Instruction Manual

Fisher Scientific

accumet

®

Basic (AB)

Benchtop Meters

AB150 ● AB200 ● AB250

68X613601 Rev 0 July 2012

Table of Contents

1. Introduction ................................................................................................................ 3

2. Keypad & Display ....................................................................................................... 4

Connections: ............................................................................................................................... 6

3. System Setup & Configuration ................................................................................. 7

STABILITY .................................................................................................................................. 7

EXPORT DATA ........................................................................................................................... 7

DATE & TIME .............................................................................................................................. 8

PASSWORD ............................................................................................................................... 8

FACT RESET .............................................................................................................................. 9

CONTRAST ................................................................................................................................. 9

STIRRER ..................................................................................................................................... 9

SAMPLE ID ................................................................................................................................. 9

LANGUAGE ................................................................................................................................ 9

BEEP ........................................................................................................................................... 9

4. Setup pH & mV ........................................................................................................... 10

BUFFER (pH Only) ..................................................................................................................... 10

RESOLUTION (pH Only) ............................................................................................................ 10

ALARM ........................................................................................................................................ 10

STD DUE (pH Only) .................................................................................................................... 10

5. pH Standardization (With Preset Buffer Group) ...................................................... 11

6. pH Standardization (With Custom Buffers) ............................................................. 12

7. mV Standardization (Offset Adjustment) ................................................................. 13

8. Temperature Setup .................................................................................................... 13

9. Temperature Standardization ................................................................................... 14

10. Conductivity, TDS, Salinity, & Resistivity Setup ..................................................... 15

STD METHOD (Conductivity Mode Only) ................................................................................... 15

STD POINTS ............................................................................................................................... 15

PURE WAT COEF (Pure Water Coefficient) .............................................................................. 16

TEMP COEFFICIENT (Linear) .................................................................................................... 16

NORMALIZATION TEMPERATURE (ºC) ................................................................................... 16

TDS FACTOR (TDS Mode Only) ................................................................................................ 16

CELL CONST (Cell Constant) ..................................................................................................... 16

ALARM ........................................................................................................................................ 17

STD DUE ..................................................................................................................................... 17

1

11. Conductivity Standardization (Automatic) .............................................................. 17

12. Cond/TDS/Salinity/Resistivity Standardization (Manual Adjustment) .................. 18

13. Ion Setup ..................................................................................................................... 20

MEASURE UNIT ......................................................................................................................... 20

ALARM ........................................................................................................................................ 20

STD DUE ..................................................................................................................................... 20

STANDARDS .............................................................................................................................. 20

14. Ion Standardization .................................................................................................... 21

15. Viewing, Transferring, and Printing Data ................................................................ 22

16. Standardization Report ............................................................................................. 23

17. Troubleshooting ......................................................................................................... 24

18. USB Driver & Boot Loader Documentation ............................................................. 25

19. Specifications ............................................................................................................. 37

20. Replacements and Accessories ............................................................................... 40

21. Warranty ..................................................................................................................... 42

22. Return of Items ........................................................................................................... 42

23. Notice of Compliance ................................................................................................ 43

24. Declaration of Conformity ......................................................................................... 44

2

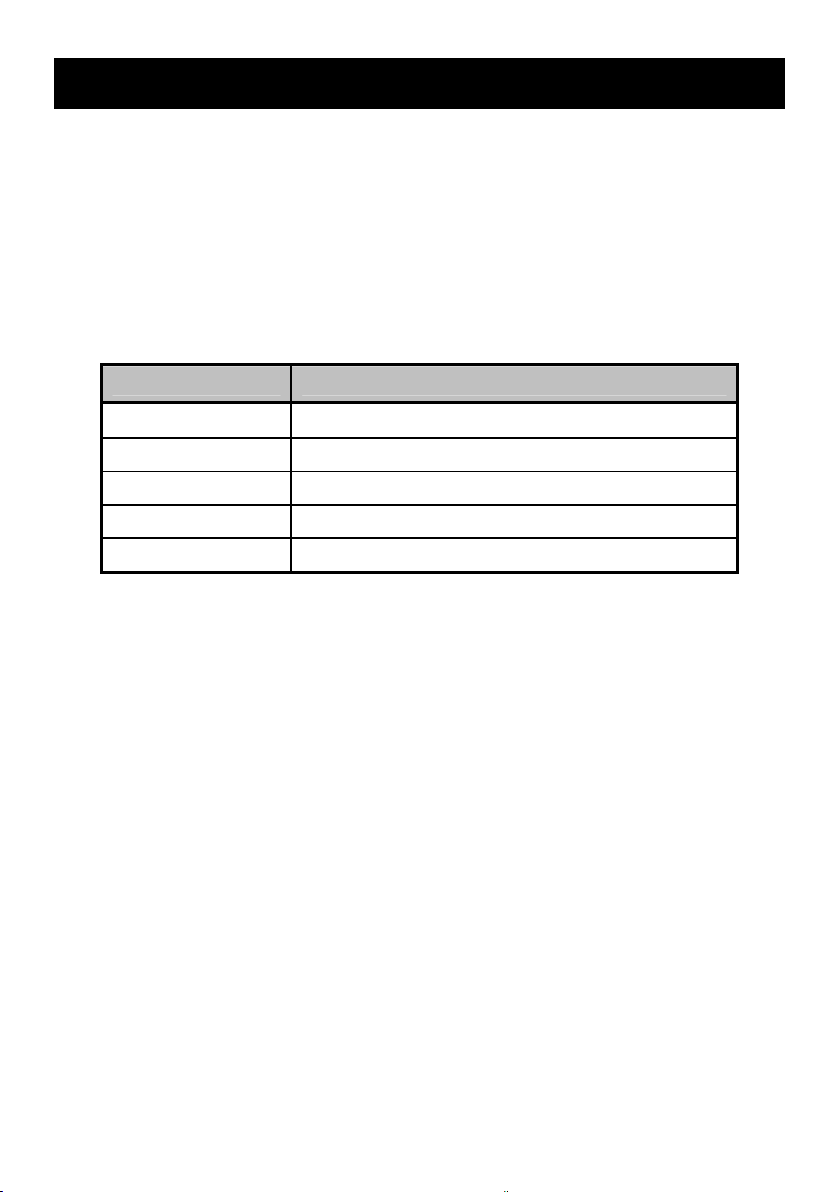

1. Introduction

Thank you for selecting the Fisher Scientific accumet AB series benchtop meter.

All models include an electrode arm with metal bracket (13-637-671), 110/220

universal power supply (13-636-104), RS-232, and USB cable. The electrode arm

can be attached to the left, right, or center of the meter according to your

preference using a Phillips screwdriver.

The AB150 replaces the AB15 and AB15Plus series while the AB200 and AB250

are new introductions to the product line.

Please note that this manual serves three models, so not all sections of the

manual are relevant to each model. The chart below lists the parameters served

for the various models:

13-637-671 13-636-104

3

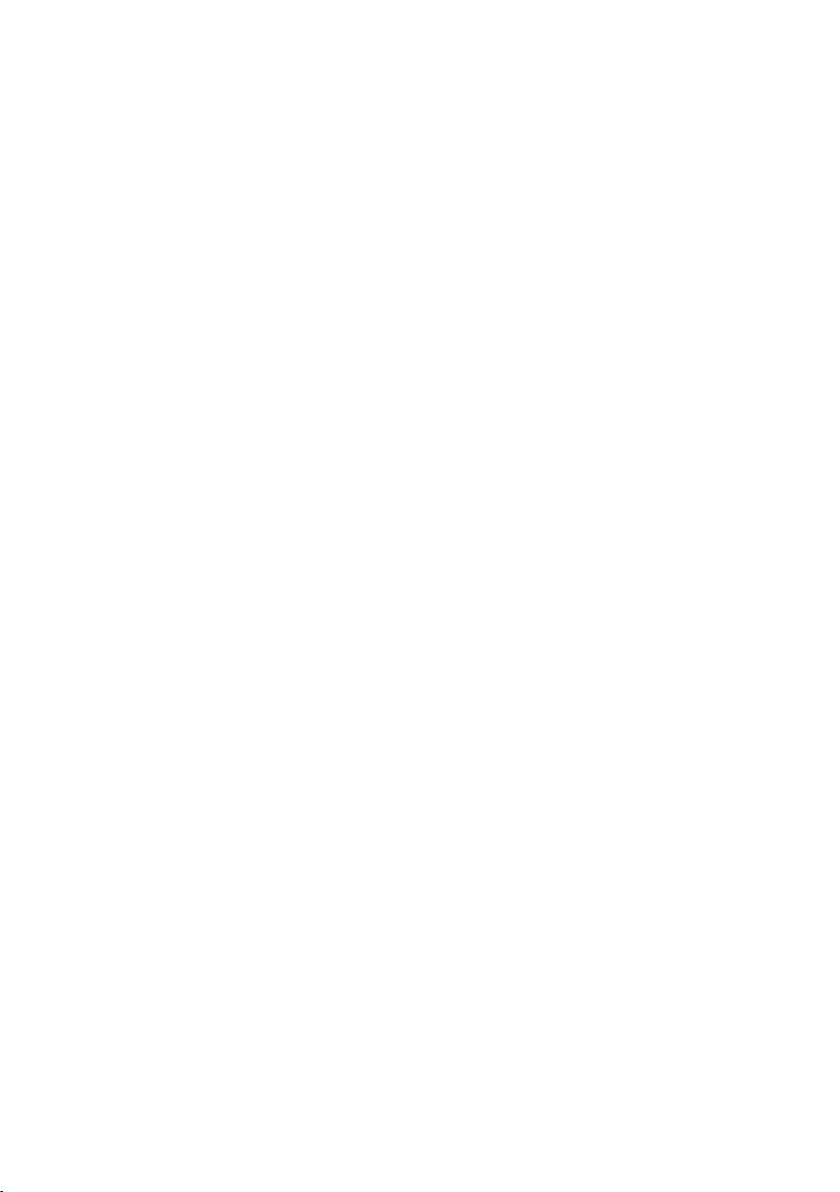

2. Keypad & Display

FIXED KEY DESCRIPTION

to initialize and complete standardization (calibration) of

STD

displayed parameter

MODE

SETUP

PRINT / ENTER

SAVE / ▲

VIEW / ▼

STIRRER

POWER / BACKLIGHT

SOFT KEY DESCRIPTION

HELP

DISPLAY

REPORT

TEMP STD

ACCEPT

CLEAR

BACK

to toggle between available measurement modes

to enter Setup mode; use to change system settings or

measurement parameters

to print, also to confirm selection during setup

to record into memory without printing, also increment

to examine saved data, also decrement

to turn 13-620-BSP stirrer (optional separately) on / off

to adjust backlight brightness, also hold >3 seconds to power off

to view screen specific assistance

to toggle between available display types

to examine current standardization data such as slope

to initialize temperature standardization (calibration)

to accept existing values

to erase existing values

to return to previous screen

ESC

to escape or cancel from the current display

4

Stable

(ATC)

(MTC)

USB port is active.

