Page 1

ACTIVESMART™ INTEGRATED

FRENCH DOOR REFRIGERATOR FREEZER

RS2A72 and RS6A72 models

INSTALLATION GUIDE

US CA

862212C 08.19

Page 2

Page 3

CONTENTS

SAFETY AND WARNINGS

1

COMPONENTS

2

TOOLS

3

APPLIANCE AND CAVITY DIMENSIONS

4

CABINETRY OPTIONS

5

DOOR PANEL DIMENSIONS

6

CUSTOM DOOR PANEL INSTALLATION DIMENSIONS — RS32A72

7

CUSTOM DOOR PANEL INSTALLATION DIMENSIONS — RS36A72

7

CUSTOM DOOR PANEL INSTALLATION TEMPLATE (RS32A72)

8

CUSTOM DOOR PANEL INSTALLATION TEMPLATE (RS36A72)

8

DOOR CLEARANCE

9

ELECTRICAL AND PLUMBING

!0

BEFORE INSTALLATION

!1

CAVITY PREPARATION

!2

WATER SUPPLY CONNECTION

!3

POWER SUPPLY CONNECTION

!4

INSTALLATION PREPARATION

!5

TOP TRIM INSTALLATION

!6

POSITIONING INTO CABINETRY

!7

ALIGNING INSIDE CABINETRY

!8

DOOR PANEL INSTALLATION — STAINLESS STEEL

!9

@4

CABINET TRIMS

INSTALLATION — [A] FLEXIBLE SPRING CLIP METHOD

@5

OR

FIXING TO CABINETRY

@1

WATER FILTER INSTALLATION

@2

TOE KICK INSTALLATION

@3

COVERS AND TRIMS INSTALLATION

OR

FINAL CHECKLIST

@7

DOOR PANEL INSTALLATION — CUSTOM

@0

CABINET TRIMS

INSTALLATION — [B] FIXED SCREW METHOD

@6

IMPORTANT!

SAVE THESE INSTRUCTIONS

The models shown in this installation guide may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country,

go to our website fisherpaykel.com or contact your local Fisher & Paykel dealer.

1

Page 4

Page 5

1 SAFETY AND WARNINGS

!

WARNING!

Electric Shock Hazard

Read and follow the safety and warnings

outlined in this installation guide before

operating this appliance.

Failure to do so can result in death, electric

shock, fire or injury topersons.

!

WARNING!

Cut Hazard

Take care — panel edges are sharp. Failure to

use caution could result in injury or cuts.

!

WARNING!

This appliance is top-heavy and must

be secured to prevent the possibility of

tippingforward.

To ensure that the appliance is stable under

all loading conditions, theanti-tip bracket

and fittings supplied must be installed

according tothe following installation steps

by a professional installer.

IMPORTANT!

●

It is very important for the installer to follow the instructions in this installation guide

to ensure proper installation and operation of the appliance. Ensure that you read the

installation guide thoroughly and understand all information.

●

The water connection to your Ice and water appliance must be installed by a qualified

plumber or Fisher & Paykel trained and supported service technician andcomply with

all state and local laws.

●

Installation and use MUST comply with all state and local plumbing codes. Checkwith

your local public works department for plumbing codes. You must follow their

guidelines as you install the water filtration system.

●

To avoid serious illness or death, only connect your water filter to safe drinking water.

●

The water filter cartridge needs to be changed when the replacement indicator icon

illuminates. This will happen every 6 months.

●

If the water filtration system has been allowed to freeze, replace filter cartridge.

Failureto replace the disposable filter at recommended intervals may lead to reduced

filter performance and failure of the filter, causing property damage from water

leakage or flooding.

●

In cases of excessively reduced filter life — we recommend that you consult a local

plumber or your water supplier for advice on suitable filtration requirements for the

water supplied to your home.

●

Filter replacement is the consumer’s responsibility and will not be covered by the

warranty except in the case of faulty parts or materials within the filter cartridge.

●

If the water has not created ice for some time or ice has an unpleasant taste or odor

dispose of ice and refer to the flushing instructions detailed in the installation section

ofthis user guide / installation guide. If unpleasant taste or odor persists, you may wish

tofit a new filter cartridge.

●

Use new tubing supplied with the appliance. DO NOT reuse old tubing from old water

andice connections.

●

Your water filtration system can withstand up to 120psi (827kPa) of water pressure.

Ensure the supplied pressure reducing valve is installed before installing the water

filtration system. DO NOT install if water pressure exceeds 120psi (827kPa).

To reduce the risk associated with property damage due to water leakage or flooding:

●

DO NOT install systems in areas where ambient temperatures may go above 100°F

(38°C) or drop below 33°F (0.6°C).

●

DO NOT install on hot water supply lines. The maximum operating water temperature

ofthis filter system is 100°F (38°C).

●

DO NOT install where water hammer conditions may occur. If water hammer conditions

exist, you must install a water hammer arrester.

WARNING!

To reduce the risk associated with choking:

●

DO NOT allow children under 3 years of age to have access to small parts during the

installation of the water filter.

3

Page 6

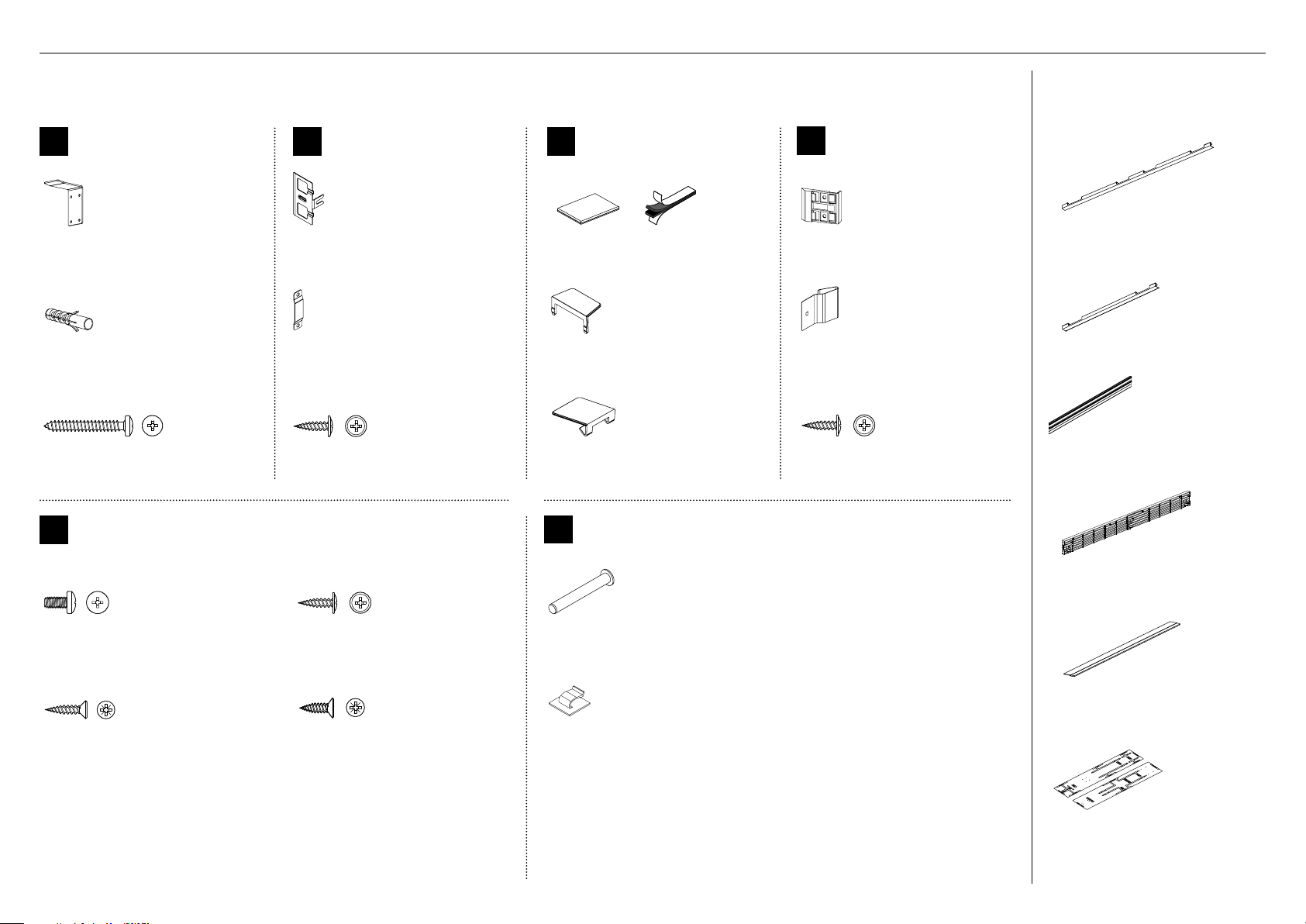

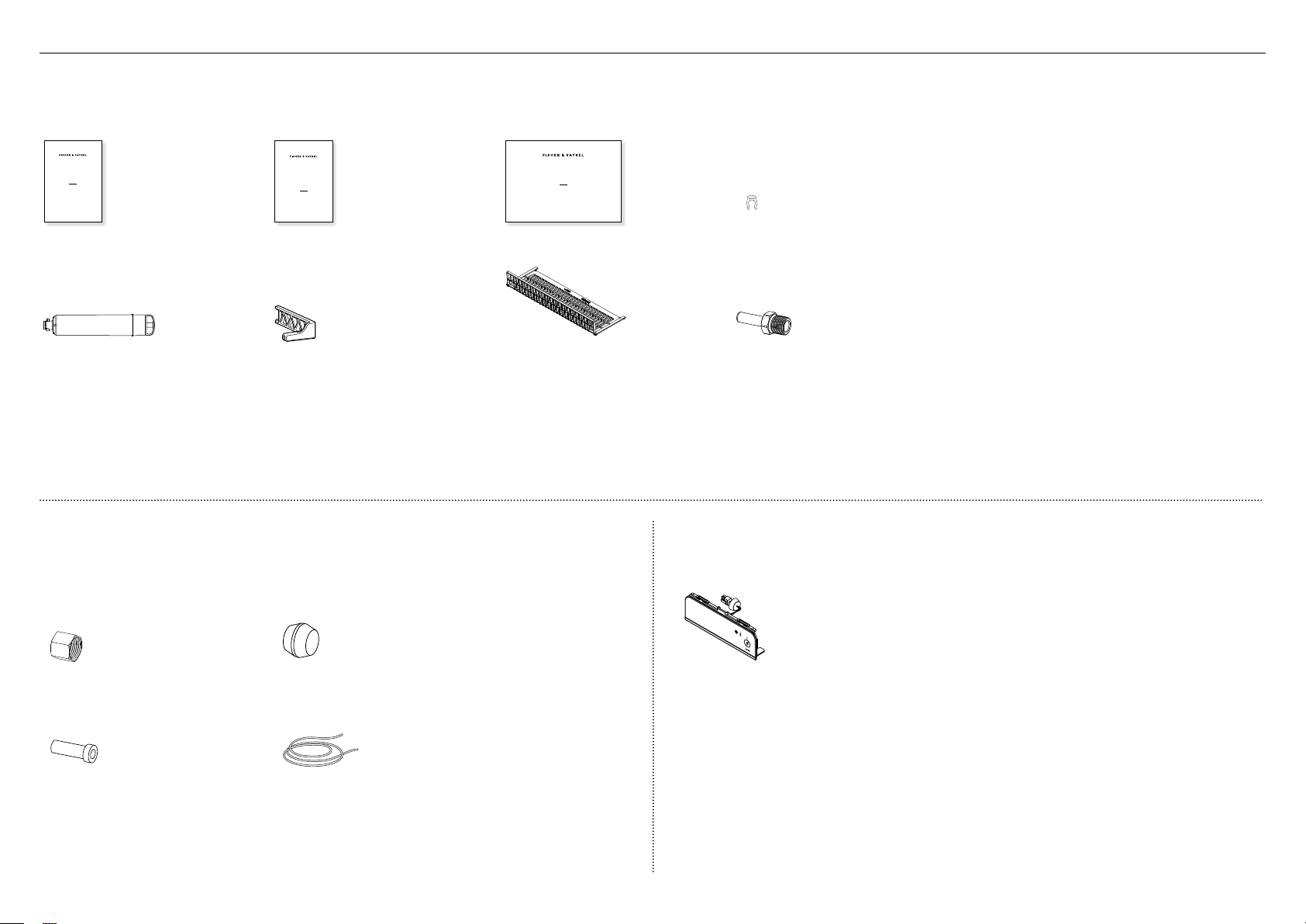

2 COMPONENTS

Internal box (Installation kit)

Located inside appliance

Anti-tip bracket

A

assemblykit

Anti-tip bracket

(1)

Masonry plug

(4)

#10x40 cross-head screw

(4)

Install fasteners kit

X

Door panel attachment

B

kit

Side bracket

(10)

Side strap

(10)

#8Gx16 countersunk screw

(36)

Door/drawer trim

C

installkit

Dual adhesive tabs (6 per each strip)

(12)

Side cover

(4)

Top cover

(2)

Y

Miscellaneous

components

Cabinet side trim

D

installkit

Side trim bracket

(6)

Spring clip

(6)

#8x16 mush washer screw

(12)

External box

Located at back panel of appliance

Door side trim

(2)

Drawer side trim

(2)

Top trim

(1)

M5x10 cross-head screw

(10)

#8Gx19 twin thread screw (2)

Not used for this model

4

#8Gx16 flat head screw

(2)

#12x12 Countersunk screw

(2)

Toe kick grille

(1)

Hinge limiting pin

(1)

Drawer top trim

(1)

Power cord/water tube clip

(2)

Double-sided door panel template

(1)

Page 7

Miscellaneous items (MI) pack

Located inside the appliance

2 COMPONENTS

ACTIVESMART™

INTEGRATED REFRIGERATOR

RS90A, RS9120W,

RS36A72, RS36A80 & RS36W80 models

USER GUIDE

NZ AU GB IE HK SG IN US

User guide

(1)

Water filter

(1)

SERVICE & WARRANTY

SERVICE ET GARANTIE

ΣΈΡΒΙΣ ΚΑΙ ΕΓΓΎΗΣΗ

SERVIZIO E GARANZIA

SERVICE & GARANTIE

HUOLTO JA TAKUU

SERVICE OG GARANTI

保修和维修

服務和保修

Service and Warranty

(1)

