Page 1

599116A,03,2003

Uii!!i i:il

_NSTALLAT_ON_NFORMAT_ON

2 WARNINGSandSAFETYINFORMATION

3 DIMENSIONSand CLEARANCES

8 INSTALLATIONINSTRUCTIONS

_NFORMAT_O_aSSUR L1NSTALLATHON

8 AVERTISSEMENTSet INFORMATIONSSURLASECURITE

9 DIMENSIONSet DEGAGEMENTS

10 INSTRUCTIONSD'INSTALLATION

_NFOR_vlAC_O_aSOBRELA INSTALAC_ON

14 ADVERTENCIASe INFORMACIONSOBRESEGURIDAD

15 DIMENSIONESy DISTANCIASDESEPARACION

16 INSTRUCCIONESDEINSTALACION

Page 2

WARNINGSAND SAFETYINFORMATION

CA_T_O_!

_ Thisappliance shallbe installedin accordancewith

the installation requirementsof the localgas

authority or the appropriate installation code or inthe

absence of localcodes with the latest NationalFue!

GasCodeANSIZ2231 orCAN B149.1,2(Canada}

Localbuildingandelectricalcodesmust be adheredto

_J When this applianceis installed it shallnot be used

as a space heater

_ No combustiblematerial or productsshouldbe

placed on this applianceat any time

_ Donot spray aerosolsin the vicinity of this appliance

while it is inoperation

_ Not to beinstalled in a bathroomor

bedroom/sleepingquarters

_ Flexibleapplianceconnectors shallmeet the

requirementsof ANSI Z2124 and State Boards

Theyshallnot exceed36 inches in length

@ Inorderto avoidhazardthese productsmust be

installedaccordingto theseinstructions

@ This product shouldnot be sealedinto the bench

with silicone or glue Thiswill makeanyfuture

servicingdifficult Fisher8 Payke!will not be liable

for costs associatedwith releasingsuchproducts,

norfor damageincurredas a result

_ Thisproduct must be installed by anauthorized

person(W_ll@; this product must be installedby

a licensedplumberor gasfitter when within the

Commonwealthof Massachusetts}

_ Pleaseleavethese instructions with the appliance

Informthe customer to retain for future reference

_ Thisproduct issupplied with anadditional label

containingthe modeland serialnumbers It may be

affixed to the undersideof the product, the inside of

a cupboardor to the User Guide

F_eet_iea_ Shec_ _aza_d

@seen_ect pewe_ befe_e

servicing the p_ed_ct.

