Page 1

Installation Instructions

US Installation Irlformation

ES Informaci6n sobre la instalaci6n

FR Informations sur ]'installation

2

12

22

@.

,@.

,@.

@

@.

GC36

01

GC912

GC912M

599203B 11,2004 US

Page 2

Safety & warnings

Electrical Shock Hazard

Disconnect power

before servicing the

product.

Failure to do so could

result in death or

electrical shock.

Cut Hazard

Flexible appliance connectors shall

meet the requirements of ANSI Z21.24

and State Boards. They shall not

exceed 36 inches in length.

A CAUTION!

In order to avoid hazard these products

must be installed according to these

instructions.

This product should not be sealed into the

bench with silicone or glue. This will make

any future servicing difficult. Fisher& Paykel

will not be liable for costs associated with

releasing such products, nor for damage

incurred as a result.

Beware of sharp edges.

Use polystyrene end

caps when carrying

the product.

Failure to use caution

could result in injury

or cuts.

A WARNINGS!

This appliance shall be installed in

accordance with the installation

requirements of the local gas authority

or the appropriate installation code

or in the absence of local codes with

the latest National Fuel Gas Code ANSI

Z223.1 or CAN B149.1,2(Canada). Local

building and electrical codes must be

ad hered to.

IMPORTANT!

This product must be installed by an

authorized person (Warning this product

must be installed by a licensed plumber or

gas fitter when within the Commonwealth

of Massachusetts).

Pleaseleave these instructions with the

appliance. Inform the customer to retain for

future reference.

This product is supplied with an additional

label corltairling the model and serial

numbers. It may be affixed to the underside

of the product, the inside of a cupboard or

to the UserGuide.

Page 3

Before you start

Cabinet Preparation

Ensurethe countertop issquare and level

and ensure no structural members interfere

with space requirements.

Make sure the countertop is made of a heat

resistant material.

We record]mend that the exposed bare

wood edges of the cutout be sealed

with an oil based paint or moisture proof

polyurethane to prevent possible damage

from moisture creeping between the

cooktop trim and the benchtop.

Electrical

Ensurethat there isa power supply

receptacle (1] 0-120V 60Hz) within reach

of the cooktop power cord (30"from the

middle of the product). The main cable

should not touch any hot metal parts.

Make sure the cooktop is connected to

a power supply socket that iselectrically

grounded in accordance with local codes

or in the absence of local codes, with the

National Electric Code ANSI/FPA70 or CSA

22.2(Canada).

The power supply must be properly

polarized. Reversepolarity will result in

continuous sparking of the electrodes, ever]

after flame ignition. If the power supply is

not properly polarized, it is the responsibility

of the customer to have the polarity

corrected.

If there is any doubt as to whether the

wall receptacle is properly grounded or

polarized, have it checked by aqualified

electrician prior to installing the cooktop.

Parts checklist

GasCooktop base unit

Literature pack (includes LPGkit)

Elbow & blue washer (taped to power cord)

Regulator (in Polystyrene)

Burner headsand caps (check polystyrene

carefully before discarding)

3x Burner grates/trivets (1 x center,

2x outer)

Accessories pack (GCg]2M only)

Tools needed

Phillips No. 2 screwdriver

Plumbing fittings as required

Woodworking tools as required

Shut-off valve

Oil based paint (for sealing cutout)

For LP Conversio_

O 7/64"x 13A"(Q2.Sx 4Smm) flat screwdriver

9/32"(7mm) box spanner

For GC912M LP Conversion

Q 7/64"x 13A"(Q2.Sx 4Smm) flat screwdriver

Phillips No. 1screwdriver

9/32"(7mm) box spanner

13/32"(10mm)ring spanner

Page 4

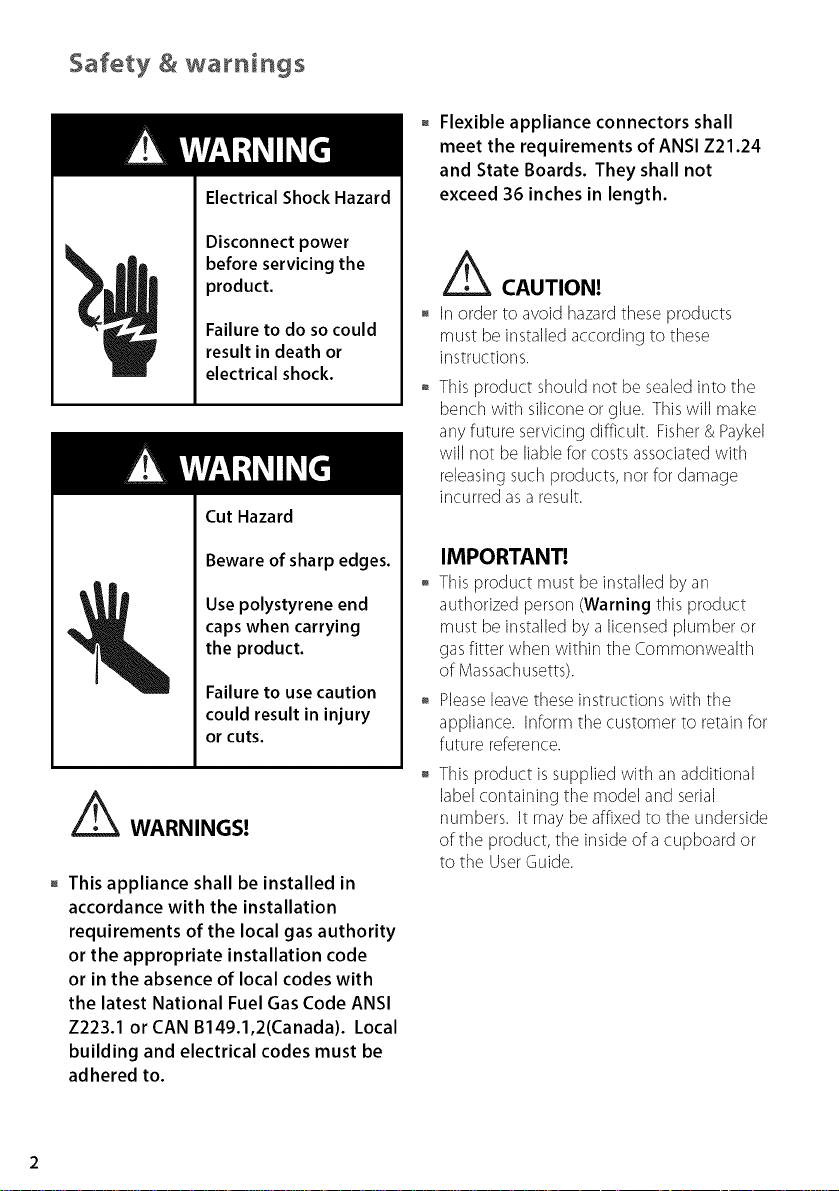

C

manifold

F center line

_- D

Product

GC36 GC912/GC912M

A Width 36"(914 ram) 36"(914 ram)

13 Depth 21"(533 turn) 211/2"(546 ram)

C Height ]S/s"(41.5 rnrn) 2g/16"(65 ram) GC912

3"(76 ram) GC9]2M

Cutout

GC36 GC912/GC912M

D Width 34_A"(870 ram) [3P/s" 34sA'1 34_A"(870 ram) [33// 3_i/,,/]

I;:Depth 19_14"(494 iT]m) [183/ii" 193/_'_ 19_14"(494ram)[191/_/'POS/_(']

F Radius R3/s"(lOram) R3/s"(lOram)

G 1"(25 ram) 1"(25 rnm)

H ] 3/16" (30 rTlrT)) 3/4" (20 rYlrY1)

NOTE:cutout dimensions are given as:'nominal measurement' ('otherwise acceptable range')

Page 5

a

a 36"= Minimum horizontal distance between overhead cabinets installed on either side of

this appliance.

b 30"= Minimum clearance from combustible surface centered above the cooktop.

C 13"= Maximum overall depth of overhead cabinetry.

d 18"= Minimum clearance from countertop to overhead cabinetry.

e 4"(GC36)or 11/2"(GC912& GC912M) = Minimum clearance from cooktop to the left side wall.

f 1"= Minimum clearance from cooktop to the right side wall.

g 11/2"(GC36)or 11/4"(GCgl 2 & GC912M)= Minimum clearance from cooktop to the rear wall.

h 21/2" (GC36)or 11/4"(GC912& GC912M)= Minimum distance from front edge of counter to

front edge of appliance. Where this reduces the distance between the back edge of the

appliance and the adjacent wail to lessthan the rnirlimum of 11/2"(GC36)or 1_/4"(GC912&

GC912M), this wail must be of non combustible material (see note below).

i 23/8"(GC36)or 3s/16"(GC912 & GC912M) = Minimum clearance below countertop to any

combustible surface.

j 30"= Maximum distance to nearest grounded power outlet from the center of the cooktop.

The power cord must not touch any hot metal surfaces.