Filter cartridge tool

(1)

Water fittings kit

(Ice and Water models only)

Not supplied and can be purchased in your local hardware stores

ACTIVESMART™ INTEGRATED

SLIDE-IN REFRIGERATOR

RS90 & RS90AU models

INSTALLATION GUIDE

NZ AU GB IE HK SG IN

844219B 02.19

Installation guide

(1)

Toe kick filter

(1)

Collet locking clip

(1)

1/4" (6mm) adaptor

(1)

Ice and Water display

(Ice and Water models only)

Located inside the appliance

1/4"(6mm) Compression nut

(1)

1/4" (6mm) Tube insert

(1)

1/4"(6mm) Compression sleeve

(1)

1/4" (6mm) plastic tubing

(1)

External display module

(1)

5

Page 8

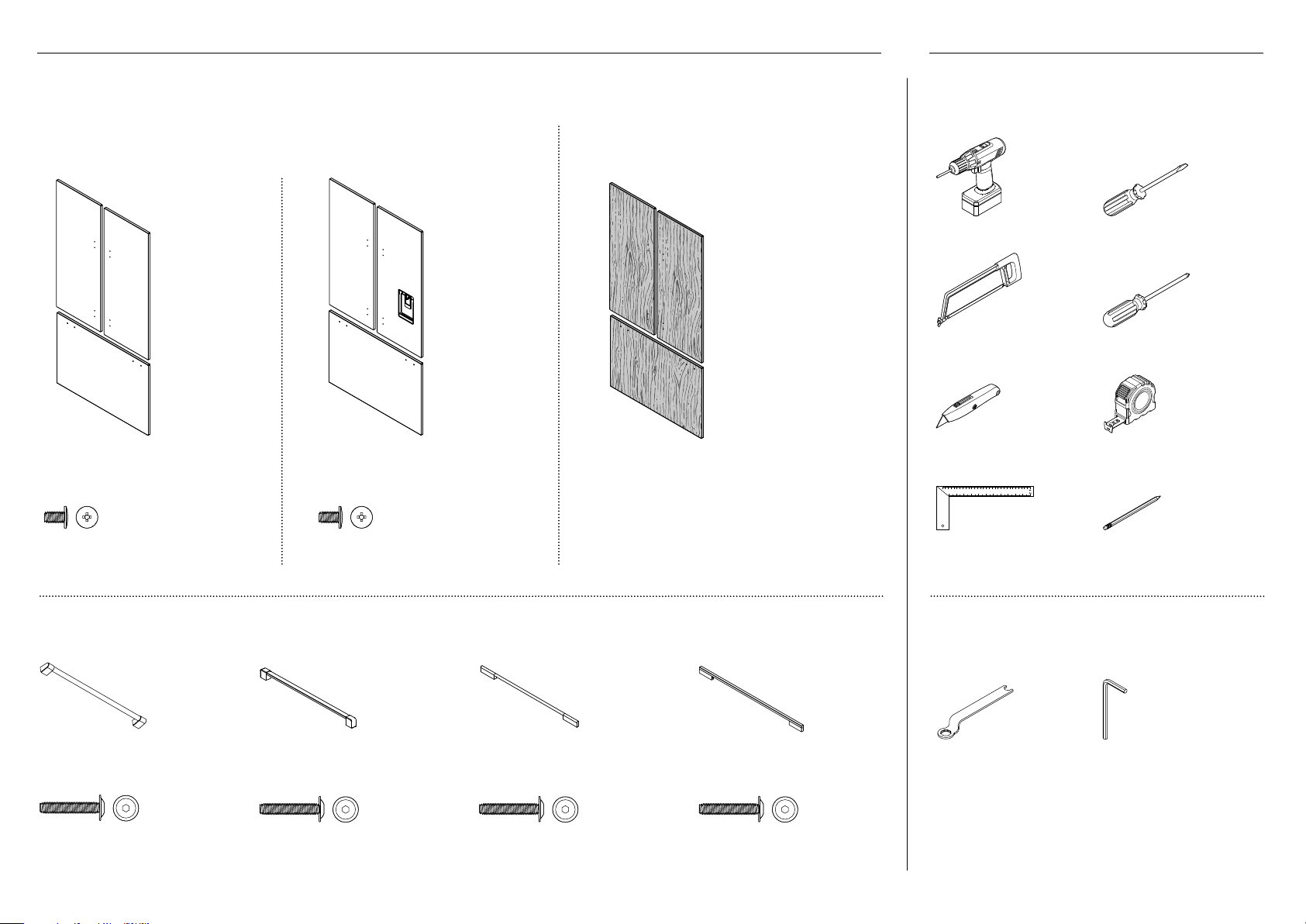

2 COMPONENTS 3 TOOLS

Door panel set

Not supplied and must be purchased separately

Stainless steel (Fisher & Paykel) door panel set:

Includes 2x French door panels and 1x drawer panel.

Ice only door panel set

(RD36A72/RD32A72)

Ice and Water door panel set

(RD36A72U/RD32A72U)

Required tools

Not included with appliance

Custom door panel set:

Supplied by customer to match their cabinetry.

Applicable for Ice only appliance models.

Powered driver Flathead screwdriver

Hacksaw Cross-head screwdriver

Cutter Measuring tape

M5x14 mush cross-head (SS) screw

(34)

M5x14 mush cross-head (SS) screw

(34)

Door handle kit

Not supplied and must be purchased separately. Select between the options below:

Professional rounded

door handle (3x)

M5x25 pan head socket

screw (12x)

Professional square

door handle (3x)

M5x25 pan head socket

screw (12x)

Contemporary round

door handle (3x)

M5x25 pan head socket

screw (12x)

6

Contemporary square

door handle (3x)

M5x25 pan head socket

screw (12x)

Ruler Pencil

Supplied tools

Included in internal box

FPA spanner

(1)

Hex key

(1)

Page 9

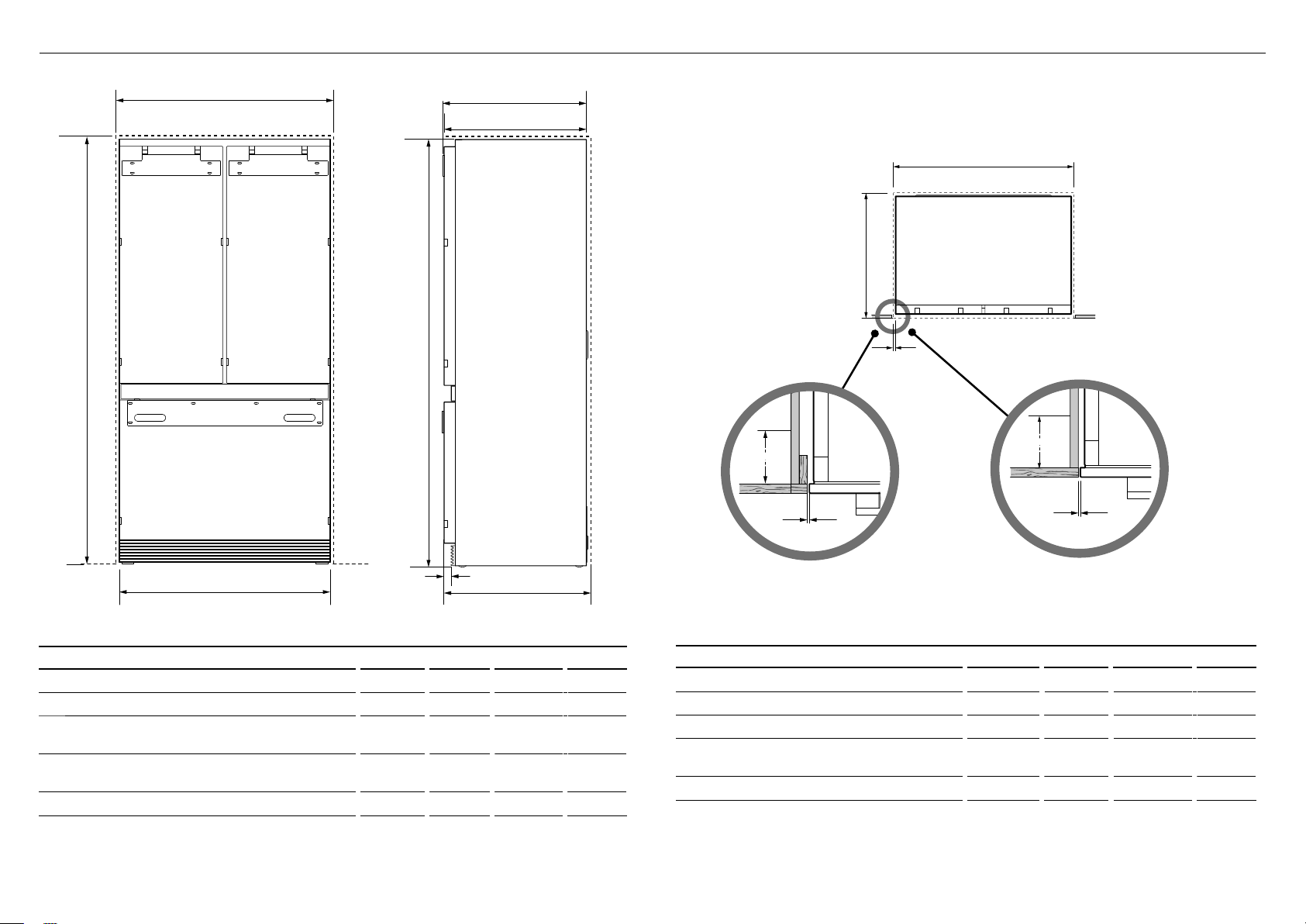

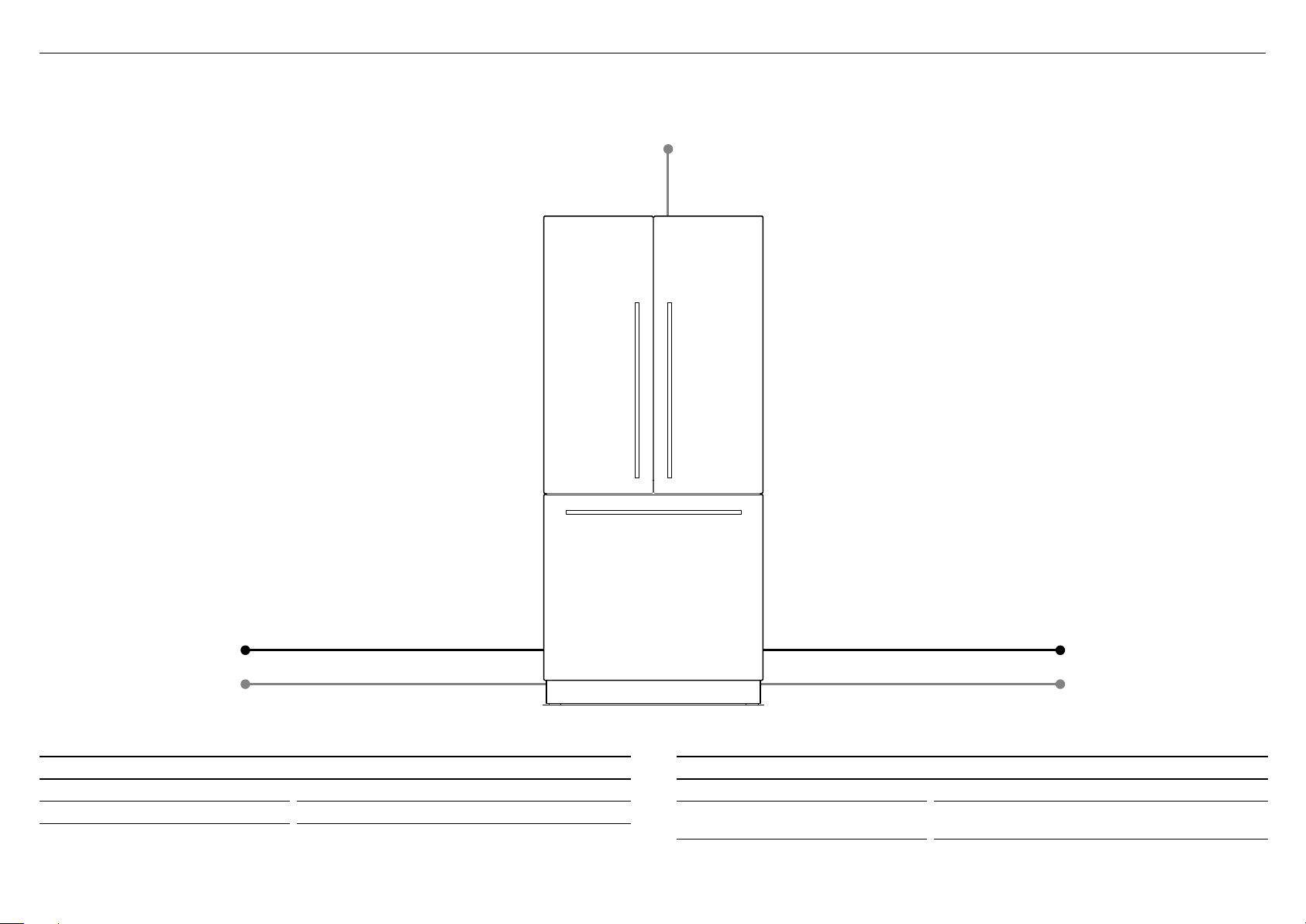

4 APPLIANCE AND CAVITY DIMENSIONS

B

J

L GF

F

g

I

J

F

G

A

D

c

IMPORTANT!

For ease of installation, ensure cavity width is consistent

top to bottom and height isconsistent left to right.

