DC100 Digital Dispenser

Operating Manual

© 2015 Fisnar | Phone: (262)253-8600 | E-mail: info@fisnar.com

Table of Contents

Product Safety Statement 4

Specifications 6

Accessories 6

External Controls 7

Machine Setup 8

Dispense Setup 9

Operation 10

Controls 11

Dispense Modes 13

DC100 Digi

tal Dispenser Operatin

g Manual

Purge Mode

Teach Mode

Timed Mode

Time+ Mode

Int Mode

Function Menu 18

Unlock / Lock

Add Dispense T i me

Glue Alarm

Pressure Alarm

Vacuum Alarm

Auto Purge

Power Switch

Dispense Count

Dispense Time

Used Time

Calibration 29

Pressure Regulator Calibration

Vacuum Regulator Calibration

External Control

13

14

15

16

17

19

20

21

23

24

26

27

27

28

28

30

31

32

I/O Connections

I/O Schematic

Multiple Dispensers

© 2015 Fisnar | Phone: (262)253-8600 | E-mail: info@fisnar.com

© 2015 Fisnar

32

33

34

- 2 - DC100 Rev G

DC100 Digital Dispenser Operatin

g Manual

OVERVIEW

Model DC1

The DC100 digital dispenser, with its versatile design, makes it perfectly suited for a wide

variety of dispensing applications; from microdot deposits, to large potting and filling.

Adjustable air output pressure and vacuum function with digital display.

A multi-purpose, programmable alarm timer to disable the dispenser after a specific amount of

time – useful for automated applicat

(i.e. two-co

Tolerance on the input air pressure can be set to ensure consistent pressure all throughout the

dispensing

mponent, pre-mixed frozen, etc.).

.

00 Digital Dispenser

ions and materials with shortened shelf life and/or

pot life

© 2015 Fisnar

- 3 -

DC100 Rev G

DC100 Digital Dispenser Operatin

Y

SAFET

Do not operate the unit in excess of its maximum ratings / settings.

Make sure that the input air supply is clean and dry.

If corrosive or flammable fluids are being used, an inline filter must be installed to

help prevent the fluids from being sucked back into the unit.

The fluid being dispensed may be toxic and / or hazardous. Refer to the Material

Safety Data Sheet for proper handling and safety precautions.

Do not smoke or use near an open flame when flammable materials are being

dispensed.

Do not expose the dispenser directly to sunlight.

Avoid cleaning the dispenser with aggressive solvents – neutral detergents are

preferred.

Do not overfill the barrel and/or lay the barrel on its side. This will prevent fluids

from flowing back into the unit – refer to figures A & B below.

g Manual

If the DC100 malfunctions, shut down the unit immediately. This can be done by

either pressing the power switch or disconnecting the power cord.

© 2015 Fisnar

DC100 Malfunction

- 4 -

DC100 Rev G

DC100 Digital Dispenser Operatin

g Manual

Inappropriate Use

If the DC100 is used in a way other than described in this manual, it may cause damage to

self or property.

Do not use any components with the DC100 other than Fisnar authorized

components.

Do not use incompatible materials.

Do not make any modifications to the DC100.

All repairs are to be done by Fisnar trained employees.

Do not operate the unit in excess of its maximum ratings / settings.

Fire Prevention

Refer to the following instructions to avoid any fire or explosion.

Access your surroundings and the location of the nearest fire extinguisher and

Emergency Exit.

Do not smoke or use near an open flame when flammable materials are being

dispensed.

Immediately disconnect power if any sparking or smoke appears.

Do not expose the dispenser directly to sunlight.

Maintenance

The DC100 is generally a maintenance free dispenser. However, to ensure smooth

operation please follow the below instructions.

Only use non-woven cleaners on the LCD.

Avoid cleaning the dispenser with aggressive solvents – neutral detergents are

preferred.

Ensure that compressed air supply to the DC100 is clean and moisture free.

Do not lay the barrel on its side. This will prevent fluids from flowing back into

the unit.

© 2015 Fisnar

- 5 -

DC100 Rev G

DC100 Digi

tal Dispenser Operating M

SPECIFICATIONS

Dimensions: 180 × 195 × 80 (W × D × H mm)

Weight: 0.9 KG (1.9 lbs.)