Non-combustible material

Recommerlded non combustible materials are: 1/4""(6ram) flame retardant millboard covered

with not lessthan No. 28 MSG sheet steel, 0.015"(0.4rnrn) stainless steel,0.024"(0.6rnrn)

alurninium or 0.020"(0.Srnrn)copper.

Page 6

Installation Instructions

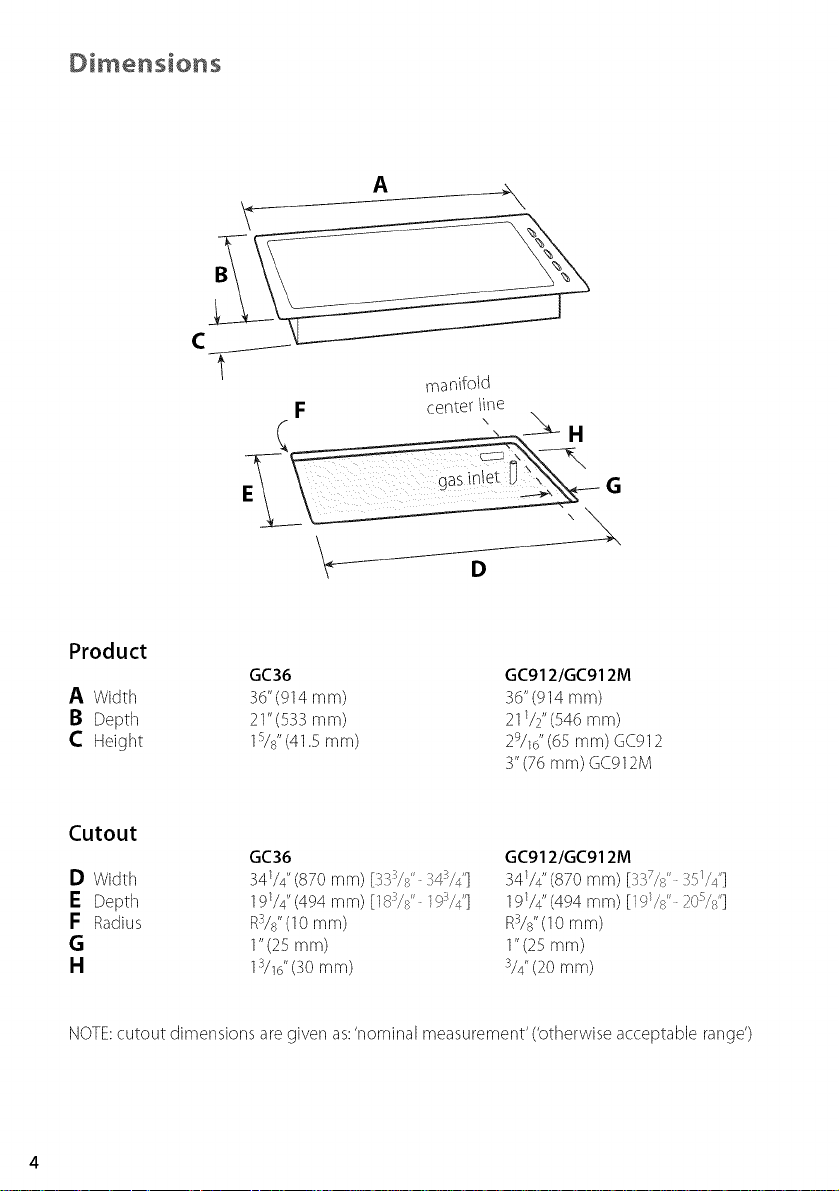

Gas supply connection

This appliance is factory set for use with

Natural Gas at 4"of water column pressure.

It carl also be usedors LPGas at 11"of water

column pressure after conversion (see pages

7&8).

A manual shut-off valve must be installed

in an accessible location in the gas line

external to the appliance for the purpose

of turning orsor shutting off gas to the

appliance. (In Massachusetts such shutoff

devices should be approved by the Board of

State Examiners of Plumbers & Gas Fitters).

Blue Elbow

Gascorsrsectiorsto the product must use

the elbow supplied with a 72" NPTexternal

thread.

Ensure the blue washer (supplied) is

located between the elbow and the

product inlet. Failure to use this will

cause a gas leak.

Gas Regulator

For use with a gas pressure regulator as

shown below. The regulator supplied can

be set for either LPgas or Natural gas.

Pressure ,4D-& .......... /

shows _ U_ .... / %.

Direction of _ _ _ ......................

GasFlow ouse supply

(Note: this didgrdm isof GC36but issimildr for GCR12ond

GC912M).

n , •

J

Page 7

Instamlation Instructions

Converting the regulator

between NG & LP

1

Unscrew the cap from the regulator.

2

Check the orientation of the plastic

conversion plug, and if necessary, unscrew,

turn over and screw back in (wide section

away from cap for LPand against cap for

NG- seediagram below for appropriate

orientation.

Clamping down the cooktop

3

Replaceregulator cap.

4

Testgas pressure (test point provision on

side of regulator). When converting the

regulator for different settings, the function

of the regulator must be checked at a

pressureat least I"WC (0.036p.s.i.)above

the specified manifold pressure.

Placethe cooktop into the cutout and

tighten it with the supplied clamps. These

will cope with the countertop thicknesses

3//_ 2"when usedin the two orientations

shown.

Do not over tighten.

Page 8

Installation Instructions

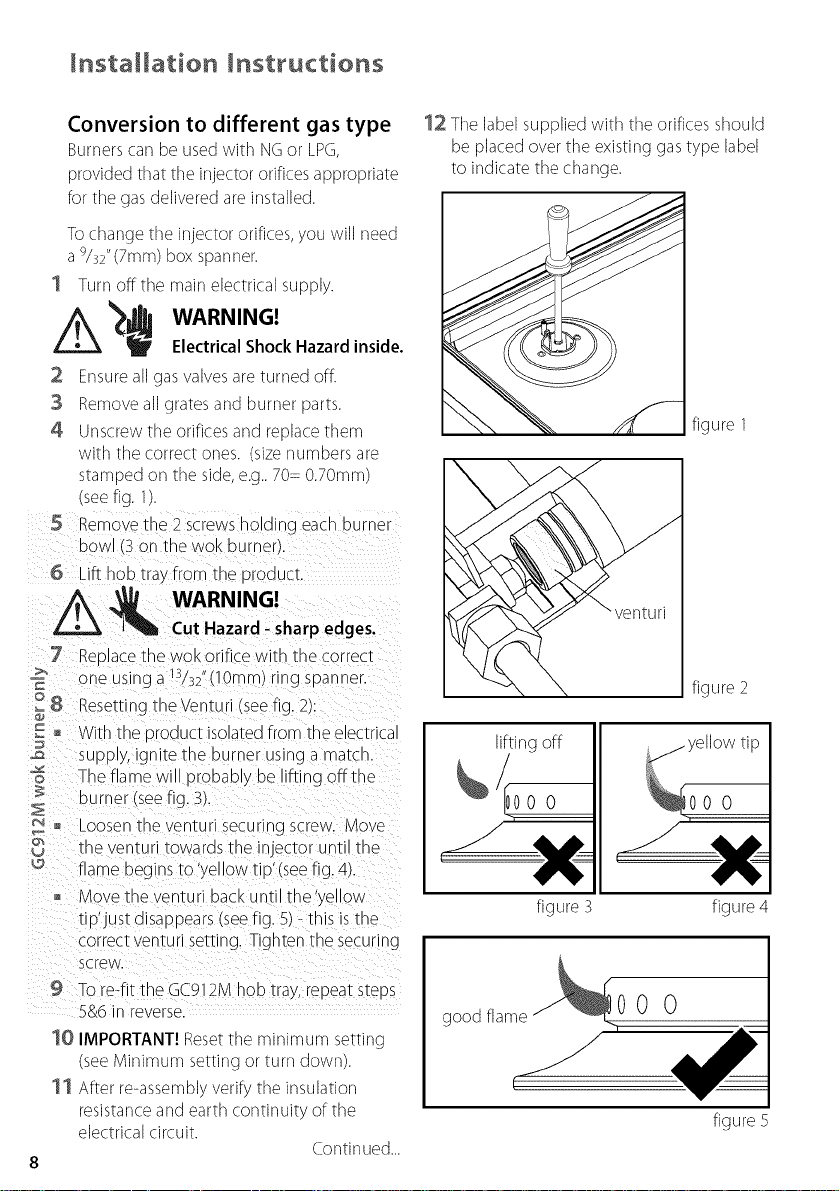

Conversion to different gas type

Burners can be used with NGor LPG,

provided that the injector orifices appropriate

for the gas delivered are installed.

Tochange the injector orifices, you will need

a 9/s2"(7mrn) box spanner.

1 Turn off the main electrical supply.

Electrical Shock Hazard inside,

2 Ensureall gas valves are turned off.

3 Remove all grates and burner parts.

4 Unscrew the orifices and replace them

with the correct ones. (sizenumbers are

stamped on the side,e.g..70= 0.70rnrn)

(seefig. 1).

