Fisher & Paykel FREESTANDING COOKER OR120 User Manual

Installation instructions

and User guide

GB IE

Freestanding cooker

OR120 double oven models

1

Safety and warnings

2

Installation instructions

6

Maintenance instructions

13

Introducing your cooker

16

Using your cooktop

17

Cooktop troubleshooting

21

Using your ovens for the first time

22

Clock and timer

23

Using your oven

24

Cooking functions

25

Automatic cooking

27

Using the warmer drawer

28

Care and cleaning

29

Warranty and service

42

Important!

SAVE THESE INSTRUCTIONS

The models shown in this User Guide may not be available in all markets and are

subject to change at any time. For current details about model and specification

availability in your country, please visit our local website listed on the back cover

or contact your local Fisher & Paykel dealer.

Contents

2

Safety and warnings

WARNING!

Electrical Shock Hazard

Always disconnect the cooker from the mains electricity supply before

carrying out any maintenance operations or repairs.

Failure to do so may result in death or electrical shock.

Important safety precautions

General

To avoid hazard, follow these instructions carefully before installing or using this product.

Please make this information available to the person installing the product as it could reduce

your installation costs.

Installation must comply with your local building and electricity regulations.

Failure to install the cooker correctly could invalidate any warranty or liability claims.

Some appliances have a protective film. Remove this film before using the cooker.

Electrical

This cooker is to be installed and connected to the electricity supply only by an authorised person.

If the installation requires alterations to the domestic electrical system, call a qualified

electrician. The electrician should also check that the electrical system is suitable for the

electricity drawn by the cooker.

The appliance must be connected to the mains, checking that the voltage corresponds to the

value given in the rating plate and that the electrical cable sections can withstand the load

specified on the plate.

A suitable disconnection switch must be incorporated in the permanent wiring, mounted and

positioned to comply with the local wiring rules and regulations. The switch must be of an

approved type installed in the fixed wiring and provide a 3 mm air gap contact separation in all

poles in accordance with the local wiring rules.

The switch must always be accessible.

The power supply cable must not touch any hot parts and must be positioned so that it does not

exceed 75

O

C at any point.

Installation

WARNING!

Cut Hazard

Take care - panel edges are sharp.

Failure to use caution could result in injury or cuts.

3

Safety and warnings

To connect the cooker to the mains, do not use adapters, reducers or branching devices as they

can cause overheating and burning.

This cooker must be connected to a suitable double pole control unit adjacent to the cooker. No

diversity can be applied to this control unit.

The cooker must be earthed.

Gas

This cooker is supplied for use with natural gas only, and cannot be used on any other gas

without modification. See the ‘Maintenance instructions’ for modification to other gas types.

This cooker can only be installed in a room with adequate ventilation. See the ‘Provision for

ventilation’ instructions in the installation instructions following .

4

Operation

Your freestanding cooker has been carefully designed to operate safely during normal cooking

procedures. Please keep the following guidelines in mind when you are using it:

WARNING!

Hot Surface Hazard

Accessible parts may become hot when this cooker is in use.

To avoid burns and scalds keep children away.

Do not touch hot surfaces inside the ovens or warmer drawer.

Use oven mitts or other protection when handling hot surfaces such as oven

shelves or dishes.

Take care when opening the oven doors.

Let hot air or steam escape before removing or replacing food.

Do not touch the cooktop components, burners, trivets/pan supports or the

base when hot.

Before cleaning, turn the cooker off and make sure it is cool.

Failure to do so could result in burns and scalds.

WARNING!

Electrical Shock Hazard

Switch the cooker off at the wall before replacing fuses or the oven lamp.

Failure to do so may result in death or electrical shock.

Safety and warnings

WARNING!

Explosion Hazard

Do not store flammable materials such as gasoline near the cooktop.

Do not store flammable material in the ovens or in the drawers.

Do not spray aerosols near the cooktop during use.

Failure to do so may result in death or serious injury.

5

Important safety precautions

Isolating switch: make sure this cooker is connected to a circuit which incorporates an isolating

switch providing full disconnection from the power supply.

Household appliances are not intended to be played with by children.

Children, or persons with a disability which limits their ability to use the appliance, should have a

responsible person to instruct them in its use. The instructor should be satisfied that they can use

the appliance without danger to themselves or their surroundings.

Safe food handling: leave food in the oven for as short a time as possible before and after

cooking. This is to avoid contamination by organisms which may cause food poisoning. Take

particular care during warmer weather.

Do not place aluminium foil, dishes, trays, water or ice on the oven or warmer drawer floor during

cooking as this will irreversibly damage the surface.

Do not line the walls with aluminium foil.