Input Voltage: 100 – 240 VAC

Rated Power: 18W

Cycle Rate: 600+/min

Relative Humidity: 20 – 90% (no condensation)

anual

Operating Temperature:

10 – 40Ԩ (50 – 104Ԭ)

Timer: 0.008s – 9999s

Air Input: 100 psi ( 7 bar ) max

Air Output: 0 – 100 psi ( 7 bar)

ACCESSORIES

Item Quantity

Power Adapter (Input: 100 – 240 VAC / Output: 24 VDC ) 1

Foot Pedal 1

Air Inlet Hose 1

Syringe Holder

Push To Connect Tube Fitting 1/4" Stem OD X 5/32" Tube OD

Push Tube Fitting 1/4" OD Tube x1/8" NPT

1

1

1

● Note: Consumable kit (part # QK-CSK) & needle sample kit (part # QK-NSK) available to purchase

separately.

© 2015 Fisnar

Part # QK-

CSK

Part # QK-NSK

-

6 - DC100 Rev

G

DC100 Digital Dispenser Operatin

g Manual

EXTERNAL CONTROLS

IFICATIONS

Item Illustration Item Illustration Item Illustration

1 Vacuum Control 7 Scroll Buttons 13 Air Inlet Port

2 Air Outlet Port 8 Shot / Purge Button 14

3 Power Button 9 Display 15 Fuse

4

5

6 Set Button 12 I/O Connector

© 2015 Fisnar

Function / Escape

Button

Mode Button

FIG. 1: Exte

10

11 Power Input Connector

rnal Controls

Air Pressure

Regulator

- 7 -

Foot Switch Connector

16 Exhaust Port

DC100 Rev G

DC100 Digital Dispenser Operating M

anual

MACHINESETUP

FIG. 2: Front and Back Views

1. Connect air hose (1) from compressed air 70-100psi (5-7 bar) to the air inlet port on the back

of the dispenser. See FIG. 2.

2. Insert the Foot Switch connector (2) to the port on the back of the dispenser. See FIG. 2.

3. Connect Electrical Power Cord (3) to the port on the back of the dispenser. See FIG. 2.

© 2015 Fisnar

8 - DC100 Rev G

-

DC100 Digital Dispenser Operating Manual

DISPENSE SETUP

4. Fill the barrel (with barrel tip cap on the barrel) with material to be dispensed. Attach barrel to

barrel adapter head as shown below. See FIG. 3.

Do not overfill the barrel and/or lay the barrel on its side. This will prevent fluids

from flowing back into the unit – refer to figures A & B below.

5. Connect the barrel adapter air tube with the “Air Out” port on the front of the dispenser. (4)

See FIG. 2.

FIG. 3: Dispenser Set Up

© 2015 Fisnar - 9 - DC100 Rev G

DC100 Digital Dispenser Operatin

OPERATION

Manual

g

Program

Mode

Features

Parameters

Main Screen Display

Displays the currently selected program. Up to ten (10) individual programs can be

saved to the DC100 for future recall.

Displays the current mode the saving program is in. There are five (5) dispense modes

available: PURGE, TEACH, TIMED, TIME+ and INT.

Displays which feature(s) are currently turned ON (i.e. Lock, Glue Alarm, Pressure

Alarm, Vacu um Alarm and Auto Purge).

Displays the values of the saved parameters (i.e. dispensing time, pressure and

vacuum).

