Fisher Scientific MARATHON 3000, MARATHON 3000R, 04-977-3000R, 04-977-3000, 04-977-3001 Operation Manuals

...

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

2000 Park Lane Pittsburgh, PA 15275

Tel. (800) 766-7000 Fax (800) 926-1166

MARATHON 3000(R)

General Purpose Centrifuge

Operation Manual

Model 3000 3L Ventilated Centrifuge

Cat. No. 04-977-3000 -- 120 VAC, 60 Hz

Cat. No. 04-977-3001 -- 220, 230, 240 VAC, 50/60 Hz

Model 3000R 3L Refrigerated Centrifuge

Cat. No. 04-977-3000R -- 120 VAC, 60 Hz

Cat. No. 04-977-30001R -- 220, 230, 240 VAC, 50 Hz

Cat. No. 04-977-30002R -- 230 VAC, 60 Hz

Part No. 04-977-3000M Rev. 4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of Contents

Section 1 - Introduction Page

1.1 General Product Description...............................................................................................4

1.2 About This Manual.............................................................................................................5

1.3 Warnings, Cautions and Notes............................................................................................6

Section 2 - Installation

2.1 Receiving the Unit ..............................................................................................................7

2.2 Site Preparation...................................................................................................................7

2.3 Power Configuration............................................................................................................9

2.4 Moving the Unit.................................................................................................................10

2.5 The Front Panel (Keys and Displays)................................................................................11

Section 3 - Operation

3.1 Rotor and Accessories .......................................................................................................15

3.2 Starting and Stopping a Run..............................................................................................18

3.3 Stored Programs................................................................................................................19

3.4 Rotor Recognition System.................................................................................................21

3.5 3000R Refrigeration..........................................................................................................22

3.6 Diagnostic Messages and Error Codes..............................................................................23

Section 4 - Applications

4.1 Introduction.......................................................................................................................26

4.2 Speed and Force Tables....................................................................................................28

4.3 Derating Tables.................................................................................................................31

4.4 Chemical Resistance Tables..............................................................................................33

4.5 Decontamination Table.....................................................................................................34

4.6 RCF Nomograph...............................................................................................................35

Section 5 - Maintenance

5.1 Introduction.......................................................................................................................36

5.2 Care and Cleaning.............................................................................................................36

5.3 Cover Interlock Bypass.....................................................................................................39

5.4 Fuses Not Replaceable By Operator..................................................................................39

5.5 Condition of Returned Equipment ....................................................................................40

5.6 Warranty ...........................................................................................................................40

Section 6 - Specifications

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MARATHON Series Operation Manual

2

Copyright ©, 1998

Fisher Scientific

Printed in the USA

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MARATHON Series Operation Manual

3

1.1 General Product Description

Marathon series units are low-speed, general purpose

centrifuges, used in medical, industrial, and scientific

applications.

The Marathon 3000 Series is available in two models:

ventilated (3000) and refrigerated (3000R). Sections of

this manual that apply to the refrigerated version will be

designated 3000R or refrigerated only.

Both models accommodate swinging bucket style rotors of

either 4 x 750 mL or 6 x 250 mL. They can process a

variety of tubes, bottles, and microsample tubes. The 4 x

750 mL rotor can process both standard and deepwell

microplates. Also available are pear shape and short form

conical oil tube rotors.

Each centrifuge has an easy to use front panel that provides

two modes of operation: Manual and Programmed.

Manual mode is used for entering temperature (3000R

only), speed/force, and time values for individual runs.

Program mode allows you to define and save a maximum

of ninety-nine specific sets of run parameters, to recall and

reuse.

1 Introduction

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MARATHON Series Operation Manual

4

The Marathon Series features a maintenance-free, brushless

motor, and an easy-to-use front panel, which provides three

versatile timing modes: automatic timed run, short spin

(momentary), and hold (continuous mode). Acceleration

and brake rates may be controlled, to optimize runs: rapid

for fast separations or slow for delicate samples. Repeat

runs, with the same speed and time settings, may be

achieved at the touch of a key.

A fail-safe cover interlock insures that the cover is closed,

before a run can begin, and keeps the cover closed, until the

rotor has reached a safe low speed (below 100 rpm), even

in the event of a power failure.

The rugged steel cabinet and rigid construction provide

quiet operation and long term reliability.