Do not stand on the doors, or place heavy objects on them.

Do not use harsh abrasive cleaners or sharp metal scrapers to clean the oven door glass since

they scratch the surface, which may result in shattering of the glass.

Do not use a steam cleaner to clean any part of the cooker.

Do not use an asbestos mat or decorative covers between the flame and the saucepan as this may

cause serious damage to your cooktop.

Do not place aluminium foil or plastic dishes on the cooktop burners.

Do not let large saucepans or frying pans overlap the bench as this can deflect heat onto your

benchtop and damage the surface.

Do not let large saucepans, frying pans or woks push any other pans aside. This could make them

unstable or deflect heat onto your benchtop and damage the surface.

Saucepan handles may be hot to touch. Ensure saucepan handles do not

overhang other gas burners that are on. Keep handles out of reach of children.

If the electrical supply cord is damaged, it must only be replaced by an authorised person.

This cooker is not to be used as a space heater.

The use of a gas cooking appliance results in the production of heat and moisture in the room in

which it is installed. Ensure the kitchen is well ventilated. Keep natural ventilation holes open or

install a mechanical ventilation device (mechanical extractor hood).

Prolonged intensive use of the appliance may call for additional ventilation, for example opening

of a window, or more effective ventilation, for example increasing the level of mechanical

ventilation where present.

Safety and warnings

6

Installation instructions

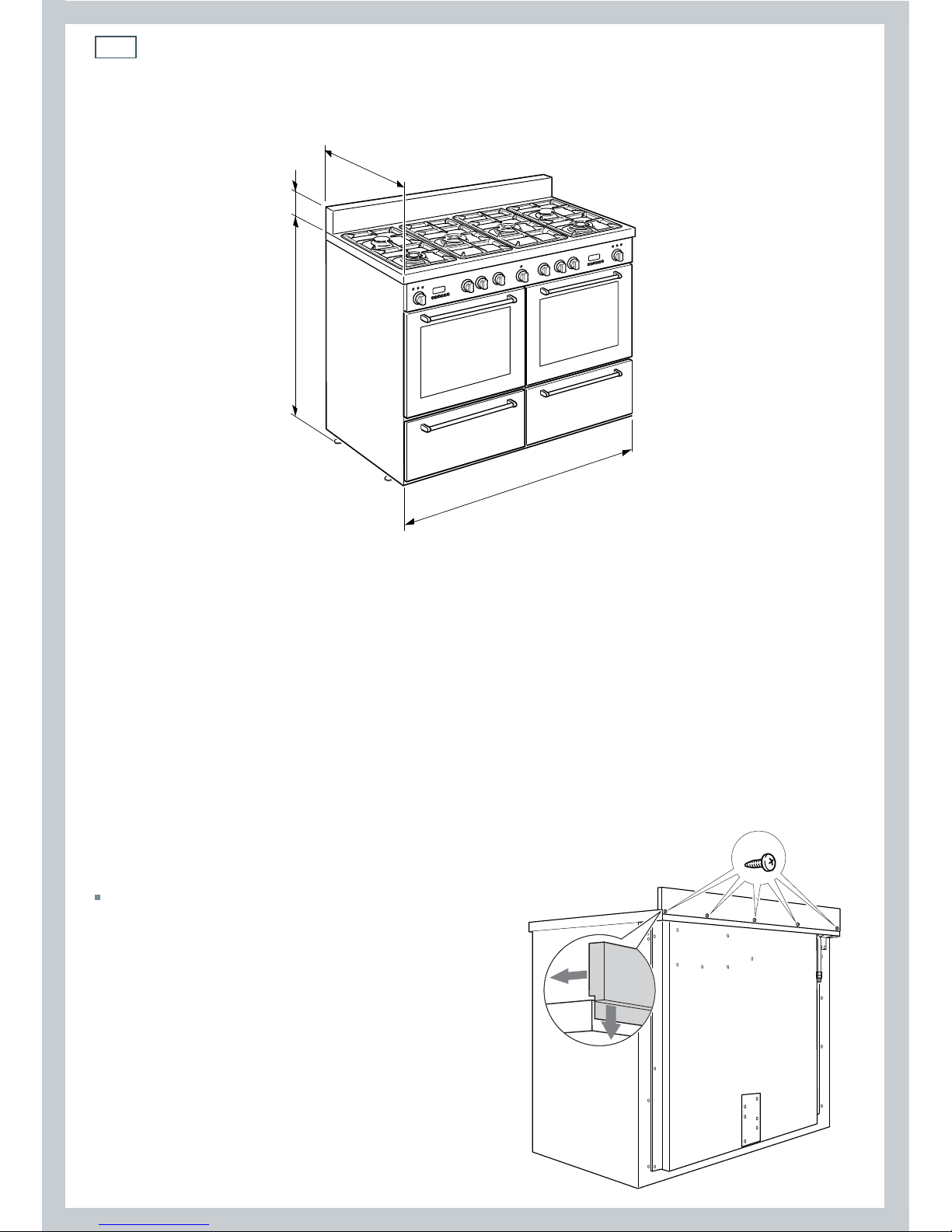

600 mm

1200 mm

MAX 927 mm

MIN 915 mm

120 mm

Fig. 1

Location

The installation conditions, concerning protection against overheating of the surfaces adjacent

