To fit on a spread bore 4-BBL manifold

will require an inexpensive adapater plate to avoid leaks.

Note that the FiTech throttle body will bolt directly to a

spread bore 4-BBL manifold but may leak without the

Coolant Temperature Sensor Installation.....................................4

Wiring the EFI System.................................................................5

Fan Circuit Wiring........................................................................5

Wiring Chart..............................................................................10

Wiring Schematics............................................................7 thru 9

adapter plate. Suitable adapter plates are available from

several suppliers such as Summit Racing (SUM-G1420).

The Fitech Go EFI System is self tuning once the simple

initial setup is performed using the Handheld Controller.

When the necessary initial inputs are made with the Hand-

Page 2

held Controller the Go EFI System creates a base fuel

MAP to get the engine running. Then the self tuning programming will fine tune the MAP to produce optimum

power and performance. Through the use of a wide band

O

sensor the system can continuously make adjust-

2

ments in the fuel delivery to provide the correct air/fuel

ratio under all climate and altitude conditions.

The ECU (computer) is mounted on the throttle body

thus eliminating the necessity of remote mounting the

ECU module and the need for an unsightly harness

draped over your engine. Several sensors are also integral to the throttle body assembly including the throttle

position sensor (TPS), manifold absolute pressure

(MAP), intake air temperature (IAT), and a fuel pressure

sensor.

Initial Programming: This simple procedure is performed using the Handheld Controller. A laptop computer

is not required. This unit plugs into the throttle body ECU.

After a few initial inputs are made the Handheld Controller

can be removed or left connected. When connected, there

is a dashboard and gauges screen that will show engine

parameters in real time.

Fuel Delivery Systems: You may have chosen one of the

two optional Fuel Delivery System Kits from FiTech. Instructions come with each kit. If using other fuel delivery

components you must use a 30-micron filter ahead of the

fuel inlet fitting on the Fitech throttle body.

Wide Band O

Sensor: This is the key component of any

2

EFI system. Only one sensor is required. This sensor continuously monitors the exhaust gas mixture and sends

the information to the ECU where adjustments are con-

stantly made to maintain the air/fuel targets.

Trigger Tach Signal: The FiTech EFI requires an rpm/trigger reference to operate. This is obtained by a connection

to the negative post on a 12V coil. On HEI distributors,

this connection is made to the "Tach" terminal that is indicated on the HEI distributor cap.

FiTech #40003 Fuel Command Center

Fuel Delivery Requirements

FiTech offers two different fuel delivery options. One is

the 40003 Fuel Command Center. When using this option,

you can configure the system to operate on a returnless

basis. The other fuel delivery system is the 40005 Frame

Mount Inline External Pump. Using this pump the system

must have a return line. The Fuel Command Center uses

your existing carbureted fuel pump and fuel lines to deliver the fuel to the Command Center which is mounted

in the engine compartment. The only plumbing required

is from the Center to the EFI.

High pressure hose and fittings are supplied with this

kit to plumb from the Command Center to the EFI throttle

body. A 340 L/PH EFI pump is submerged in the fuel in

the Command Center sump tank. The Center also has a

regulator and fuel pressure gauges.

When using the 30001/30002 Go EFI kits, the Com-

mand Center is suitable for engines making from 200 HP

to 600 HP. Either fuel delivery system can be used with

these EFI systems. When using the 8-injector 30012 Go

EFI System and the Fuel Command Center, the system is

suitable for engines making up to 800 HP. When combining the 30012 Go EFI System with the 40005 Inline

Pump, it is suitable for engines up to 600 HP.

Note: If you have elected to use the Fuel Command

Center and your vehicle currently has a high pressure fuel

injection pump, it must be replaced with a low pressure

carbureted style pump. Note that vehicles equipped with

factory high pressure EFI pumps are not compatible with

the Fuel Command Center.

If you choose to use some other fuel delivery system

other than FiTech, it is important to make sure that you

confirm its compatibility with the FiTech EFI system. Contact the FiTech technical staff to check compatibility. Failure to do so can void your warranty.

2

Page 3

Note the following special instructions:

• We recommend using the Fuel Command Center for all installations. A submerged pump is quieter and lasts longer.