1.2 About This Manual

The Operations Manual contains all of the information

needed to install, operate, and maintain a Marathon Series

centrifuge. Refrigerated and ventilated models operate

similarly, and any differences are highlighted and noted,

throughout this manual. This manual, also, contains speed

and force, derating, chemical resistance, and

decontamination tables. The last chapter lists the units’

specifications.

This manual is written for centrifuge operators. In addition

to operation information, it contains a few basic

troubleshooting techniques, and a chapter on maintenance.

This Operation Manual is not a guide for servicing

centrifuge units.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MARATHON Series Operation Manual

5

1.3 Warnings, Cautions, and Notes

The terms warning, caution, and note have specific

meanings in this manual.

• A Warning advises against certain actions or situations

that could result in personal injury.

• A Caution advises against actions or situations that

could damage equipment, produce inaccurate data, or

invalidate a procedure.

• A Note provides useful information regarding an

operation, function, or procedure.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MARATHON Series Operation Manual

6

2.1 Receiving the Unit

Fisher Scientific ships the centrifuge in a carton that

protects it from shipping hazards. Follow the unpacking

instructions on the carton. Be sure to complete and return

the postage-paid warranty card.

2.2 Site Preparation

The unit normally resides on a bench top. The 3000

(ventilated model) can be placed in a cold room (no colder

than 4°C), for processing temperature-sensitive samples.

When you remove the centrifuge from a cold environment,

do not operate for a minimum of two hours, so that any

condensation will evaporate.

Note: When used in a cold room environment, some

bearing noise may become evident. The bearing lubricant

thickens at low temperatures. As the centrifuge speeds up,

it is thinned and distributed more evenly. Once this occurs,

any noise should subside.

2 Installation

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MARATHON Series Operation Manual

7

The following table lists the physical dimensions for the

3000 and 3000R:

Sample Loading Height

Cover Closed Height

Cover Open Height

Width

Depth

A clearance of 8 cm (3 inches) should be provided on each

side of the unit, to ensure proper ventilation. Place the

centrifuge on a clean, dry surface, to make certain that the

suction feet at the bottom grip the surface firmly. Keep the

area beneath the unit free of debris and loose materials.

The resting surface must be level, to ensure quiet,

vibration-free operation. A rigid and stable location is

important. An improperly loaded centrifuge may vibrate or

move.

Warning: International Electrotechnical Commission

standard 1010 part 2-20 limits the permitted movement

of a laboratory centrifuge to 300 mm (12 in) in the unlikely

event of a disruption. Laboratory management procedures

should require that no person or any hazardous materials

enter within this boundary while the centrifuge operates.

3000R

14.7” (37.3 cm) 14.7” (37.3 cm)

16.5” (41.9 cm) 16.5” (41.9 cm)

41” (104.1 cm) 41” (104.1 cm)

30” (76.2 cm) 23.3” (59.1 cm)

25.8” (65.4 cm) 25.8” (65.4 cm)

3000

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MARATHON Series Operation Manual

8

2.3 Power Configuration

The Marathon Series uses AC power in different

configurations, appropriate for use throughout the world.

Please check the catalog number of the model that you

have purchased, to ensure that the machine you have is the

proper power configuration. For best results, the

refrigerated centrifuge, 3000R, should be used on a

dedicated line. Variations in line voltage or frequency

affect the unit’s speed and other characteristics. Less than

nominal line voltage may prevent the centrifuge from

reaching maximum published specifications of speed

and/or temperature. Power line voltage, at some locations,

may sag, when the refrigeration system turns on.

Power Cord The unit requires a grounded power supply (3 prong

outlet). If your facility does not have grounded power

outlets, arrange for a proper grounding. The power cord

plugs in on the left side of the unit.

Warning: Do not remove the grounding pin from the centrifuge

power cord. Do not use the bare wired power cord to attach a

power plug that does not have a grounding pin.

The power cord provided with the unit is correctly rated for the

highest current demand. This power cord should not be

interchanged with cords from equipment with lower current

demand. Exchange of power cords between equipment may

create a fire hazard.

Main Power Switch The main power switch is located on the left side of the

centrifuge, next to the power cord. Press this rocker switch

to power the unit on or off according to the picture below:

OFF ON

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MARATHON Series Operation Manual

9

Circuit Breaker The system provides an automatic circuit breaker, for

2.4 Moving the Unit

emergency situations, such as power surges, that could

damage the unit.