to the cooker, must conform to Fig.3a or 3b.

The appliance must be kept no less than 200 mm away from any side wall which exceeds the

height of the hob surface (Fig. 3a or 3b).

The appliance must be housed in heat resistant units.

The walls of the units must be capable of resisting temperatures of 75 °C above room temperature.

Do not install the appliance near flammable materials (eg. curtains).

If the cooker is located on a pedestal, provide safety measures to prevent it falling out.

Assembling the backguard

It is mandatory to install the backguard

Assemble the backguard as shown in Fig. 2

and fix it by screwing the five screws “A”.

A

Fig. 2

7

Installation instructions

450 mm

minimum

minimum

650 mm

0 mm

0 mm

500 mm minimum

200 mm minimum

450 mm

minimum

minimum

650 mm

20 mm

20 mm

500 mm minimum

200 mm minimum

Gas connection made

using rigid or flexible

metal pipe.

Class 2

Subclass 1

Class 1

Gas connection made

using rubber hose

which must be visible

and easily inspected or

using rigid or flexible

metal pipe.

Fig. 3a

Fig. 3b

8

Installation instructions

+ 8 mm

+ 8 mm

0 mm

+ 12 mm

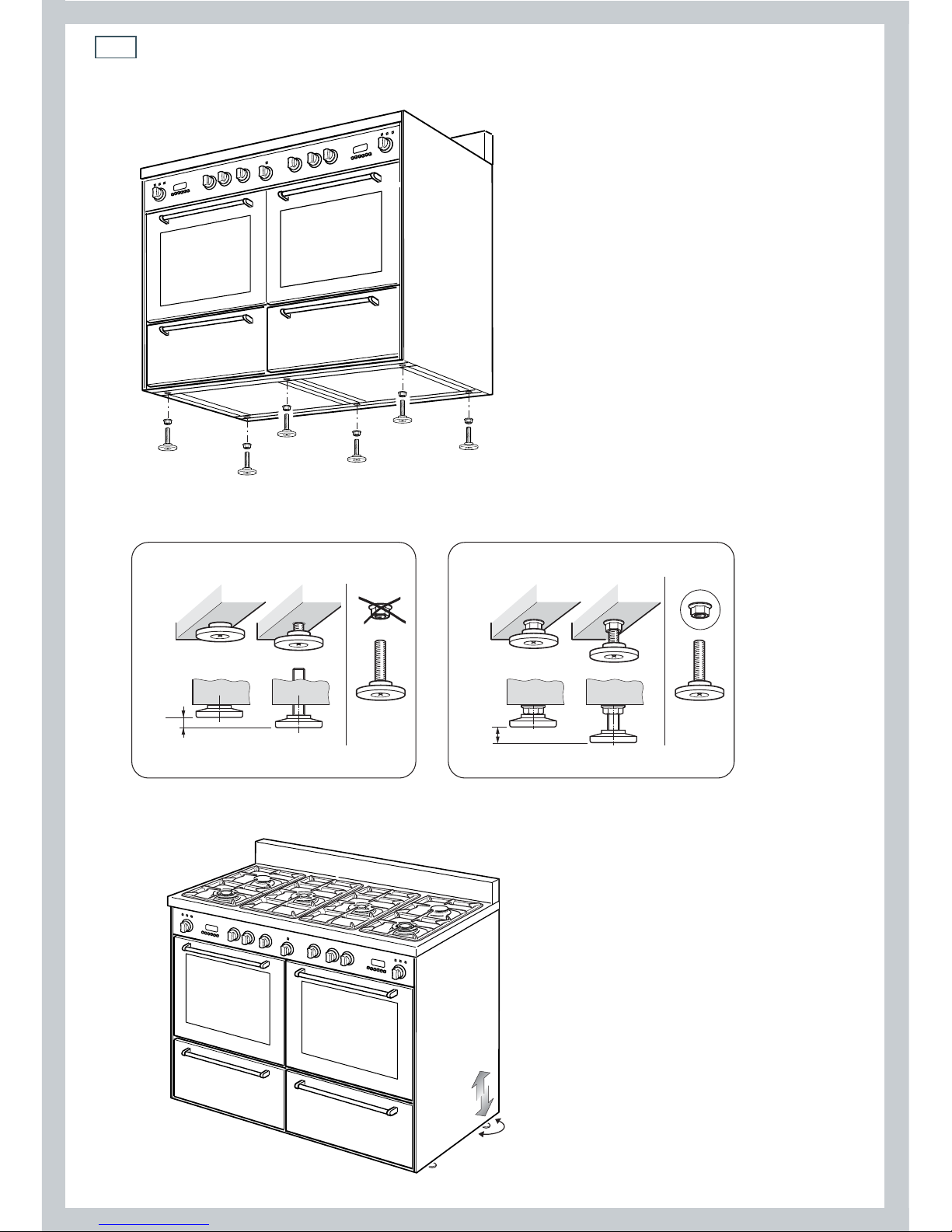

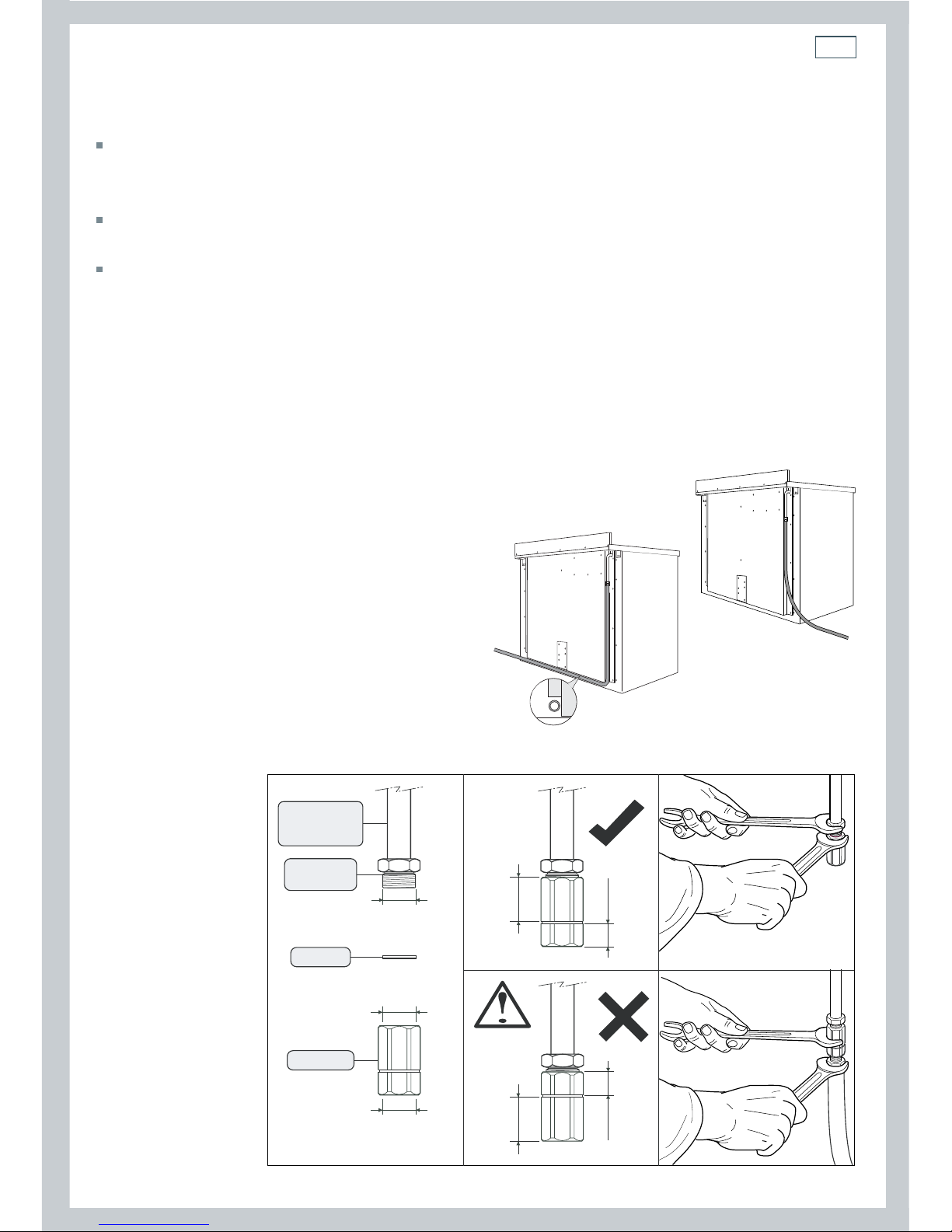

Levelling the cooker

Important!