© 2015 Fisnar

- 10 - DC100 Rev G

DC100 Digital Dispenser Operatin

g Manual

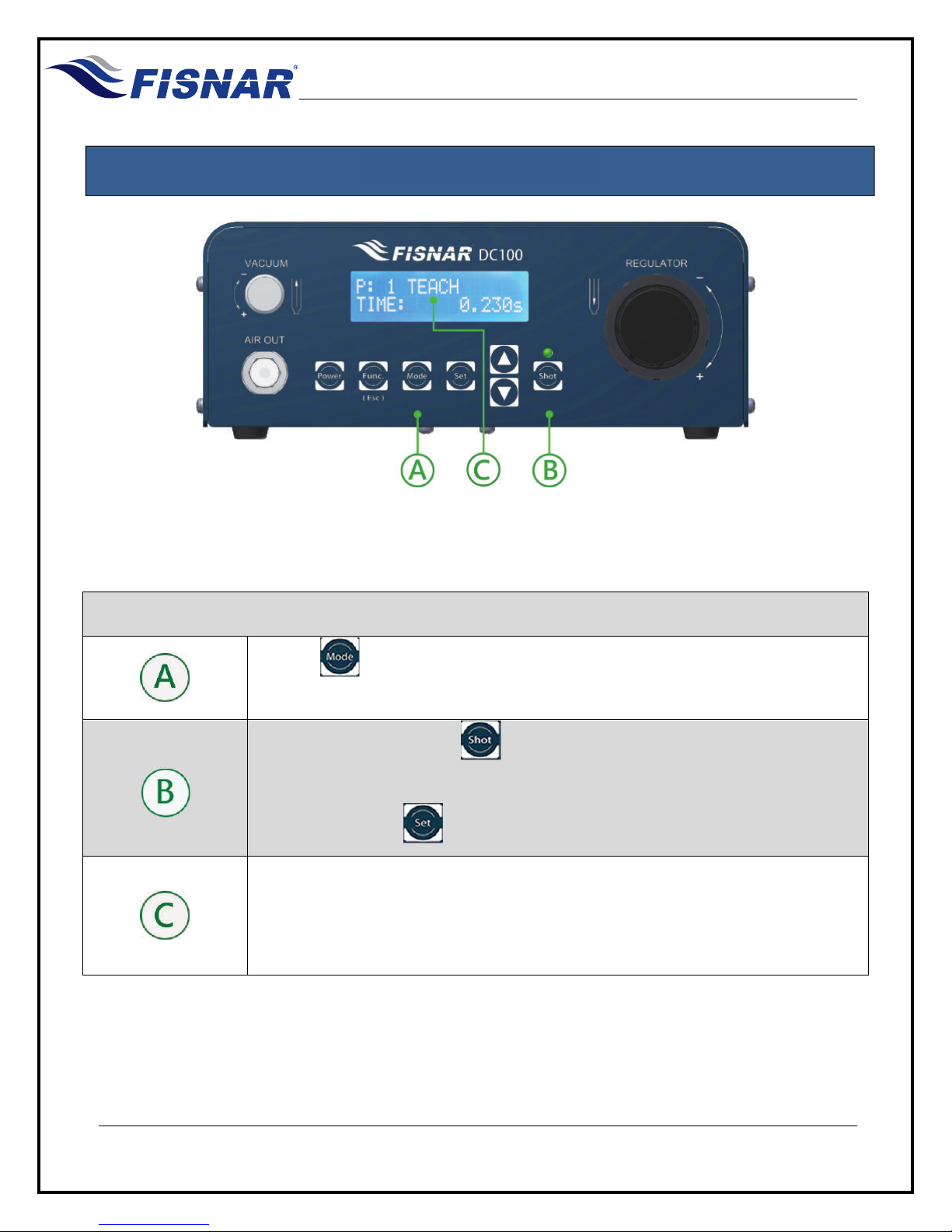

CONTROLS

Power On

Power Off

Switch Modes

Set Parameters

Switch Programs

Press the key when the machine is OFF to turn the machine ON.

Press the key when the machine is ON to save everything and turn the

machine OFF.

Press the key to set the program to the required dispense mode (i.e.

PURGE, TEACH, TIMED, TIME+, INT).

Press the key to scroll through the dispense parameter settings (i.e.

TIME, PRES and VAC).

Press the keys to switch programs – see below.

Set Pressure

Set Vacuum

Switch Units

© 2015 Fisnar

Press the key to display the current setting. Turn the regulator knob

clockwise to increase the pressure as needed.

Press the key to display the current setting. Turn the vacuum knob

clockwise to increase the vacuum as needed.

Press the keys while adjusting pressure or vacuum to switch

between pressure unit displays (i.e. psi, kgf/cm2, MPa, kPa and bar).

FIG. 4: Con

- 11 -

trols

DC100 Rev G

DC100 Digital Dispenser Operatin

g Manual

CONTROLS

Press the key to display the current setting. Press the keys to

change the time values. Note that the time can only be set under TIMED, TIME+

or INT modes.

Press the key again to choose which decimal place to edit, including the

position of the decimal point.

Set

Time/Interval

Enter Function

Menu

Press and hold the key to save.

Press the key to enter the function menu.

FIG. 5: Controls

Dispense Shot

© 2015 Fisnar

Press the key to run the currently selected program and actuate the

machine.

- 12 -

DC100 Rev G

DC100 Digital Dispenser Operatin

g Manual

DISPENSE MODES

FIG. 6: Disp

ense Modes

PURGE MODE

Use the key to switch to PURGE mode.