5 Remove the 2 screws holding eacn burner

_)ovs 3 on _neWOKburner,.

6 Lift hob _rayfrom the proauc_.

Cut Hazard - sharp edges.

7 Reolaceme WOKorifice with the correct

one using a 13/32"(10mm)ring spanner

8 Resettirg me Venturi (seefig. 2):

E _ JViththe Product isolated from tie electrica

supply, ignite the burner using a ma_cn.

The flame wi sroDaDlybe lifting offthe

burner seefig. 3).

_ Loosen me venturl securing screw. Move

me venturi towards the injector unti _ne

flame begins to 'yellow riD'(seefig. 4).

£ove the venturi back until _neyeuow

riD'just disappears lsee fig. 5)- this is the

zorrectventuri setting. Tighten me securing

screw.

9 To re-fit the GC9 2M "/ODTray,repea_s_eps

S&6 in reverse.

10 IMPORTANT! Resetthe minimum setting

(see Minimum setting or turn down).

11 After re-assembly verify the insulation

resistance and earth continuity of the

electrical circuit.

Continued...

12 The label supplied with the orifices should

be placed over the existing gas type label

to indicate the change.

figure 1

figure 2

lifting off

figure figure 4

good flame

00

figure 5

Page 9

Installation Instructions

Leak testing

Leaktesting of the appliance shall be

conducted according to the manufacturer's

instructions.

The appliance and it's individual shutoff

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system in excessof _/sp.s.i.

(3.5kPa).

The appliance must be isolated from the

gas supply piping system byclosing it's

individual manual shutoff valve during any

pressuretesting of the gas supply piping

system at test pressuresat or lessthan

1/2p.s.i.(3.SkPa).

Maximum inlet gas supply pressure 20"W.C.

(SkPa)

Minimum gas supply pressurefor regulator

testing 5"W.C. Natural Gas,12"W.C.LPgas.

After installing the gas supply and making

all cor]r]ections check thoroughly for

possible leaks.

1

Turn all control knobs on unit to 'bff"

position.

2

Open the valve on the gas supply.

3

Using a leakdetection fluid (e.g. Rocol

leak detection spray) check each gas

connection one at a time by brushing

the solution over the connection. The

presence of bubbles will indicate a leak.

4

If necessary,tighter] the fitting and recheck

for leaks.

5

Turn on burner valve and light each

burner.

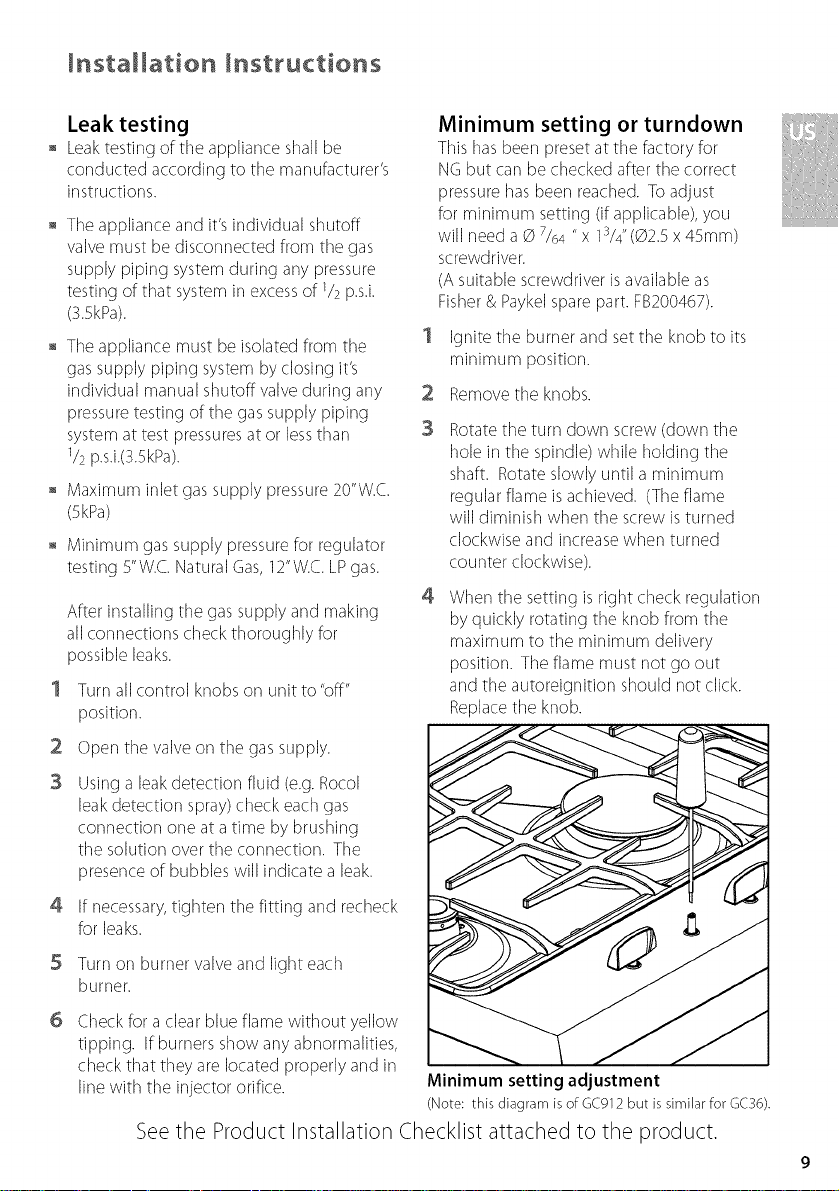

Minimum setting or turndown

This has beer] preset at the factory for

NG but carl be checked after the correct

pressure has beer] reached. Toadjust

for rninirT]urT]setting (ifapplicable), you

will need aO 7/64"x lSA"(Q2.5 x 45mm)

screwdriver.

(A suitable screwdriver isavailable as

Fisher & Paykelspare part. FB200467).

1

Ignite the burner and set the knob to its

minimum position.

2

Remove the knobs.

3

Rotate the turn down screw (down the

hole in the spindle) while holding the

shaft. Rotate slowly until a mir]imum

regular flame is achieved. (The flame

will diminish when the screw isturned

clockwise and increase when turned

counter clockwise).

4

When the setting is right check regulation

by quickly rotating the knob from the

maximum to the minimum delivery

position. The flame must not go out

and the autoreignition should not click.

Replacethe knob.

"----..d%

6

Check for a clear blue flame without yellow

tipping. If burners show any abnormalities,

check that they are located properly and in

line with the injector orifice.

See the Product Installation Checklist attached to the product.

Minimum setting adjustment

(Note: this diagram is of G¢912 but is similar for G¢36).

Page 10

Installation Instructions

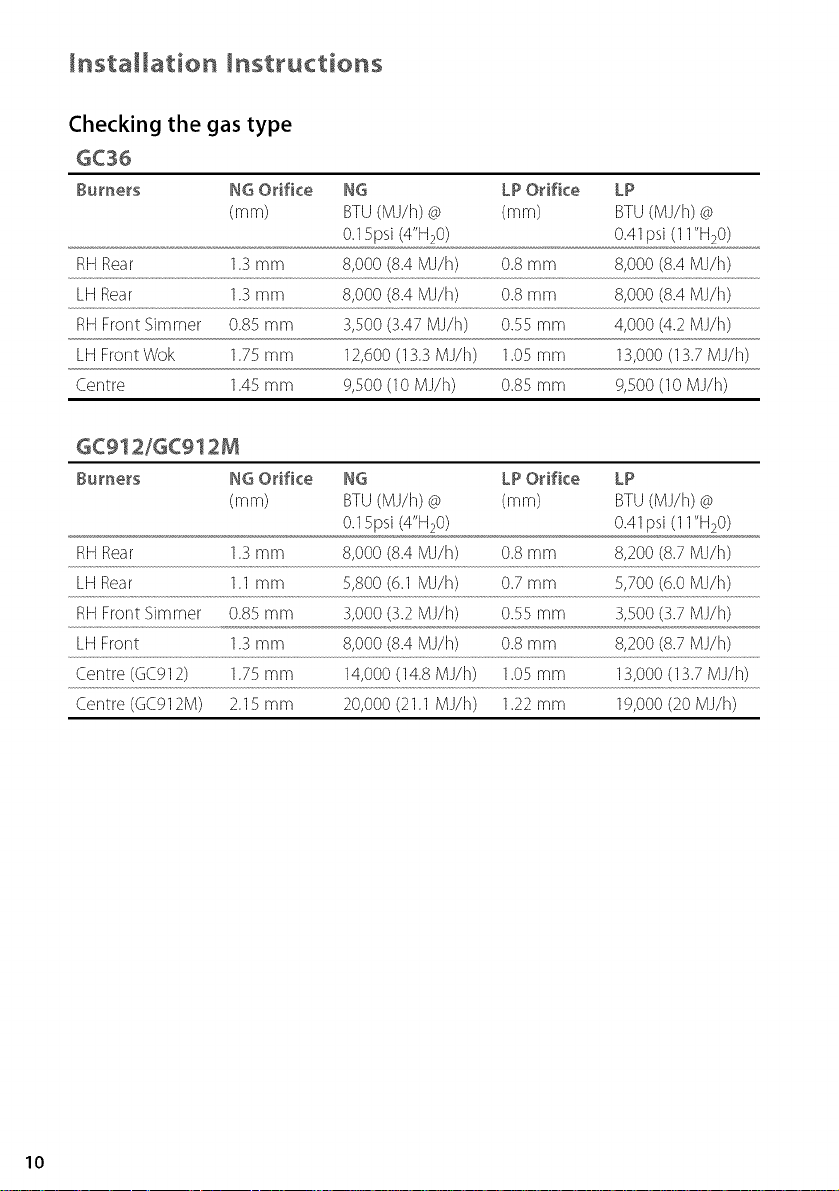

Checking the gas type

GC36

Bu_ae_s NG OHfke NG LP Odfke LP

(ram) BTU(MJ/h) @ (ram) BTU(MJ/h) @

0.15psi (4"H20) 0.41psi (1l"H20)