PLAN VIEW

J

J

J

J

I

Flush with front

of cabinetry

I

b

APPLIANCE DIMENSIONS in mm in mm

Overall height of appliance*

A

Overall width of appliance

B

Overall depth of appliance

c

(without door panels and hanging brackets) 23 11/16" 602 2311/16" 602

Overall depth of appliance

D

(with hanging brackets only) 23 3/4" 604 23 3/4" 604

Depth of toe kick (excluding front of door panel)

e

* Includes mounted rollers (20mm adjustment upwards)

FRONT VIEW PROFILE VIEW

E

RS32A RS36A

7 1 7/ 8 " 1825" 717/8" 1825**

31 1/8" 790 35 1/16” 890

2" 50 2" 50

H

Framed: Finished return top and sides

CAVITY DIMENSIONS in mm in mm

Overall height of cavity

F

Overall width of cavity

G

Overall depth of cavity

H

Minimum cabinetry gap clearance

I

from edge of appliance 3/16 4 3/16 4

Minimum required finished return

J

Flush install

Frameless: Finished return top and sides

min 3 1/2 min 89 min 3 1/2 min 89

Flush install

RS32A RS36A

72 1829 72 1829

32 813 36 914

25 635 25 635

7

Page 10

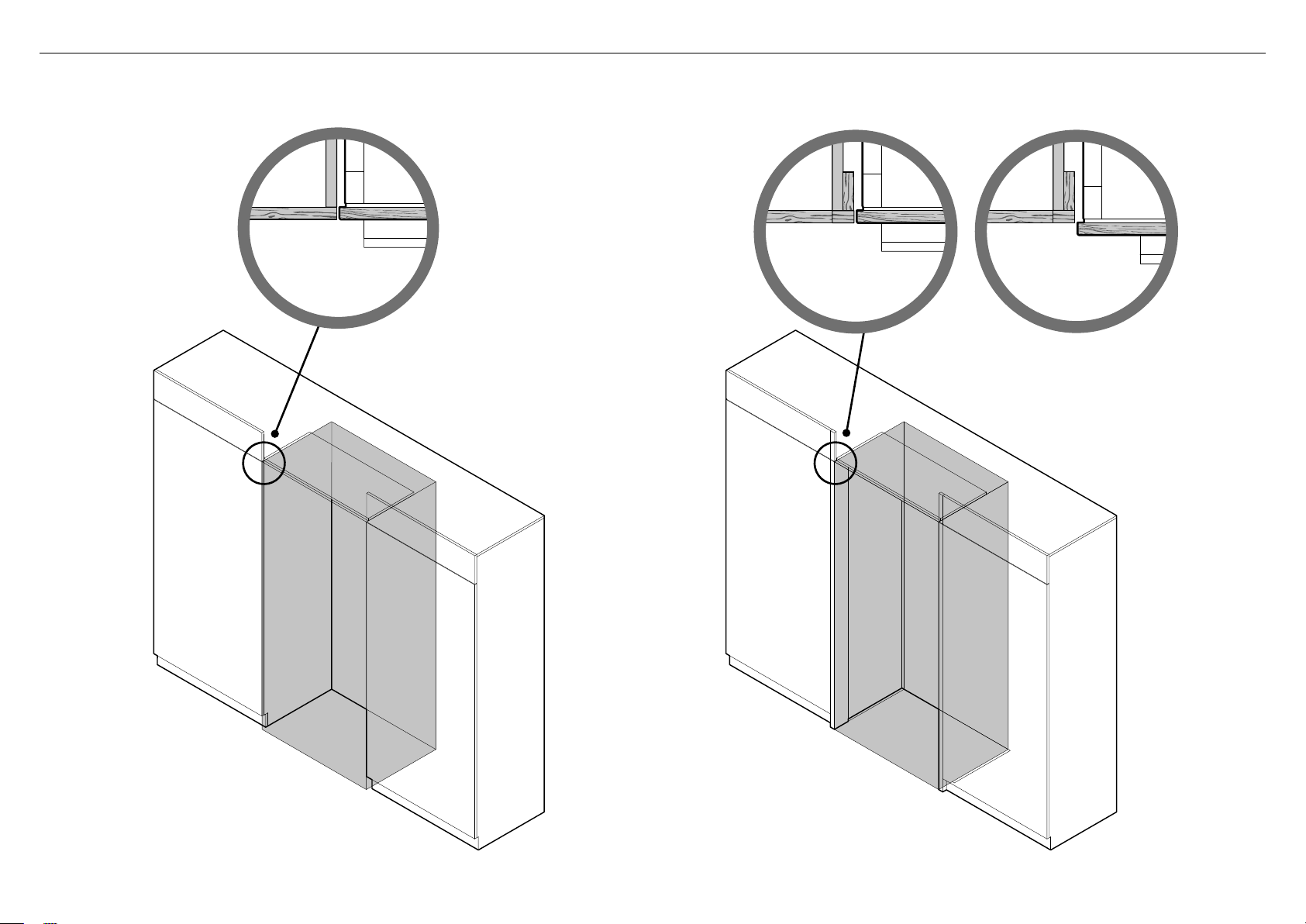

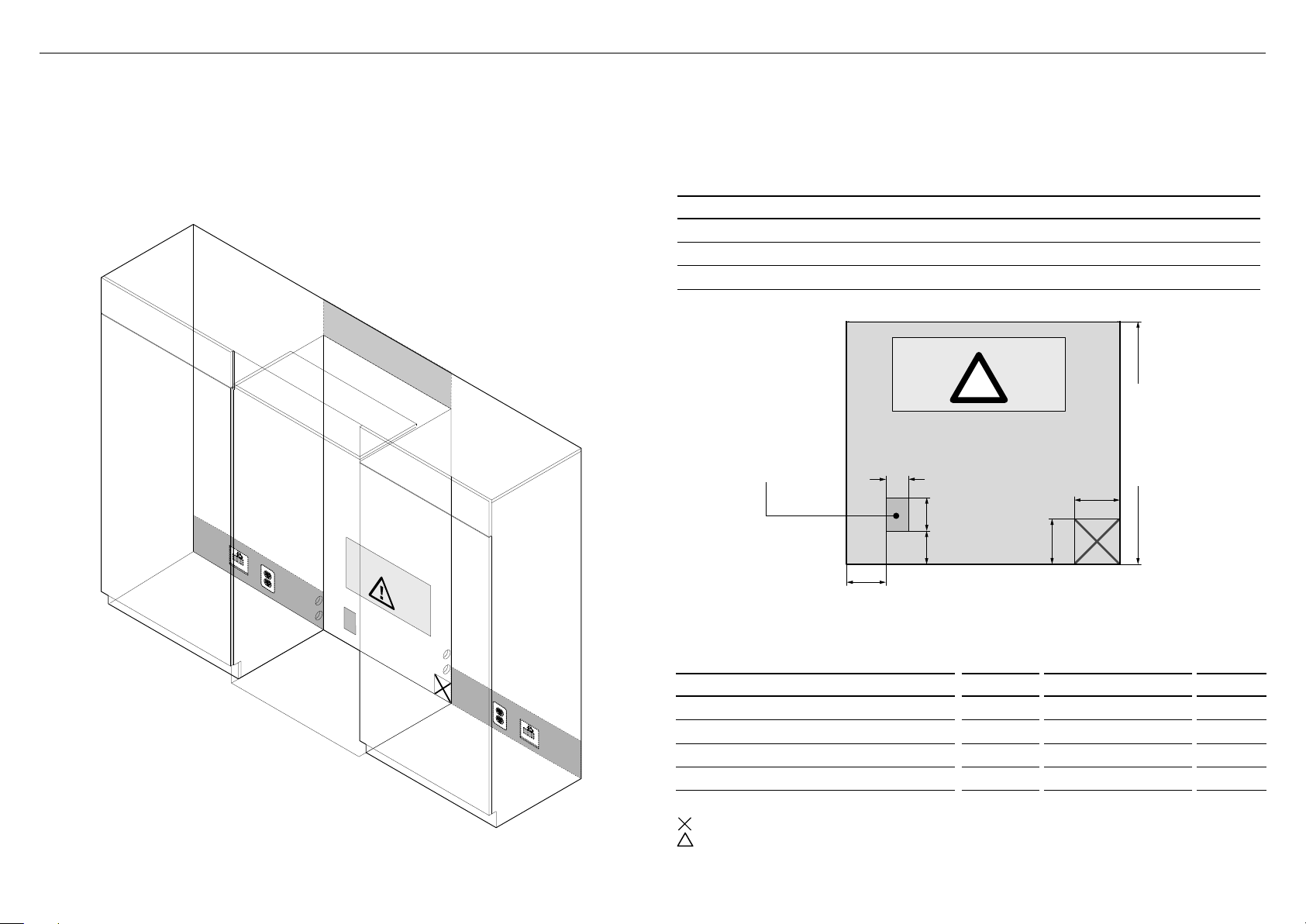

5 CABINETRY OPTIONS

FRAMELESS CABINETRY

(Aligns the appliance with the cabinetry)

FRAMED CABINETRY

(Aligns the appliance with the frame of the cabinetry)

Flush

installation

Proud

installation

Note: Drawings are only for reference and not the actual cavity width of the cabinetry.

8

Page 11

IMPORTANT!

D

g

A

E

h

I

h

●

Custom door panels can only be used for non-Water dispensing models.

●

Custom door panels to be manufactured and fitted by cabinetmaker.

●

Door handle kit must be purchased separately.

B

C

A

D

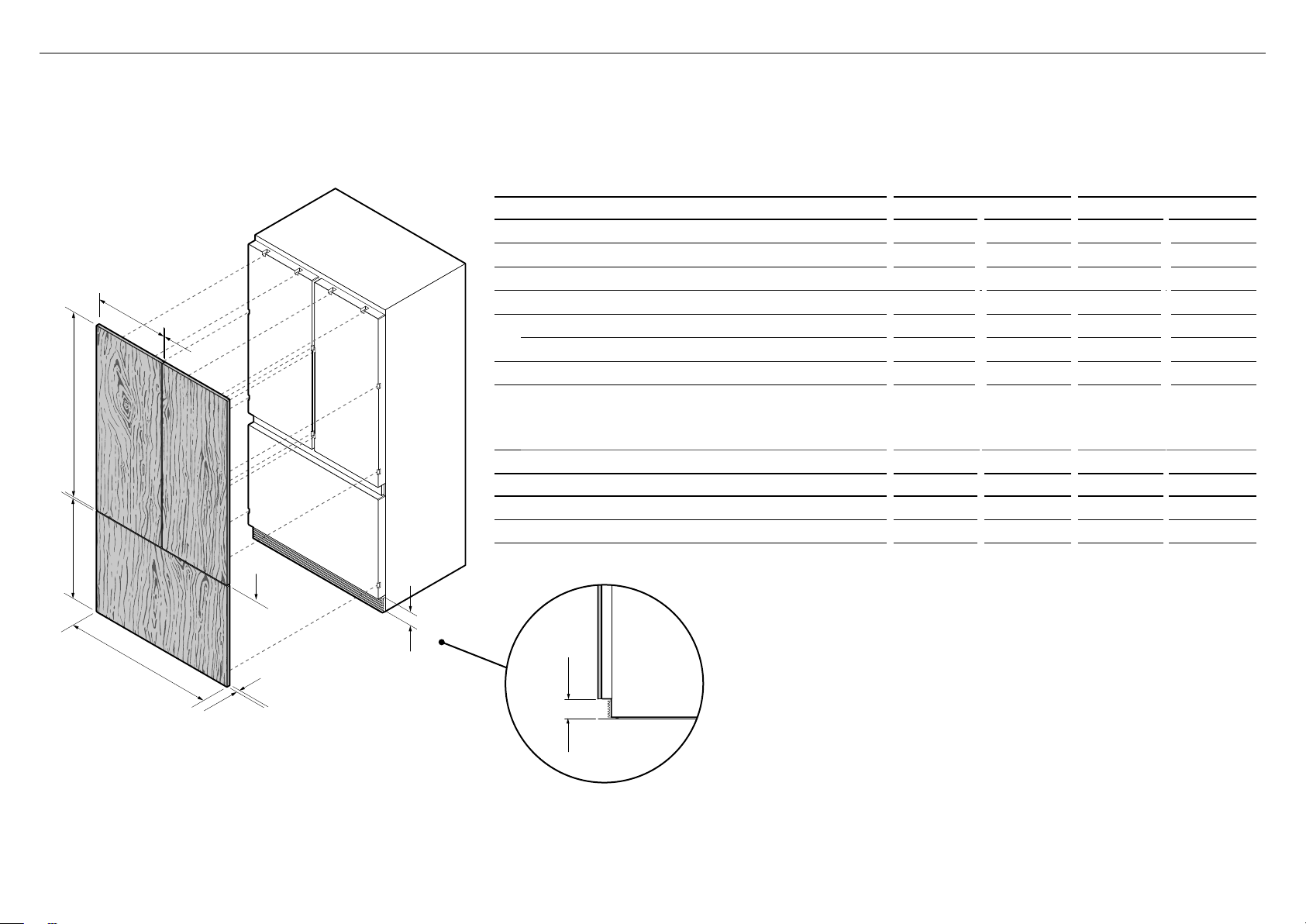

6 DOOR PANEL DIMENSIONS

STAINLESS STEEL/CUSTOM DOOR PANELS RS32A72 RS36A72

DIMENSIONS in mm in mm

Height of each top door panel

A

Width of each top door panel

B

Gap between top door panels

C

Height of bottom drawer panel

D

Height from bottom of product to top of drawerpanel

e

Width of bottom drawer panel

f

Gap between top door panels and bottom drawer panel

g

Depth of door and drawer panels (excluding handle)

h

Stainless steel

Custom

Height of toe kick (from bottom of drawer to floor)

i

DOOR PANEL WEIGHT lbs kg lbs kg

Maximum weight of each top door panel (with handle)

Maximum weight of bottom drawer panel (with handle)

44 3/16" 1123 44 3/16" 1123

15 3/4" 400 17 3/4" 451

3/16" 4 3/16" 4

23 7/16" 596 23 7/16" 596

27 1/2" 698 27 1/2" 698

31 11/16" 805 35 11/16" 906

3/16" 4 3/16" 4

3/4"

5/8"-3/4"

3 15/16 100 4" 102

22 10 22 10

24 1/4 11 24 1/4 11

19

16-19

3/4"

5/8"-3/4"