• If using the Frame Mount Inline Fuel Pump, it should be mounted

s close to the fuel tank as possible and also as low as possible. It

a

should be within two to three feet of the tank. This type of pump is

designed to pump, not draw, and works best when gravity fed.

• Only use hard fuel lines when using proper EFI rated flared fittings.

Make sure that you remove ALL low pressure flex joints on factory

fuel lines and replace them with EFI rated fuel hose and use proper

flared connections and clamps. Be careful not to mix 45° and 37°

AN fittings , they look similar but will not work together. 45° fittings

usually come from a hardware store or auto parts store while 37°

AN fittings are the ones supplied by Fitech and most speed shops.

Remember that your system will be running at 58 PSI so consult a

rofessional if you are not certain about this portion of your instal-

p

lation. Fitech does not recommend aluminum fuel lines EVER! Or

ou can use the supplied EFI high pressure fuel hose that is supplied

y

in your Fuel Delivery Kit.

• Use the supplied push lock style hose ends only with the supplied

hose and vice versa. Intechanging hose ends and hose with other

rands could cause leaks.

b

VERY IMPORTANT NOTE: Your fuel tank must have a vent to prevent

pressure building up inside the tank.

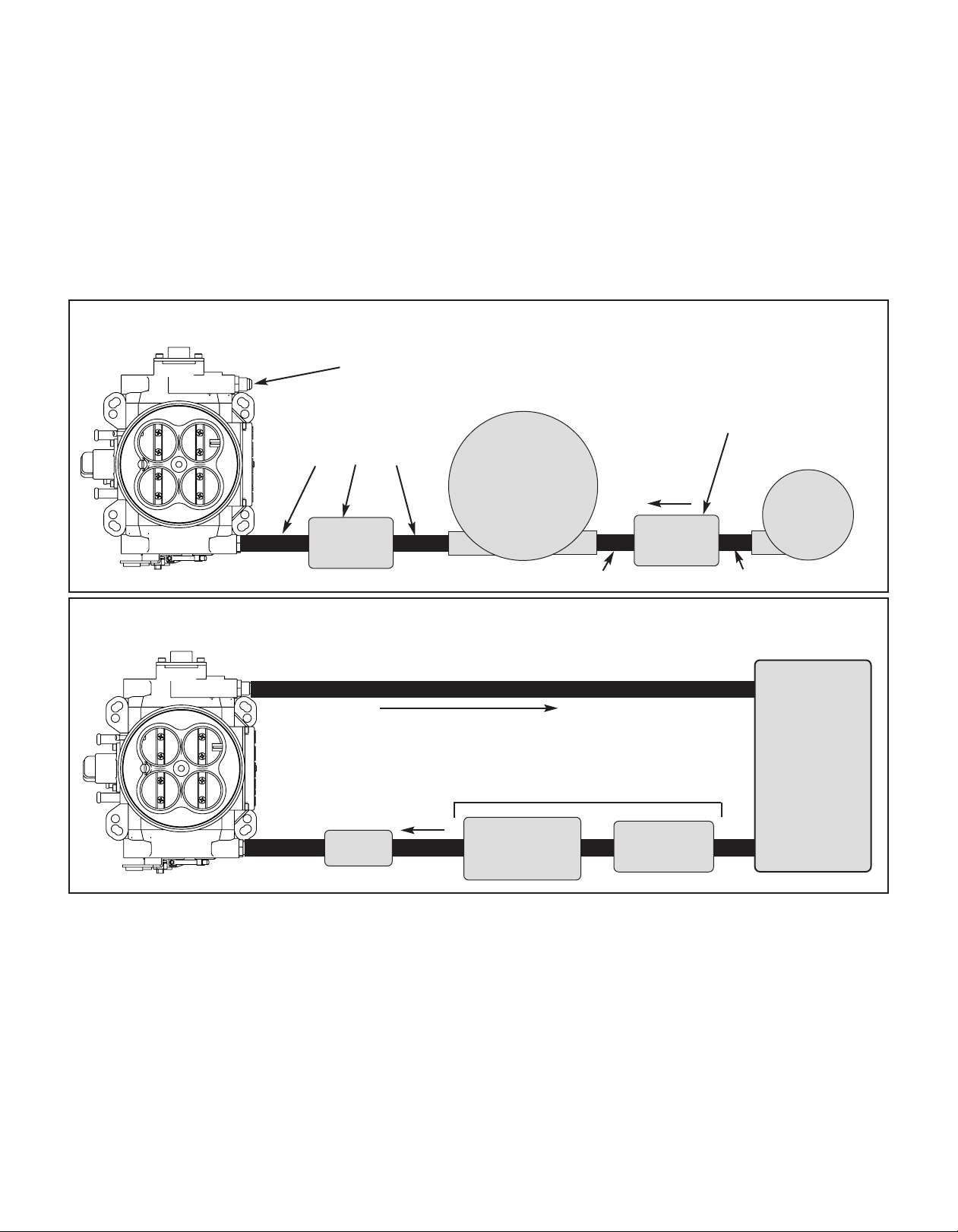

Plumbing Schematic for Fuel Command Center - Fuel Delivery Kit #40003

See separate Instruction Sheets that were provided witih this pump kit for complete details

Cap off Return Port

A carb style pre-filter is required to keep

Supplied EFI Grade Fuel Hose

plus push-lock style hose

ends, a fuel filter and fittings.

Fuel

Command

Center

Fuel Filter

debris from sticking the needle and seat

that is installed in the Command Center.

This replaces Stock Fuel Line

Plumbing Schematic for External Inline Pump - Fuel Delivery Kit #40005

See separate Instruction Sheets that were provided with this pump kit for complete details

Return fuel Line to tank

IN

3-8 PSI

Fuel Filter

Figure 1

Stock

Fuel

Pump

Figure 2

Must be mounted as low as the lowest point

IN

Post-Filter

Note:

Before starting any installation, disconnect the

ground connection on the battery. Be very careful when

disconnecting any fuel lines to let the fuel drain into a re-

Oxygen Sensor Installation

The supplied O2Sensor can be installed in either exhaust

bank. The Sensor cable connects to one of the cables

coming out of the ECU on the throttle body.

A. The ideal location for the Sensor is 2-4 inches after the