RHRear 1.3 mm 8,000 (8.4 MJ/h) 0.8 mm 8,000 (8.4 MJ/h)

LH Rear 1.3 mm 8,000 (8.4 MJ/h) 0.8 mm 8,000 (8.4 MJ/h)

RHFront Simmer 0.85 mm 3,500 (3.47 MJ/h) O.SSmm 4,000(4.2 MJ/h)

LH Front Wok 1.75mm 12,.600(13.3MJ/h) 1.05 mm 13,000(13.7 MJ/h)

Centre 1.45mm 9,500 (10 MJ/h) 0.85 mm 9,500 (10 MJ/h)

GC912/GC912M

Burners NG OHfke NG LP Otifke LP

(ram) BTU(MJ/h) @ (ram) BTU(MJ/h) @

0.15psi (4"H20) 0.41psi (1l"H20)

RHRear 1.3 mm 8,000 (8.4 MJ/h) 0.8 mm 8,200 (8.7 MJ/h)

LH Rear 1.1 mm 5,800 (6.1 MJ/h) 0.7 mm 5,700 (6.0 MJ/h)

RHFront Simmer 0.85 mm 3,000 (3.2 MJ/h) O.S5mm 3,500 (3.7 MJ/h)

LH Front 1.3 mm 8,000 (8.4 MJ/h) 0.8 mm 8,200 (8.7 MJ/h)

Centre (GC912) 1.75 mm 14,000(14.8 MJ/h) 1.05mm 13,000 (13.7 MJ/h)

Centre (GCg12M) 2.15 mm 20,000 (21.1 MJ/h) 1.22mm lg,O00 (20 MJ/h)

10

Page 11

Trouble shooting

Trouble shooting

Burners correctly assembled?

Dirty Electrodes?

Gas pressure correct?

Low Setting correct?

Jets incorrect or blocked?

Power supply polarity / earth ok?

Supply voltage ok?

Draft / extraction? (Cust. Adv.)

Contact details

AService Summary isattached to the

underside of the product.

Slow to Ignite Doesn't Doesn't Doesn't

or Yellow Ignite? Stop stay lit?

flames? Sparking?

ii [

For replacement parts or if further help is

needed concerning this appliance call:

Toll Free 1 888 9 FNP USA(1888 936 7872)

or write to:

Fisher & Paykel Appliances Inc.

5900 Skylab Road

Huntington Beach, CA 92647

or contact us through our web site,

www.usa.fisherpaykel.com

11

Page 12

Advertencias e infor aci6n sobre seguridad

Los conectores flexibles del aparato

deben cumplir con los requisitos

del ANSI Z21.24 y de los Consejos

Peligro de

Electrocuci6n

Desconecte la

corriente el_ctrica

antes de reparar el

producto.

Si no Io hace, puede

motif o electrocutarse.

Peligro de Cortes

Tenga cuidado con los

bordes filosos.

Utilice los extremos

de poliestireno para

acarrear el producto.

Si no actua con

precauci6n puede

sufrir heridas o cortes

menores.

A iADVERTENCIA!

Este aparato el_ctrico deber_ ser

instalado de acuerdo con los requisitos

de instalaci6n de la autoridad local

de gas, o la norma de instalaci6n

apropiada, o a falta de normas locales,

siguiendo el C6digo Nacional de

Gas Combustible ANSI Z223.1 o CAN

B149.1,2 (Canada) m_s reciente.

Se deber_n seguir las especificaciones

de construcci6n y el_ctricas locales.

Estatales. No pueden exceder las 36

pulgadas de largo.

A iCUIDADO!

Paraevitar cualquier peligro, estos productos

deben instalarse de acuerdo con las

instrucciones que aquf se indican.

Esteproducto no debereisellarsea la mesa

de trabajo con silicona o pegarnento.

Estodificultara"cualquier trabajo de

r_]antenir_]ier]too reparaci6n futuro. Fisher

& Paykel no se responsabilizara"por los

costos asociados con la liberaci6n de tales

productos, ni por el dar_oen que seincurra

debido a Io anterior.

ilMPORTANTE!

Esteproducto deber3 set instalado pot una

persona autorizada para ello (iATENClON[

dentro del Estadode Massachusetts este

producto debe set instalado pot un plornero

o especialista en gas calificado).

Pot favor conserve estas instrucciones junto

con el aparato. Indique alcliente que las

conserve para referencia en el futuro.

Esteproducto sesuministra con una

etiqueta adicional que contiene los n0rneros

del modelo y de serie. Sela puede adherir al

extremo inferior del producto, al interior de

una alacena oa la Guia del Usuario.

12

Page 13

Antes de empezar

Preparaci6n de la mesa donde

ir_ colocada la parrilla °

Aseg0rese de que la superfide est6 en

a'ngulo recto y nivelada yaseg0rese de que

ninguna parte estructural interfiera con los

requerimientos de espacio.

Aseg0rese de que la superficie est6

construida de un material resistente al calor.

Le recomer_damos que selle los bordes

expuestos de madera del corte con una

pintura de aceite o poliuretano a prueba

de humedad para prevenir posibles daF/os

ocasionados por la humedad que se

deposite entre el borde de la parrilla la

superficie.

Instalaci6n El_ctrica

AsegOresede que haya un contacto

(110-120V-60HZ) de suministro el6ctrico

al alcance del cable de alirnentaciOn de

la parrilla (a 30 pulgadas del centro del

producto). Elcable principal no deber3 tocar

ninguna pieza de metal caliente.

AsegOresede que laparrilla est6 conectada

a un tomacorriente el6ctrico conectado a

tierra de acuerdo con las normas locales

o a falta de elias, con el C6digo Nacional

de Electricidad ANSI/FPA-70o CSA22,2

(Canad3).

AsegOresede que el suministro el6_ctrico

est6_debidamente polarizado. Si la polaridad

est3 al rev6_s,ocasionar3 chisporroteo

continuo de los electrodos a0n despu6_s

de la ignition de la flama. Siel surninistro

el6_ctricono est_ debidamente polarizado,

ser3responsabilidad del cliente el corregirlo.

Siexistiera alguna duda de si el contacto de

pared se encuentra debidamente a tierra

o polarizado, verifiquelo con su electricista

calificado antes de instalar la parrilla.

Lista de verificaci6n de piezas

Unidad de basede la parrilla a gas

Paquete con information (incluye juego gas

LP)

Codo y arandela azul (asegurados al cable

de alimer]taciOn)

@

Regulador (de polistireno)

@

Cabezasy tapas de quemadores (verifique

el poliestireno cuidadosamente antes de

desecharlo)

3 rejillas/tr[podes de quemador (1 central, 2

externas)

Paquete de accesorios (Modelo GC912M

Onicamente)

Herramientas necesarias

Desarmador Phillips No.2

Adaptadores de tuberias seg0n sea

necesario

Herrarnientas para trabajar la madera

seg0nse requiera

Va'lvulade cierre

Pintura de aceite (para sellar el torte)

Para conve_sibn a gas LP

Desarmador piano de @7/64"x 13/4"

(@2,5x 45ram)

Llavede tubo de 9/32" (7ram)

Para conve_sibn de[ GC912M a gas LP

Desarmador piano de @7/64"x 13/4"

(@2,5x 45ram)

@

Desarmador Phillips No. 1

@

Llavede tubo de 9/32" (7rnrn)

@

Llavede anillo de 13/32"(10turn)

13

Page 14

Dimensiones y distandas de separad6n

C

I: G

o

Producto

GC36 GC9121GC912M

A Ancho 36"(914 ram) 36"(914 ram)

B Profundidad 21"(533 mm) 21_/2"(546 ram)