16-19

19

F

ISO VIEW

g

H

i

9

Page 12

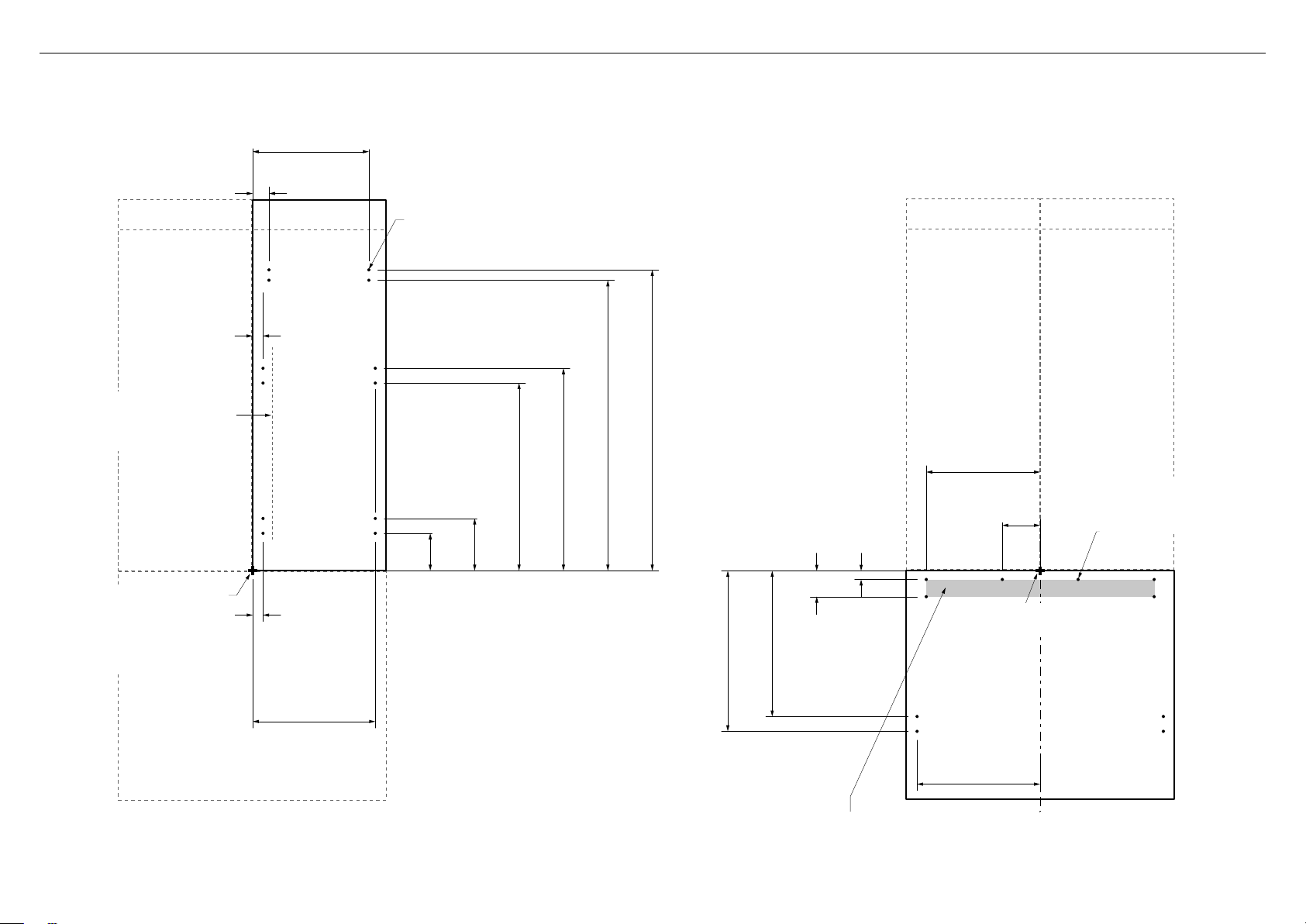

7 CUSTOM DOOR PANEL INSTALLATION DIMENSIONS — RS32A72

Dimensions apply for the preparation and installation of custom door panels. For Dwg and Dxf files of the below panel preparation download the folder on http://thekitchentools.fisherpaykel.

com/downloads/.

13 1/2" (342.3mm)

2 3/16" (54.8mm)

Ø 2mm REF

12x Pilot holes recommended for bracket attachment.

(Do not penetrate front surface).

1 3/8" (34.7mm)

Ensure handle is mounted

65mm from inner edge of panel

to the center — this will avoid

interference with brackets.

All measurements to be made

from inner bottom corner.

Forthe second panel mirror

and repeat dimensions using

inner bottom corner as the

reference point.

1 3/8" (34.7mm)

415/16"

(126.1mm)

615/16"

(176.1mm)

2415/16" (633.6mm)

2615/16" (683.6mm)

40" (1016mm)

385/8" (981mm)

19 3/8" (492mm)

21 5/16" (542mm)

1 1/8" (29.1mm)

3 7/16" (87.2mm)

13 3/16" (335mm)

4 3/8" (111.5mm)

All measurements to be made

from top and centerline.

Ø 2mm REF

10x Pilot holes recommended

forbracket attachment.

(Do not penetrate front surface).

10

4 5/16" (364mm)

TOP PANEL — REAR VIEW

14 7/16" (366mm)

Cut outs are located in attachment bracket for Fisher & Paykel handles only.

Iflocating custom handle in the shaded area above, ensure handle screw heads

are counter sunk into back of panel to avoid interference with hanging bracket.

BOTTOM PANEL — REAR VIEW

Page 13

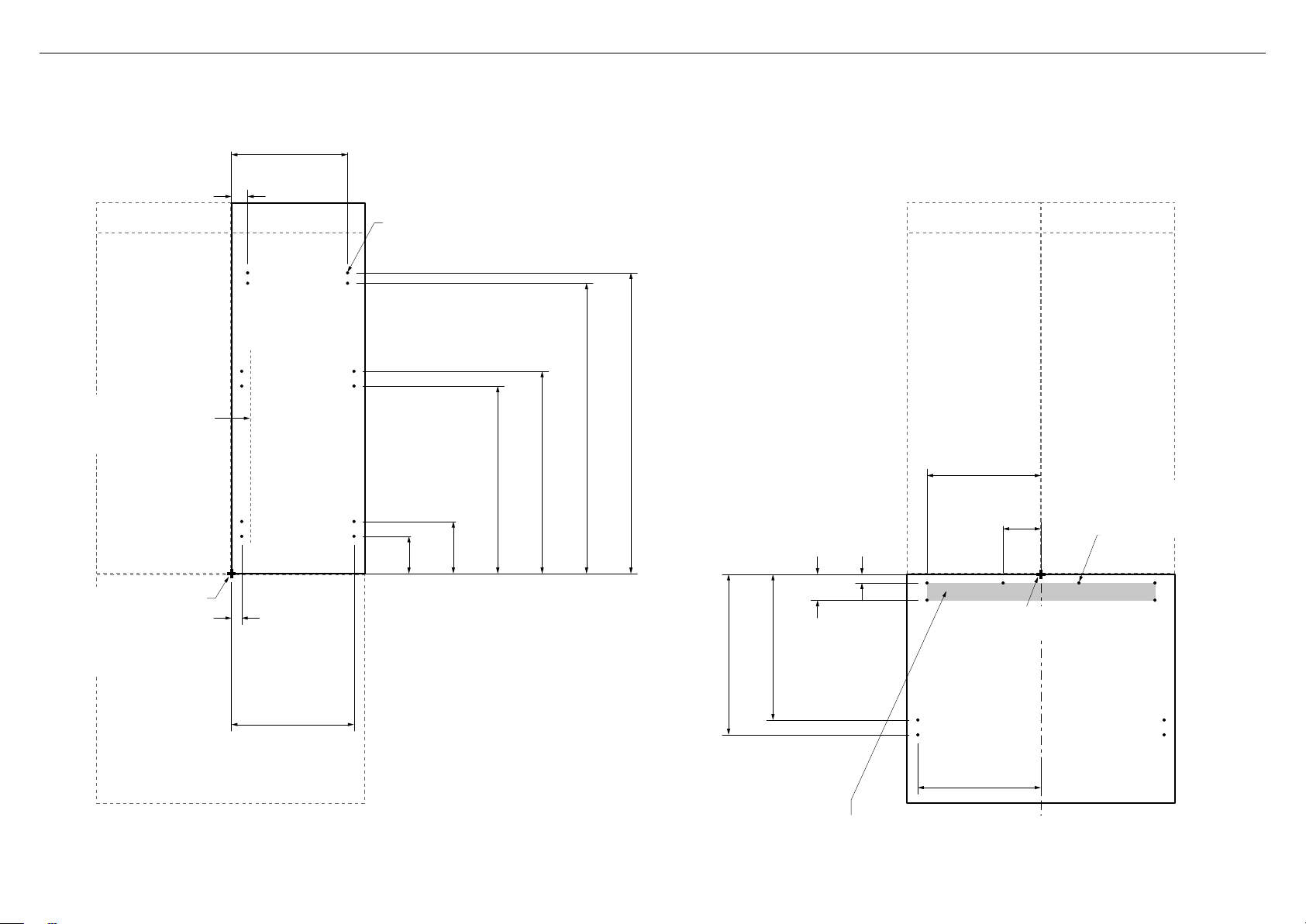

7 CUSTOM DOOR PANEL INSTALLATION DIMENSIONS — RS36A72

Dimensions apply for the preparation and installation of custom door panels. For Dwg and Dxf files of the below panel preparation download the folder on thekitchentools.fisherpaykel.com.

157/16" (392.3mm)

23/16" (54.8mm)

Ø 3/32" (2mm) REF

12x Pilot holes recommended for bracket attachment.

(Do not penetrate front surface).

Ensure handle is mounted

29/16" (65mm) from inner edge

of panel to the center — this will

avoid interference with brackets.

415/16"

(126.1mm)

615/16"

(176.1mm)

2415/16" (633.6mm)

2615/16" (683.6mm)

40" (1016mm)

385/8" (981mm)

11/8"

(29.1mm)

153/16" (385mm)

51/16"

(128mm)

Ø 3/32" (2mm) REF

10x Pilot holes recommended

forbracket attachment.

(Do not penetrate front surface).

All measurements to be made

from inner bottom corner.

Forthe second panel mirror

and repeat dimensions using

inner bottom corner as the

reference point.

13/8" (34.7mm)

165/16" (414mm)

TOP PANEL — REAR VIEW

193/8" (492mm)

215/16" (542mm)

37/16"

(87.2mm)

Cut outs are located in attachment bracket for Fisher & Paykel handles only.

Iflocating custom handle in the shaded area above, ensure handle screw heads

are counter sunk into back of panel to avoid interference with hanging bracket.

All measurements to be made

from top and centerline.

163/8" (416mm)