Using the supplied adjustable feet is

MANDATORY. For safety reasons and to

ensure adequate ventilation, the cooker

chassis MUST NOT sit directly on the floor, a

plinth, or other support surface.

The cooker is already fitted with six

levelling feet. Level the cooker by

screwing or unscrewing the feet

(Fig. 4d). Make sure you follow the

instructions in Figs. 4a, 4b, and 4c.

Note: bolts are supplied with the cooker

in a separate kit.

Fig. 4a

Fig. 4b Fig. 4c

Fig. 4d

9

Installation instructions

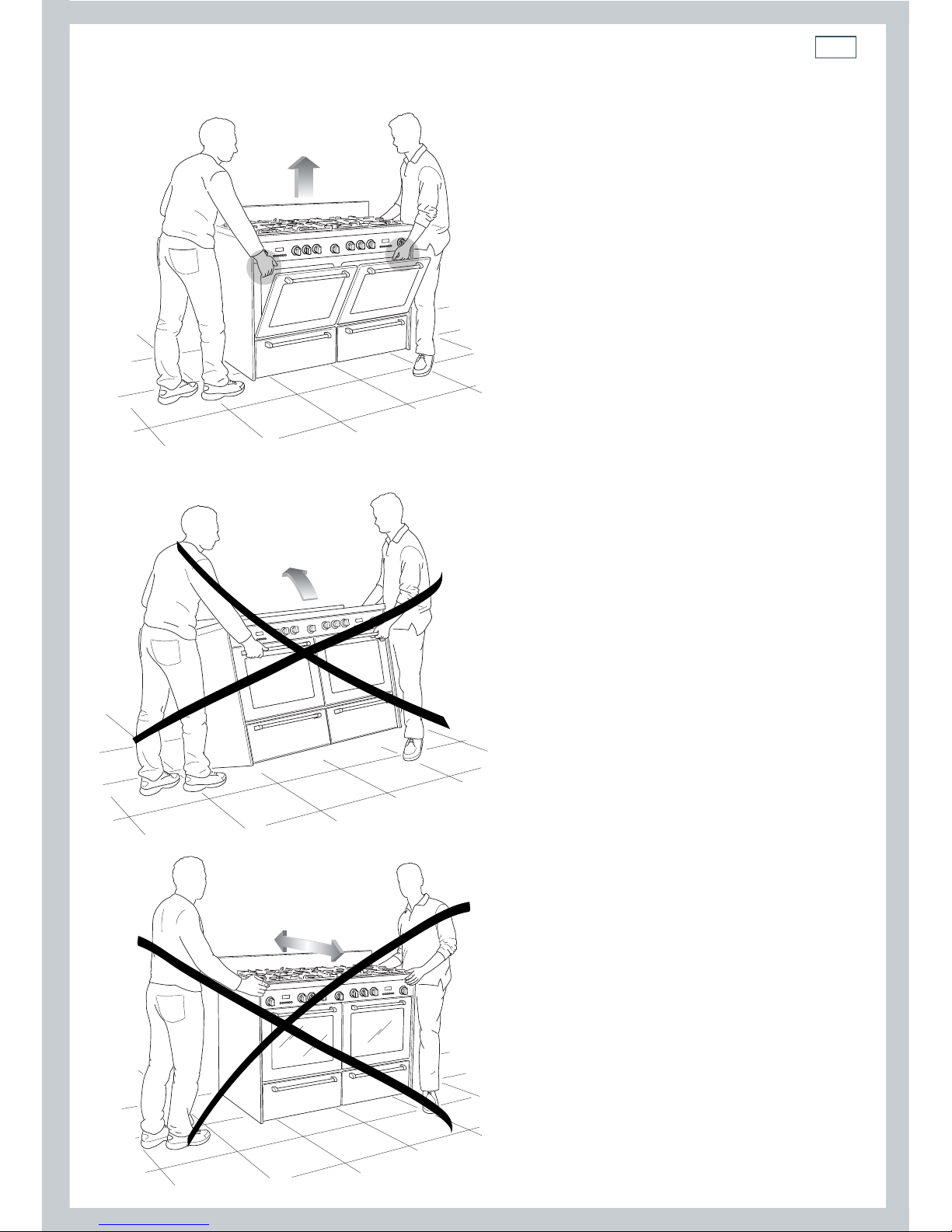

Moving the cooker

Important!

Two people must always raise the cooker, as

shown, to prevent damaging the adjustable

feet.

Do not lift the cooker by the door handles.

DO NOT DRAG the cooker. Lift the feet clear

of the floor.