C Altura I s/s"(41.5 ram) 29/]6"(65 ram) GC912

3"(76 ram) GC912M

Corte

GC36 GC912/GC912M

D Ancho 34Y4"(870 ram) [_33/s" 34sA"] 34Y4"(870 ram) [_34/' 3_3/,,/]

I:: Profunidad 19_/4"(494ram) [183/_/' 193/S] 19s/4"(494ram) [191/_/' 2()5/s"]

F Radio Rs/s"(lO rTlrT]) R3/8"(10 rTlrT])

G 1"(25 ram) 1"(25 rnm)

H 13/16"(30 rTlrT)) 3/4" (20 rYlrY1)

NOTA:lasdimer_siones del torte sedan como"medida nominal" (o, el rango aceptable)

14

Page 15

Dimensiones y distandas de separad6n

a

a

36"= Distanciahorizontal minima entre alacenaselevadasinstaladasacadalado de este producto.

b

30"= SeparaciOn minima de superficie combustible centrada por encirna de la parrilla.

c

13"= Profundidad ma'xima total de alacena elevada.

d

18"= SeparaciOn minima de la superficie de la mesa a la alacena elevada.

e

4"(GC36) o 11/2"(GC912y GCg12M)= SeparaciOnminima de la parrilla a lapared izquierda.

f

1"= SeparaciOnminima de la parrilla a la pared derecha.

g

11/2"(GC36)o 11/4"(GC912y GC912M)= SeparaciOn m[r]ima de la parrilla a la pared posterior.

h

21/2" (GC36)o 11/4"(GCgl2y GCgl 2M) = Distancia r_l[rlimadesde el borde delantero de la

superficie al borde delantero del aparato. Cuando esto reduce ladistancia entre el borde

posterior del aparato y la pared adyacente a menos del m[nimo de 11/2"(GC36) o 11/4"

(GC912yGC912M),esta pared debe ser de material no combustible (vea la nota al pie).

i

23/8" (GC36)o 3s/16"(GCgl2 y GCgl 2M) = SeparaciOn m[r]ima desde la parte inferior de la

superficie acualquier superficie combustible.

J

30"= Distancia ma'ximaaltomacorriente a tierra ma'scercano desde el centro de laparrilla. El

cable de alimentaciOn no debe tocar ninguna superficie de metal caliente.

Material no combustible

Los materiales no combustibles recomendables son: I_mina aislante de combustion lenta de

1/4"(6ram) recubierta por Io menos con una 13minade acero MSGNo.28,acero inoxidable de

0,015"(0,4mm), aluminio de 0,024"(0,6ram), o cobre de 0,020"(0,Smm).

15

Page 16

Instrucciones de Instalaci6n

Conexi6n a la alimentaci6n de

gas

Esteaparato viene configurado de fa"brica

para suempleo con Gasnatural a 4"de

presi0n de agua de columna. Puede

utilizarse tambi6n con GasLPa 11"de

presi0n de agua de columna despu6s de la

conversion (v6asep_ginas 7 y 8).

Parapoder abrir o cerrar el paso del gas

hacia el aparato debe instalarse una %lvula

de cierre manual en una posici0n accesible

en la tuberfa de gas externa al aparato.

(EnMassachusetts tales %lvulas de cierre

deben seraprobadas por el <<Boardof State

Examinersof Plumbers & Gas Fitters>>).

LaconexiOn de gas al producto debe utilizar

el codo surninistrado con una rosca NPT

externa de 1/2" (12turn).

Asegurese de que la arandela azul

(incluida) est_ ubicada entre el codo y la

boca de entrada del producto. Si no la

utiliza ocasionar_ fuga de gas.

Arandela azul

(Nora: este diagrama represen ta al moddo GC3d,

Codo

Regulador de Gas n_roessimilarparaGcgl2yGCgI2M).

Parasuempleo corno regulador de presiOn

de gastal corno se indica en la ilustraciOn

de abajo. El regulador que se incluye

puede ajustarse tanto para gas LP como

para gas.

Elregulador f-@p,_ ............. / '!_

d_ I _V_', _Y_/ \

direcciOn _ _ J ..............................

del fluido de acasa

gas

16

9

Page 17

Instrucdones de Instalad6n

C6mo convertir el regulador

entre GN ygas LP

1

Desenrosque la tapa del regulador.

2

Verifique la orientaci6n del tap6n

pl_stico de conversi6n, y de sernecesario

desenr6squelo, d61evuelta y vuelva a

enroscarlo (con la parte ancha lejos de la

tapa para gas LPy contra la tapa para GN:

vea el diagrama de ma'sabajo para una

mejor informaci6r]).

3

Vuelva a colocar la tapa del regulador.

4

punto de prueba al costado del regulador).

Cuando altere el regulador para diferentes

corlfiguraciones, debe controlarse la

funciOn del regulador a una presiOnde por

Io menos ]"WC (0,036 p.s.i.)por encima de

la presiOndel mOltiple especificada.

pow un

C6mo fijar la parrilla

Ubique la parrilla dentro del torte y

ajOstelacon los soportes de fUaciOn

suministrados. Estossirven para grosores

de superficies de 3/4"- 2"cuando se

utilicen en lasdos orientaciones que se

ilustran.

No apriete demasiado.

A

3//, 2"

(19ram - SOmm'

17

Page 18

Instrucciones de instalaci6n

Conversi6n a un tipo diferente de gas

Losquemadores se pueden utilizar con GN

o gas LP,siempre y cuando se instalen los

orificios inyectores apropiados para elgas

surninistrado.

Paracambiar los orificios inyectores,

necesitar_ una Ilave de tubo de 9/32" (7rnm).

1 Apague el surninistro el6ctrico principal.

Peligro de descarga electrica adentro.

2 AsegOresede que todas las v31vulasde gas

est6n cerradas.

3 Extraiga todos los tr[podes y lascabezas de

quemador.

4 Desatornille los agujeros y reempl_celos por

los correctos (los nOrneros de los tamaflos

est_ingrabados en el costado, p.r. 70 = 0.0

rnm) (%ase lafig. 1).

5 Retire los 2 tornillos sujetando cada platillo

ae auemaaor (3 en e_a Jemaaor ae WOK.

6 Le/an[e la olatillo del oroauc_o

I'_b Riesgo de cortes- bordes afilados

7 Reemplace el agujero ael WOKDOte

correcto uti izando Jna Ilave de anillo ae

©

= 13/32"/10 mm).

8 Reajus_ede ven_ur v6asefig. 2):

_ Con e oroducto aislado de suministrc

el6ctrico, encienda el auemador utilizando

un cerillo. Laflam_ orot)aDlemen_esaldr_ del

quemador lv6asefig. 3)

_ Afloje el tc'nillo que fija el ven_uri. Mueva el

u

venturi en el inyector hastaque la punta de

aflama comience a oonerse amarilla v6ase

fig. 4.

v'ueva aCOlocaren su sitio e venturi hasta

due aesalaarezcala DuRraamarilla de la

flama Cv6asefig 51:este es el a us_ecorrec_c

ael venturi. Aorie_ee tornillo de fijacion.

9 Parareajustar e_olatillo GC912M, reoita los

pasos5 y 6 er sentido inverso.

10 ilMPORTANTEL Reajusteal rn[nirno (vea

Ajuste rn[nirno o bajar el nivel).

11 DespuF_sde volver aensamblar, verifique

18

ContinOa...

la resistencia de aislamiento y la tierra

continua del circuito elF_ctrico.

12 Laetiqueta suministrada con los orificios

debe colocarse sobre la etiqueta de tipo de

gas existente para indicar el cambio.

figura 1

figura 2

flarna hacia

arriba

!ioo

figura figura 4

O0

flama correcta

figura 5

Page 19

Instrucdones de instalaci6n

Comprobaci6n de fugas

Lacornprobaci0rl de fugas del aparato debe

Ilevarseacabo siguiendo las instrucciones

del fabricante.

Elaparato y su v_lvula de cierre individual

deben desconectarse del sistema de tuberfa

de alirnerltaci0r_ de gas durante cualquier

tipo de prueba de presi0n de ese sistema

que supere 1/2 pal. (3,SkPa).

Elaparato debe desconectarse del sistema

de tuberfa de alirner_taci()rlde gas cerrando

su v_lvula de cierre manual individual

durante cualquier prueba de presiOndel

sistema de tuberfa de alirner_taciOr_de gas

a presiones de prueba de o rnenores a 1/2

p.s.i.(3,SkPa).

Presi0nde entrada de gas rna'xirna20"W.C.

(SkPa).

PresiOnminima de alimentaciOn de gas para

prueba del regulador 5"W.C.de Gas Natural,

12"W.C.gas LR

Despu6_sde instalar el suministro de gas

y hater todas las conexiones, revise

cuidadosamente en busca de posibles

fugas.

1

Gire todas las perillas de control en la

unidad hasta la posici©n de apagado.

2

Abra la v31vulade alir_]entaci©n de gas.