PURGE mode allows the operator to activate the machine on demand

whenever the dispense signal is tripped (i.e. foot pedal is pressed).

Press the foot pedal or the key to start the machine. Release to stop.

The TIME shown will reset to zero (0) seconds every time the machine is

cycled.

© 2015 Fisnar

- 13 -

DC100 Rev G

DC100 Digital Dispenser Operatin

g Manual

DISPENSE MODES

FIG. 7: Dispense Modes

TEACH MODE

Use the key to switch to TEACH mode.

TEACH mode allows the operator to record the dispense time.

Press the foot pedal or the key to start the machine. Release to stop.

The TIME shown will be cumulative from every time the machine is cycled.

Press and hold the key to reset the timer to zero (0).

The time shown on the screen will be the total time the machine is cycled.

Once the time required is obtained, switch to TIMED, TIME+ or INT mode to

save the value.

© 2015 Fisnar

- 14 -

DC100 Rev G

DC100 Digital Dispenser Operatin

g Manual

DISPENSE MODES

FIG. 8: Disp

ense Modes

TIMED MODE

Use the

TIMED mode allows the operator to dispense material at a fixed time interval.

Press the keys to change the time values.

,

Press the key again to choose which decimal place to edit, including the

position of the decimal point.

Press and hold the key to save.

Press the foot pedal or the key to start the machine. The machine will

continue dispensing until the set time is satisfied.

Pressing the key will stop the dispensing regardless of whether the set

time is up or not. This shot will be considered “incomplete” and will not count

towards the cumulative dispense counter. The timer will reset to the original

programmed time value.

key to switch to TIMED mode.

© 2015 Fisnar

- 15 -

DC100 Rev G

DC100 Digital Dispenser Operatin

DISPENSE MODES

g Manual

FIG. 9: Dispense Modes

TIME+ MODE

Use the key to switch to TIME+ mode.

TIME+ mode allows the operator to program a second timed shot, useful for making

slight adjustments on the dispense time without changing the original value in

TIMED mode.

This mode is suitable for sensitive (temperature, humidity, short pot life, etc.)

materials that require tweaking of the timed value (or pressure) over time to achieve

consistency on the dispensed amount.

Press the keys to change the value.

Press the foot pedal or the key to start the machine. The machine will continue

dispensing until the set time is satisfied.

Pressing the key will stop dispensing regardless of whether set time is up or not.

This shot will be considered “incomplete” and will not count towards the cumulative

dispense counter. The timer will reset to the original programmed time value.

The time value saved under TIME+ mode will not affect the values in other modes

(i.e. TIMED, INT). However, changing the time value in other modes will also change

the value in TIME+ mode.

© 2015 Fisnar

- 16 -

DC100 Rev G

DC100 Digital Dispenser Operatin

g Manual

INT

DISPENSE MODES

FIG. 10: Dispense Modes

INT MODE

Use the key to switch to INT mode.

INT mode allows the operator to control the material being dispensed within the

programmed dispense time interval. This combines the precision of a timed shot

with the flexibility of an operator control shot.

,

Press the keys to change the time values.

Press the key again to choose which decimal place to edit, including the

position of the decimal point.

Press and hold the key to save.

Press the foot pedal or the key to start the machine. Release to stop. The

timer will continue to count down until, either: (1) the foot pedal is released, or; (2)

the set time is satisfied.

The timer will only reset to the original programmed time value once it reaches zero

(0).

A full shot cycle is counted towards the cumulative dispense counter whenever the

timer reaches zero (0).

© 2015 Fisnar

- 17 -

DC100 Rev G

DC100 Digital Dispenser Operatin

g Manual

FUNCTION MENU

TheDC100 controller offers built-in functions that provide additional control to any dispensing

application.

Instructions:

Press the key to enter the Function menu.

Press the

keys to scroll through the available built-in functions.

Press the

Press the

Overview:

Function Description

1. Unlock / Lock Locks or unlocks the controls.

2. Add Dispense

Time

3. Glue Alarm

4. Pressure Alarm

5. Vacuum Alarm

6. Auto Purge

7. Power Switch

8. Dispense Count

9. Dispense Time

10. Used Time

key to enter the selected function menu.

key to exit.

Sets the amount of time added to the TIME+ value after a

predetermined number of shots.

Sets the tot

barrel or cartridge.