Failure to _e so corm _es_lt in

death e_ electrical shecL

C_t Hazard

Page 3

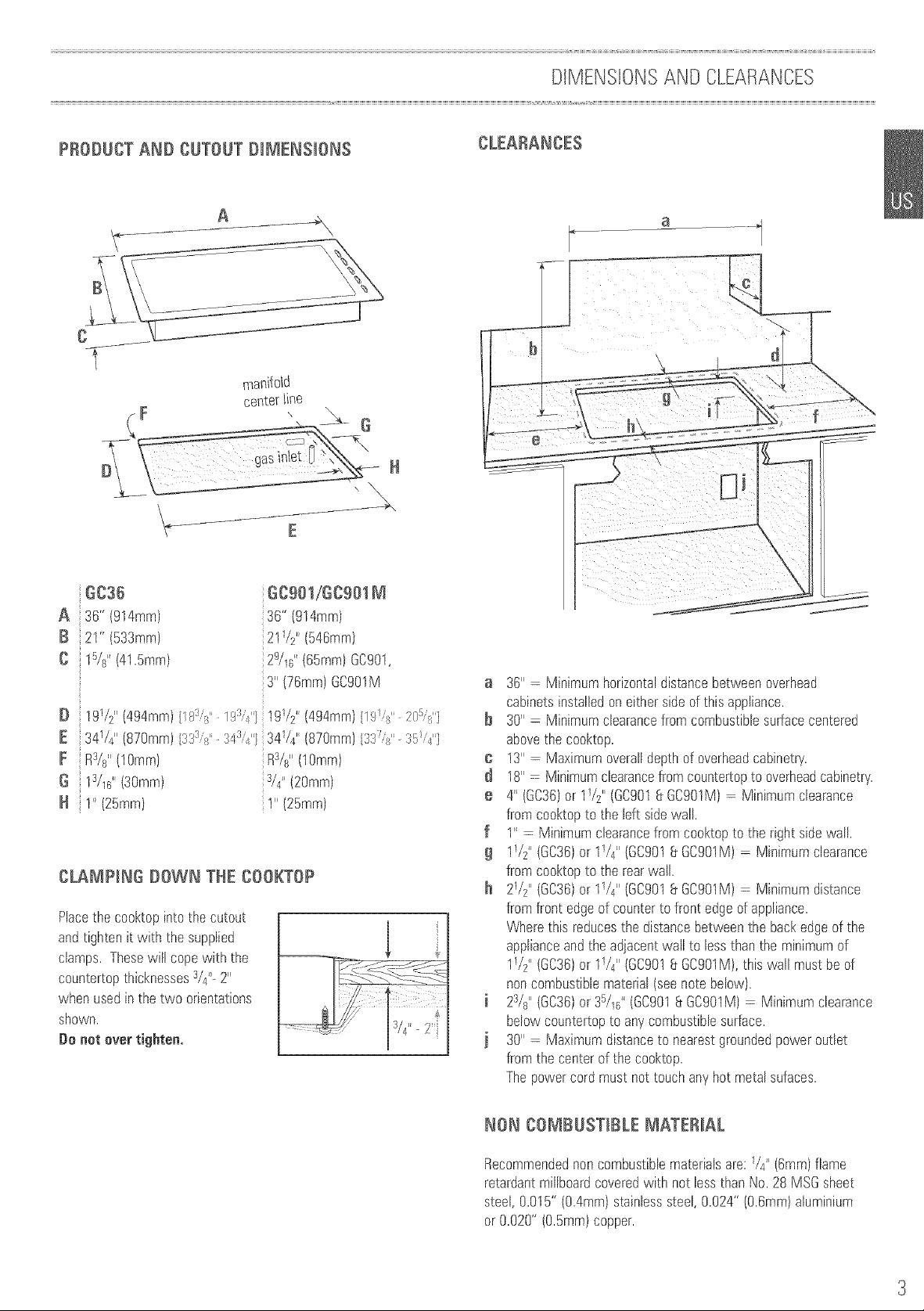

DIMENSIONSANDCLEARANCES

t

G0901/'_C901M

A 36" (914mm) 36" (914mm)

B 21" (533mm) 211/2'(546mm)

B 15/8' (41.5mm) 29/16' (65ram)6C901,

3' (76ram)66901M

#

191/2, (494mm)[18s/6'' 9:_//'] 191/2' (494mm)[9/,6 '' 20J/8'']

E

34V4' {870ram)[33:;&'' 34:_,',:"}34V4' (870ram)['/37& '' 3_?/4"

F

R9/8' (10ram) Rg/s' (10ram)

G

19/16' (30ram) 3/4'(20ram)

1' (25ram) 1' (25ram)

CLAM?_NG #OWN TNE COOKTO?

Placethecooktopintothe cutout

andtightenit with thesupplied

damps. Thesewill copewith the

countertopthicknesses3/4'-2'

whenusedinthetwo orientations

shown.

[}o not evertighten.

a 36' - Minimumhorizontaldistancebetweenoverhead

cabinetsinstalledoneithersideofthis appliance.

b 30' - Minimumclearancefromcombustibbsurfacecentered

abovethe cooktop.

o 13' - Maximumoveralldepthof overheadcabinetry.