3

Utilizando un I[quido de detection de

fugas (por el. el vaporizador de detection

de p6_rdidasRocol) verifique cada conexiOn

de gas una a lavez frotando lasolution

sobre la conexiOn. La presencia de

burbujas indicara"una fuga.

4

De ser necesario,ajuste el adaptador y

vuelva a verificar en busca de fugas.

5

Abra la veilvula del quemador y encienda

cada quemador.

6 Busque una flama azul claro sin punta

amarilla. Silos quemadores presentan

anormalidades, verifique que est6_n

ubicados correctamente y de acuerdo con

el orificio de inyecciOn.

Calibraci6n minima

Estaha sido configurada de fa'brica para GN

pero se puede controlar luego de haber

alcanzado la presiOncorrecta. Paraajustar

la calibration m[rlima (de ser necesario),

necesitara"un desarmador de 07/64"x 13/4"

(02,5 x 45ram) (Fisher& Paykeldispone de

un desarmador apropiado para este

propOsito bajo el nOmero de pieza

FB200467).

1 Encienda el quemador y mueva la perilla

hastasu position m[r_ima.

2 Extraiga lasperillas.

3 Gireel tornillo (en el orificio en el v3stago)

mientras sujeta el eje.Gire lentamente

hastaalcanzar una flama regular m[r]ima.

(Laflama disminuira"cuando segire el

tornillo en la direction de las manecillas

del reloj, y aumentar3 cuando segire en la

direction opuesta).

4 Cuando la calibration sea la correcta,

verifique la regulation rotando velozmente

la perilla de la position ma'xima a la

m[rlima. Laflama no debe apagarse y

el reencendido automa'tico no debe

chisporrotear. Vuelva a colocar la perilla.

Ajuste de calibraci6n minima

(Nora: este diagrama representa al moddo G(912,

pero es similar para el modelo GC36).

Vea la Lista de Verificaci©n de Instalaci©n del Producto que se adjunta al producto.

19

Page 20

[nstrucciones de instamaci6n

Verificar el tipo de gas

GC36

Quemado_es Orificio GN GN Orificio Gas Gas LP

(ram) BTU(MJ/h) @ LP BTU(MJ/h) @

0,15psi (4"H20) (ram) 0,41psi(11"H20)

Der.trasero 1,3 mm 8,000 (8,4 MJ/h) 0,8 mm 8,000 (8,4 MJ/h)

Izq.trasero 1,3 mm 8,000(8,4 MJ/h) 0,8 mm 8,000(8,4 MJ/h)

Der.deJantero de 0,85 mm 3,500 (3,47 MJ/h) 0,55 mm 4,000 (4,2 MJ/h)

cocciOn [enta

Izq.delantero para 1,75mm 12,600 (13,3MJ/h) 1,05mm 13,000(13,7 MJ/h)

wok

Central 1,45mm 9,500 (10 MJ/h) 0,85 mm 9,500 (10 MJ/h)

GC912/GC912M

Quemado_es OHficio GN GN OHficio Gas Gas LP

(ram) BTU(MJ/h) @ LP BTU(MJ/h) @

0.15psi (4"H20) (ram) 0,41psi(11"H20)

Der.trasero 1,3 mm 8,000 (8,4 MJ/h) 0,8 mm 8,200 (8,7 MJ/h)

Izq.trasero 1,1 mm 5,800(6,1 MJ/h) 0,7 mm 5,700(6,0 MJ/h)

Der.delantero de 0,85 mm 3,000 (3,2 MJ/h) 0,55 mm 3,500 (3,7 MJ/h)

cocciOn lenta

Izq.delantero 1,3 mm 8,000 (8,4 MJ/h) 0,8 mm 8,200 (8,7 MJ/h)

Central (C912) 1,75 mm 14,000 (14,8 MJ/h) 1,05 mm 13,000(13,7 MJ/h)

Central (GC912M) 2,15 mm 20,000 (21,1 MJ/h) 1,22mm 19,000 (20 MJ/h)

2O

Page 21

So[ud6n de D_ob[emas

[__ento para

encender o

Tabla de Soluci_n

de problemas

[_st&n losquemadorescorrectamente

ensamblados?

[_lectrodos sucios?

[_s correcta la presi6n de gas?

[_s correcto el ajuste bajo?

E_alidasmal colocadas u obstruidas?

[g%laridaddelsuministro de energia

y la tierra correctos?

[_Correcto suministro de voltaje?

[_Corriente de aire o extracci6n?

flama amarilla?

I_d_l_ _;01

C6mo ponerse en contacto con

nosotros

En [aparte inferior de[ producto encontrara"

un resumen de los servicios de

rnar_ter_irniento

[_1o enciende?

0oo 0o

,00,,0 0

i

i

I

[_1o deja _o

de chispor, permanece

rotear? prendido?

Parapiezasde repuesto o siprecisa de ma's

ayuda en relation a este aparato, Ilame

sin costo al:

1 888 9 FNP USA (1 888 936 7872)

o escribanos a:

Fisher & Paykel Appliances Inc.

5900 Skylab Road

Huntington Beach, CA 92647

o pOngase en contacto con nosotros a

trav6s de nuestro sitio en Internet:

www.usa.fisherpaykel.com

21

Page 22

Avert[ssements de s cur[t

Risque d'_lectrocution

D_brancher I'alimentation

_lectrique avant de

proc_der _ I'entretien

du produit,

Tout d_faut d'observer

cette precaution

pourrait entrainer

la mort ou une

_lectrocution.

Risque de coupure

Attention aux bords

tranchants.

Utiliser les extr_mit_s

en polystyrene Iors

du transport de ce

produit, _ d_faut de

quoi il pourrait y avoir

des risques de coupure

ou de blessure.

A AVERTISSEMENT!

Cet appareil devra _tre install_

en conformit_ avec les exigences

d'installation du fournisseur de gaz

local ou avec le code d'installation

applicable ou, en I'absence de

r_glementation locale, avec la plus

r_cente version du code d'installation

du gaz CAN B149.1.2 (Canada) ou

du National Fuel Gas Code ANSI

Z223.1 (l_tats-Unis). Lescodes Iocaux

r_glementant I'_lectricit_ et la

construction devront _tre respect_s.

22

Les connecteurs flexibles de I'appareil

devront satisfaire aux exigences du

code ANSI Z21.24 et des State Boards

(aux I_.-U.). IIs ne devront pas d_passer

91 cm de Iongueur.

A ATTENTION!

Pour 6viter tout danger, i[ est imp6ratif que

ces produits soient install6s en conformit6

aux pr6sentes instructions.

Ce produit ne devra pas __treco116au plan

de travail avec de la colle ou du silicone au

risque de rendre tout entretien ult6rieur

difficile 3 entreprendre. Fisher & Paykelne

pourra en aucun cas_tre tenu responsable

des frais associ__savec le retrait de tels

produits et des dommages caus__sen

cons__quence.

IMPORTANT!

Ce produit dolt __treinstall6 par une

personne dOment autoris__e.Avertissement :

Sice produit est installS_auxE.-LJ.,il est

irnp__ratifqu'il le soit par un plornbier

ou par installateur de gaz agr____clans le

Commonwealth du Massachusetts.

Veuillez laisserces instructions avec

I'appareil et informer le consommateur

de lesconserver en vue de s'y rapporter

ult6_rieurernent.

Ce produit est livr__avec une 6tiquette

suppl6rnentaire sur laquelle sont indiqu__s

les num_ros de mod__leet de s__rie.Elle

pourra __trecoll__esous le produit, b

I'int6rieur d'un placard ou sur le guide de

I'usager.

Page 23

Avant de Commencer

Preparation de la carrosserie

V6rifierque le rev__ternentdu comptoir est

au car@et b niveau et qu'aucun 616rnent

structurel n'interf__reavec I'espacerequis.

V6rifierque le rev__tementde cornptoir

est cornpos6 d'un rnat6riau @sistantbla

chaleur.

IIest recornmand6 de vitrifier les bords en

bois nu expos6s par la forme d6coup6e avec

une peinture 3 I'huile ou de polyu@thane

6tanche b I'humidit6_pour emp__chertout

endommagement possiblement cause_

par I'humidit6_ entre le bord de la table de

cuisson et la table de travail.

I_lectricit_

V6rifierqu'il y a une prise de courant

(110-120 V 60 Hz) b proximit6_du cordon

d'alimer_tation de la plaque de cuisson (762

rnrn du centre du prod@t). II ne faut pas que

le cable principal entre en contact avec une

pi__cern__talliquechaude.

V__rifierque la plaque de cuisson est

branch__eb une prise de courant reli6e b la

masseen conforrnit6_avec les codes Iocaux

ou, en I'absence de codes Iocaux, avec le

code national r__glementant I'__lectricit6_

ANSI/FPA70ou CSA 22,2 (Canada).

IIfaut que I'alimer]tatior] __lectriquesoit

polaris6e de f%-on appropri__e.Une polarit6_

invers__eproduira des 6tincelles continues

sur les_iectrodes, m_me ap@sI'allumage de

la flamrne. Si I'alimentation _iectrique n'est

pas polaris6e de f%-on appropri__e,le client

est responsable de faire corriger la polarit6_.