Sets the pressure and to

dispensing conditions.

Sets the vacuum and tol

conditions.

Sets the dispense time and delay time for auto

material.

Unit is turned on by power being supplied to it instead of using

the on/off switch.

Displays the total number of disp

cycle. This counter is resettable.

Displays the total dispense time made per work cycle. This timer

is resettable.

Displays the total numb

This timer is not resettable.

al amount of dispense time required to empty the

lerance required for optimum

erance required for optimum dispensing

matic purging of

ensed shots made per work

er of hours the machine is being used.

© 2015 Fisnar

- 18 -

DC100 Rev G

DC100 Digital Dispenser Operatin

g Manual

FUNCTION MENU

1. Unlock / Lock

This funct

the button will function if the lock is engaged.

1.

ion allows the user to lock the dispenser controls so it cannot be inadvertently modified. Only

FIG. 11: Unlock/Lock Function

There is only one (1) parameter required for this function: MODE. Use the buttons to

toggle between locked and unlocked state. See FIG. 11.

2.

A letter “L” will show on the main screen when the machine is locked. See FIG. 12.

© 2015 Fisnar

FIG. 12: Locked

- 19 -

DC100 Rev G

DC100 Digital Dispenser Operatin

FUNCTION MENU

2. Add Dispense Time

g Manual

This functio

predetermined number of shots were made. This functionality is particularly useful to control the dispensed

material amount as the barrel or cartridge empties over time.

This function is used in conjunction with the TIME+ mode.

1.

2.

3.

n allows the user to program a cumulative time offset added to the original timed shot after a

FIG. 13: Add Dispense Time

There are three (3) parameters required for this function: MODE, Trigger Count and Add Time. Press

the key to scroll through these parameters.

Use the keys to turn the Add Dispense Time MODE On or Off.

Use the keys to set the Trigger Count value (predetermined number of shots). Press and

hold the key to save.

Use the keys to set the Add Time value. Press the key again to choose which

4.

decimal place to edit, including the position of the decimal point. Press and hold the key to

save.

A plus “+” symbol will show on the main screen when this function is turned ON.

5.

FIG. 14: Ad

© 2015 Fisnar

d Dispense Time

- 20 -

DC100 Rev G

DC100 Digital Dispenser Operatin

Manual

g

FUNCTION MENU

3. Glue Alarm

io

This funct

material is either no longer useable, or its optimal working life has been reached. This functionality is

particularly useful for sensitive (moisture, temperature, light, etc.) or multi-component materials which have

strict pot-life or working life dispensing requirements.

n allows the user to set a timer that will trigger a visual and audible alarm to indicate when the

FIG. 15: Glue Alarm

There are three (3) parameters required for this function: MODE, Reset Time and Glue Time. Press

1.

the key to scroll through these parameters.

2.

Use the keys to turn the Glue Alarm MODE On or Off.

3.

Reset Time shows the time left before the alarm sounds. Press and hold the key while under

Reset Time to reset the timer.

Use the keys to set the Glue Time value. Press the key again to choose which

4.

decimal place to edit, including the position of the decimal point. Press and hold the key to

save.

A letter “G” will show on the main screen when this function is turned ON.

5.

© 2015 Fisnar

- 21 - DC100 Rev G

DC100 Digital Dispenser Operating M

FUNCTION MENU

FIG. 16: Glue Alarm

Once the Glue Time has been reached, the letter “G” on the display will start blinking (see FIG.

6.

16), and the key indicator light will turn ON. See FIG. 17. Pressing the

stepping on the foot pedal at this point will trigger an alarm.

button or

anual

7.

Press the key to clear the alarm screen. Reset the alarm timer.

© 2015 Fisnar

FIG. 17: Alarm Timer

- 22 - DC100 Rev G

DC100 Digital Dispenser Operating M

anual

FUNCTION MENU

4. Pressure Alarm

This function allows the user to set a pressure value threshold (as well as a corresponding percentage

tolerance) before the machine can be operated. A visual and audible alarm will trigger if the pressure is not

within tolerance.

FIG. 18: Pressure Alarm

There are three (3) parameters required for this function: MODE, Pressure and Tolerance. Press

1.

the key to scroll through these parameters.

2.

Use the keys to turn the Pressure Alarm MODE On or Off.

3.

Use the keys to set the required Pressure. Press and hold the key to save the

current pressure setting.