BOTTOM PANEL — REAR VIEW

11

Page 14

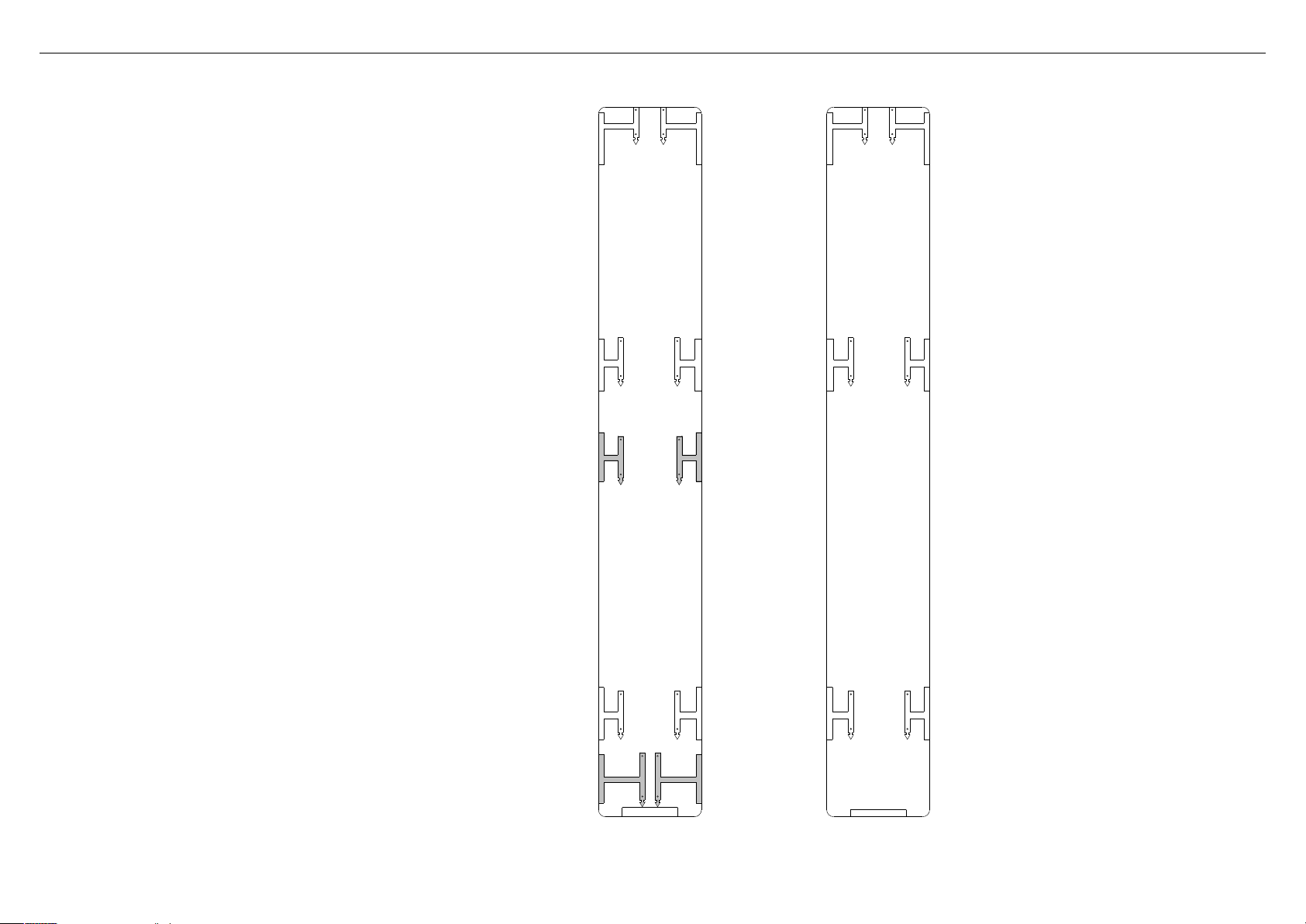

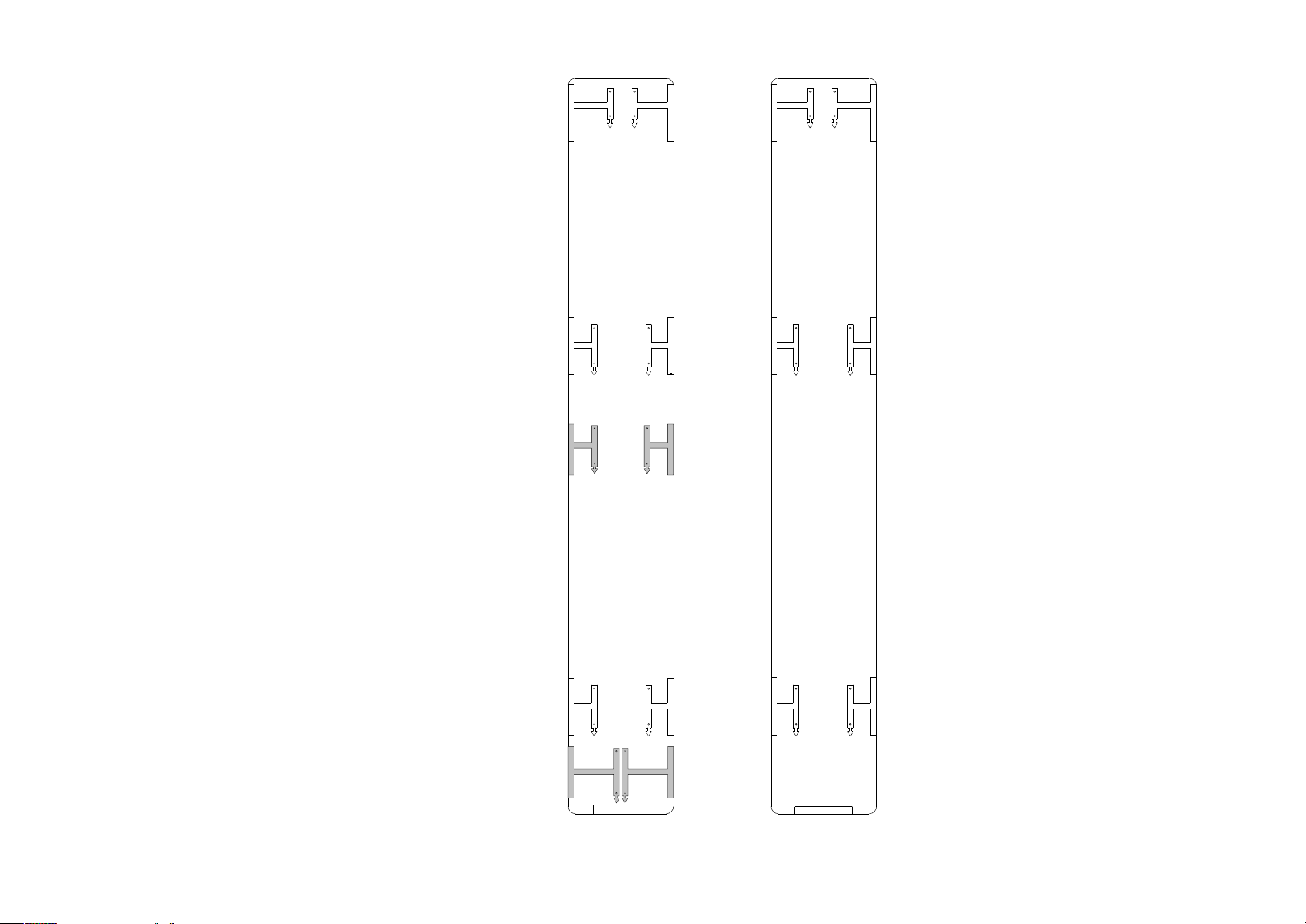

8 CUSTOM DOOR PANEL INSTALLATION TEMPLATE (RS32A72)

LH DOOR PANEL HINGE SIDE

LH DOOR PANEL HANDLE SIDE

HANGING BRACKET

HOLES

HANGING BRACKET

HOLES

FLIP FOR RIGHT

HAND DOOR PANEL

LH DOOR PANEL HANDLE SIDE

LH DOOR PANEL HINGE SIDE

SIDE BRACKET HOLES

SIDE BRACKET HOLES

DRAWER PANEL LEFT EDGE

DRAWER PANEL RIGHT EDGE

DRAWE PANEL HANGING

BRACKET HOLES

DRAWE PANEL HANGING

BRACKET HOLES

DRAWER PANEL LEFT EDGE

DRAWER PANEL RIGHT EDGE

DRAWE PANEL

SIDE BRACKET HOLES

DRAWE PANEL

SIDE BRACKET HOLES

LEFT PC PANEL BOTTOM EDGE

DRAWER PANEL TOP EDGE

LEFT DOOR PANEL

AND DRAWER TEMPLATE

849549

LH DOOR PANEL HANDLE SIDE

LH DOOR PANEL HINGE SIDE

SIDE BRACKET HOLES

SIDE BRACKET HOLES

This template is a single double-sided sheet used as a

guide to drill screw holes for installing your Custom door

and drawer panels. The actual template is included with

this installation guide.

Refer to ‘Door panel installation—Custom’, (page 30)

formoreinformation.

LH DOOR PANEL HINGE SIDE

HANGING BRACKET

HOLES

HOLES

HANGING BRACKET

LH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

HANGING BRACKET

HOLES

HOLES

HANGING BRACKET

RH DOOR PANEL HANDLE SIDE

12

LEFT DOOR PANEL

AND DRAWER TEMPLATE

849549

LH DOOR PANEL HINGE SIDE

SIDE BRACKET HOLES

SIDE BRACKET HOLES

DRAWER PANEL RIGHT EDGE

SIDE BRACKET HOLES

DRAWE PANEL

DRAWE PANEL

FLIP FOR RIGHT

HAND DOOR PANEL

LH DOOR PANEL HINGE SIDE

SIDE BRACKET HOLES

SIDE BRACKET HOLES

DRAWER PANEL RIGHT EDGE

DRAWE PANEL HANGING

BRACKET HOLES

BRACKET HOLES

DRAWE PANEL HANGING

DRAWER PANEL TOP EDGE

LEFT PC PANEL BOTTOM EDGE

LEFT DOOR

PANEL SIDE

SIDE BRACKET HOLES

LH DOOR PANEL HANDLE SIDE

DRAWER PANEL LEFT EDGE

LH DOOR PANEL HANDLE SIDE

DRAWER PANEL LEFT EDGE

RIGHT DOOR

PANEL TEMPLATE

849549

RH DOOR PANEL HANDLE SIDE

SIDE BRACKET HOLES

FLIP FOR LEFT HAND DOOR

AND DRAWER HOLES

RH DOOR PANEL HANDLE SIDE

SIDE BRACKET HOLES

RH DOOR PANEL BOTTOM EDGE

RIGHT DOOR

PANEL SIDE

SIDE BRACKET HOLES

SIDE BRACKET HOLES

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HINGE SIDE

Page 15

8 CUSTOM DOOR PANEL INSTALLATION TEMPLATE (RS36A72)

This template is a single double-sided sheet used as a

guide to drill screw holes for installing your Custom door

and drawer panels. The actual template is included with

this installation guide.

Refer to ‘Door panel installation—Custom’, (page 29)

formoreinformation.

LEFT DOOR PANEL HINGE SIDE

HANGING BRACKET

HOLES

LEFT DOOR PANEL

AND DRAWER TEMPLATE

849551

LEFT DOOR PANEL HINGE SIDE

SIDE BRACKET HOLES

DRAWER PANEL RIGHT EDGE

SIDE BRACKET HOLES

DRAWE PANEL

FLIP FOR RIGHT

HAND DOOR PANEL

DRAWE PANEL

SIDE BRACKET HOLES

SIDE BRACKET HOLES

HOLES

HANGING BRACKET

LEFT DOOR PANEL HANDLE SIDE

LEFT DOOR PANEL HANDLE SIDE

DRAWER PANEL LEFT EDGE

RH DOOR PANEL HANDLE SIDE

HANGING BRACKET

HOLES

RIGHT DOOR

PANEL TEMPLATE

849551

RH DOOR PANEL HANDLE SIDE

SIDE BRACKET HOLES

FLIP FOR LEFT HAND DOOR

AND DRAWER HOLES

SIDE BRACKET HOLES

HOLES

HANGING BRACKET

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

LH DOOR PANEL HINGE SIDE

SIDE BRACKET HOLES

DRAWER PANEL RIGHT EDGE

BRACKET HOLES

LEFT PC PANEL BOTTOM EDGE

LEFT DOOR

PANEL SIDE

DRAWE PANEL HANGING

BRACKET HOLES

DRAWE PANEL HANGING

RH DOOR PANEL HANDLE SIDE

SIDE BRACKET HOLES

SIDE BRACKET HOLES

LH DOOR PANEL HANDLE SIDE

DRAWER PANEL LEFT EDGE

DRAWER PANEL TOP EDGE

RH DOOR PANEL BOTTOM EDGE

SIDE BRACKET HOLES

RH DOOR PANEL HINGE SIDE

RIGHT DOOR

PANEL SIDE

13

Page 16

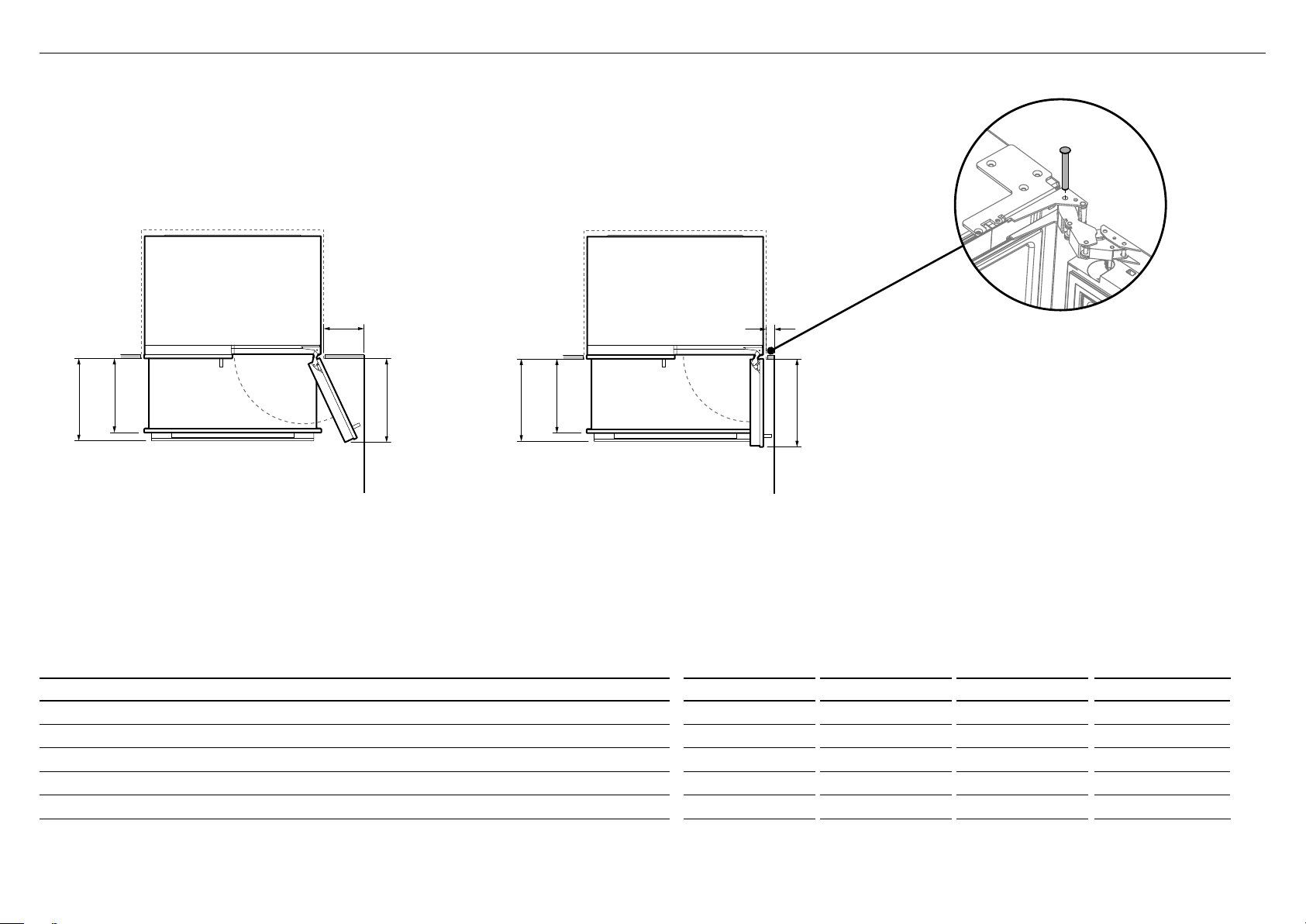

9 DOOR CLEARANCE

B

C

A

E

D

C

B

115° DOOR OPENING

(FULL INTERNAL ACCESS)

DIMENSIONS in mm in mm

Depth of door (widest opening) measured from front of door 15 9/16" 395 171/2" 445

A

Depth of drawer (open) measured from front of drawer, including handle 15 3/4" 400 153/4" 400

B

Depth of drawer (open) measured from front of drawer, excluding handle 14 3/16" 360 14 3/16" 360

C

Minimum door clearance* to adjacent wall (115° — full internal access) 11" 280 1113/16" 300

D

Minimum door clearance* to adjacent wall (90° — reduced internal access) 3 15/16" 100 313/16" 100

E

A

Wall

B

C

90° DOOR OPENING

E

Insert hinge limiting pin

A

Wall

RS32A72 RS36A72

WARNING!

●

Before opening the doors, ensure that the appliance is

stable.

●

Follow these steps to avoid risks that can cause serious

injury or death.

For 90° door swing, a hinge limiting pin is supplied with

your appliance. This pin fits in the boreholes of the top

hinge (B).

Open door to 90°.

1

Insert the hinge limiting pin vertically into the bore hole.

2

– Apply a gentle tap to the pin if it does not

slide smoothly.

* Measured from front cabinetry edge, includes 2mm cabinetry gap.