Encas doute bsavoir si la prise murale est

ad6quatement raise b la terre ou polaris6e,

faitesda v6rifier par un __lectriciencornp@ent

avant d'installer la table __lectrique.

Liste de v_rification des pi_ces

Unit6_de base de la table de cuisson au gaz

Documentation (Kit GPL inclus)

Rondelle bleue et coude (enrubann__sau

cordon d'alimer]tation)

R__gulateur(en polystyr__ne)

T_tes de brOleur et capuchons (v__rifier

soigrleusernent le polystyr__neavant de le

jeter)

3xgrilles/supportspour brOleur(1x centre,

2x bords)

Coffret d'accessoires (6C912M uniquernent)

Outils n_cessaires

Tournevis Phillips n°2

Accessoires de plornberie au besoin

Outils b bois au besoin

Soupape de coupure ou d'arr__t

Peinture _ I'huile (pour vitrifier la d__coupe)

Pour _aconversiona_ GPL

Tournevis b t@teplate @7/64 pox 13/4 po

(@2,5x 45 ram)

CI__,_pipe 9/32 po (7r'@r'@)

Po_ la <o_ve_sio_ a_ GPL du module

GC912M

Tournevis b t_te plate @7/64 pox 13/4 po

(@2,5 x 45 ram)

Toumevis Phillips n° 1

CI__,_pipe 9/32 po (7 r'@r'@)

CI__,_anneau 13/32 po (10 r'@r'@)

23

Page 24

A

C

Rampe

F

Orf ce d'admission a_ G

gaz centra/e

o

Produit

A Largeur S6 po (914 ram) 36 po (914 ram}

B Profondeur 21 po (533 ram) 211/2po (546 ram)

C Hauteur lS/spo (41,5 rnrn) 2g/16po (65 ram) GC912

D_coupe

D Largeur 341/4po (870 rnm) 341/4 po (870 ram)

I= Profondeur 191/4 po (494 ram) 191Apo (494 ram)

F Rayon RS/spo (10 ram) RS/spo (10 ram)

G 1po (25 ram) I po (25 ram)

GC36 GC912/GC912M

3po (76 rnrn) GC912M

GC36 GC912/GC912M

[}Ss/spo. 34sA po] [33>/spo 35/4 po]

[I 8s/spo 19sApo] [19_/_po 20s/spo]

H 1s/1_po(30ram) s/4po(20ram)

REMARQUE•Lesdimerlsions de la d_.coupe sont donn@s 3 titre de <<cote nominale >>

(dirner_sionsautrement acceptables)

24

Page 25

a

a

36 po (914 ram) = Distance horizontale minimum entre les placards de plafond install6s de

chaque c0t6 de cet appareil.

b

30 po (762 mm) = D6gagement minimum de la surfacecombustible centr6e au-dessus de la

table de cuisson.

c

13 po (330 ram) = Profondeur g6n6rale maximum des placards de plafond.

d

18 po (457 ram) = D6gagement minimum entre le rev__tementde cornptoir et lesplacards

de plafond.

e

4 po (101 ram) (GC36)ou 1/2 po (38 ram) (GC912& GC912M)= D6_gagernentminimum entre

la table de cuisson et le tour lat6_ralgauche.

f

1 po (25 rnrn) = D6_gagementminimum entre latable de cuisson et le tour lat6_raldroit.

1 1/2 po (38 ram) (GC36)ou 1 1/4 po (31 ram) (GCgl 2 &GCgl 2M) = D6_gagementminimum

g

entre la table de cuisson et le tour arri6re.

h

2 1/2 po (63 ram) (GC36)ou 1/4 po (31 mm) (GCCpl2& GCCpl2M) = Distance mirlimum entre

le bord avant du cornptoir et le bord avant de I'appareil. Dans le casoQcela r6_duitladistance

entre le bord arri__rede I'appareil et le tour adjacent b une valeur inf6_rieureau mirlimurn de

38 mm (GC36)ou de 31 mm (GCCpl2& GCCPl2M), il importe que ce tour soit cornpos__de

rnat@iau non combustible (voir la remarque ci-dessous).

i

2 3/8 po (60 rnm) (GC36)ou 3 5/16 po (84 rnrn) (GC912& GCgl2M) = D6_gagementrr_inirr_urn

entre le dessous du cornptoir et route surface combustible.

J

30 po (762 ram) = Distance maximum de la prise de courant raise _ la terre la plus proche

depuis le centre de la table de cuisson. Lecordon d'alimentation ne dolt pastoucher une

quelconque surface m__talliquechaude.

Mat_riau non combustible

Lesmat@iaux non combustibles recommarld6_ssont lessuivants :Carton gris ignifuge 1/4 po

(6 ram) recouvert au minimum d'une tOle d'acier MSGn° 28, d'acier inoxydable 0,015 po (0,4

rnrn), d'alurniniurn 0,024 po (0,6 rnrn) ou de cuivre 0,020 po (0,5rnrn).

25

Page 26

Instructions d'installation

Raccord d'alimentation au gaz

Cetappareil est r6g16en usine pour __tre

utilis6 avec du gaz naturel sous une pression

de 10,15cm (4 po) de colonne d'eau. IIpeut

aussi__treutilis6 avec du gaz naturel liqu6fi6

une pression de 28 cm (11 po) de colonne

d'eauapr__sconversion (voir les pages 7 et 8).

Une soupape d'arr__trnanuelle dolt __tre

insta%e darts un endroit accessible sur la

canalisation de gaz ext6rieure 3 I'appareil

aux fins de Ibuverture ou de lafermeture de

I'alimentation en gaz de I'appareil. (Darts le

Massachusetts, lesdispositifs d'arr__tde ce

type devront __treapprouv6_spar le Board of

State Examiners of Plumbers & Gas Fitters).

Rondelle bleue

Lecoude fourni avec un filetage ext6rieur

NPTde 12 mm dolt __treint6gr6_au raccord

de gaz du produit.

V_rifier que la rondelle bleue fournie

sesitue entre le coude et I'orifice

d'admission du produit. Autrement, il

pourrait y avoir un risque de fuite de gaz.

R_gulateur de pression de gaz

Cetappareil est destin# 3 _tre utilis6_avec

un r6_gulateurde pression de gaz, cornme

I'illustre I'exemple ci-dessous. Le r6_gulateur

foumi peut __trer6_g16_soit pour le GPL,soit

pour le gaz naturel, n , ,

26

Le

.... / \_

ae gaz _ ,__ .....................

montre la

direction du_ ion domestlque

flux du gaz

Page 27

Instructions d'installation

Conversion du r_gulateur entre

GN et GPL

1

D6visser le capuchon du r6gulateur.

2

V6rifier Ibrier]tation de lafiche de

conversion en plastique et, si n6cessaire,la

d6visser, la retourner et la revisseren place

(section large b 1'6cartdu capuchon pour

le GPLet contre le capuchon pour le GN

- vous r6f_rer au sch6ma ci-dessous pour

Ibrientation appropri6e).

3

Remettre en place lecapuchon du

r6gulateur.

4

Tester la pression du gaz (point de test

fourni sur le cot6 du r6gulateur). Lorsde

la conversion du r6gulation en fonction

de cliff, rents r6glages, il faut v6rifier la

fonction du r6gulateur b une pression

de colonne d'eau s'61evantau moins b

0,036 psi (1 po) de plus que la pression

d'adrnission indiqu6e.

Fixation de la table de cuisson

Placerla table de cuisson darts la d6coupe

et la fixer en position en utilisant les

fixations fournies. Cesderni__ressont

compatibles avec une 6paisseur de

cornptoir de 19 rnm b 50 rnm Iorsqubn

les utilise darts les deux orientations

indiqu6es.

Ne pas les setter excessivement.

3/4po - 2 po

(19ram b50rnrn

27

Page 28

Instructions d'installation

Conversion _ des types de gaz

diff_rents

les br(]leurspeuvent_tre utilis6savecdu gaz

natureloudesGPLa condition que lesorificesde

I'irjecteur appropri_saugazfournissoientinstall6s.

Pourchanger lesorificesde I'injecteur,vousaurez

besoind'une cl6 b pipe de 7 turn (9/32e po).

1 Couper I'alimentation 61ectrique principale.

Risque d'_lectrocution

I'int_rieur

2 V6rifierque lesroutes les soupapes de gaz

sont ferm6es.

3 Retirerrouteslesgrilleset lespiecesdesbrQleurs.

4 D6visserlesorificeset lesremplaceravecles

orificesappropri6s.Lesdimensionssontmarqu6es

surlec6t6 D.ex.,70= 0,70mm (voirfigure 1)

5 D_Svisserlesorificese_esrerr olaceravecles

orificesapprcories.Lesdimensionsson_marquees

surlecOt_s o.ex.,70= 0,70mm (voirfigure 1/

Soulever le Dlal:eaunors au oroduit

A "_ AVERT ISSEMENT!