RS-232 port is active.

Based on the stability speed selected, instrument has detected a

stable reading.

Data was sent to the printer; either manually by pressing PRINT key or

automatically at timed intervals as entered thru the System Setup mode.

“High Alarm”, “Low Alarm”, or “Std Due” alarm limit had been reached.

Note: High/Low alarms also use an audible notification.

Standardization detail.

Measuring Range # of displayed value. Applicable to Conductivity, TDS,

Salinity, or Resistivity measurements only.

Automatic Temperature Compensation is active; temperature is being actively

acquired with attached electrode. ATC is recommended.

Manual Temperature Compensation is active. This occurs when a temperature

sensor may not be attached and the default temperature is used.

See Section 9 – Temperature Standardization to calibrate the ATC or MTC

temperature values.

5

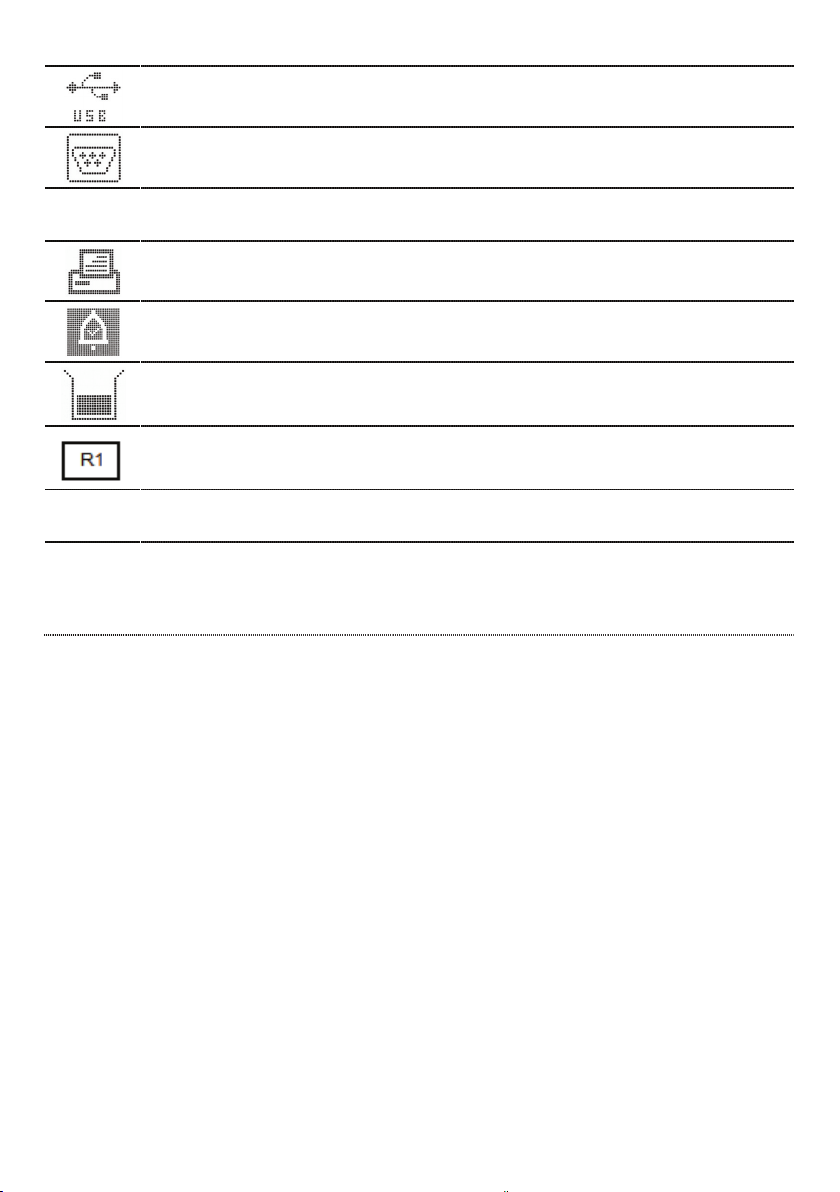

Connections:

Power

RS-232

MINI-B

USB

2/4 Cell

TEMP

GROUND

BNC

Power supply, 110/230 VAC, 9 VDC, 18 W, center positive.

Use only model 13-636-104 (included).

RS-232 serial communication output, 2.5 mm jack.

For use with RS-232 cable 13-637-681 (included).

USB communication for field software upgrades (cable included)

and data output.

8-pin DIN connection for 2-cell or 4-cell

Con/TDS/Resistivity/Salinity/Temperature electrodes.

Automatic Temperature Compensation probe (13-620-19) and

pH electrodes that also include ATC.

For electrical grounding / electrical noise reduction.

For combination pH, mV (ORP, Redox), or

Ion Selective Electrodes (ISE). Half-cell indicating electrodes

require 13-620-489 adapter.

6

3. System Setup & Configuration

Use the System Setup to customize operation of your AB series meter.

Press SETUP from the measurement screen and then press PRINT/ENTER

when SYSTEM is highlighted to access these settings.

The following settings can be customized for each model:

STABILITY STIRRER

EXPORT DATA SAMPLE ID

COMM SETUP LANGUAGE

DATE & TIME BEEP

PASSWORD

FACT RESET

CONTRAST

STABILITY

Adjust how quickly and frequently the ‘Stable’ indicator appears. There are four

levels of adjustment; SLOW, MEDIUM, FAST, or OFF (prevents the Stable

indicator from appearing in measurement mode). To display ‘Stable’ more

quickly and more often, use “FAST” setting. MEDIUM or SLOW is recommended

for most applications.

SLOW: The ‘Stable’ indicator will take longer to appear and will appear less

frequently. Use this setting if you want the best results and don’t mind waiting

longer to get them.

MEDIUM: This is the factory default setting. It provides a balanced response

which works best for most applications.

FAST: The ‘Stable’ indicator will appear quickest of any setting. If you find that

the indicator appears and disappears too frequently, you may want to select a

slower setting. This setting is often not suitable for use with most non-refillable

(gel filled) electrodes which are generally slower to respond.

Tip: Select a lower pH resolution X.XX instead of X.XXX to decrease

stabilization time.

EXPORT DATA

Printing: Select ON or OFF.

Datalog: Select ON or OFF.

7

Timed: When either printing or datalog is ON, the option to select Timed

readings ON or OFF appears. Select “ON” to automatically print or save data

at selectable intervals. Select “OFF” to save data manually using the

PRINT/ENTER key.

Time Interval: (MM:SS) (Minutes:Seconds). When timed reading is ON, you

must select an interval at which the data will be sent to the Printer and/or Datalog

memory. Choose from 3 seconds to 60 minutes. Data will be collected until the

data limit is reached or the option is turned “OFF”. This feature is useful for

gathering data from a single sample over time. Note that “SAVE” is not available

during TIMED setting. To view the stored data, use “VIEW” key.

COMM SETUP (Communication Setup)

Format: To send data as a comma separated value, choose CSV – best for

exporting data into spreadsheet software. Choose PRINTER to send the data in

an easily viewable format – best for printing.

Communication Setup: Choose RS-232 (9600 or 19200 baud rate) or USB.

Baud Rate: When RS-232 is selected, choose (9600 or 19200)

DATE & TIME

Setting the correct date and time is required for GLP and will apply to power on,

measurement, data log, and print functions. Factory reset will not apply to date

and time setting once it has been set. Changes related to daylight savings time

must be manually entered.

Date Format: Select (MM DD YY) or (DD MM YY)

Time Format: Select 12Hrs (AM/PM) or 24Hrs

PASSWORD

Select “ENABLE” to restrict access to Calibration and Setup modes. When

password protection is enabled, password entry is required before performing any

calibration, or making changes to the setup mode. Setup parameters can be

viewed, but not changed without correct password entry. The password is a user

selectable number from 1 to 99999.

Select “DISABLE” if password protection is not desired.

The meter does not allow you to edit setup parameters or perform a new

calibration unless you enter the correct password. If an incorrect password is

entered 3 consecutive times, the meter returns to measurement mode.

If a password has been ENABLED but cannot be recovered, a password can be

provided via a written request. The instrument serial number and your contact

information are required.

8

FACT RESET

Select “YES” to reset the to the factory default settings except; Date & Time

setting, and data stored into memory.

CONTRAST

Optimize the contrast setting of your display for best visibility in your surrounding

lighting conditions. Test various contrast settings for best results. This setting will

be applied to both backlight and non-backlight conditions.

STIRRER

Set the stirring speed of the 13-620-BSP Benchtop Stirring Probe (optional

accessory) when stirrer is on. Choose from 5 different speeds.

SAMPLE ID

This is a user selectable number from 1 to 99999. Incorporating a sample ID to

identify one or more data points is useful to distinguish data that is saved into

memory or sent to a PC or printer. Use the ▲/▼ key to adjust the values and

ENTER to move the cursor of a previous Sample ID.