14

Page 17

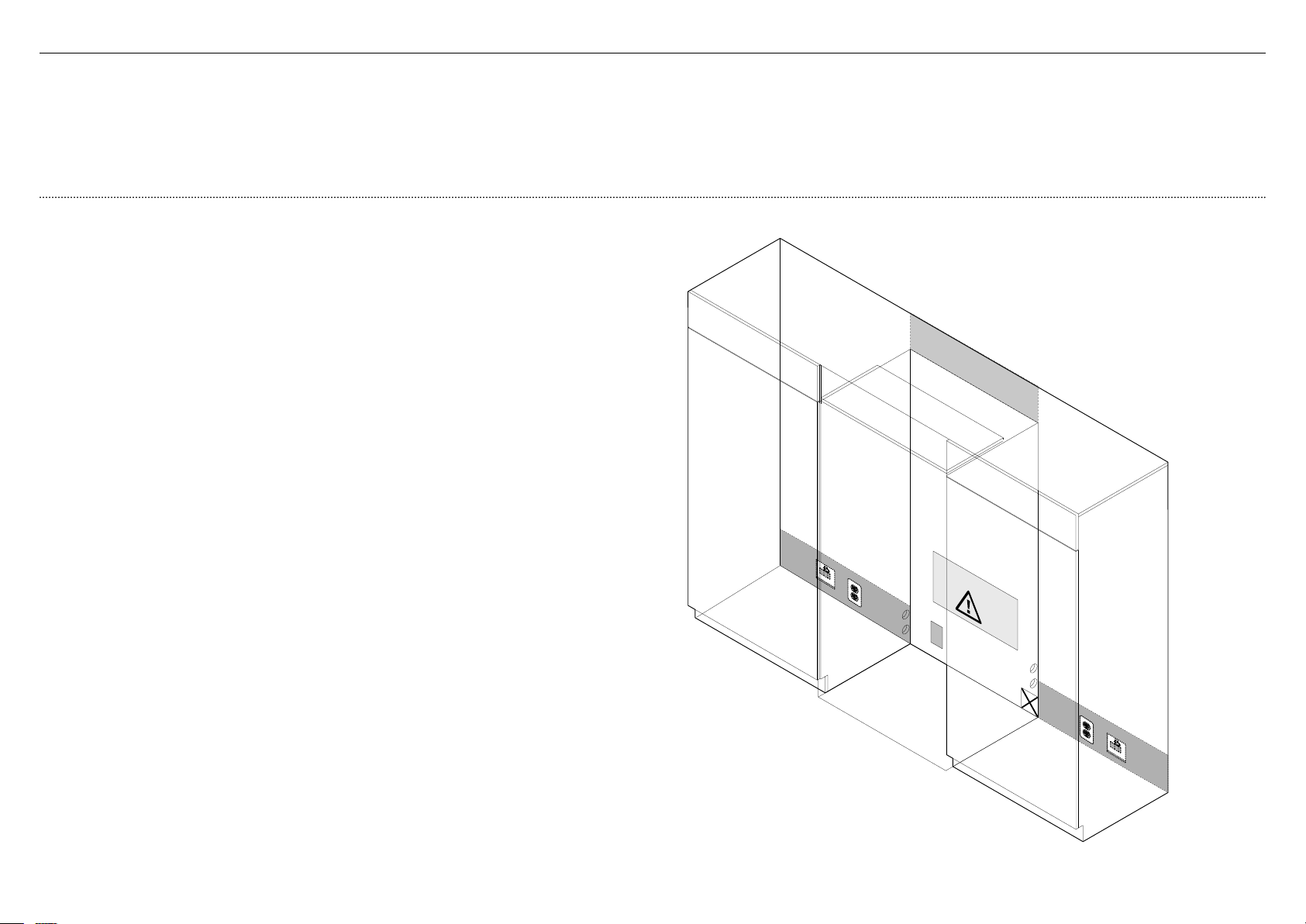

!0 ELECTRICAL AND PLUMBING

IMPORTANT!

●

Electrical connection should be located in an adjacent cabinet to either side

oftheappliance or above the appliance cavity.

●

We recommend to use an isolating switch that is easily accessible to the user

aftertheappliance is installed.

2

1

WARNING!

●

Electrical shock hazard. Assume all parts are live.

●

Disconnect supply before servicing and installation.

ELECTRICAL AND PLUMBING CONNECTIONS

Recommended location for connections in adjacent area or unit

1

Alternative location for connections above the cavity

2

Alternative location for connections at rear of cavity

3

Left side

of cavity

!

Optional electrical

and water connection

location*

Floor

b

A

D

5 15/16"

(150mm)

5 15/16"

(150mm)

31 1/2" (800mm)

31 1/2" (800mm)

3

B

1

C

Electrical and water connections must be within this space if located

behind the appliance and must not protrude from the back wall.

RS32A72 RS36A72

ELECTRICAL AND PLUMBING DIMENSIONS in mm

Overall height of supply area 4 5/16" 110 4 5/16" 110

A

Overall width of supply area 2 15/16" 75 2 15/16" 75

B

Distance from left side of cavity 5 1/16" 129 5 1/6" 129

C

Distance from the floor 4 5/16" 110 4 5/16" 110

D

Note: Dimensions are based on minimum depth of cavity.

Do not locate water or electricity in this area, keep clear of connections.

CAUTION: Central area can only fit water outlet and electrical plug if they are placed within a recessed cavity.

!

* In this location the water tap needs to be recessed into the wall, the recess must allow for an 80mm bend radius for

the watertube.

15

Page 18

Maximum distance of hose and power cord

Checking your appliance

Detach accessories box taped to

1

back panel ofappliance.

Refer to 'Components' (page 5).

IMPORTANT!

Be aware when removing the

carton that the accessories box

may have dislodged from

the rear of the appliance during

transit.

!0 ELECTRICAL AND PLUMBING

Power cord (excl. plug) — 31 1/2" (800mm)

Water inlet hose—125 3/16" (3180mm) Water inlet hose—1543/4" (3930mm)

Power cord (excl. plug)—8011/16" (2050mm)

ELECTRICAL SPECIFICATIONS

Supply 115VAC, 60Hz

Service 10 amp circuit

16

RIGHT HAND SIDELEFT HAND SIDE

Power cord (excl. plug)—8011/16" (2050mm)

PLUMBING SPECIFICATIONS

Supply 1/4" (6mm) comp. Stainless steel braided hose

Pressure min. 22psi (150kPa)

max. 120psi (827kPa) @ 68°F (20°C)

Page 19

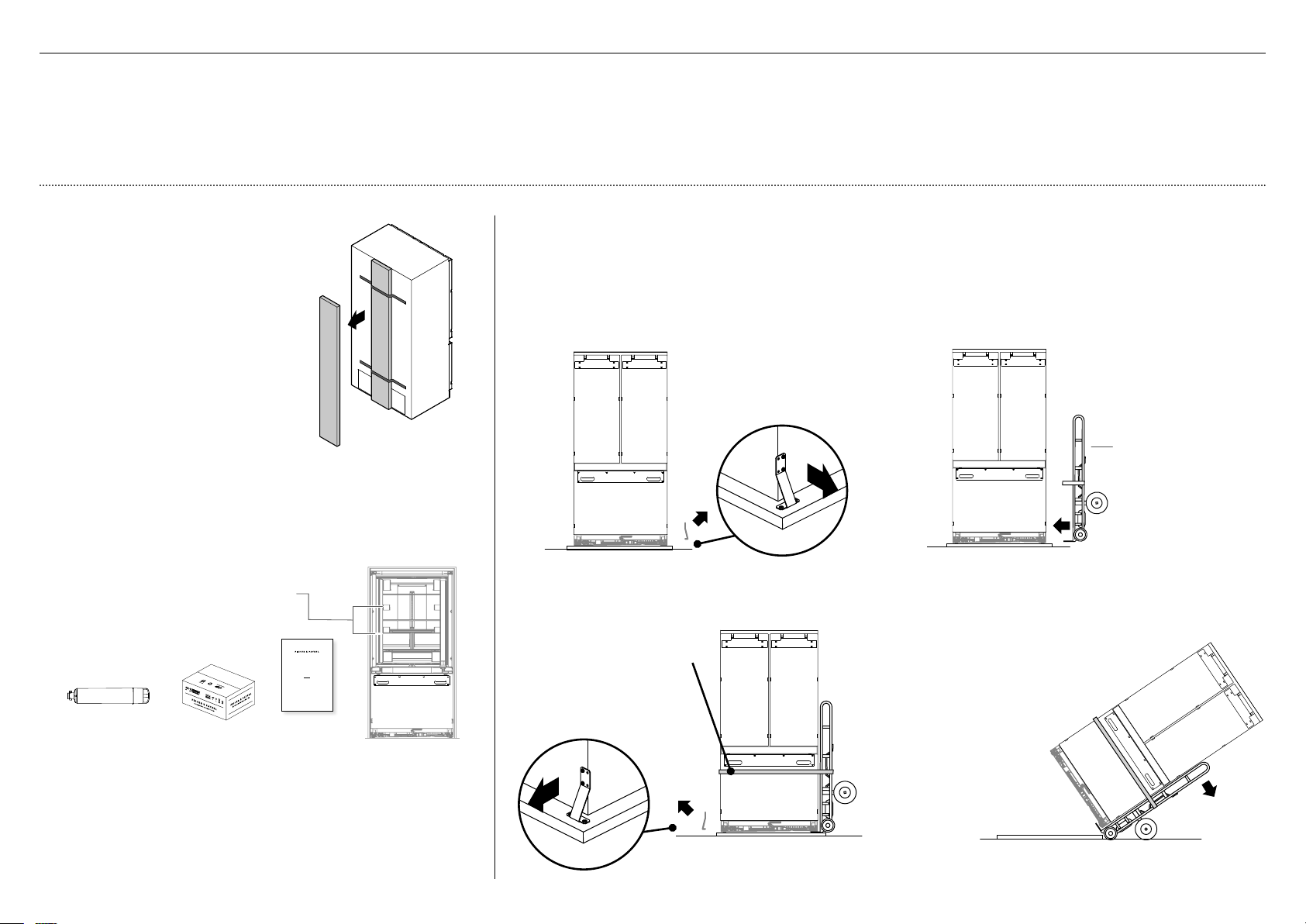

!1 BEFORE INSTALLATION

IMPORTANT!

●

Be careful when unpacking to prevent damage to the surface of your appliance.

●

Ensure that the appliance is stable to prevent from tipping over when unpacking.

●

Do not open the doors to prevent the appliance from tipping over.

●

The appliance is heavy and requires a minimum of 2persons to unpack and install.

●

Ensure that the feet of the appliance are retracted.

●

If the appliance is damaged, contact your Fisher & Paykel dealer.

●

Take note of your model and registration numbers located at the lower right side of

theappliance. You will need these to request for servicing or repair of your appliance.

Checking your appliance

Detach accessories box taped to

1

back panel ofappliance.

Refer to 'Components' (page 5).

IMPORTANT!

Be aware when removing the

carton that the accessories box

may have dislodged from

the rear of the appliance during

transit.

Remove the water fittings and water filter

2

kits, Installation kit, andMiscellaneous

itemspack from inside the appliance.

Refer to 'Components' (pages 4 – 5).

Water fittings and

Water filter kits Installation kit

ACTIVESMART™

INTEGRATED REFRIGERATOR

RS90A, RS9120W,

RS36A72, RS36A80 & RS36W80 models

USER GUIDE

NZ AU GB IE HK SG IN US

Miscellaneous

items pack

Moving your appliance

Remove the brackets from one side of the

1

appliance. (For single door models, remove the

brackets on the non-hinged side of the appliance.)

Note: Location of brackets depends on the

modelof your appliance.

Restrain the appliance

4

to the cart with straps.

Remove the brackets

5

on the other side of

the appliance.

Tilt the appliance

2

slightly to the

opposite side.

Tilt the appliance backward

6

onto the cart.

Set aside the pallet and

7

push the cart to the

installation location.

Insert the hand truck

3

under the side of the

appliance where the

brackets were removed.

Do NOT insert the hand

truck to the front or

back of the appliance.

hand truck

17

Page 20

!1 BEFORE INSTALLATION

IMPORTANT!

●

Your appliance is fitted with front and rear rollers designed for moving the appliance

forward and backward. Donot move the appliance sideways as this may damage the

rollers or the floor covering / surface.

●

The appliance must be installed by a qualified installer, or Fisher & Paykel trained and

supported service technician to avoid faulty electrical connection and water leaks.

Check installation location

Check the cabinetry

1

– Check the dimensions — height, width, depth, floor level,

finishedalcovereturns.

– Ensure that the ventilation openings in the cabinetry are clear of obstruction.

– For integrated installation, a finished return of solid material is required

across thetopand sides of the new or existing alcove.

– Refer to the ‘Appliance and cavity Dimensions’ (page 7) prior to installation

of the appliance.

Check the power supply

2

– Ensure that there is a separate power outlet for the appliance.

– Avoid sharing the power point with other appliances to prevent the

appliancefromaccidentally switching off.

– For power requirements, refer to the information on the serial plate.

Thisislocated atthe front right-hand side of the drawer when open.

– Ensure your appliance is properly grounded (earthed).

– Connect the appliance to the electrical supply (115 VAC, 60 Hz) with fitted

plug andlead.

– We recommend to use an isolating switch that is easily accessible to

theuserafterthe appliance is installed.

– Follow the National Electrical Code and all local codes and ordinances

wheninstallingthis appliance.

●

All connections for water, electrical power and grounding must comply with local codes

and ordinances and be made by licensed personnel when required.

●

Avoid installation of the appliance/s under a ground fault circuit interrupter (GFCI).

●

Ensure the appliance is installed properly. Improper installation that results in appliance

failure is not covered under the appliance warranty.

Check the water supply (for Ice and Water models only)

3

– Ensure that there is a separate water supply connection for the appliance.

– Your appliance must be installed by a qualified appliance installer as

incorrect plumbingcanlead to water leaks.

– Fisher & Paykel is not liable for damage (including water damage) caused

byfaultyinstallation or plumbing.