If the circuit breaker trips:

1. Unplug the unit.

2. Press the white button, on the left side of the unit.

3. Plug the unit back in.

Suction cups, at the bottom of the unit, keep it anchored to

the work surface. Keeping the unit stationary is a safety

feature.

To move the unit to a new location:

Caution: The unit can weigh up to 145 lb. (65.8 kg). Use

precaution when moving to avoid any injury.

1. Check that the new site meets the criteria in Section 2.2

before moving the unit.

2. Position a flat object, such as a tongue depressor, near a

suction cup at the bottom of the unit.

3. Lift up an edge of the cup, and insert the flat object far

enough to break the vacuum seal.

4. When all four cups are disengaged, lift the unit from the

work surface.

Caution: When the unit is in its new location, ensure that

the suction cups adhere correctly to the work surface.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MARATHON Series Operation Manual

10

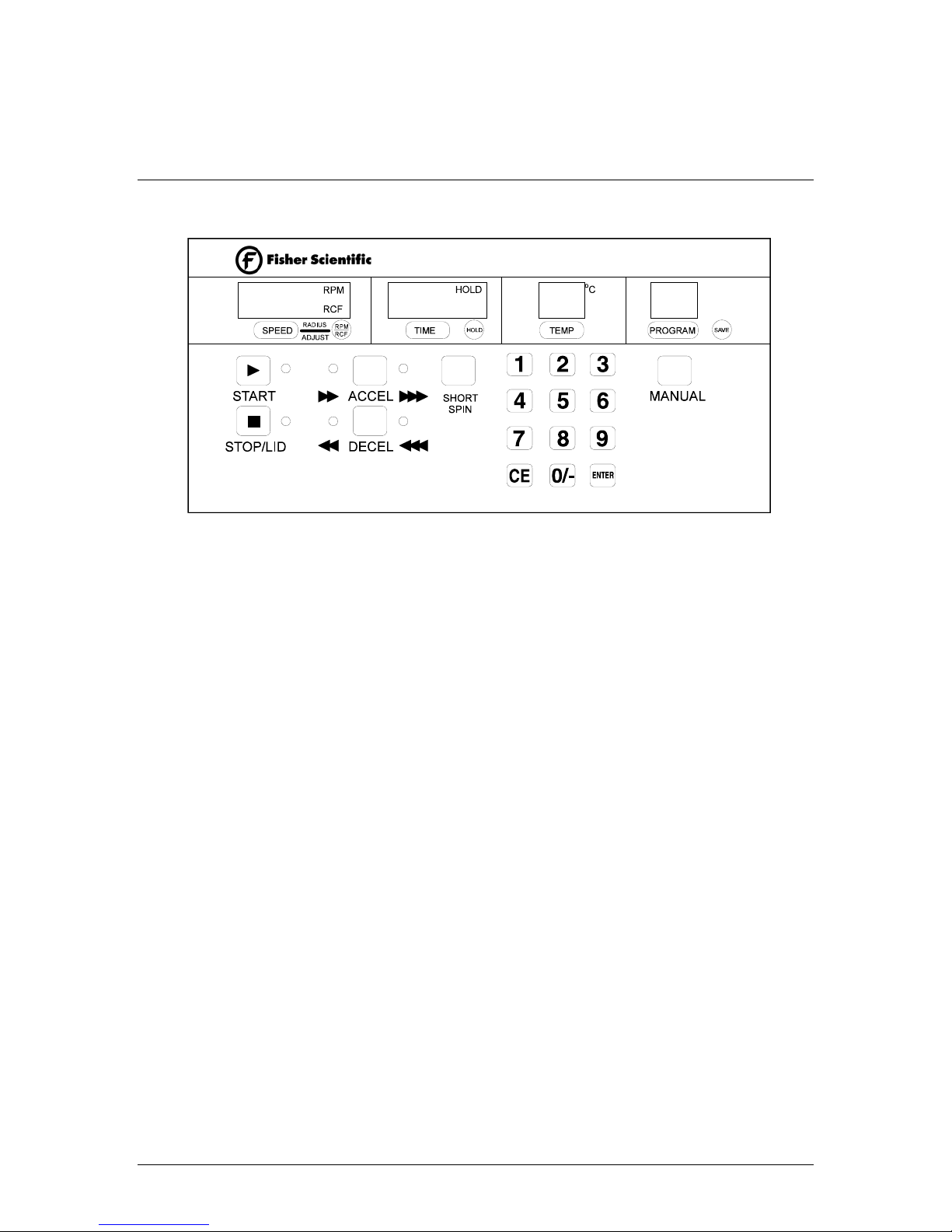

2.5 The Front Panel

The Front Control Panel

(3000R Model Shown)

The control panel contains numeric displays for RPM/RCF

(Speed/Force), Time, program, and Temperature

(Refrigerated only). These displays have two states or

modes: Actual (bright display) and Set (dim display).