18' - Minimumclearancefromcountertoptooverheadcabinetry.

e 4' (G636)or11/2' (GC901866901M) - Minimumclearance

from cooktoptothe leftsidewall.

f 1' - Minimumclearancefrom cooktopto therightsidewall.

g 1V2'(GC36)or 1V4'(GC9018 6C901M)- Minimumclearance

from cooktoptothe rearwall.

h 21/2' (6C36)or1V4'(6C90I 8 6C90IM) - Minimumdistance

fromfront edgeofcounterto frontedgeof appliance.

Wherethisreducesthedistancebetweenthebackedgeof the

applianceandtheadiacentwallto lessthanthe minimumof

1V2'(6C36)or 11/4"(6C9018 GC901M),this wall mustbe of

noncombustiblematerial{seenotebelow).

i 29/8' (GC36)or 35/16' (GC9018 Gcg01M)- Minimumclearance

belowcountertopto anycombustiblesurface.

i 30' - Maximumdistancetonearestgroundedpoweroutlet

from the centerofthe cooktop.

Thepowercordmust nottouchanyhot metalsufaces.

NON COMBUSTIBLE MATER_AL

Recommendednoncombustiblematerialsare: 1/4'(6ram)flame

retardantmillboardcoveredwith not lessthanNo.28 MS6 sheet

steel,0.015"(0.4ram)stainlesssteel,0.024"(0.6ram)aBminium

or 0.020" (0.5ram)copper.

Page 4

INS ,S,LLA]IONINSTRUCTIONS

BEFOREYOU START _AS SUPPLYCO_/ECT_O_

@ Ensurethe countertopissquareandlevelandensureno

structuralmembersinterferewith spacerequirements.

@ Ensurethat thereis a powersupplyreceptacle(I 10-120V60Hz)

within reachofthe cooktoppowercord(30'fromthe middleof

theproduct).Themaincableshouldnottouchanyhot metalparts.

@ Makesurethecooktopisconnectedto a powersupplysocket

that is electricallygroundedinaccordancewith localcodesor

in the absenceoflocalcodes,with the NationalElectricCode

ANSI/FPA70or CSA22.2(Canada).

@ Makesurethecountertopismadeof aheat resistantmaterial.

@ We recommendthatthe exposedbarewoodedgesofthe

cutoutbesealedwith anoil basedpaintor moistureproof

polyurethaneto preventpossibledamagefrom moisture

creepingbetweenthe cooktoptrim andthe benchtop.

@ We recommendusingeasy-to-cleanfinishesforthewall

surfacessurroundingthe cooktopto aid removalofanycooking

stainsresultingfromuse of thecooktop.

PA_TS C_EC_L_ST

@ GasCooktopbaseunit

@ Literaturepack(includesLP6kit)

@ Elbow8 bluewasher(tapedto powercord)

@ Clampingbrackets8 screws(6C36-0nbaseunit)

@ Regulator(inPolystyrene)

_d2Burnerheadsandcaps(checkpolystyrenecarefully

beforediscarding)

@ 3 x Burnergrates/trivets(1 x center,2 x outer)

_d2Accessoriespack

@ Thisappliancecanbe usedwith eitherLPgasor Naturalgasand

isfacter_ set for rise with _at_ral flas.

@ A manualshut-offvalvemustbe installedinanaccessible

locationinthe gaslineexternalto theappliancefor thepurpose

ofturningon orshuttingoff gasto the appliance.(In

Massachusettssuchshutoffdevicesshouldbeapprovedbythe

BoardofStateExaminersof Plumbers8 GasFitters).

_;26asconnectionto theproductmustusetheelbowsuppliedwith

a _/2'NPTexternalthread.

@ Ensure the b_e washer (s_pplied) is _ocatedbetween the

elbow and the predict inlet. FaiI_rete _se this will cause

a gas _eak.

@ore:thisdiagramisof

6636butissimilarfor

66901and68901M/,

Elbow

BlueWasher

@ Forusewith a gaspressureregulator.The regulator s_pplie_

can be set for either LPgas er _at_ral _asand _st be

use_ with this appliance, it hasa1/2'NPTthread.