18

Page 21

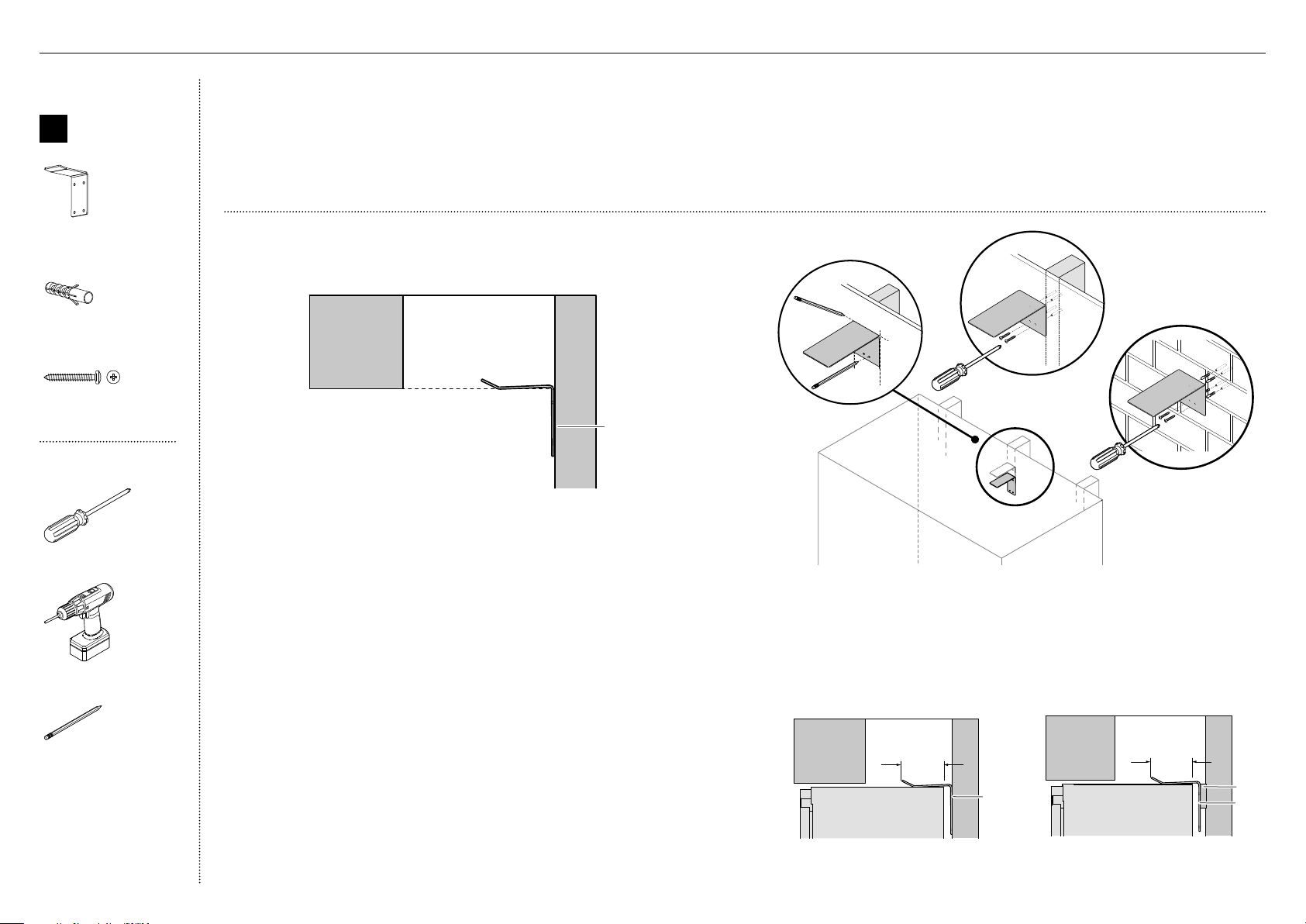

!2 CAVITY PREPARATION

Internal box

Anti tip

A

bracket kit

Anti-tip bracket

(1)

Masonry plug

(4)

#10x40 cross-head screw

(4)

Tools

IMPORTANT!

●

The anti-tip bracket and fittings supplied must be fitted to the wall

ofthefinished enclosure to withstand 220lbs (100kg) load.

●

Ensure that anti-tip bracket is installed correctly to prevent the

appliancetipping forward when door is open.

●

Ensure the bracket is secured to structural beams or wall studs

nearesttothe center of the alcove.

Attach anti-tip bracket

A

Anti-tip

bracket

WARNING!

Read the following before fastening with masonry plugs and / or screws:

●

Ensure the screws avoid electrical, gas and water conduits.

●

Ensure lightweight masonry material such as cinder block

andnewconcrete (no curing time) are not used in installation.

●

Do not use metallic materials that may corrode, stain and / or

damagetheenclosure.

B

C

D

E

Cross-head screwdriver

Powered driver (optional)

Pencil

Project horizontally from the bottom edge of the finished enclosure towards

1

the center of the back wall (A). This will locate the contact surface between

the bracket and appliance.

Mark the location for placement of the anti-tip bracket. Place the bracket so

2

the top edge of the contact surface aligns with the mark (B).

Mark the locations of the screw holes on the wall based on the most central

3

wall stud (C).

Drill screw holes to the marked locations.

4

For wooden/plaster board wall installation:

5

– Fix the bracket to the wall with 10x40 pan head cross-head screws, and

screw tightly (D).

For solid wall installation:

6

– Hammer masonry plugs into the wall until flush.

– Fix the bracket to the wall with 10x40 pan head cross-head screws

(4x), and screw tightly (E).

IMPORTANT!

When positioning the appliance

in the cabinetry, ensure that the

anti-tip bracket overlaps the

appliance by a minimum 2 3/8"

(60mm) for a secure hold.

.

2 3/8" (60mm)

overlap

Anti-tip

bracket

If the minimum 60mm

overlap cannot be

achieved, install a solid

spacer to the wall stud

behind the bracket.

.

2 3/8" (60mm)

overlap

Spacer

Anti-tip

bracket

19

Page 22

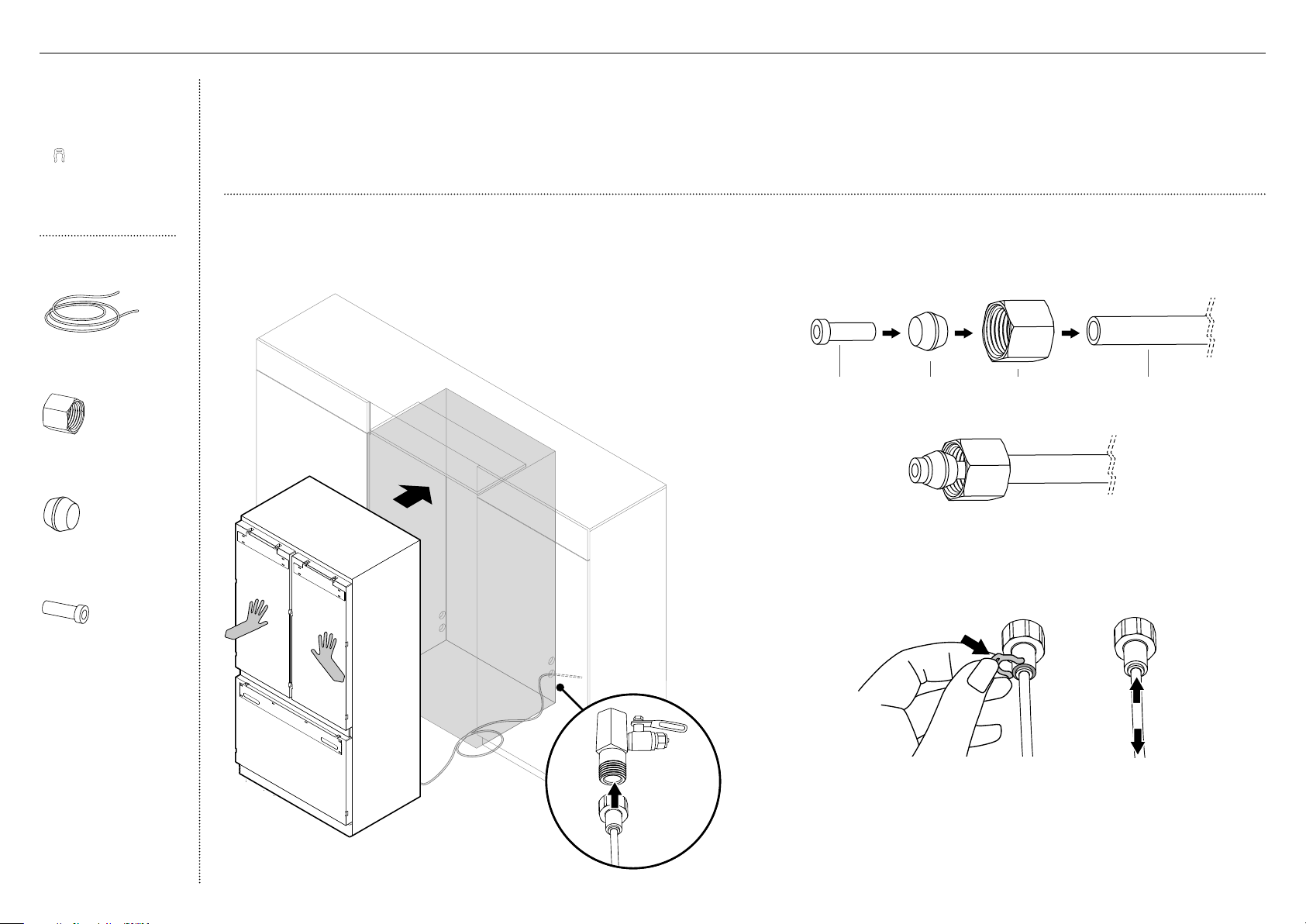

!3 WATER SUPPLY CONNECTION

Miscellaneous items

(MI) pack

Collet locking clip

(1)

Water fittings kit

1/4" (6mm) plastic

tubing (1)

1/4"(6mm) Compression

nut (1)

IMPORTANT!

●

The water connection instructions below are intended only for

theprofessional installer.

●

The appliance comes with a pre-connected plastic water tubing.

●

Water fittings are not supplied and must be purchased separately.

●

Ensure the appliance isconnected to its own isolating switch.

Connect to water supply (Ice and Water models only)

Move the appliance in front of the cabinetry close enough that you still have

1

access behind for power and waterconnections (A).

A

●

Ensure there is enough tubing for the water connection and to pull

theappliance outforservice, if required.

●

Flush water through the hose prior to connection to the appliance

toremoveany debris in the hose.

Assemble the water fittings components onto the free end of the water

2

tubing.

Insert tube Compression

sleeve

Compression

nut

Final water tube connection

Water tubing

1/4"(6mm) Compression

sleeve (1)

1/4" (6mm) Tube insert

(1)

20

Secure connection by inserting a locking key (B) to the water fittings and

3

water tubing. Pull gently to ensure it is locked in (C).

B

C

D

Connect the water tap adaptor to a water tap (D).

4

– Flush water through the hose prior to connection to the appliance

toremove any debris in the hose.

Turn on the water tap and check all connection are dry and free of drips.

5

Page 23

DETAIL B

SCALE 1 : 5

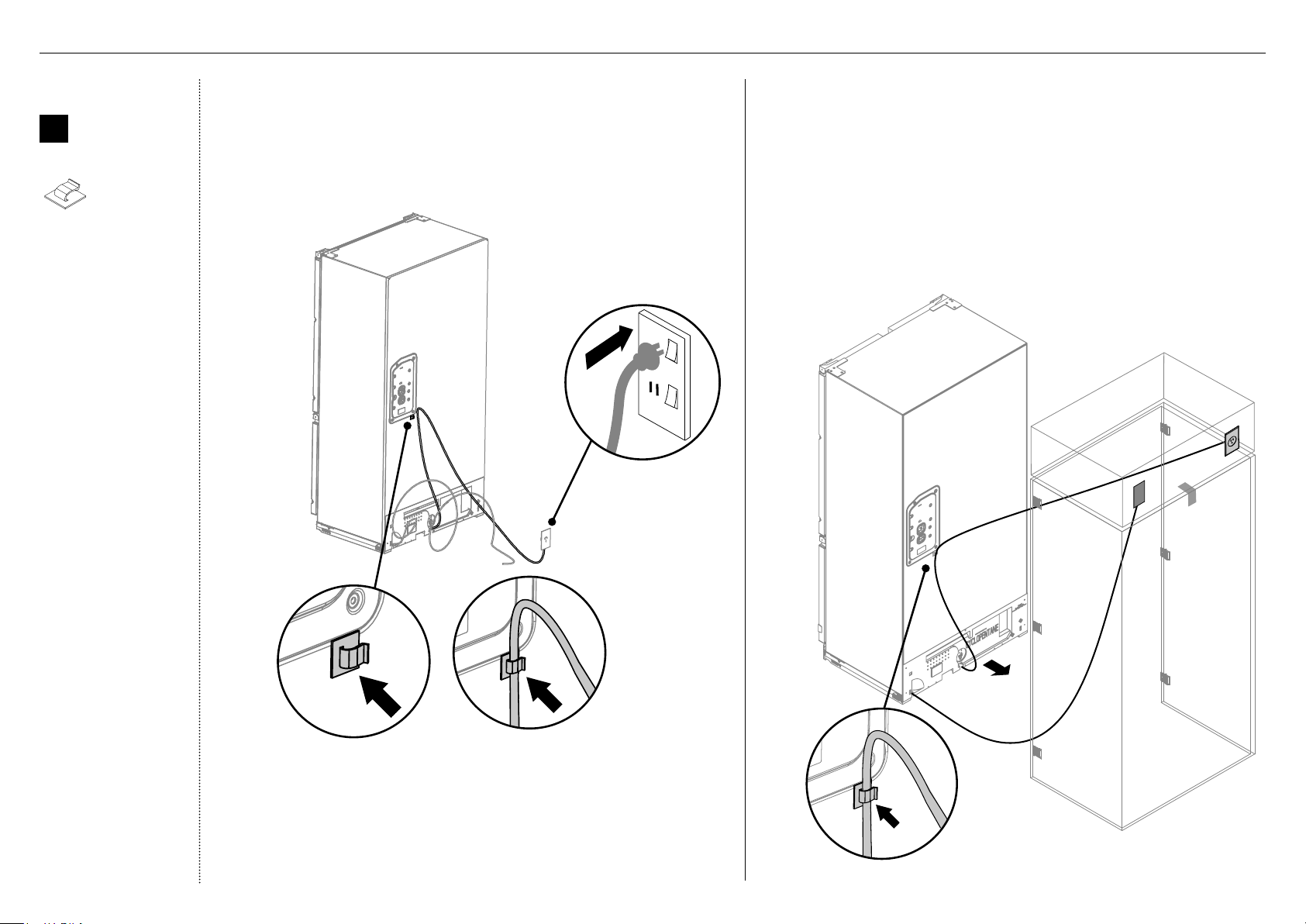

!4 POWER SUPPLY CONNECTION

Internal box

Miscellaneous

Y

components

Power cord clip

(2)

Connect to power supply

Locate the power cord and connect the fitted plug to the electrical supply

1

(115V, 60Hz). Turn ON the appliance.