LANGUAGE

Select the preferred language that is displayed on the instrument. Choose from

English, Deutsch, 中文, Français, Italiano, & Español.

Tip: Check www.fishersci.com/accumet

updates which may include additional languages.

for free instrument software

BEEP

Enable or disable an audible tone with each key press.

9

4. Setup pH & mV

Use Setup pH or mV mode to customize these parameters. Note: mV setup offers

Alarm setting only.

Press SETUP from the measurement screen and then press ENTER when pH or

mV is selected.

BUFFER (pH Only)

Choose one of (5) pH buffer groups for calibration; The pH values in the selected

buffer group are used for auto-recognition during pH calibration. Choose the

appropriate buffer group based on the pH calibration standards you intend to use.

Buffer Group pH Values

USA 2.000, 4.010, 6.997, 10.013, 12.000

NIST 1.678, 4.010, 6.865, 9.184, 12.460

DIN 19267 1.090, 3.060, 4.650, 6.790, 9.230, 12.750

FSCI 1.000, 3.000, 6.000, 8.000, 10.000, 13.000

CUSTOM Any 2-5 values, ≥ 1.0 pH unit apart

RESOLUTION (pH Only)

Select your desired pH resolution: X.X, X.XX, X.XXX

ALARM

Use a visual and audible alarm to alert you when High or Low values that have

been set from this menu are exceeded. “High Alarm” or “Low Alarm” will blink on

the display if the values are exceeded while simultaneously, a loud, intermittent

beeping sound is heard. The alarms will continue until the conditions are no

longer met, and will only be active during measurement mode.

STD DUE (pH Only)

When enabled, the “Cal Due” indicator blinks if the number of days since the last

calibration has been exceeded. Set the time from 8 hours, 16 hours, or from 1 to

31 days.

10

5. pH Standardization (With Preset Buffer Group)

For best results, periodic standardization (calibration) with known accurate

standards is recommended prior to measurement. Use standards that bracket

your intended measuring range while including a neutral point (7.00, 6.86, or

6.79). For example, if you expect to measure samples from pH 6.2 to 9.5,

calibration with 4.01, 7.00, and 10.01 will work well.

The following pH calibration buffers in the groups listed below are automatically

recognized:

Buffer Group pH Values

USA 2.000, 4.010, 6.997, 10.013, 12.000

NIST 1.678, 4.010, 6.865, 9.184, 12.460

DIN 19267 1.090, 3.060, 4.650, 6.790, 9.230, 12.750

FSCI 1.000, 3.000, 6.000, 8.000, 10.000, 13.000

To eliminate temperature errors associated with the pH electrode, attach the

automatic temperature compensation (ATC) probe for best accuracy. Without

temperature compensation, pH accuracy will decrease as samples deviate from

25 ºC and pH 7.

If the pH electrode has been stored dry, soak in storage solution for 10 minutes

before standardization to saturate the pH electrode surface and minimize drift. If

storage solution is not available, use a neutral pH buffer. Do not reuse buffer

solutions after calibration.

1) Turn meter on, press MODE if needed for pH measurement mode.

2) Rinse the pH and ATC electrodes with clean water then submerse in your first

pH standard buffer.

3) Press STD to enter standardization mode.

If the meter is password protected, you will be prompted to

enter a password.

4) The AB meter automatically searches for the appropriate standard from

the chosen buffer group in the secondary display. This value will blink

when the ‘Stable’ indicator appears. Selecting CLEAR will clear existing

calibration values.

11

5) Press STD to accept the value of the measured buffer. If successful, the

Standardization Report will show the accepted value along with other data.

The percentage slope is visible after two or more calibration points have

been completed.

6) Repeat Steps 4 & 5 with additional pH buffers.

6. pH Standardization (With Custom Buffers)

Buffer Group pH Values

CUSTOM Any 2-5 values, ≥ 1.0 pH unit apart

1) Turn meter on, press MODE if needed for pH measurement mode.

2) Rinse the pH and ATC electrodes then submerse in your custom pH buffer –

any pH value can be used.

3) Press STD to enter standardization mode. When stable, use ▲/▼ keys to

adjust the custom pH buffer value.

For best results, enter the value of the custom buffer that

corresponds to the measured temperature. For example, pH

10 buffer is actually 10.06 at 20°C, so the value should be

adjusted to 10.06 instead of 10.00 if the temperature is 20°C.

4) Press STD to accept the value.

5) Rinse the pH and ATC electrodes then submerse in next custom pH buffer.

Use any pH value that is at least 1.0 pH unit from custom pH standards that

have already been calibrated. Press CLEAR to clear existing values – this will

be necessary when repeating a standardization using the same buffer value.

6) When stable, use ▲/▼ keys to adjust the custom pH buffer value. Previously

accepted values will be visible inside of a beaker icon. Press STD to accept

the new value. Percentage slope is visible after two or more values have

been completed.

7) Repeat Steps 2 thru 4 with additional pH buffers (up to 5 custom buffers) in

any order.

12

7. mV Standardization (Offset Adjustment)

Oxidization Reduction Potential (ORP or Redox) as measured by an ORP

electrode in milliVolt (mV) units is not a precise measurement, but is useful as a

relative indicator. As such, mV offset adjustment is not meant to enhance

accuracy, but rather to make readings comparable to a reference.

Commercial ORP solutions are commonly used as a check standard – a

meter/electrode system is verified to be close to a given value although

adjustments are not made. These solutions can be used as a calibration standard

in which adjustments are made in an attempt to match the ORP value, however

results are often difficult to reproduce.

1) Turn meter on, connect a combination ORP electrode (such as 13-620-81),

and press MODE if needed for mV (or R.mV) measurement.

2) Dip the ORP electrode into a solution with a known mV value (i.e. Zobel,

Light’s, quinhydrone, or iodidetriiodide) with brief or slow stirring.

3) Press STD to begin standardization.

4) Adjust the value using ▲/▼ keys, press STD when the reading is stable to

accept the calibration offset. The maximum adjustable value is ±150 mV from

the factory default mV value.

5) To view the Ion Standardization Report at any time from the measure screen,

press REPORT.

When an offset has been stored successfully, R.mV replaces

mV in measurement mode.

8. Temperature Setup

Use Setup Temperature mode to desired temperature units; ºC or ºF.

Press SETUP from the measurement screen and then press ENTER when

TEMPERATURE is selected.

Choose ºC or ºF units of measure.

Automatic Temperature Compensation (ATC) is automatically applied when a

temperature sensor is connected.

Manual Temperature Compensation (MTC) of 25 ºC is used if the temperature

sensor is not connected. See Section 9 – Temperature Standardization

the MTC temperature value.

13

to adjust

9. Temperature Standardization

The thermistor sensor used for automatic temperature compensation and

measurement is both accurate and stable, so require frequent calibration isn’t

required. Temperature calibration is recommended upon electrode replacement,

whenever the temperature reading is suspect, or if matching against a certified

thermometer is desired.

1) Connect the temperature probe and place into a solution with a known

accurate temperature such as a constant temperature bath. The temperature

probe may be separate or as part of a pH or Conductivity electrode. *The

AB200 has two temperature inputs – one built into 2/4 conductivity cell, and

another for use with the BNC connection.

2) When the reading is stable, press STD from any measurement mode, then

press TEMP STD.

3) The upper display shows the active temperature while the lower display

shows the factory default temperature without calibration.

4) Adjust the upper display using ▲/▼ keys, press ENTER to accept the

calibration temperature. The maximum adjustable value is ±5 ºC (or ±9 ºF)

from the factory default temperature value.

Additional Temperature Calibration Notes:

For Manual Temperature Compensation (MTC) the procedure is the same

although the maximum adjustable value is the full temperature range of the

parameter, and connection of a separate ATC probe is not necessary. ATC is

recommended for most applications.

If temperature standardization is performed, be sure that the

thermometry source being used as a reference is accurate!

14

10. Conductivity, TDS, Salinity, & Resistivity Setup

Use Setup mode to customize Conductivity, TDS, Salinity, & Resistivity

parameters.

Press SETUP from the measurement screen and then press ENTER when

Conductivity, TDS, Salinity, or Resistivity is selected.