CO_VEBT_G T_E BE_ULATOB BETWEE_ _ 8 LP

1 Unscrewthe capfromthe regulator.

TOOLS_EEBEB

@ PhillipsNo.2 screwdriver

@ Plumbingfittingsasrequired

@ Woodworkingtoolsasrequired

@ Shut-offvalve

_2 Oilbasedpaint(for sealingcutout)

For LP Conversion

@ O7/64' x 1 3/4'(@2.5x45ram)flat screwdriver

_2 9/32'(7ram)boxspanner

For GC901@LPConversion

@ _ 7/64"x 1a/4"(@2.5x 45mm)flat screwdriver

@ PhillipsNo.1 screwdriver

@ 9/32"{Tram)boxspanner

@ ls/32'(1gram)ringspanner

2 Checkthe orientationofthe plasticconversionplug,andif

necessary,unscrew,turnoverandscrewbackin {widesectionaway

from capfor LPandagainstcapfor NG- see diagrambelowfor

appropriateorientation.

3 Replaceregulatorcap.

Testgaspressure(test pointprovisionon sideof regulator).

Whenconvertingtheregulatorfor differentsettings,thefunctionof

theregulatormustbe checkedata pressureat least1' WC(0.036

p.s.i.)abovethe specifiedmanifoldpressure.