In Actual mode (bright display), they indicate current run

conditions, such as:

• rotor speed or force

• elapsed time of, or time remaining in, the run

• actual temperature (Refrigerated only)

• program number

In Set mode (dim display), the display indicates the desired

settings for the run. Set mode is activated when:

• SPEED, TIME, TEMP., or PROGRAM are pressed

• briefly, at the start of a run

• briefly, after the unit is switched ON

The numeric displays can, also, display warning or error

messages (see Section 3.5). Descriptions of the displays

appear on the following pages.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MARATHON Series Operation Manual

11

SPEED Speed Key: Pressing the SPEED key switches the display

from Actual to Set mode. Select the desired speed using the

numeric keypad, and then press ENTER. A selection must

begin before 5 seconds elapse or the display will revert to

the Actual reading.

RPM

RCF

Speed/Force key and display: The number in the

speed/force display represents the rotor speed in RPM or

force in RCF. Press this key to toggle between RPM and

RCF. When RPM is selected, the display indicates

revolutions per minute. When RCF is selected, the display

indicates relative centrifugal force. Use the numeric keys

to change the set speed or force. Select speed in increments

of 50 RPM, from 500 through 3,600 RPM (depending on

the max. allowable speed limit for the particular rotor).

Select RCF from 500 - 3,000 xg (depending on the max.

allowable RCF limit for the particular rotor) in increments

of 50 xg.

Rotor Radius SPEED & RPM/RCF: Pressing these keys together

allows the user to change the radius of rotation. Select the

radius using the numeric keypad, and then press ENTER.

Also see Section 3.4 Rotor Recognition System.

TIME

HOLD

SHORT

SPIN

Time key: Pressing the TIME key switches the display

from Actual to Set mode. Select the desired time using the

numeric keypad, and then press ENTER. A selection must

begin before 5 seconds elapse or the display will revert to

the Actual reading.

Time display: The number in the display indicates time.

Time is displayed as minutes:seconds up to 99 minutes.

The timer begins counting at the start of a run, i.e. when

START is pressed. In manual mode, the timer counts

down from the set point. In time HOLD or SHORT SPIN

modes, the timer counts up.

Hold display: The hold feature is used to initiate an

indefinite spin. Press the HOLD key so that HOLD

appears in the display. Pressing START will then begin a

run at the set parameters. The timer will count up, and the

run will not end until the STOP key is pressed.

Short Spin: The short spin is used for quick separations.

Pressing SHORT SPIN will begin a run at the set

parameters. The timer will count up, and the run will not

end until the SHORT SPIN key is released.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MARATHON Series Operation Manual

12

TEMP

(3000R only)

PROGRAM

SAVE

MANUAL

Temperature key: Pressing the TEMP key switches the

display from Actual to Set mode. Select the desired

temperature using the numeric keypad, and then press

ENTER. A selection must begin before 5 seconds elapse or

the display will revert to the Actual reading.

Temperature display: The number in the display

represents temperature in degrees Celsius, from − 9 °C

through + 40 °C.

Note: If the Actual rotor chamber differs by more than 5°C

from a selected set point temperature, the °C display will

switch between the actual and set/programmed

temperatures, until the two temperatures come within 5°C.

Program key: Pressing the PROGRAM key switches the

display from Manual to Program mode.

Save key: This key saves the currently displayed desired

settings as stored programs 1 through 99 (see Section 3.3).

The numeric display shows the stored program number and

mode of operation (see Section 3.2).

Manual key: The manual returns the unit to manual

operation from Program mode.