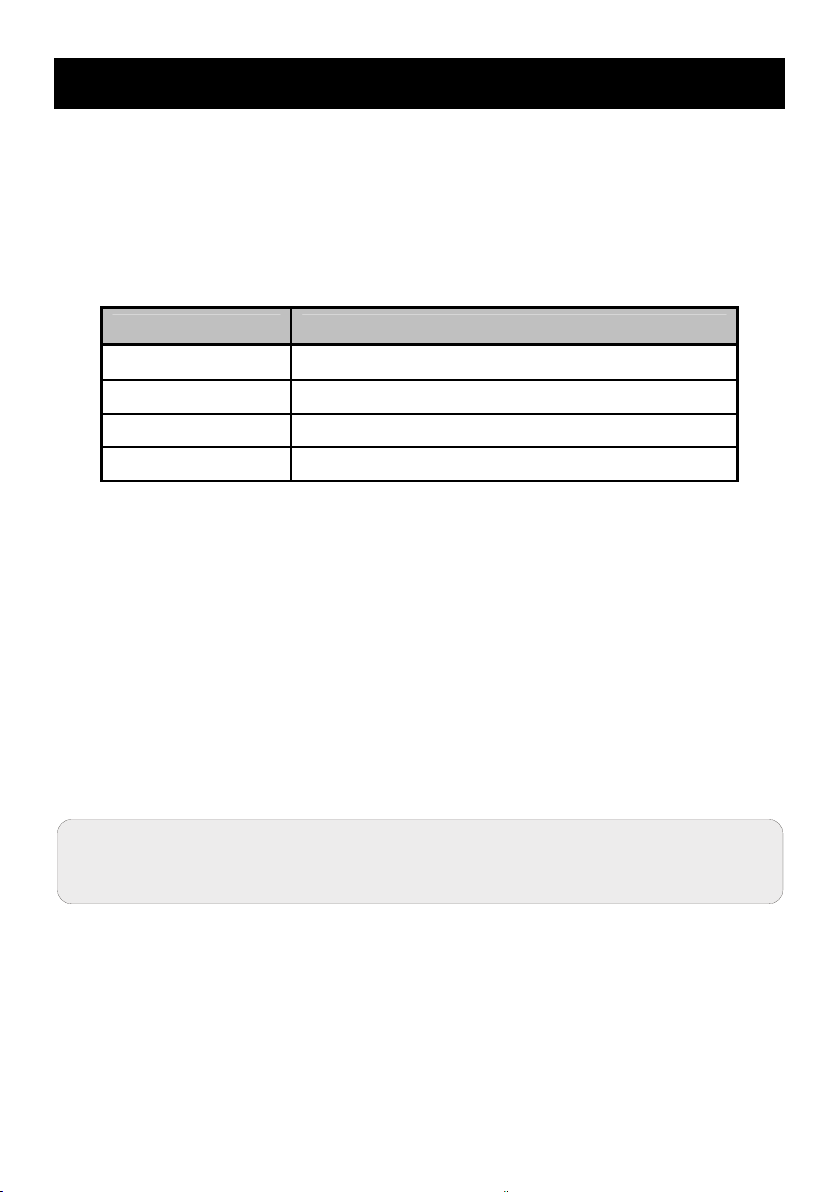

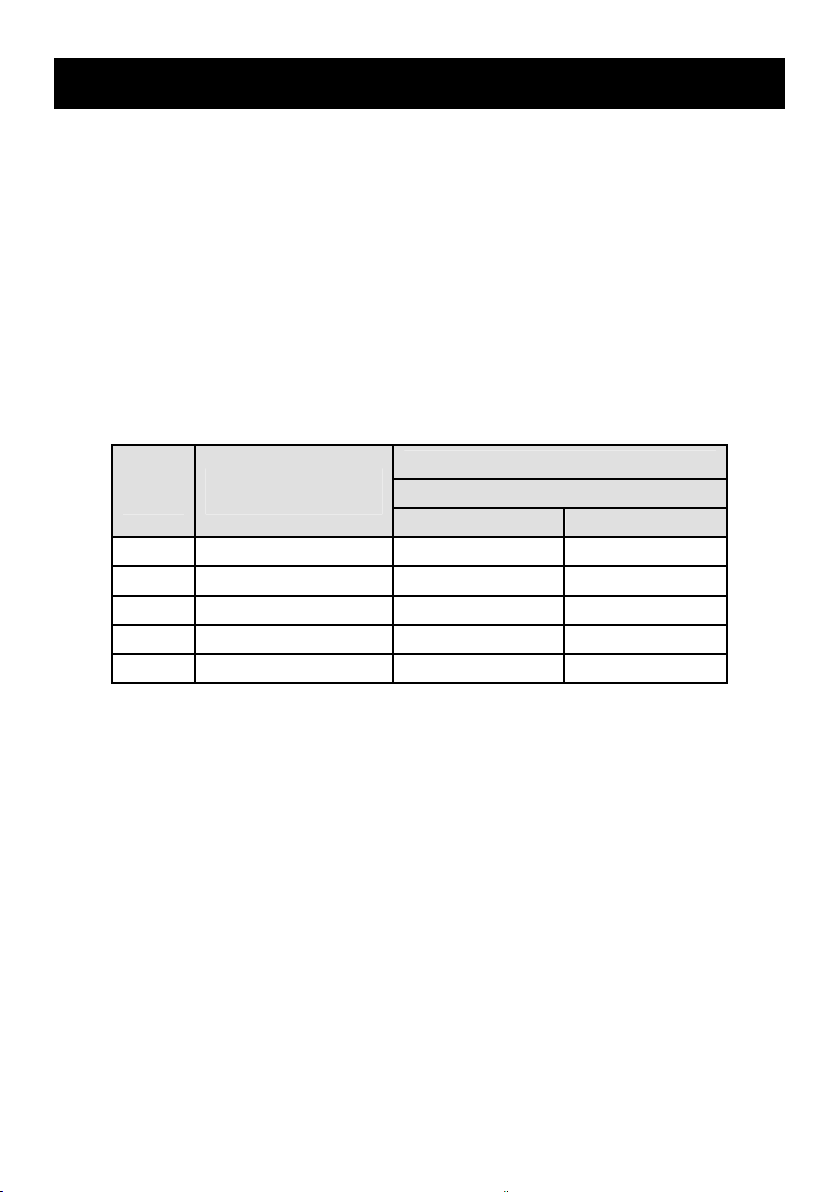

STD METHOD (Conductivity Mode Only)

Choose automatic or manual standardization for conductivity, and manual

standardization for TDS, Salinity, and Resistivity. This option allows you to select

AUTO (automatic) or MANUAL conductivity calibration.

In the automatic calibration mode, the meter will automatically select one of (4)

conductivity calibration standard values depending on the range and

normalization temperature being used (see table below).

Range

#

r 1 0.00 – 19.99 µS None None

r 2 20.00 – 199.9 µS 84 µS 76 µS

r 3 200.0 – 1.999 mS 1413 µS 1278 µS

r 4 2.000 – 19.99 mS 12.88 mS 11.67 mS

r 5 20.00 – 500.0 mS 111.8 mS 102.1 mS

If you will only use one or more of the (4) calibration standards listed here,

automatic calibration is recommended. Otherwise, manual calibration should

be selected.

The factory default is automatic conductivity calibration. Note that automatic

calibration is not available for conductivity range 1.

Conductivity

Range

Automatic Calibration Values

Normalization Temperature

25 ºC 20 ºC

STD POINTS

Use SINGLE for Single-Point Calibration (SPC) to apply a single calibration value

across all ranges.

Use MULTI for Multi-Point Calibration (MPC) to calibrate each range individually.

This will restrict an individual calibration so that it is applied to one range only.

When using multi-point calibration, perform a calibration in each range that you

expect to use for best results.

The factory default is SPC. SPC or MPC will be shown with the calibration details

in measurement mode.

15

PURE WAT COEF (Pure Water Coefficient)

Choose ENABLE to automatically apply pure water temperature correction for

measurements below 2 µS/cm (ultra pure water).

Note: this option does not apply to Salinity mode.

TEMP COEFFICIENT (Linear)

The temperature coefficient is the amount of change in conductivity per degree

temperature (% per ºC). The factory default setting is a temperature coefficient of

2.1 % per ºC. For most applications this will provide good results. The meter

allows adjustment from 0.0 to 10.0.

Note: this option does not apply to Salinity mode.

Select 0.0 % for uncompensated measurements.

The temperature will be measured by the electrode and

displayed in measurement mode – but without compensation.

NORMALIZATION TEMPERATURE (ºC)

When Automatic Temperature Compensation is used, measurements are

adjusted by the temperature coefficient %, to the normalization temperature. This

value is adjustable from 15.0 to 35.0 ºC.

Use the normalization temperature that is referenced on your calibration

standard(s) – usually 25 ºC.

TDS FACTOR (TDS Mode Only)

The TDS conversion factor is a multiplication factor used to convert from

conductivity to TDS. The TDS conversion factor automatically adjusts the reading.

Select the desired TDS factor from 0.400 to 1.000.

CELL CONST (Cell Constant)

The AB200 kit includes a probe with a nominal cell constant (k) of 1.0.

Use probes with k = 0.1 and 10 (sold separately) for improved performance in

extreme sample ranges. The factory default is 1.0 to match the included probe.

Cell constant can be adjusted from 0.010 to 10.000.

k = 0.1 ideal for low measurements <20 µS (<10 ppm).

k = 1.0 ideal for mid-range measurements

k = 10 ideal for high measurements >20 mS (>10 ppt).

16

ALARM

Use a visual and audible alarm to alert you when High or Low values that have

been set from this menu are exceeded. “High” or “Low” will blink on the display if

the values are exceeded while simultaneously, a loud, intermittent beeping sound

is heard. The alarms will continue until the conditions are no longer met, and will

only be active during measurement mode.

STD DUE

When enabled, the “Std Due” indicator blinks if the number of days since the last

calibration has been exceeded. Set the time from 8 hours, 16 hours, or from 1 to

31 days.

11. Conductivity Standardization (Automatic)

For best results, periodic standardization (calibration) with known accurate

standards is recommended prior to measurement. Use standards that are close in

value to your intended sample(s).

When using multi-point calibration, perform a calibration in each range that you

expect to use for best results.

If the conductivity electrode has been stored dry for some time, soaking in alcohol

or clean water for a few minutes can help performance.

1) Turn meter on, press MODE if needed for conductivity measurement mode.

2) Rinse the electrode with clean water then submerse in your first your

conductivity standard – for automatic mode, this is either 84 µS, 1413 µS,

12.88 mS, or 111.8 mS. Provide stirring for best results.

3) Press STD to enter standardization mode.

4) When ‘Stable’ appears, use the ▲/▼ keys to adjust the cell constant

manually or press STD without adjustment to keep the nominal cell constant

value displayed and proceed with automatic calibration.

5) Wait for the meter to lock on the standard and press STD after ‘Stable’

appears to confirm the value. The calibrated value, Range (R) that was

calibrated and the calculated cell constant are now shown.

6) For multi-point calibration repeat steps 2 & 3 with additional standards.

Calibrate one point per range, up to 4.

7) To view the Conductivity Standardization Report at any time from the

measure screen, press REPORT.

17

Additional Notes On Automatic Conductivity Calibration:

A maximum of one calibration point per range can be performed. If multiple

calibration points are used in the same range, the most recent one will replace

the previous one.

If the electrode is replaced, it is best to clear the calibration to the factory

default values.

Rinse or immerse the probe before standardization and between samples with

clean water (deionized water is ideal).

For best results always begin with your lowest calibration standard value,

followed by the next lowest, and so on.