Ventilation requirements (GB & IE

only)

The appliance should be installed in

a room or space with an air supply in

accordance with BS 5440-2:2000.

For rooms with a volume of less than 5

m

3

: permanent ventilation of 100 mm3

free area will be required.

For rooms with a volume of between 5

m

3

and 10 m3 : permanent ventilation

of 50 cm

3

free area will be required

unless the room has a door which opens

directly to the outside air, in which case

no permanent ventilation is required.

For rooms with a volume greater than

10 m

3

: no permanent ventilation is

required.

Note: regardless of room size, all rooms

containing the appliance must have

direct access to the outside air via an

openable window or equivalent.

Where there are other fuel burning

appliances in the same room, BS

5440-2:2000 should be consulted to

determine the correct amount of free

area ventilation requirements.

Fig. 5a Correctly raising the cooker

Fig. 5c Incorrectly raising the cooker

Fig. 5b Incorrectly moving the cooker

10

Installation instructions

Gas installation (GB & IE only)

Important!

This cooker uses NATURAL GAS only and cannot be used on any other gas without modification. This

appliance is manufactured for conversion to LPG if required. If the injectors are not supplied they can be

obtained from the After-Sales Service.

Installation and service regulations

Important!

This appliance must be installed and serviced only by a suitably qualified and registered person, and in

accordance with the current editions of the following standards and regulations or other locally applicable

regulations:

Gas Safety (Installation and Use) Regulations

Building Regulations

British Standards

Regulations for Electrical Installation

Failure to install the appliance correctly could invalidate any manufacturer’s warranty

and lead to prosecution under the above-quoted regulation.

Gas connection

The installation of the cooker to Natural Gas or LP Gas must be carried out by a qualified

gas engineer. Installers shall take due account of the provisions of the relevant British

Standards Code of Practice, the Gas Safety Regulations and the Building Standards (Scotland)

(Consolidation) Regulations issued by the Scottish Development Department.

Note: It is recommended that the gas connection to the cooker is installed with a flexible

connecting tube made to BS 5386.

Installation to Natural gas

Installation to Natural Gas must conform to the Code of Practice, etc. The supply pressure for

Natural Gas is 20 mbar.

Installation to Liquid Petroleum gas

This appliance must only be connected to LPG after an LPG conversion kit has been fitted. The

installation must conform to the relevant British Standards.

Important!

Only a suitably qualified and registered person may convert the appliance to a different gas type.

When using Butane gas a supply pressure of 28 -30 mbar is required.

When using Propane gas a supply pressure of 37 mbar is required.

11

Notes:

Flexible hoses can be used where the sited ambient temperature of the hose does not exceed

70°C. These hoses must be manufactured in accordance with BS669 part 1 and be of the correct

construction for the type of gas being used.

Gas hoses designed for natural gas MUST NOT be used for supplying LPG gas (LPG gas hoses can

be identified by a either a red band or stripe on the rubber outer coating of the hose).

The hose should not be crushed or trapped or be in contact with sharp or abrasive edges. It

should also not be subjected to corrosion by acidic cleansing agents.

To connect the gas supply:

1

Fit the 1/2” BSP (female) connector (supplied with the cooker in a separate kit) to the gas inlet at

the rear of the cooker interposing the gasket. Check the correct positioning of the connector as

shown and always use two suitable spanners (Fig 6b).

2

Connect the gas supply to the gas inlet at the rear of the cooker. If the pipe has to cross the

cooker, it must be positioned under the protected area of the cooker (see Fig 6a)

3

To avoid damage to the appliance gas rail

inlet pipe tighten the fittings using two

suitable spanners (Fig. 6b).

4

Using a suitable leak detection fluid solution

(e.g. Rocol) check each gas connection one

at a time by brushing the solution over the

connection. The presence of bubbles will

indicate a leak. If there is a leak, tighten the

fitting and then recheck for leaks.

IMPORTANT!

Do not use a naked flame to test for leaks.

1/2” BSP (female)

1/2” G cylindrical

(ISO 228-1) male

1/2” G cylindrical

(ISO 228-1) female

20 mm

10 mm

20 mm

10 mm

Cooker manifold

Manifold male

pipe fitting

Gasket (*)

Connector (*)

(*) Supplied with the appliance in a separate kit.