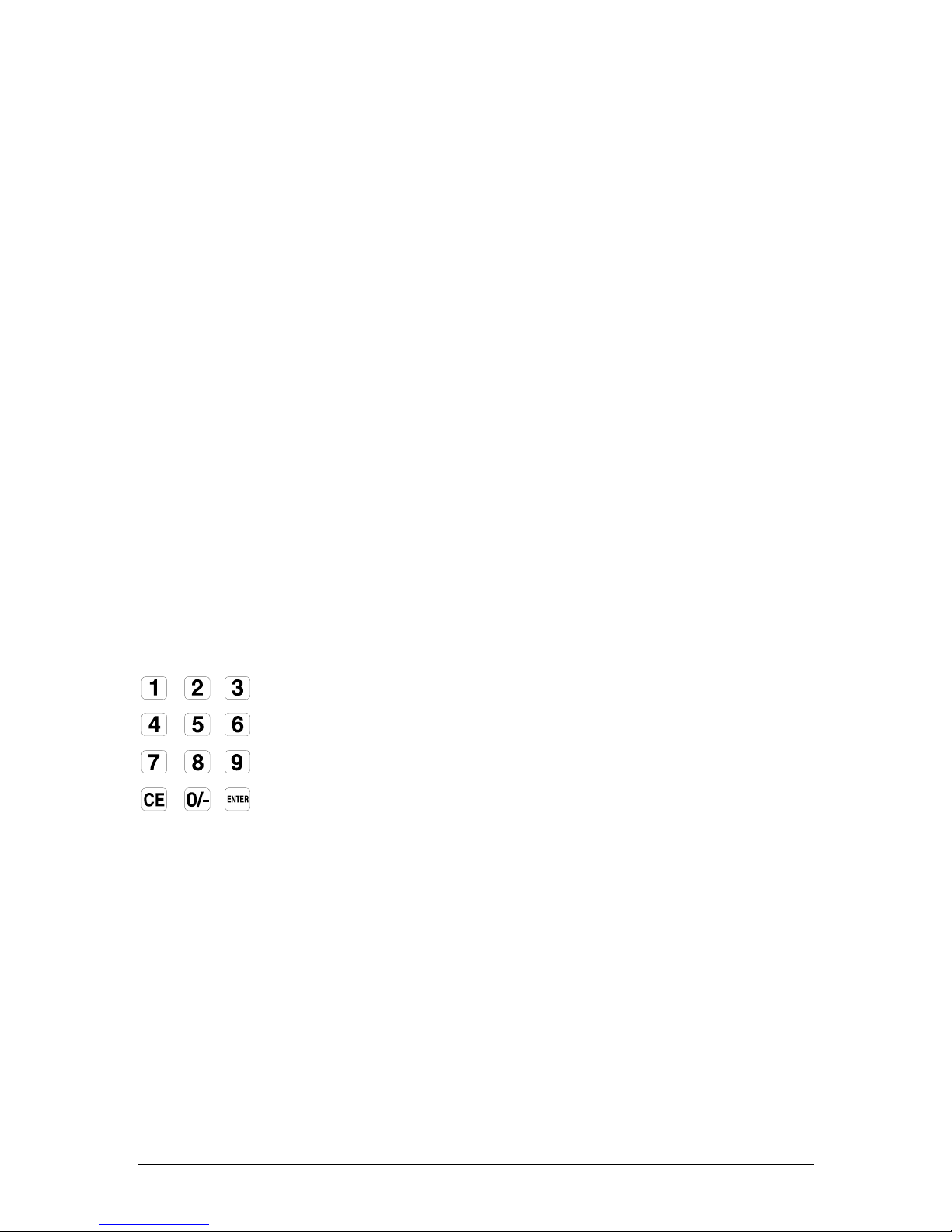

Numeric Key Pad: The numeric key pad is used to change

the Set parameters for Speed/Force, Time, Temperature

(Refrigerated only) Rotor/Radius, or Program. When any

of the mode keys such as the SPEED, TIME, TEMP or

PROGRAM key is pressed, the numeric display switches

from Actual readings to Set parameters, without changing

them. The numeric key pad may be used to change the

parameter value. A selection must begin before 5 seconds

elapse or the display will revert to the Actual reading.

The CE key is used to clear a selection that has not yet

been entered to memory.

The 0/- key may be used to select a negative temperature.

Note: Temperature control range is specified from +4 °C

to ambient at maximum rated speed. Lower temperatures

can be achieved at less than maximum speed.

The ENTER key must be pressed after each parameter

selection to enter the value into memory.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

MARATHON Series Operation Manual

13

Loading...

Loading...