exhaust collector. It must always be at least 18-inches

from the exhaust tip. Where short or open headers are

utilized, install the sensor in the primary tube of the rear

Fuel Tank

of the Fuel Tank and within 2-feet of it

Fuel Pump

Pre-Fuel Filter

ceptacle or a dry cloth. Do not allow raw fuel to collect

on the engine as this is a fire hazard. Please observe extreme caution when working with the fuel system.

cylinder. Must be at least 8-inches from the exhaust port.

It will not work on "zoomie" style headers.

B.The sensor should be at least 10° above horizontal (see

figure #3) to allow condensation to run off. If this is not

adhered to, the sensor is susceptible to water damage.

C. Never position the sensor on the outside of a bend in

the tubing.

3

Page 4

D. The sensor must always be mounted ahead of any catalytic converter if so equipped.

E. Drill a 7/8" diameter hole in the desired location.

F. The supplied bung kit can either be welded in place or

clamped onto the pipe. The clamp-on style works well

and will not leak. If welded, make sure the bung is welded

completely all the way around and does not leak.

G. Install the sensor into the bung. WARNING: Do not

start the engine wiithout the sensor cable connected to

the throttle body and the EFI system is fully operational

or damage will occur to the sensor.

AIR LEAKS: It is important that no air leaks exist anywhere in the exhaust system between the sensor and the

engine. Any exhaust leaks will cause the unit to receive

Throttle Body Installation

Installing the throttle body is no different than replacing

the carburetor. Disconnect the throttle linkage and the

fuel line. Remove the existing carburetor from the intake

manifold. Clean the gasket surface of the manifold.

Vacuum Ports: Before installing the throttle body determine the engine's need for vacuum accessories. The

FiTech throttle body has five vacuum ports including

ported and manifold. These ports cover accessories such

as power brakes. There are three 3/16" male nipples and

two 3/8" male nipple. If you need more vacuum connections than this, you can purchase vacuum tees and vacuum hose at your local auto parts store. See Figures 4,

and 5 for location and use of various vacuum nipples.

Throttle Body Installation: Place the supplied gasket

onto the manifold and place the throttle body onto the

gasket. The throttle body linkage must be on the driver's

side of the engine. Install the original nuts and washers

onto the four carburetor studs. Tighten to 16 lb. ft. of

torque.