4.

Use the keys to set the required Tolerance.

5.

A letter “P” will show on the main screen when this function is turned ON.

Whenever the pressure value is outside of its tolerance, the letter “P” on the display will start

6.

blinking, and the key indicator light will turn ON. Pressing the button or stepping on the

foot pedal at this point will trigger an alarm.

7.

Press the key to clear the alarm screen. Check the inlet pressure and adjust it as needed.

© 2015 Fisnar

- 23 - DC100 Rev G

DC100 Digi

tal Dispenser Operatin

g

Manual

FUNCTION MENU

FIG. 19: Pressure Alarm

5. Vacuum Alarm

This function allows the user to set a vacuum value threshold (as well as a corresponding percentage

tolerance) before the machine can be operated. A visual and audible alarm will trigger if the vacuum is not

within tolerance.

FIG. 20: Vacuum Alarm

© 2015 Fisnar

- 24 - DC100 Rev G

DC100 Digital Dispenser Operatin

There are three (3) parameters required for this function: MODE, Vacuum and Tolerance. Press the

1.

key to scroll through these parameters. See FIG. 20.

2.

Use the

3.

Use the keys to set the required Vacuum. Press and hold the key to save the

current vacuum setting. See FIG. 20.

4.

Use the keys to set the required Tolerance.

5.

A letter “V” will show on the main screen when this function is turned ON. See FIG. 21.

keys to turn the Vacuum Alarm MODE On or Off. See FIG. 20.

Manual

g

FUNCTION MENU

FIG. 21: Tolerance

Whenever the vacuum value is outside of its tolerance, the letter “V” on the display will start

6.

blinking, and the

stepping on the foot pedal at this point will trigger an alarm.

7.

Press the key to clear the alarm screen. Check the vacuum setting and adjust as needed.

key indicator light will turn ON. See FIG. 22. Pressing the

FIG. 22: Vacuum Alarm

button or

© 2015 Fisnar

- 25 - DC100 Rev G

DC100 Digital Dispenser Operatin

FUNCTION MENU

Manual

g

6. Auto Purge

io

This funct

unit is idle. This functionality is particularly useful for sensitive (moisture, temperature, light, etc.) or

multi-component materials which have strict pot-life or working life dispensing requirements. This

prevents premature curing of material along the fluid lines or at the tip.

n allows the user to set an automatic dispense time in pre-defined intervals whenever the

FIG. 23: Auto Purge

There are three (3) parameters required for this function: MODE, Delay Time and Dispense Time.

1.

Press the key to scroll through these parameters.

2.

Use the keys to turn the Auto Purge MODE On or Off.

Use the keys to set the Delay Time value. Press the key again to choose which

3.

decimal place to edit, including the position of the decimal point. Press and hold the key to

save.

Use the keys to set the Dispense Time value. Press the key again to choose

4.

which decimal place to edit, including the position of the decimal point. Press and hold the

key to save.

A letter “A” will show on the main screen when this function is turned ON.

5.

© 2015 Fisnar

FIG. 24: Dispense Time

- 26 - DC100 Rev G

DC100 Digital Dispenser Operating M

anual

FUNCTION MENU

7. Power Switch

This function allows for

the power button on the unit. This can be helpful when the DC100 is being used as part of a larger

system that has a main power switch, the unit can now start up and be ready for use when the main

power is turned on to the system.

1.

When you are at the Power Switch mode press the key to enter the settings page for

the Power Switch function.

the DC100 to be turned

FIG. 25: Power Switch

on by supplying power to the unit instead of pushing

2.

Use the keys to turn the Power Switch Mode On or Off.

3.

After selecting your mode press the key to store and exit the function.

8. Dispense Count

This function displays the total number of completed cycles made by the mac

dispensing signal from all modes (except for shots made under Teach mode) is accumulated to

the Dispense Count counter. Auto Purge and incomplete timed shots however, are not recorded.

The counter is resettable.

FIG. 26: Dispense Count

hine. Every

1.

When you are at the Power Switch mode, press the key to enter the settings page for

the Power Switch function.

© 2015 Fisnar

27 - DC100 Rev

-

G

DC100 Digital Dispenser Operating M

anual

FUNCTION MENU

9. Dispense Time

This function displays t

dispensing time from all modes is accumulated to the Dispense Time timer regardless of whether

the full timed shot was completed.

The timer is resettable.

1.