Low conductivity standard solutions (less than 20 µS) are unstable and are very

temperature dependent. As a result, reproducible calibration results are

challenging in lowest measurement range (0.00 to 20.0 µS).

“2 Cell’ or “4 Cell’ electrode is automatically detected and

displayed on the measurement screen when connected.

12. Cond/TDS/Salinity/Resistivity Standardization

(Manual Adjustment)

For best results, periodic standardization (calibration) with known accurate

standards is recommended prior to measurement. Use standards that are close in

value to your intended sample(s).

When using multi-point calibration (MPC), perform a calibration in each range that

you expect to use for best results.

If the conductivity electrode has been stored dry for some time, soaking in alcohol

or clean water for a few minutes can help performance.

1) Turn meter on, press MODE if needed for the appropriate mode.

2) Rinse the electrode with clean water then submerse in your first your

conductivity standard. Press STD to enter standardization mode.

3) When ‘Stable’ appears, use the ▲/▼ keys to adjust the cell constant

manually or press STD without adjustment to keep the nominal cell constant

value displayed and proceed with automatic calibration.

18

4) The upper display is the active reading while the lower display is the factory

default value. Use the ▲/▼ keys to adjust the upper display to match the

desired value.

5) Press STD after ‘Stable’ appears to confirm the value. The calibrated

value, Range (R) that was calibrated and the calculated cell constant are

now shown.

6) For multi-point calibration repeat steps 2 thru 5 with additional standards.

Calibrate one point per range, up to 5.

7) To view the Conductivity Standardization Report at any time from the

measure screen, press REPORT.

Additional Manual Calibration Notes:

A maximum of one calibration point per range can be performed. If multiple

calibration points are used in the same range, the most recent one will replace

the previous one.

When the electrode is replaced, it is best to clear the calibration to the factory

default values.

Rinse or immerse the probe before calibration and between samples with clean

water (deionized water is ideal).

For best results always begin with your lowest calibration standard value,

followed by the next lowest, and so on.

Low conductivity standard solutions (less than 20 µS) are unstable and are very

temperature dependent. As a result, reproducible calibration results are

challenging in lowest measurement range #1 (0.00 to 20.0 µS).

19

13. Ion Setup

Use Setup ISE mode to customize this parameter. Press SETUP from the

measurement screen and then press ENTER when ISE is selected.

MEASURE UNIT

Select ppm, molar, or mg/L ion concentration units.

ALARM

The AB250 offers a visual and audible alarm to alert you when the High or Low

values that have been set from this menu are exceeded. “High Alarm” or “Low

Alarm” will blink on the display if the values are exceeded while simultaneously, a

loud, intermittent beeping sound is heard. The alarms will continue until the

conditions are no longer met, and will only be active during measurement mode.

STD DUE

When enabled, the “Std Due” indicator blinks if the number of days since the last

calibration has been exceeded. Set the time from 8 hours, 16 hours, or from 1 to

31 days.

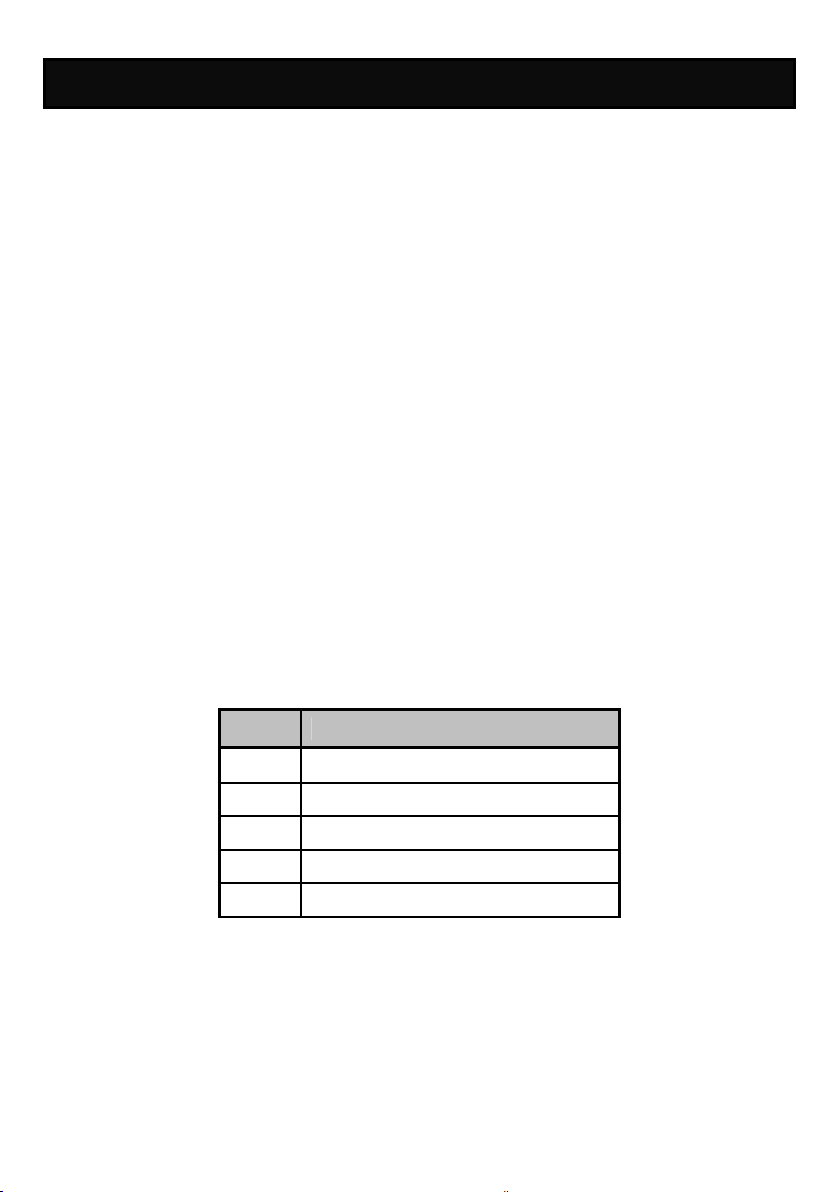

STANDARDS

Choose one of (5) ISE buffer groups available for standardization, based on the

standard calibration values you intend to use.

Group ISE Values

1 0.001, 0.01, 0.1, 1, 10, 100

2 0.01, 0.1, 1, 10, 100, 1000

3 0.1, 1, 10, 100, 1000, 10000

4 0.02, 0.2, 2, 20, 200, 2000

5 0.05, 0.5, 5, 50, 500, 5000

20

14. Ion Standardization

The AB250 can measure ion concentration such as ammonia or fluoride when

using an ion selective electrode (ISE) for the specific ion of interest.

Ion standardization is required with at least two calibration standards in order for

the instrument to calculate the measurement.

The primary display will show “- - - -” when ion calibration is

required for ion measurement.

Prepare ion standards that bracket your measurement range. Follow the ion

selective electrode instruction manual for the appropriate ionic strength

adjustment and sample preparation.

For best results always begin with your lowest standard value, followed by the

next lowest, and so on.

1) Connect the ISE and press MODE as needed for concentration mode.

2) Rinse the ISE with clean water then dip into your lowest calibration standard

and stir. Observe the lower display which contains the mV reading of the ISE.

3) Press STD. Use ▼/▲ keys to match the upper display to your ISE calibration

standard value.

4) After ‘Stable’ appears, press STD to accept the standardization value.

5) Rinse the ISE with clean water and dip into your next lowest calibration

standard and stir. Press STD after “Stable” appears to accept the next

standardization value.

6) The mV/decade slope value will be displayed upon a successful calibration.

“Slope Error” indicates that the calibration for the current point was not

successful. This occurs when the slope (mV difference between two

consecutive points) is <15 mV/decade or >90 mV/decade.

7) Repeat steps 4 & 5 with additional ISE standards if desired.

8) To view the Ion Standardization Report at any time from the measure screen,

press REPORT.

Refer to your Ion Selective Electrode instruction manual for

details on conditioning, storage, maintenance, calibration

standard preparation, Ionic Strength Adjustment,

troubleshooting, etc. Each ISE is unique and requires care and

operation that is specific to the electrode and ion of interest.

21

15. Viewing, Transferring, and Printing Data

To send data directly to a printer or PC you will require the appropriate RS-232 or

USB cable.

Press VIEW key to view calibration or stored data directly on the display.

Press REPORT soft key to view calibration data directly on the display.

Press PRINT key to print/export stored data manually to a dedicated printer

or computer.

Press PRINT key to print/export calibration data manually to a dedicated

printer or computer.

Use the TIMED Datalog function to print/export live data automatically at

intervals to a dedicated printer or computer (3 second minimum rate). See

EXPORT DATA within the SYSTEM SETUP MENU to use this setting.

Choose the “PRINTER” format option to transfer the data in an easily viewable

format – best for printing.

Choose the “CSV” format option to send the data as a comma separated value –

best for exporting data into software

Press VIEW and select DELETE ALL to erase all saved data that was manually

or automatically stored into memory. This step is most commonly required when

the TIMED Datalog interval is not turned off and as a result, fills the memory to

capacity. When the memory is full, deleting the saved data is required in order to

save additional data. The instrument will never erase old data in favor of new data

when the memory is full.

If you wish to view, print or send the saved data to a PC before deleting, use the

PRINT key.

To make changes to the printer, datalog, and output settings, see Section 3 –

EXPORT DATA.

22

16. Standardization Report

The Standardization Report provides detailed information on the most recent

calibration. It includes date & time, calibration standard(s), offset, temperature,

number of days calibration is overdue, and slope information.

The Standardization Report is automatically displayed every time a standard has

been successfully accepted.

Important Note For pH Standardization:

If the calculated pH slope is not within 80.0 % - 110.0 %, the value is rejected and

returns to standardization mode after the following message is displayed;

"Slope Error! Allowable limit is 80 % to 110 %"

If the calculated pH slope is within 80.0 % - 110.0 %, but not within

90.0 % - 102.0 %, the value is accepted after the following message is displayed;

"Warning: Slope is not within 90-102 %.