Page 5

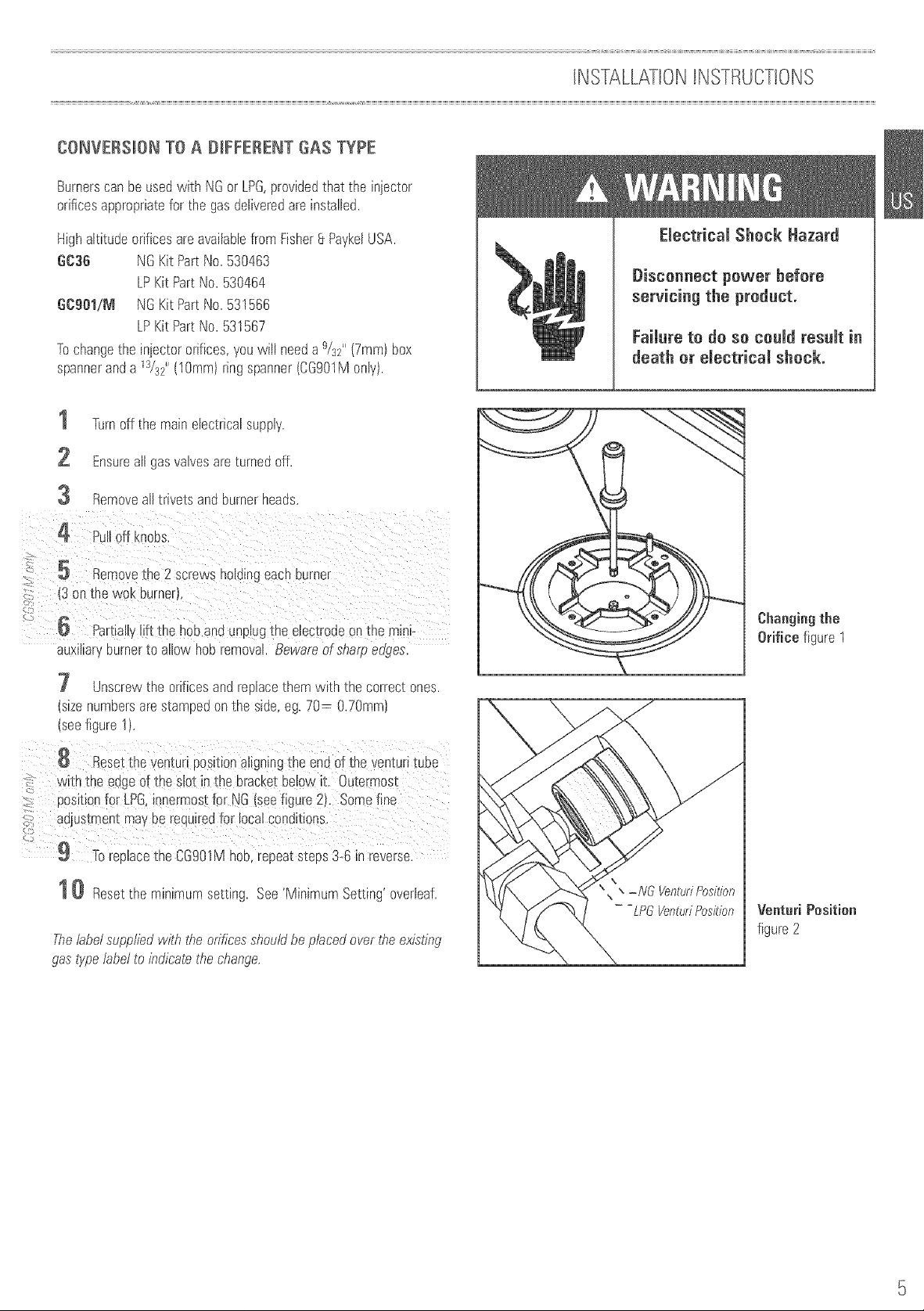

CONVERSIONTO A #_FFERENTGAS TYPE

Burnerscanbeusedwith N6 or LP6,providedthatthe iniector

orificesappropriatefor thegas deliveredareinstalled.

INSTALLATIONINSTRUCTIONS

HighaltitudeorificesareavailabbfromFisher8PaykelUSA.

GC36 NGKit PartNo.530463

LPKitPartNo.530464

GC901/M NGKitPartNo.531566

LPKitPartNo.531567

Tochangetheiniectororifices,youwill needa 9/32' (7ram/box

spanneranda Is/s2'(10ram)ringspanner(C6901Monly}.

1 Turnoff the main ebctrical supply.

2 Ensureall gas valves are turned off.

Remove all trivets and burner heads.

Pulloff Knobs.

Removethe 2 screws notqmgeacn burner

(3 on me WOKDL,qerl.

Par_:_a. lift the hoban{]unD g mee_ec[ror_eor theF""

auxmaryburner[oaHo_,_nodremoval.Bewareofsharpeoges.

7 Unscrewthe ori%esandreplacethemwith thecorrectones.

(sizenumbersarestampedonthe side,eg.70- 0.70mm)

(seefigureI).

Dectrica_ Sheck Hazard

Discennect pewer befere

servicing the preduct.

Failure te do se could result in

death er ebetrieal shock.

Withthe edgeOftheSlotinthe bracketbelowit. Outermost

qb

::; positionfor L?G,innermostfor N6 {s_efigure2). Somefine

Toreplacethe06901M hob,repeatsteps3-_6inreverse.

1 _ Resettheminimumsetting. See'MinimumSetting'overleaf.

Thelabelsupp//adwiththeorificesshouldbeplacedovertheexisting

gastypelabelto indicalethechange.

Venturi Pesitbn

figure2

Page 6

INSTALLA£IONINSTRUCTIONS

LEA_ TEST_

_J Leaktestingof theapplianceshallbe conductedaccordingto

themanufactureCsinstructions.

_d2Theapplianceandit's individualshutoffvalvemustbe

disconnectedfromthe gassupplypipingsystemduringany

pressuretestingof that systeminexcessof _/2p.s.i.(3.SkPa}.

_d2Theappliancemust beisolatedfromthegassupplypiping

systemby closingit's individualmanualshutoffvalveduringany

pressuretestingof thegassupplypipingsystemat test

pressuresat or lessthan _/2p.s.i.(3.SkPa/.

_J Maximuminletgas supplypressure4' W.C.Natural6as,

11'W.C.LPgas.

_2 Minimumgassupplypressurefor regulatortesting5' W.C.

NaturalGas,12'W.C.LPgas.

After installingthe gassupplyandmakingallconnectionscheck

thoroughlyforpossibleleaks.