Installation instructions

Fig. 6b

Fig. 6a

12

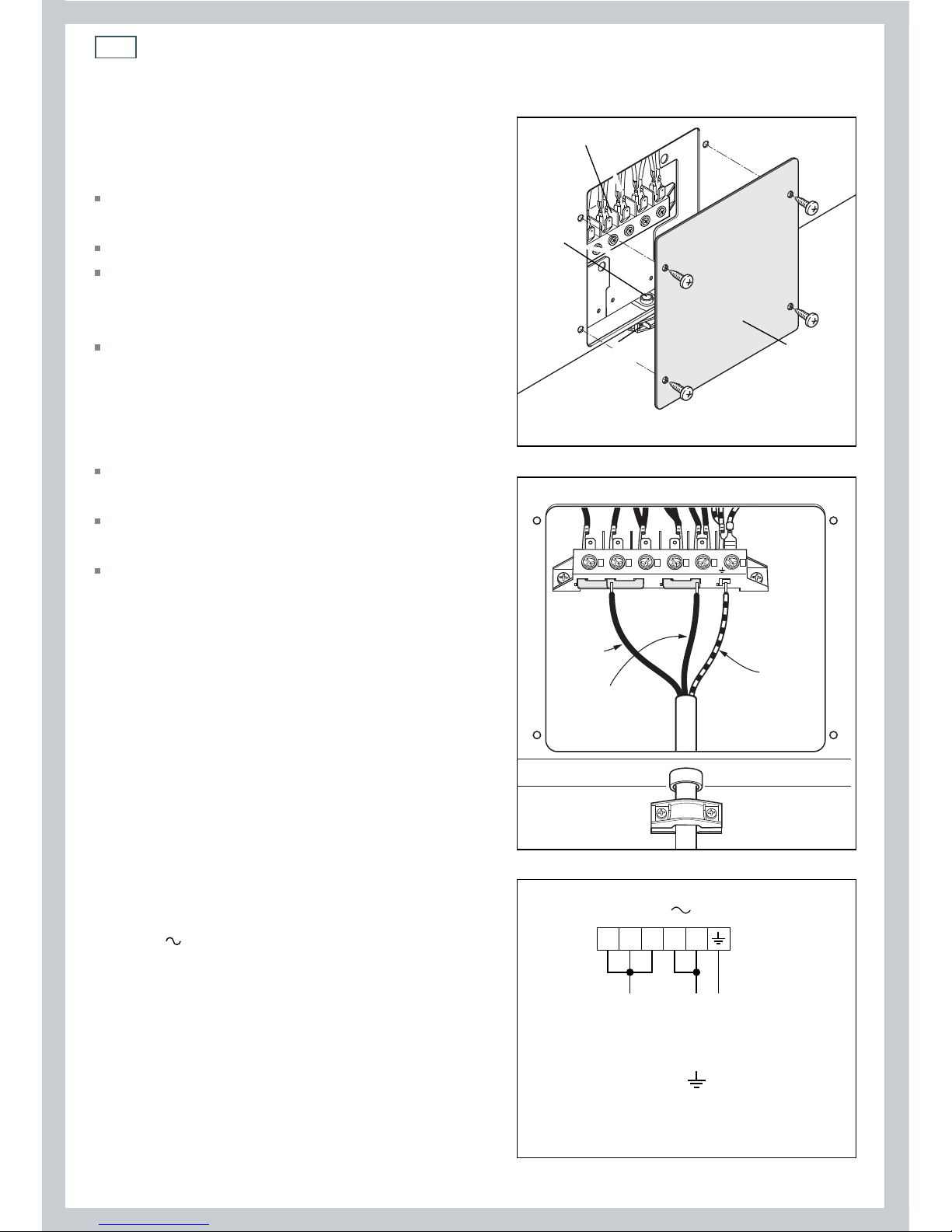

Installation instructions

C

D

A

B

Feeder cable section

“TYPE H05RR-F”

230V 3 x 2.5 mm2 (**)

(**) - Connection with wall

box connection.

PE

12345

N (L2)L1

230 V

Red or

Brown

(Live)

Black or

Blue

(Neutral)

Green

and

Yellow

(Earth)

23451

N(L2)

PE

L1

PE Earth

N Neutral

L Live

Connecting the feeder cable

To connect the feeder cable to the cooker:

Remove the four screws that hold shield “A”

behind the cooker.

Open the cable clamp “D” completely.

Check the position of the U bolts on the

terminal block “B” (Fig. 7a) according to the

diagram in Fig. 7b and Fig. 7c.

Insert the feeder cable into the cable clamp

“D”

and into the cable protector “C”. The

supply cable must be of a suitable size for

the current requirements of the appliance;

see ‘Feeder cable section’ following.

Connect the phase and earth cables to

terminal “B” according to Figs. 7b and 7c.

Pull the feeder cable and block it with the

cable clamp “D”.

Re-mount shield “A”.

Note: the earth conductor must be left

about 30 mm longer than the others.