Check electrode / buffer / temperature or clear values."

Important Note For ISE Standardization:

The allowable limit for ISE slope is 15 to 90 mV per decade.

To view the calibration report at any time, press REPORT from the desired

measurement screen. To send the calibration report data to a printer or PC, press

PRINT/ENTER key.

Check out www.fishersci.com/accumet for the latest

software available for your meter and other useful information.

23

17. Troubleshooting

Parameter Cause Solution

pH Cal points are

too close

pH Reading is 7.00 and

won’t change

pH or Ion Slope error /

Standardization

error

Ion Display reads “- - -“ 2-point standardization has not

Conductivity Can’t adjust /

can’t calibrate

Conductivity 2nd Calibration point

replaces the 1st

Custom pH buffer calibration values must

be at least 1.0 pH unit apart.

Electrode tip may be cracked or broken.

Replace electrode.

Calibration values are too far apart,

or too far from ideal values. Check the

electrode, use fresh buffers, and check

meter settings. Electrode may require

filling solution, conditioning, or complete

replacement. Refer to electrode manual.

been performed.

AUTO calibration values (84 µS, 1413

µS, 12.88 mS, or 111.8 mS) are not

used. Change Cal Method to MANUAL.

Only one point per range can be

calibrated. Re-consider your SINGLE or

MULTI Cal Method setting.

TDS Standard does

not match

Temperature Instrument reads

inaccurate

temperature

ANY “OR” or “UR” error

message

ANY I forgot my

password

Adjust TDS factor as needed to

correct value.

Calibrate using water bath or known

accurate thermometer. Faulty thermistor

– repair or replace.

Over Range or Under Range condition.

Check that electrode is connected.

Please send a written request with your

name, contact information, and

instrument serial number; a temporary

24

password will be provided.

ALL My problem is not

listed here.

Please contact your Fisher Scientific

representative or email technical

support directly with your feedback:

accumet@fishersci.com

18. USB Driver & Boot Loader Documentation

This document is intended to guide the reader through the process of A) installing

the USB driver for communication with a PC, and B) boot loading (upgrading) the

latest firmware for Fisher Scientific accumet

meters which may become available.

USB Driver Installation Guide For Windows XP:

To install the USB device driver under Windows XP, follow the instructions below.

This will allow your computer to recognize the instrument.

1. Obtain the USB driver file (via web download, disc, email, etc.) and save

on your computer in a location that can be easily found.

2. Connect the meter to a spare USB port on your PC using the USB cable

provided with the instrument. Once the USB is connected, Windows

Found New Wizard will launch as shown below:

®

AB150, AB200, and AB250 series

25

3. Select “Install from a list or specific location (Advanced)” as shown in

figure above and then click “Next”.

4. Select “Search for the best driver in these locations” and enter the file

path in the combo-box (“C:\Accumet_AB_USB_Driver” as in figure below)

or browse to it by clicking the browse button. Once the file path has been

entered in the box, Click “Next” to proceed.

26

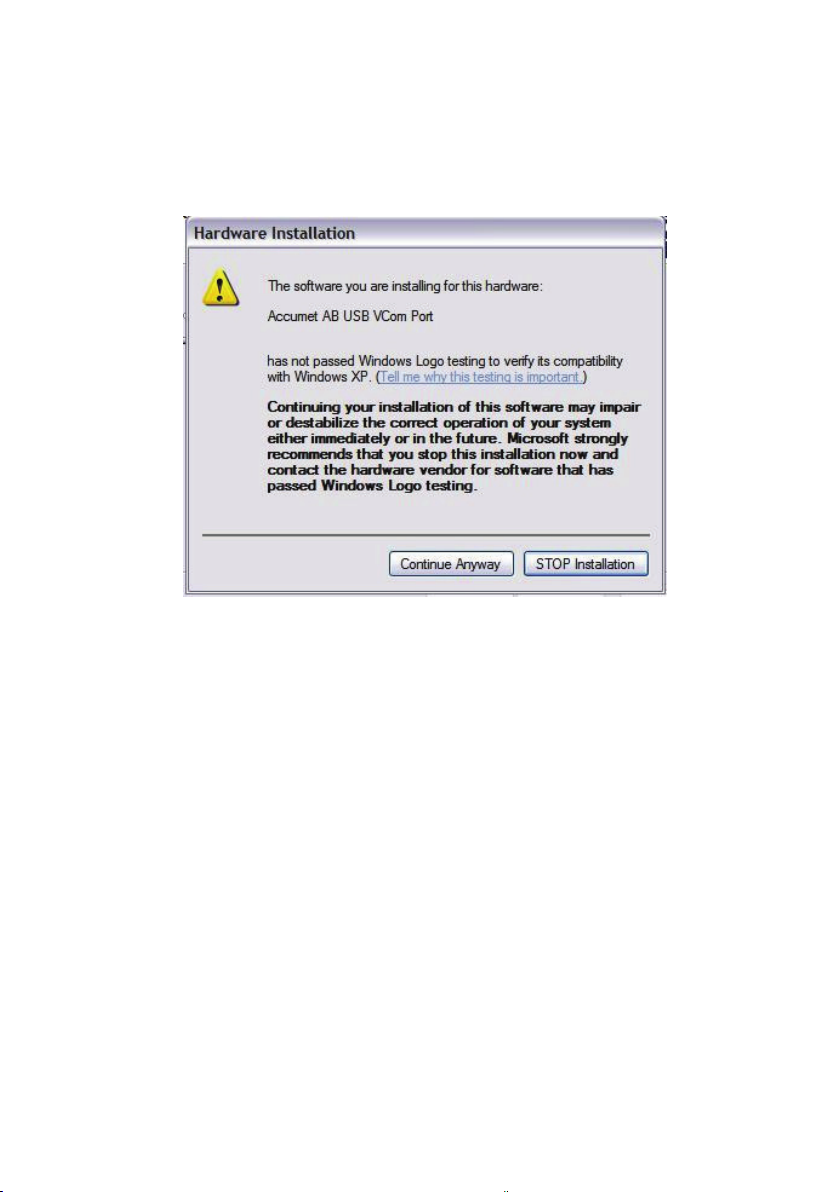

5. If Windows XP is configured to warn when unsigned (non-WQHL

certified) drivers are about to be installed, the message dialogue

shown in figure below will be displayed unless installing a Microsoft

WHQL certified driver. Click on “Continue Anyway” to continue with

the installation.

27

6. The screen shown in the figure below will be displayed as Windows XP

copies the required driver files.

7. Once the installation is successful as shown in the figure below.

Click “Finish” to complete.

28

USB Driver Installation Guide For Windows 7:

To install the USB device driver under Windows 7, follow the instructions below.

This will allow your computer to recognize the instrument.

1. Obtain the USB driver file (via web download, disc, email, etc.) and save

on your computer in a location that can be easily found.

2. Connect the meter to a spare USB port on your PC using the USB cable

provided with the instrument.

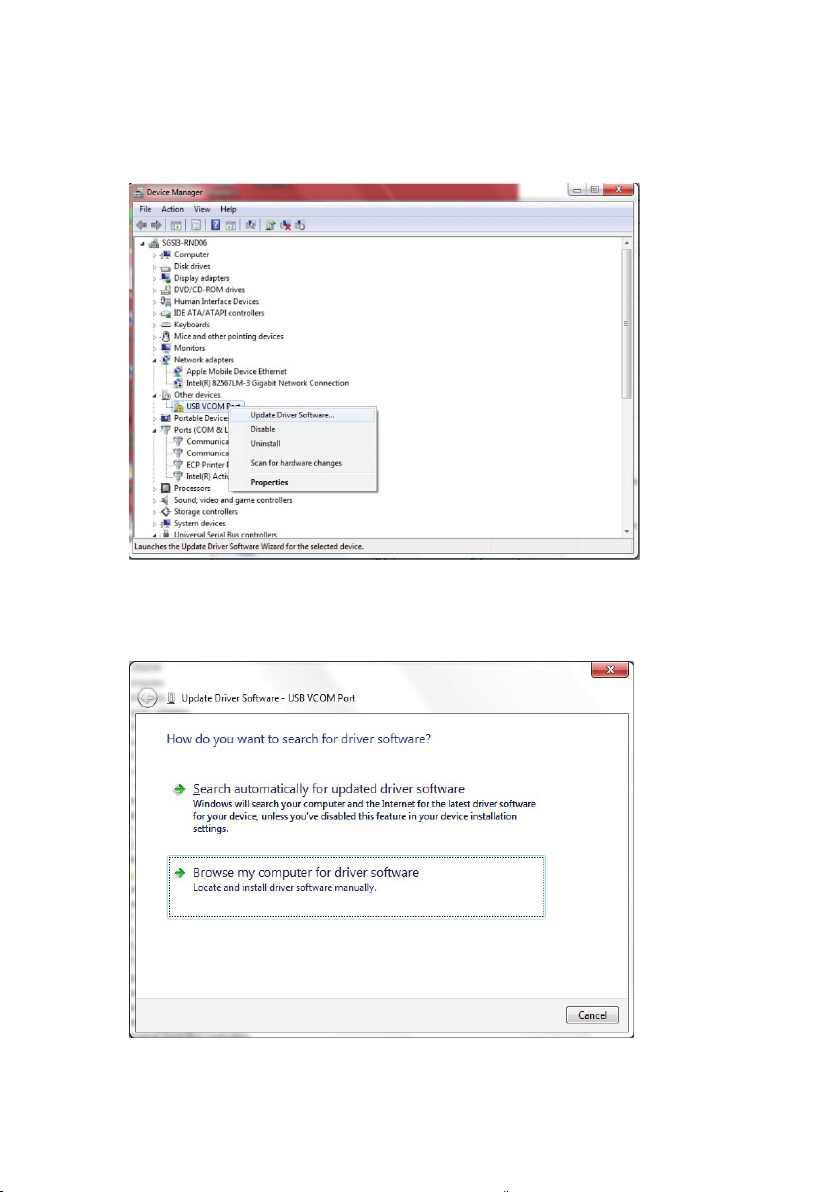

3. Open the Device Manager:

In the Device Manager window there will be a device under Other

Devices with a yellow warning symbol to indicate a problem i.e. no driver

installed with text “USB VCOM Port”.