I Turnall controlknobsonunit to 'off' position.

2 Openthevalveon the gassupply.

M_MUM SETTinG OB TUB_BOW_

Thishasbeensetat thefactoryforNGbutcanbecheckedafter

thecorrectpressurehasbeenreached.Toadiustfor minimum

setting(ifapplicable),youwill needa_ 7/64' x 1 3/4"(_2.5x

45mm)screwdriver.(Asuitablescrewdriverisavailableas

Fisher8Paykelsparepart.FB200467).

ignitethe burnerandset the knobto its minimumposition.

2 Removetheknobs.

Rotatethe turndownscrew (downthe holeinthe spindle)

whileholdingtheshaft. Rotateslowlyuntila minimumregular

flameisachieved. {Theflamewill diminishwhenthe screwis

turnedclockwiseandincreasewhenturnedcounterclockwise).

Whenthe settingis rightcheckregulationby quicklyrotating

theknobfromthemaximumto the minimumdeliveryposition.The

flamemustnotgo outandtheautoreignitionshouldnotdick.

Replacethe knob.

3 Usinga leakdetectionfluid (e.g.Rocolleakdetectionspray)

checkeachgasconnectiononeat atime by brushingthesolution

overthe connection.Thepresenceofbubbleswill indicatealeak.

4 If necessary,tightenthe fitting andrecheckfor leaks.

5 Turnonburnervalveandlight eachburner.

6 Checkfora clearblueflamewithout yellowtipping. If burners

showanyabnormalities,checkthattheyarelocatedpropedyandin

linewith theiniectororifice.

See the Product Insta%tionChecklist attached to the product.