The FiTech throttle body has four fuel ports. Three inlet

and one return. Any one of three can be the inlet. The out-

let port is marked with the word "Return." On a returnless

setup the outlet port is plugged. Three plugs are provided

in the kit for the unused ports. Two plugs are installed in

the throttle body with one loose one in the kit. All three

plugs will be used on returnless configurations and only

two wil be used when the system will have a return line.

false readings. This

will lead to poor engine

performance, includ-

O2Sensor

Minimum

of 10°

ing misfires, and the

inability to properly

auto-tune the EFI. Continued running of the

system with an ex-

Exhaust

Collector

Figure 3

haust leak can create detonation and possible severe engine damage. Incorrect installation of the sensor, exhaust

leaks, and any resulting damage is not covered by the

FiTech manufacturer's warranty. Make sure your exhaust

is leak-free. This is very important.

Use this 3/8" nipple

for brake booster.

Use this 3/16" nipple for any

un-ported vacuum need, such

as transmission modulator.

Figure 4

Use this 3/16" nipple for ported

vacuum. (Distributor Advance)

Use this 3/8" nipple

for PCV connection.

A

Figure 5

Coolant Temperature Sensor Installation

The Temperature Sensor should be threaded into one of

the ports in the intake manifold or cylinder head. The sensor threads are 3/8-NPT. Some manifolds have 1/2-NPT

ports and in this instance use supplied pipe reducer. Con-

nect the Yellow/Black wire lead from the throttle body to

the sensor. Snap the connector into the sensor. Use

Teflon tape or a quality pipe sealant on both the pipe reducer (if used) and on the temperature sensor.

4

Page 5

Wiring the EFI System

The supplied Harness "A" (see Figure 7) plugs into mating Connector "B" from the throttle body mounted ECU.

See Figure 8. The various wires will need to be extended

to make required connections. See the Wire Chart on

page 6 which lists each wire used in the system and what

it connects to. It is strongly suggested that any wire extensions are made with the same gauge and color wire

as is used in the

supplied Harness. Make connections as a

soldered joint

rather than as a

crimped connection. Utilize a

shrink wrapped

sleeve covering

all connections.

round

G

Fan 1 - Yellow Wire, or

Fan 2 - Black Wire

ee Wire Chart on Pg. 6

S

Fan Circuit

Fuse

Battery

30

6

8

5

8

elay

R

87

Fan

Ground

Ign/Acc

Circuit Fuse

G

round

Wiring Harness

"A"

6-Pin

Figure 7

Connector

Harness "A" plugs into connector "B" from throttle body

mounted ECU. See Figure 8 and page 6 Wiring Chart.

Connects to O

Sensor Cable

Connects to Coolant

Temperature Sensor

Yellow/Black Wires

2

Handheld Controller

connections

Figure 8

The above photo shows all of the cables that are associated with the FiTech Go EFI System throttle body. The

large cable at the bottom left connects to the supplied

6-Pin Connector "B"

connects to Harness "A"

shown in Figure 7

Harness "A" which contains the main six wires used in

the system. The large coiled cable at top left connects to

the supplied Oxygen Sensor cable.

5

Page 6

Wiring Chart

The Chart below lists all of the wires in the FiTech Go EFI

System. The wires are color coded and the wires that are

part of Harness "A" are all marked for where they go.

There are six wires in Harness "A." Four of them are required connections and two are optional. More detailed

connection information (Figures 9 through 11) is provided on later pages of these instructions.

The Following Wires Are Used In All Systems (6-Pin Connecctor)

Req./Opt. Wire Color Description

Required Red (Large) Main power. Connect this wire directly to the positive (+) terminal of the battery. This circuit

needs to be live even when the switch is off so that the self learning files are maintained. This is

fused with a 25 amp fuse.

Required Yellow/Black This wire connects to the Engine Coolant Temperature Sensor

Required Blue This is the tach input wire which triggers the system. It connects to the 12V Negative terminal of

the coil. On HEI distributor it connects to the "Tach" terminal on the distributor cap or connects

to a tach output on a CDI box.