Press and hold the key to reset the Dispense Count counter.

he total number of minutes of dispensing made by the machine. Every

FIG. 27: Dispense Time

10. Used Time

This function displays the cumulative lifetime hours that the machine is being used. The timer starts

counting as soon as the unit is turned ON.

The timer is NOT resettable.

FIG. 28: Cumulative Lifetime Hours

© 2015 Fisnar

28 - DC100 Rev G

-

DC100 Digital Dispenser Operating M

anual

CALIBRATION

The dispenser controller unit offers a calibration feature to precisely calibrate the pressure and

vacuum regulators.

Instructions:

Under PURGE, TIMED or INT modes, press the Press the key until the screen displays the

current pressure or vacuum setting.

Press and hold the simultaneously for 2 seconds to enter the calibration menu

FIG. 29: Calibration

.

© 2015 Fisnar

29 - DC100 Rev

-

G

DC100 Digital Dispenser Operating M

CALIBRATION

anual

Pressure Calibration

This feature allows the user to calibrate the pressure regulator. There are two calibration points

available: one at 0psi, and the other at 70psi. There is also a default calibration setting which was

the set point when the dispenser is pre-calibrated at the factory.

FIG. 30: Pressure Calibration

There are three (3) calibration options for this feature: In 0psi, In 70psi, and Rst Pres Value.

o In 0psi means calibrating the machine at 0psi.

1.

2.

3.

o In 70psi means calibrating the machine at 70psi

o Rst Pres Value means loading the original calibration parameters.

Press the key to scroll through these options.

Attach a pressure gauge to the air outlet of the dispenser. Activate the dispenser and adjust

the pressure regulator until the gauge reading matches the calibration point selected (i.e. if In

70psi is selected, set the pressure to 70psi).

Press and hold the key to save and press the key to exit.

FIG. 31: Calibration

© 2015 Fisnar

- 30 - DC100 Rev G

DC100 Digital Dispenser Operating M

anual

CALIBRATION

Vacuum Calibration

This feature allows the user to calibrate the vacuum regulator. There are two calibration points

available: one at 0psi, and the other at 7psi. There is also a default calibration setting which was

the set point when the dispenser is pre-calibrated at the factory.

FIG. 32: Vacuum Calibration

There are three (3) calibration options for this feature: In 0psi, In 7psi, and Rst Vac Value.

o In 0psi means calibrating the machine at 0psi.

1.

o In 7psi means calibrating the machine at 7psi

o Rst Vac Value means loading the original calibration parameters.

Press the key to scroll through these options.

Attach a vacuum gauge to the air outlet of the dispenser. Activate the dispenser and adjust the

2.

vacuum regulator until the gauge reading matches the calibration point selected

(i.e. if In 7psi is selected, set the vacuum to 7psi).

3.

Press and hold the key to save and press the key to exit.

FIG. 33: Calibration

© 2015 Fisnar

31 - DC100 Rev G

-

DC100 Digi

tal Dispenser Operatin

g Manual

EXTERNAL CONTROL

I/O Connections

Input

Output

© 2015 Fisnar

A contact closure between the Input (I) and Common (C) pins will trigger a

dispense signal.

Activating the DC100 will close the contact between the Output (O) and Common

(C) pins.

If an alarm is triggered the DC100 will close the contact between the Output (O)

and Common (C) pins.

- 32 - DC100 Rev G

DC100 Digi

tal Dispenser Operatin

EXTERNAL CONTROL

g Manual

I/O Schematic

© 2015 Fisnar

FIG. 34: I/O Schematic

- 33 - DC100 Rev G

DC100 Digi

EXTERNAL CONTROL

tal Dispenser Operatin

Multiple Dispensers

g Manual

A single input signal can activate multiple dispensers. The Input (I) and Common (C) pins must be

wired in parallel for all dispensers required to actuate simultaneously.

© 2015 Fisnar

FIG. 35: Multiple Dispensers

- 34 - DC100 Rev G

DC100 Digi

tal Dispenser Operating Manual

Notes

CE Conformity checked by: Certification Experts Europe, Nieuwstad 100, 1381 CE Weesp, The Netherlands

© 2015 Fisnar

Tel: +31 294 48 33 35, Fax: +31 294 41 46

- 35 -

DC100 Rev G

W129 N10825 Washington Drive, Germantown, WI 53022 Telephone: (262)253-8600

Loading...

Loading...