29

4. Right click on the other devices (USB VCOM Port) to bring up a menu as

shown below. From the Displayed menu, select “Update Driver

Software…”.

5. Select “Browse my computer for driver software” and enter the file

path in the combo-box or browse to it by clicking the browse button.

30

6. Once the file path has been entered in the box, check “Include

subfolders” box and click “Next” to proceed.

7. If necessary, click on “Install this driver software anyway” to continue

with the installation if you receive Windows 7 security pop up window.

31

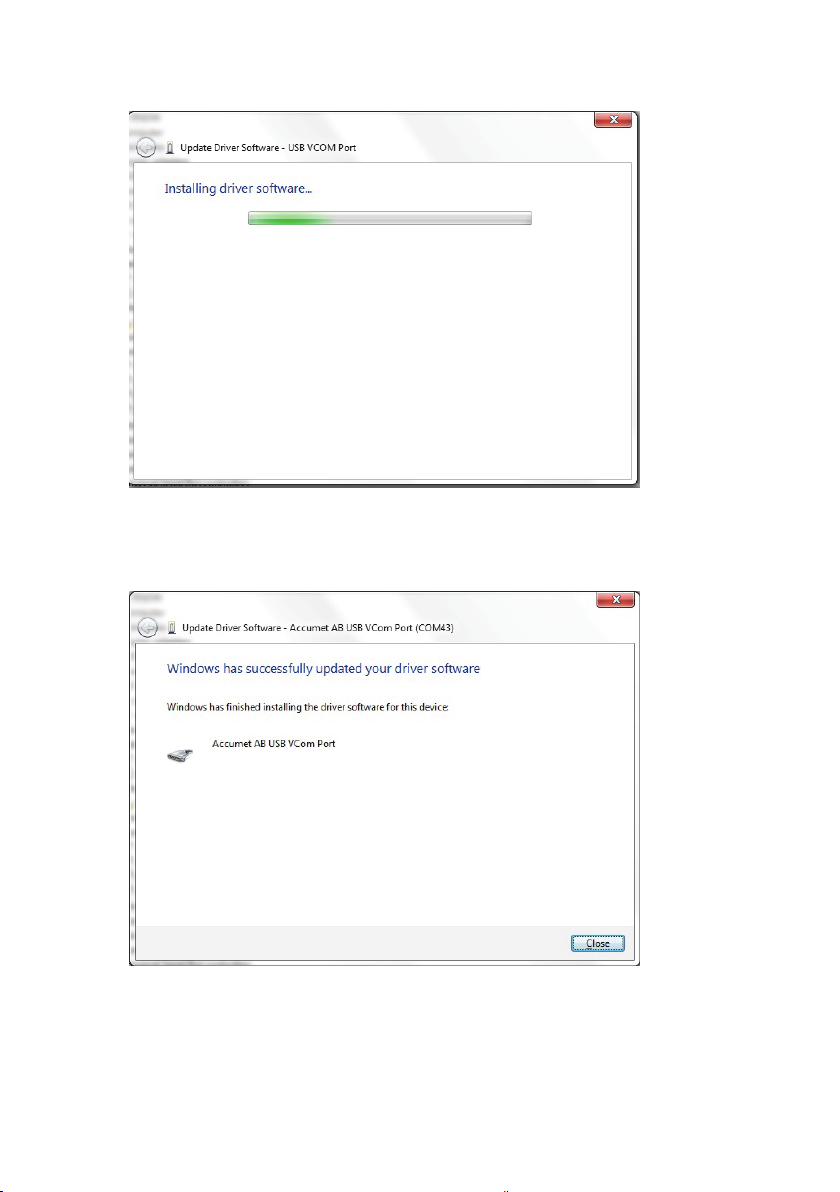

The following window appears when installation is in progress.

When the installation has finished completion screen is displayed as

shown below.

32

8. Click “Close” and go back to the Device Manager Window.

The below figure shows the successful installation of USB Driver for

Accumet AB meter.

Note: If the USB cable is removed and connected to a new (different) USB

port, please repeat the driver installation procedure for the new USB port.

33

Boot Loading Procedure:

The software version of your instrument is displayed on the screen during power

on. Check www.fishersci.com/accumet

new software is available. As new releases become available, the boot loading

procedure described here is the process by which you can upgrade your Fisher

Scientific accumet®AB150, AB200, and AB250 series meter to have the latest

firmware. This procedure applies to both Windows XP and Windows 7. Please

read the entire procedure before starting.

1. Obtain the latest firmware via web download, disc, email, etc. and save

on your computer in a location that can be easily found or retrieved.

2. Remove the power cord from the instrument.

3. Plug in the USB cable.

4. Press and hold the left soft key (see image below) as you plug in the

power cord.

or email accumet@fishersci.com to see if

34

5. The instrument will beep twice and a pop-up window will appear showing

contents of a new drive named “ACCUMET AB” on your computer

similar to the one seen below. This folder represents the hard drive

of the instrument. The left soft key can be released as soon as this

window is visible.

35

6. Similar to the method for replacing a file that resided on a thumb drive,

you will need to delete the firmware.bin

window and replace it with the new file. Highlight “firmware.bin” and

delete this file.

file as seen in the pop-up

7. Locate the new firmware file “Accumet_ABSeries.bin

paste or drag & drop it into the pop-up window.

36

” and copy &

8. Once the file is successfully transferred, close the window.

9. Remove the power cord and restart the meter as you would normally.

The new software version will be briefly visible during power on.

19. Specifications

We reserve the right to make changes, improvements and modifications to the

specifications listed here. While specification changes are quite rare, software

versions are often updated to improve the customer experience and instrument

operation. The software version is displayed during power on.

pH AB150, AB200, AB250

Range -2.000 to 20.000 pH

Resolution 0.1 / 0.01 / 0.001 pH

Accuracy ±0.002 pH + 1 LSD

Cal. Points Up to 6 preset or 5 custom

USA: 2.000, 4.010, 6.997, 10.013, 12.000

NIST: 1.678, 4.010, 6.865, 9.184, 12.460

Buffer Sets

Slope Display Yes, with offset

Multiple Slope

Display

Temp

Compensation

Temp Range

(Meter)

Inputs BNC, ATC

mV AB150, AB200, AB250

Range ±2000.0 mV

Rel. mV Range ±2000.0 mV

Resolution 0.1 mV

Accuracy ±0.2 mV or ±0.05 % whichever is greater

Offset

Adjustment

DIN: 1.090, 3.060, 4.650, 6.790, 9.230, 12.750

FSCI: 1.000, 3.000, 6.000, 8.000, 10.000, 13.000

CUSTOM: Any 2-5 values, ≥1.0 pH unit apart

Yes, up to 5 different slopes

Automatic or manual (0 to 100 ºC / 32 to 212 ºF)

0.0 to 100.0 ºC / 32.0 to 212.0 ºF

Up to ±150 mV

37

Ion AB250 Only

Range 0.001 to 19999 (±2000 mV)

Resolution 0.001 / 0.01 / 0.1 / 1 (automatic)

Units ppm, mg/L, molar

Accuracy

Cal Points

0.5 % full scale (monovalent ion)

1 % full scale (divalent ion)

2 to 6 points from one of following groups;

0.001, 0.01, 0.1, 1, 10, 100

0.01, 0.1, 1, 10, 100, 1000

0.02, 0.2, 2, 20, 200, 2000

0.1, 1, 10, 100, 1000, 10000

0.05, 0.5, 5, 50, 500, 5000

Temperature AB150, AB200, AB250

Resolution 0.1 ºC / 0.1 ºF

Accuracy ±0.3 ºC / ±0.5 ºF

Calibration

Offset in 0.1 º increments;

Offset range: ±5 ºC / 9 ºF

Conductivity AB200 Only

Range 0.00 µS to 500.0 mS

Resolution 0.01 / 0.1 µS; 0.001 / 0.01 / 0.1 mS

Accuracy ±1 % full scale

Cal. Points

Cell Constant 0.010 to 10.000

Cell Types 2 or 4 cell with ATC

Coefficient

(Per ºC)

Normalization 15.0 to 30.0 ºC / 59.0 to 86.0 ºF

Compensation Automatic with supplied cell or manual

Temp

Compensation

Automatic (4 points); maximum 1 per range

Manual (5 points); maximum 1 per range

Linear & pure; adjustable 0.000 to 10.000 %

0.0 to 100 ºC / 32.0 to 212.0 ºF

(0.0 to 80 ºC / 32.0 to 176.0 ºF with supplied cell)

TDS AB200 Only

Range 0.00 ppm to 500 ppt (@ TDS factor 1.00)

Resolution 0.01 / 0.1 ppm ; 0.001 / 0.01 / 0.1 ppt

Accuracy ±1 % full scale

Cal. Points Up to 5

TDS Factor 0.400 to 1.000

38

Salinity AB200 Only

Range 0 to 80.0 ppt

Resolution 0.01 / 0.1 ppm; 0.001 / 0.01 / 0.1 ppt

Accuracy ±1 % full scale

Resistivity AB200 Only

Range 2.000 Ω to 20.0 MΩ

Resolution 0.01 / 0.1Ω; 0.001 / 0.1 kΩ; 0.01 MΩ

Accuracy ±1 % full scale

Other AB150, AB200, AB250

Display Monogram graphics LCD

Backlight Yes, adjustable

Output RS-232 (phono plug), mini-B USB, stirrer

Adjustable

Stirrer Speed

Language

selection

Contrast

Adjustment

Memory 500 data sets, viewable

Datalogging

Cal Due Alarm Yes, user selectable from 8 hr, 16 hrs, & 1-31 days

High / Low

Alarms

Power 9 V DC adapter, center positive, 1.3 A (100 / 240 VAC, SMPS)