Fig. 7a

Fig. 7b

Fig. 7c

Green

and

Yellow

(Earth)

Black

or Blue

(Neutral)

Red or

Brown

(Live)

13

Maintenance instructions

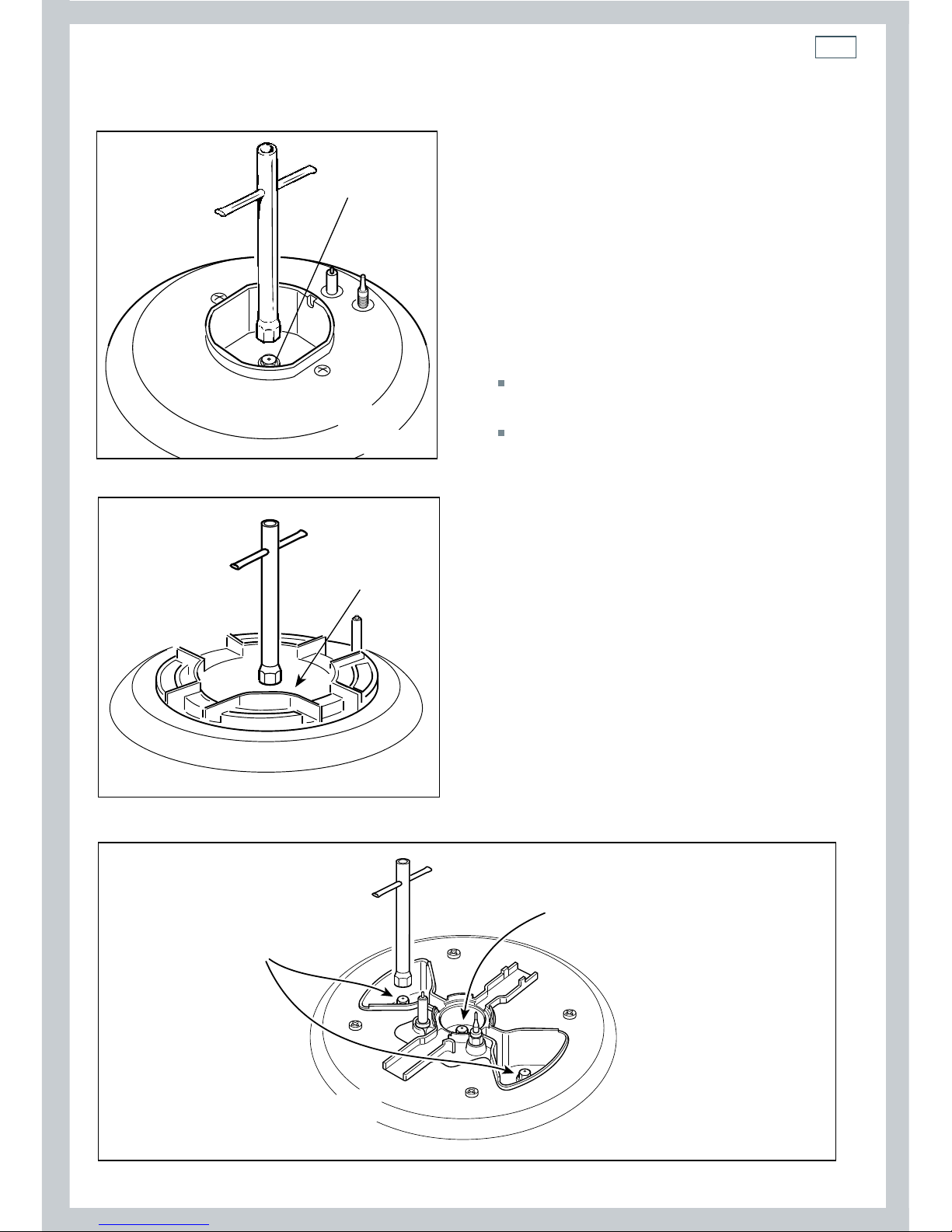

Replacing the burner injectors

If the injectors are not supplied, contact

the Fisher & Paykel Authorised Service

Centre.

Select the injectors to be replaced

according to the ‘Table for the choice of

injectors’.

To replace the injectors:

Remove pan supports and burners from

the cooktop.

Using a wrench, substitute the nozzle

injectors “J” (figs. 8a - 8b - 8c) with those

most suitable for the kind of gas used.

The burners are designed so that

adjustment of primary air is not required.

J

J

Dual burner

Triple ring wok

burner

Semi-rapid

burner

J

Injector for inner crown

Injectors for

outer crowns

Fig. 8a

Fig. 8b

Fig. 8c

J

Loading...

Loading...