Optional Black The black wire can provide the following function when grounded:

1. RPM kicks up when A/C is activated.

Required Orange (Large) Fuel Pump circuit. This wire provides 12V to the fuel pump and connects to the positive (+) ter-

minal on the pump. No relay is required.

Required 0

Required Wiring Harness A This connects to Connector "B" from ECU. See Figures 7 and 8 (Page 5).

Required White On/Off - Connect this wire to a switched 12V circuit. Must be on during both "Key On" and

Optional Yellow Fan Circuit #1. This wire goes to the ground terminal of the fan relay.

Harness This cable from ECU connects to the Wide Band Oxygen Sensor harness.

2

"Cranking." DO NOT connect to the coil terminal when using an external CDI box such as an

MSD 6A or any other CD ignition.

Wiring Diagrams

On the following three

pages are various wiring

diagrams that address the

most common ignition

arrangements that will be

found. Each diagram will

show you the specifics of

how to wire your FiTech Go

EFI System for that particular ignition setup.

#40005 Frame Mount Inline Fuel Delivery Kit

6

Page 7

Handheld Controller

Sensor

Coolant Temperature

Yellow/Black Wire

Oxygen Sensor

Ready-to-Run Distributor

(-)

Coil

distributor & coil

Existing connection between switch,

Ignition Switch

(+)

Blue Wire - Connect

to Negative Coil Post

(-)

(+)

FiTech Go EFI Throttle Body

Black Wire

White Wire

Ground

6-Pin

Connector

Large Red Wire

Battery

Vehicle

Large Orange Wire

ECU on the EFI throttle body

This harness is a permanent connection to

Wiring Connections for FiTech Go EFI System with Ready-to-Run Distributor

how to connect a ready-to-run distributor. Figure 11 is for an HEI distributor.

Selecting the correct wiring schematic: Review Figures 10 through 11 and

Figure 11 is also for a system with an external CDI box.

select the schematic that suits your particular application. Figure 10 shows

Inline Fuel Pump

shown. Connections

are the same for the

Fuel Command Center

Electric Fan

Yellow Wire (Connect to fan relay ground)

Indicates a splice. It is

recommended that all

splices be made as a

soldered connection.

Figure 9

7

Page 8

Handheld Controller

Sensor

Coolant Temperature

Yellow/Black Wire

Oxygen Sensor

HEI Distributor

Blue

Wire to "Tach"

Connect Green

terminal on cap

Blue Wire

Ignition Switch

(-)

(+)

FiTech Go EFI Throttle Body

Black Wire

White Wire

Ground

6-Pin

Connector

Large Red Wire

Battery

Vehicle

Large Orange Wire

ECU on the EFI throttle body

This harness is a permanent connection to

Wiring Connections for FiTech Go EFI System with HEI Distributor

Inline Fuel Pump

shown. Connections

are the same for the

Fuel Command Center

Yellow Wire (Connect to fan relay ground)

Indicates a splice. It is

recommended that all

splices be made as a

soldered connection.

Electric Fan

Figure 10

Use this wiring schematic if you are utilzing an HEI distributor without an

external CDI box, such as a MSD 6AL or similar aftermarket ignition box.

8

Page 9

Distributor

Sensor

Conventional Two-Wire

Coolant Temperature

Throttle Body

FiTech Go EFI

Yellow/Black Wire

Handheld Controller

Oxygen Sensor

similar aftermarket ignition box

Coil

External CDI Box such as an MSD 6Al or

from CDI Box

to "tach out" wire

Blur Wire connects

Switch

Ignition

(-)

(+)

White Wire

Ground

Black Wire

ECU on the EFI throttle body

This harness is a permanent connection to

6-Pin

Connector

Large Red Wire

Battery

Vehicle

Large Orange Wire

Wiring Connections for FiTech Go EFI System with External CDI Box

Inline Fuel Pump

shown. Connections

are the same for the

Fuel Command Center

Yellow Wire (Connect to fan relay ground)

Indicates a splice. It is

recommended that all

splices be made as a

Electric Fan

soldered connection.

Figure 11

with an external CDI box, such as a MSD 6AL or similar aftermarket ignition box.

Use this wiring schematic if you are utilzing a conventional two-wire distributor

9

Loading...

Loading...