_ I_lL Risque de coupure - bords

tranchants

_emDlacer I'orifice du wo,, ,0arI'orifice

appropri6 au moyen aune cle"polygonale

de 0 mrr [13/22e Do

8 Remiseen marcne au Venturi (voirfigure 2):

Enayan_ pris soin d'isoler le produit de

E 'alimentatior 61ectrioue. allume" e br01eur

3 I'aide aune a umette. Laflamme iaillira

proDaDlemenTau brOleur tvoir lafigure 3).

o D..<_ . . .

evls._r la vls de retenue ventun. Deplacer

le venturi vers I'injecteurjusqu% ce que

o I'extr6mit6 de la fla_ me commence _]jaunir

_voirla figure 4).

_ :_emettre e venturi darts sa oosition initiale

jusqu% ce q_e I'extr6mit6 jeune disparaisse

(voir le figure S)- il s'agit du r6glage

aoDroDri6du venturi. Serrerla visde retenue.

9 Pour remettre er olace la Table de cuisson

GCg12M. r6o6ter les 6taoes 5et 6 en orare

nverse.

10 IMPORTANT! R6gler les pararn_tres b leur

configuration minimale (voir Configuration

rninimale ou baisser).

11 Apr_s le remontage, v__rifierla r6sistance

d'isolement et la continuit6_de la rnise b la

terre du circuit __lectrique.

28

Suite...

12 II faudrait placer I'@iquette Iivr__eavec

lesorifices sur I'__tiquettedu type de gaz

existant pour refl__terle changernent.

figure 1

figure 2

__chappernent

figure figure 4

bonne

O0

flamme

figure S

Page 29

Instructions d'[nstallat[on

Essais d'_tanch_it_

Lesessaisd'6tanch6it6 r6alis6ssur I'appareil

devront seconformer aux les instructions du

fabriquant.

L'appareilet sa soupape d'arr__tdevront __tre

d6branch6s du syst__mede canalisation

d'alimentation en gaz pendant toute

@reuve sous pression dudit syst__rne

sup6rieure b 1/2 psi (3,5 kPa).

L'appareildolt _tre isol6 du syst__mede

canalisation d'alimer]tatior] en gaz en

fermant la soupape d'arr__trnanuelle

individuelle pendant toute 6preuve sous

pression du syst__mede canalisation

d'alimentation en gaz aux pressions de test

__galesou inf6rieures b 1/2 psi (3,5kPa).

Pressionmaximum de I'admission de

I'alimerltatiorl en gaz: pression de 51 cm de

colonne d'eau (5 kPa)

Pressionmaximum de %limentation en gaz

pour I'@reuve du r__gulateur:5 po CE(GN)

et 12po CE(GPL).

Apr__sI'installation de la conduite

d'alimentation en gaz et apr__savoir

terrnin__tous les brarlchements, v__rifier

soigneusernent I'installation pour d__tecter

toute __ventuellefuite de gaz.

1 Tourner tousles boutons de r6glage de

I'unit6 sur la position Off (Arr_t).

20uvrir lasoupape sur la conduite

d'alirnentation en gaz.

3 Au rnoyen d'un fluide de d__tectionde

fuite (p.ex., bombe de d__tectionde fuite

System Check),v__rifierchaque raccord de

gaz, un b la fois, en vaporisant lasolution

sur leraccord. Lapr__sencede bulles

indiquera une fuite.

4 Au besoin, serrer le raccord et v__rifierb

nouveau qu'il n'y a pas de fuite.

50uvrir lasoupape du brOleur et allurner

chaque brOleur.

6 V__rifierque laflamme est bleue et

transparente sans boutjaune. Siles

brOleurs montrent une quelconque

anomalie, v__rifierqu'ils sont bien en place

et align__savec Ibrifice de I'injecteur.

Voir la liste de v6rification de I'installation du produit ci-jointe.

R_glage minimum ou marque de

r_glage effective

R__glageminimum ou marque de r__glage

effective. Ce r6glage a __t6_effectu__b I'usine

pour le GN,mais peut __trev__rifi__une lois

que la pression correcte est atteinte. Pour

tout ajustement sur le r__glageminimum (si

applicable), vous aurez besoin d'un tournevis

O2,Sx 45 mm (0 7/64 po x 1 s4po).

(Untournevisappropri6estdisponible aupresde

Fisher& Paykel;il porte le n°de piece%200467).

1

Allumer le brOleur et tourner le bouton de

r__glageb la position minimum.

2

Retirer les boutons de r__glage.

3

Tourner la vis de marque de r__glage

effective dans le trou de la broche tout en

tenant la tige. Toumer doucement jusqu'b

Ibbtention d'une flamrne minirnale et

r__guli6re.(La flamme diminuera Iorsque la

vis est tourn__edans le sensdes aiguilles

d'une rnontre et augmentera Iorsque vous

la tournez dans le sensinverse).

4

Lorsque le r__glageest correct, v__rifier

la r__gulationen tournant rapidement le

bouton de r__glagede la position d'arriv__e

maximum vers la position d'arriv__e

minimum. II ne faut pasque la flamme

s'6teigne ou que le rallumage automatique

__mettedes olios.Remettre en place le

bouton de r__glage.

Ajustement du r_glage minimum

(Remarque : Ce sch6ma correspond au mod61e G(912,

mais il est similaire au module GC36).

29

Page 30

Instructions d'installation

V_rification du type de gaz

GC36

BrQ_eurs Orifice GN GN Orifice GPL GPL

(ram) BTU(MJ/h) @0,1S (ram) BTU(MJ/h) @0,41

psi (102 mm d'eau) psi (280 mm d'eau)

Arri_re droit 1,3 mm 8 000 (8,4MJ/h) 0,8 mm 8 000 (8,4MJ/h)

Arri_re gauche 1,3 mm 8 000 (8,4 MJ/h) 0,8 mm 8 000 (8,4 MJ/h)

Mijoteur avant 0,85 mm 3 S00 (3,47 MJ/h) 0,SSmm 4 000 (4,2MJ/h)

droit

Wok avant gauche 1,75mm 12600 (13,3 MJ/h) 1,05mm 13000 (13,7 MJ/h)

Centre 1,45mm g SO0(10 MJ/h) 0,85 mm g SO0(10 MJ/h)

GC912/GC912M

BrQ_eurs Orifice GN GN Orifice GPL GPL

(ram) BTU(MJ/h) @0,1S (ram) BTU(MJ/h) @0,41

psi (102 mm d'eau) psi (280 mm d'eau)

Arri#re droit 1,3 mm 8 000 (8,4MJ/h) 0,8 mm 8 200 (8,7MJ/h)

Arri6re gauche 1,1 mm 5 800 (6,1 MJ/h) 0,7 mm 5 700 (6,0 MJ/h)

Mijoteur avant 0,85 r'rlr'rl 3 000 (3,2MJ/h) 0,SSmm 3 S00 (3,7MJ/h)

droit

Avant gauche 1,3 mm 8 000 (8,4MJ/h) 0,8 mm 8 200 (8,7MJ/h)

Centre (GCgl2) 1,75 mm 14000 (14,8 MJ/h) 1,05 mm 13000 (13,7 MJ/h)

Centre (GCgl2M) 2,15mm 20 000 (21,1 MJ/h) 1,22 mm lg 000 (20 MJ/h)

30

Page 31

O_pannage

Allumagelent Allumage

ou flammes d_ficient?

D_pannage

Les brE_leurs sont-ils assembles

correctement?

Les _%lectrodes sont-ils sales?

La pression du gaz est-elle adequate?

Le r_%glage de faible intensity% est-il

correct?

Lejet de la flamme est-il bloqu_

ou incorrect?

La mise _ la terre ou la polarity%

sont-elles ad_quates?

La tension d'alimentation est-elle

correcte?

S%xerce-t-il un tirage ou une

extraction? (Avis aux cons.)

jaunes?

iiiiiiiiii@!i!!#!}iiii!#iiiiiiiii#iiiiiiiiiii#iiiiii_ii//@_S_iiiiii!iiiiiiiii//i}ii{iiiiiiiiil;@@!i!!!!!!!!!#!!!!!!!!S!!!!!!!!!!!!ii#!i#i#iii/iiiiii#i;iiiiiiiii!#iiiiiiiiiil

To i Toi

Coordonn_es

Un r6sum6 d'entretien est co116sousle

produit.

Pour obtenir des pi__cesde rechange ou de

I'aide pour ce prod@t, composer le num6ro

suivant :

Num_ro gratuit 1 888 9 FNP USA (1 888

936 7872)

ou 6crire b I'adresse suivante :

Fisher & Paykel Appliances Inc.

5900 Skylab Road

Huntington Beach, CA 92647

ou nous joindre via notre site Web,

www.usa.fisherpaykel.com

letincelles Dispari-

conti- tion

nues? de la

flamme?

ii !i!i!i}}ili

31

Loading...

Loading...