Yes

English, Deutsch, 中文, Français, Italiano, & Español

Yes

Manual, timed (selectable every 3 to 3600 seconds)

Printer or CSV format

Yes, user selectable, visual & audible

Instrument Operating Conditions

Operating Ambient

Temperature

Operating Relative Humidity

Storage Temperature

Storage Relative Humidity

Pollution

Overvoltage

5 to 45 °C

5 to 85 %, non-condensing

-20 to +60 °C

5 to 85 %, non-condensing

Degree 2

Category II

39

Weight

Benchtop: 720 g (without electrode plate)

Size

Regulatory and Safety

Power Rating

Shock and Vibration

Enclosure

(Designed to Meet)

Benchtop: 7 cm (H) x 18.5 cm (W) x 17.6 cm (D)

CE, TUV 3-1, FCC Class A

DC Input: 9 VDC 2A

Vibration: shipping/handling per ISTA #1A

Shock: drop test in packaging per ISTA #1A

Benchtop: IP54

Universal Power Adapter Operating Conditions

Operating Ambient

Temperature

Operating Relative Humidity

Storage Temperature

Storage Relative Humidity

Pollution

Overvoltage

0 to 50 °C

0 to 90 %, non-condensing

-20 to +75 °C

0 to 90 %, non-condensing

Degree 2

Category II

20. Replacements and Accessories

Item Description Catalog Number

AB150 pH meter only 13-636-AB150A

AB150 pH KIT includes 13-620-631 pH electrode 13-636-AB150

AB150 pH BIO KIT includes 13-620-183A pH electrode and

13-620-19 ATC electrode

AB250 pH/ISE meter only 13-636-AB250A

AB250 pH/ISE KIT, includes 13-620-631 pH electrode 13-636-AB250

40

13-636-AB150B

AB200 pH/CON meter only 13-636-AB200A

AB200 pH/CON KIT, includes 13-620-631 pH electrode and

13-620-100 conductivity cell

Fisher Scientific accumet® benchtop stirring probe 13-620-BSP

Replacement paddle for 13-620-BSP 13-620-RP

pH/ATC electrode, double junction, plastic body, refillable 13-620-631

pH electrode, double junction, glass body, refillable 13-620-183A

pH electrode, single junction, glass body, refillable 13-620-285

Temperature probe, stainless steel with 3-ft cable 13-620-19

ORP electrode, glass body, refillable 13-620-81

Conductivity cell, 2-cell, epoxy body, k=0.1 13-620-101

Conductivity cell, 2-cell, epoxy body, k=1 13-620-100

Conductivity cell, 2-cell, epoxy body, k=10 13-620-102

Conductivity cell, 4-cell, glass body, k=1 13-620-163

Conductivity cell, 4-cell, glass body, k=10 13-620-164

Conductivity cell, 4-cell, epoxy body, k=1 13-620-165

Conductivity cell, 4-cell, epoxy body, k=10 13-620-166

Fisher Scientific accumet® conductivity calibration kit 13-637-674

13-636-AB200

Fisher Scientific accuflex® electrode support arm and bracket 13-637-671

Replacement power supply, 100/240 V 13-636-104

Compact printer, 100-240 V. Includes 1 roll of paper 13-637-690

Replacement paper for 13-637-690 printer, pack of 2 rolls 13-637-691

41

21. Warranty

The Fisher Scientific Company (“Fisher”) warrants to the direct purchaser that the

accumet meters and accumet, accuTupH, and accupHast, electrodes will be free

from defects in material or workmanship for a specified warranty period. During

that period, Fisher will repair or replace the product or provide credit, at its sole

option, upon prompt notification and compliance with its instructions. For accumet

meter, that specified period is 36 months from delivery date. For electrodes, that

specified period is 12 months.

Unless otherwise agreed, the warranty is limited to the country in which the

product is sold.

No Fisher employee, agent or representative has the authority to bind Fisher to

any oral representation or warranty concerning any product sold. Any oral

representation or warranty made prior to purchase of any product and not set forth

in writing and signed by a duly authorized officer of Fisher shall not be enforceable

by the purchaser.

FISHER EXPRESSLY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

Fisher’s sole responsibility and the purchaser’s exclusive remedy for any claim

arising out of the purchase or any product listed above is repair, replacement or

credit as described above, where applicable. In no event: 1) shall the cost of the

exclusive remedy exceed the purchase price: 2) shall Fisher be liable for any

special, indirect, incidental, consequential, or exemplary damages, howsoever

arising, even if Fisher has been advised of the possibility of such damages.

Each article that Fisher furnishes will conform to the written specifications given

in this manual, or those of a further improved model. Changes are made often to

the information in the manual and will be incorporated into future edition.

22. Return of Items

A “Return Goods Authorization” (RGA) must be obtained from our Customer

Service Department or before returning items for any reason. Please include data

regarding the reason the items are to be returned. For your protection, items must

be carefully packed to prevent damage in shipment and insured against possible

damage or loss. We will not be responsible for damage resulting from careless or

insufficient packing. A restocking charge will apply to all unauthorized returns.

42

23. Notice of Compliance

This equipment generates, uses, and can radiate radio frequency energy and if

not installed and used in accordance with the instruction manual, may cause

interference to radio communications. It has been tested and found to comply

with the limits for a Class A computing device pursuant to Subpart J of Part 15

of FCC Rules, which are designed to provide reasonable protection against

such interference when operated in a commercial environment. Operation of

this equipment in a residential area is likely to cause interference in which case

the user, at his own expense, will be required to take whatever measures may

be required to correct the interference.

“This digital apparatus does not exceed the (Class A) limits for radio noise

emissions from digital apparatus set out in the Radio Interference Regulations

of the Canadian Department of Communications.”

“Le present appareil numerique n’ emet pas de bruits radioelectriques

depassant les limites applicables aux appareils numeriques (de la class A)

prescrites dans le Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.”

WEEE Compliance

This product is required to comply with the European Union’s Waste

Electrical & Electronic Equipment (WEEE) Directive 2002/96/EC. It is

marked with the symbol on the left.

Thermo Fisher Scientific has contracted with one or more recycling/disposal

companies in each EU Member State and this product should be disposed of or

recycled through them. Further information on compliance with these

directives, the recyclers in your country, and product information that may

assist the detection of substances subject to the RoHS Directive are available

from www.thermofisher.com

.

43

24. Declaration of Conformity

Manufacturer: Thermo Fisher Scientific, Inc.

Address: Ayer Rajah Crescent

Blk 55 #04-16/24

Singapore 139949

Singapore

Hereby declares that the following products rated 100-240 VAC, 50/60 Hz, 2A:

Fisher Scientific accumet AB150

Fisher Scientific accumet AB200

Fisher Scientific accumet AB250

Equipment Class: Measurement, control and laboratory, EMC Class A

Conforms to the following directives and standards:

EN61326-1:2006 Electromagnetic Compatibility

(EMC Directive) Electrical equipment for

measurement, control and laboratory use

– EMC requirements

EN61010-1:2001 Safety Standards

UL61010-1:2004

CAN/CSA C22.2 No. 61010-1-04

_____________________

Cheow Kwang Chan

QA/Regulatory Manager

Safety requirements for electrical

equipment for measurement, control and

laboratory use – general requirements

Place & Date of Issue:

July 2012, Singapore

44

Fisher Scientific

accumet

®

Basic (AB)

Benchtop Meters

● AB150

● AB200

● AB250

For technical assistence contact your Fisher Scientific representative or visit:

www.fishersci.com/accumet

or email

accumet@fishersci.com

Thermo Fisher Scientific (Australia) +1300-735-292 thermofisher.com.au

Fisher Scientific GmbH (Austria) 0043-800-208840 at.fishersci.com

Fisher Scientific (Belgium) 056-260-260 be.fishersci.com

Fisher Scientific (Canada) 1-800-234-7437 fishersci.ca

Fisher Scientific (China) +400-881-5117 fishersci.com.cn

Fisher Scientific SPOL. S.R.O. (Czech Republic) +420-466-798-230 thermofisher.cz

Fisher Scientific (Denmark) +45-70-27-99-20 fishersci.dk

Fisher Scientific (Finland) +358-9-8027-6280 fishersci.fi

Fisher Scientific (France) 03-88-67-53-20 fr.fishersci.com

Fisher Scientific GmbH (Germany) 0049-2304-932-5 de.fishersci.com

Fisher Scientific (India) +1-800-209-7001 fishersci.in

Fisher Scientific (Ireland) +35-301-899-5854 ie.fishersci.com

Fisher Scientific (Italy) 02-953-28-258 it.fishersci.com

Fisher Scientific (Korea) +02-527-0300 fishersci.co.kr

Fisher Scientific (Malaysia) +603-5122-8888 fishersci.com.my

Fisher Scientific (Netherlands) 020-487-70-00 nl.fishersci.com

Thermo Fisher Scientific (New Zealand) +0800-933-966 thermofisher.co.nz

Fisher Scientific (Norway) +47-22-95-59-59 fishersci.no

Fisher Scientific (Portugal) 21-425-33-50 pt.fishersci.com

Fisher Scientific (Singapore) +65-6873-6006 fishersci.com.sg

Fisher Scientific (South East Asia) +65-6873-6006 fishersci.com.sg

Fisher Scientific (Spain) 902-239-303 es.fishersci.com

Fisher Scientific (Sweden) +46-31-352-32-00 fishersci.se

Fisher Scientific (Switzerland) 056-618-41-11 ch.fishersci.com

Fisher Scientific (United Kingdom) +01-509-231166 fisher.co.uk

Fisher Scientific (United States) 1-800-766-7000 fishersci.com

© 2012 Thermo Fisher Scientific Inc.All rights reserved.

45

Loading...

Loading...