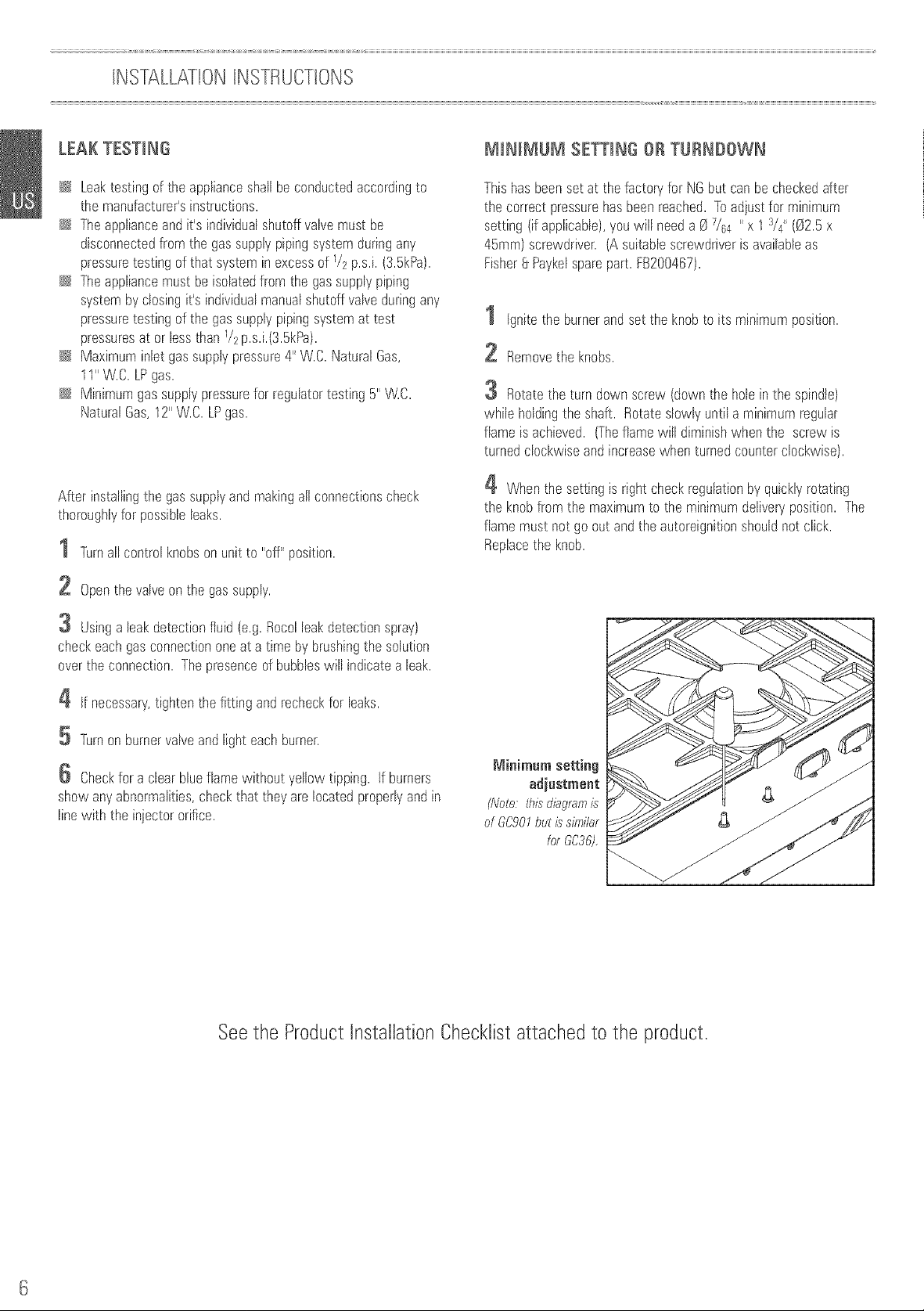

_i_i_r_ setting

a_i_stme_t

(Note: this diagramis

of 68901but issimilar

forG836),

Page 7

CHECKING THE GAS TYPE

Burners NG Orifice NG LP Brifiee LP

RHRear

LHRear

RHFrontSimmer

LBFrontWok

Center 1.45mm 9,500(10MJ/h) O.85mm 9,500(10.0tvU/h)

GC901 / GCg01M

Burners NG Orifice NG LP Orifice LP

RHRear 1.3ram 8,000 (8,4/_J/h) 0.Smm 8,200(8.7_J/h)

INSTALLATIONINSTRUCTIONS

(ram) BTU (MJ/h)@ (ram) EtTU(MJ/h)@

o.15psi(4"_o) ompsi (11"_o)

1.3ram

1.3ram

O.85ram

I. 75ram

(ram) BTU (MJ/h)@ (ram) BTU (M J/h)@

8,000(8.4IW/h)

8,ooo(84

i

3,500(8.47MJ/h)

12,000(13.3_J/h)

O.15psi (4"_20) O,# l psi (11"_20)

0.Smm 8,000(8.4l_J/h)

0.Smm 8,000(8.4MJ/h)

0.55ram ,,4,000(4.2MJ/h)

1.05mm 13,000(13.71W/h)

LHRear 1.1ram 5,800 (G.I MJ/N 0.7ram 5}700(0.0/_J/h)

RHFrontSimmer 0.85ram 3,000(8.2_J/N 0.55mm 3,500(8.7_J/h)

LHFront 1.3ram 8,000 (8.4l_J/h) 0.Smm 8,200(8.7l_J/h)

Center£c_o_} 1.75mm 14,000(14.8l_J/h) 1.05ram 13,000(I3.7 l_J/h)

Center(GC_O_M}2.15ram 20,000(2I. 1Mg/h) 1.22mm 19,000(20MJ/h)

CONTACT #ETA&S

A ServiceSummaryis attached to the undersideof the product.

Forreplacementparts or iffurther help is neededconcerningthis appliancecall:

Tell Free t 888 9 FNPUSA (1 888 936 7872)

or write to:

Fisher 8 Pa_kel Appliances _ac.

27 Habble, _rviae

CA 92618

or contact usthrough our web site,

www.asa.fis_erpaykeLcem

C

®

US

Loading...

Loading...