– We recommend to use an isolating switch that can be accessed

easilyafter the appliance is installed.

Alternative water and electrical connection (above the cavity)

Connect the water fittings to the water supply (C).

1

Plug-in the power cord to the electrical supply (D), and turn on the

2

appliance.

Attach the power cord clip to the back of your appliance, and secure the

3

excess power cord length onto the clip (E).

– When pushing the appliance into position, take care not to roll over

ordamage the power cord and / or water tubing.

Refer to 'Electrical and Plumbing' for more information on recommended

and alternative water and power connections.

C

D

A

Attach a power cord clip (A) to the back of your appliance.

2

Secure the excess power cord length onto the clip (B).

3

B

E

21

Page 24

150

C

180

L

O

P

150

C

O

P

P

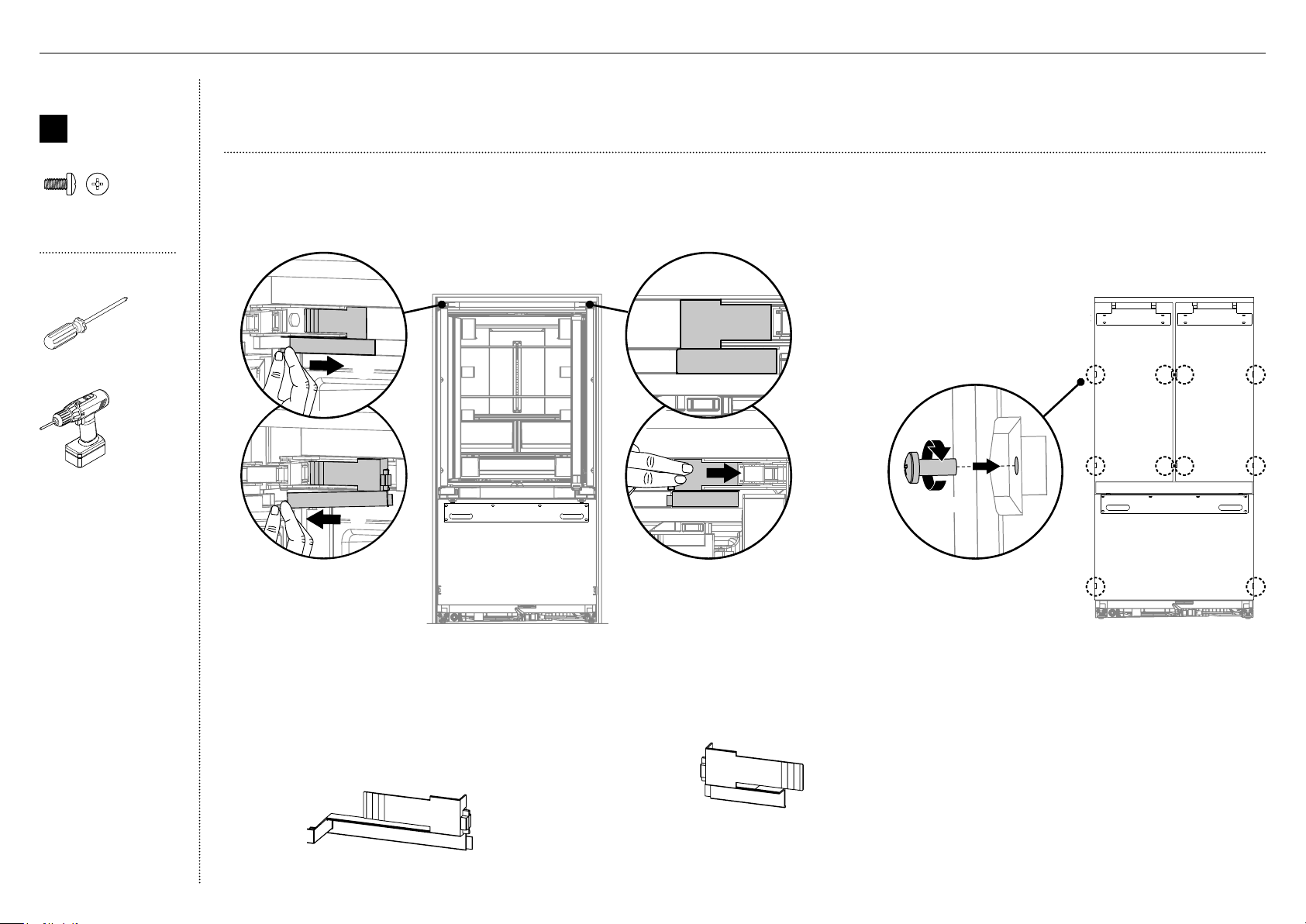

!5 INSTALLATION PREPARATION

Internal box

Install

X

fasteners kit

M5x10 cross-head screw

(10)

Tools

Cross-head screwdriver

Powered driver (optional)

WARNING!

●

Be careful when working with the appliance outside of the finished enclosure.

●

Ensure that the appliance is secured to prevent tipping forward. Tippingofappliance can lead to serious injury or death.

Remove hinge end caps

Open the French doors carefully.

1

A

D

C

1 – 2 turns

B

22

Remove the left hinge end cap.

2

– Hold onto the corner of the end cap,

firmlypush to the right to disengage the

securing hook and pull down (A).

– Pull cap gently towards the left hinge

toremove (B).

– Keep the end hinge cap for later installation.

Remove the right hinge endcap.

3

– Pressonthe center of the cap and push

towards the right hinge to remove (C).

– Keep the end hinge cap for later installation.

Loosely screw (1 – 2 turns) M5x10 cross-head

4

screws into doors (D).

Repeat this process for all appliance doors.

Page 25

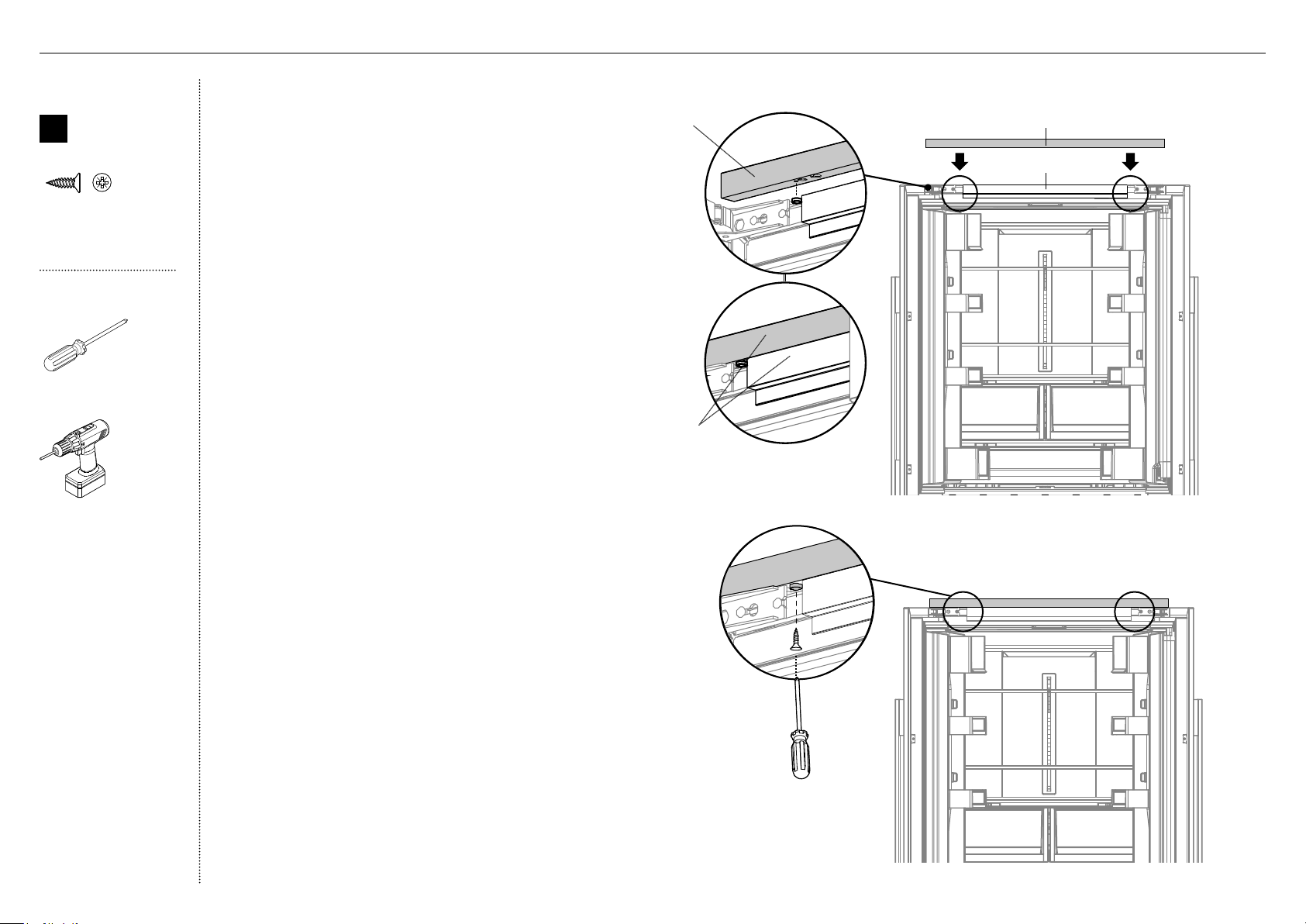

!6 TOP TRIM INSTALLATION

Internal box

Install

X

fasteners kit

#12x12 Countersunk

cross-head screw

(2)

Tools

Cross-head screwdriver

Powered driver (optional)

Install the top trim

Position the top trim on top of the top cover of the

1

appliance (A).

Align the small screw hole of the top trim with the

2

screw hole of the hinge bracket (B).

– Ensure the front face of the top trim is flush

with the front face of the top cover (C).

Do this step to both right and left hinge brackets.

Fix the top trim by screwing #12x12 countersunk

3

screws (D) through the screw holes of the top

trim and hinge brackets.

Small screw hole

Top trim front face

flush with top cover

front face

Top trim

B

A

Top cover

C

D

23

Page 26

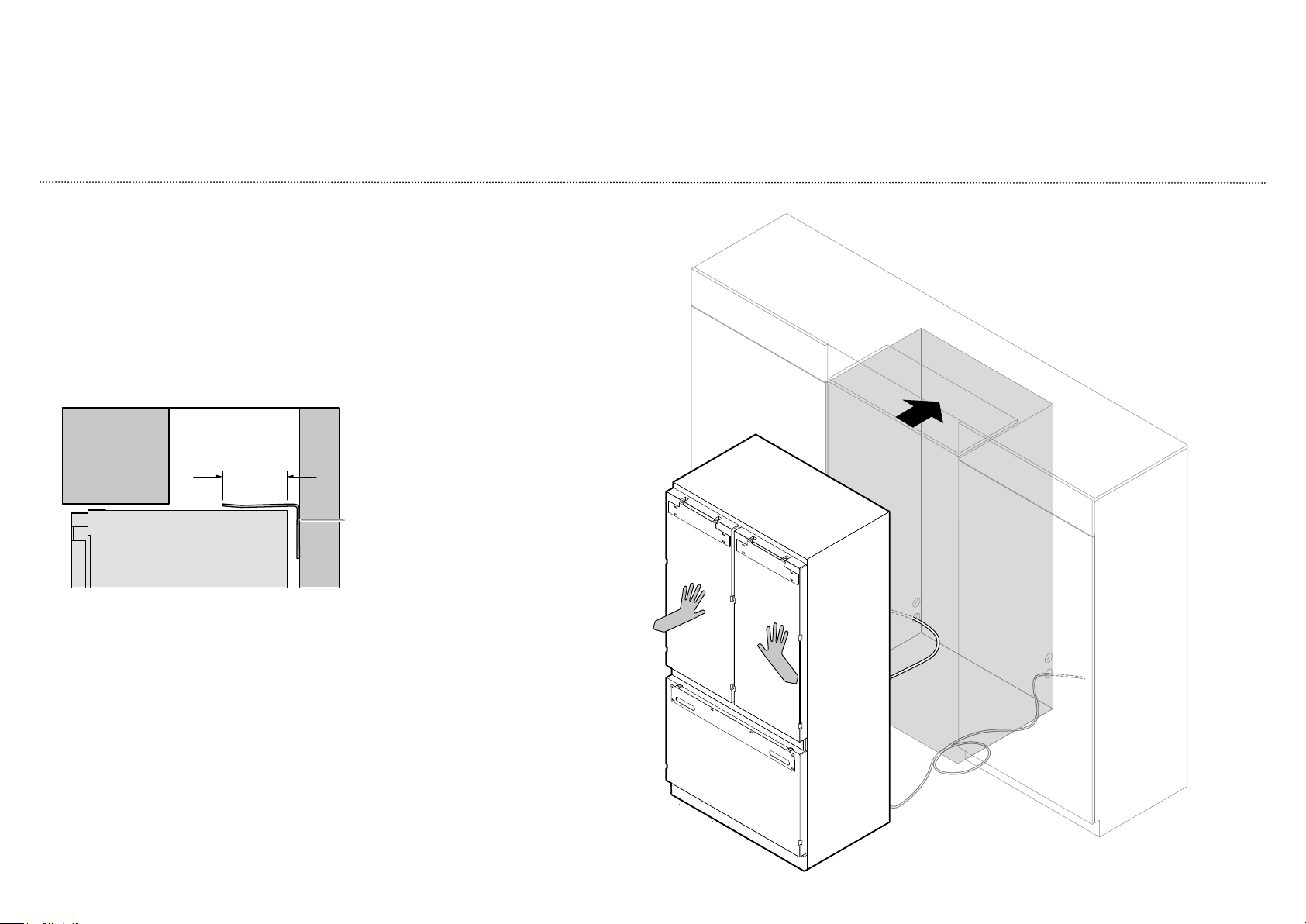

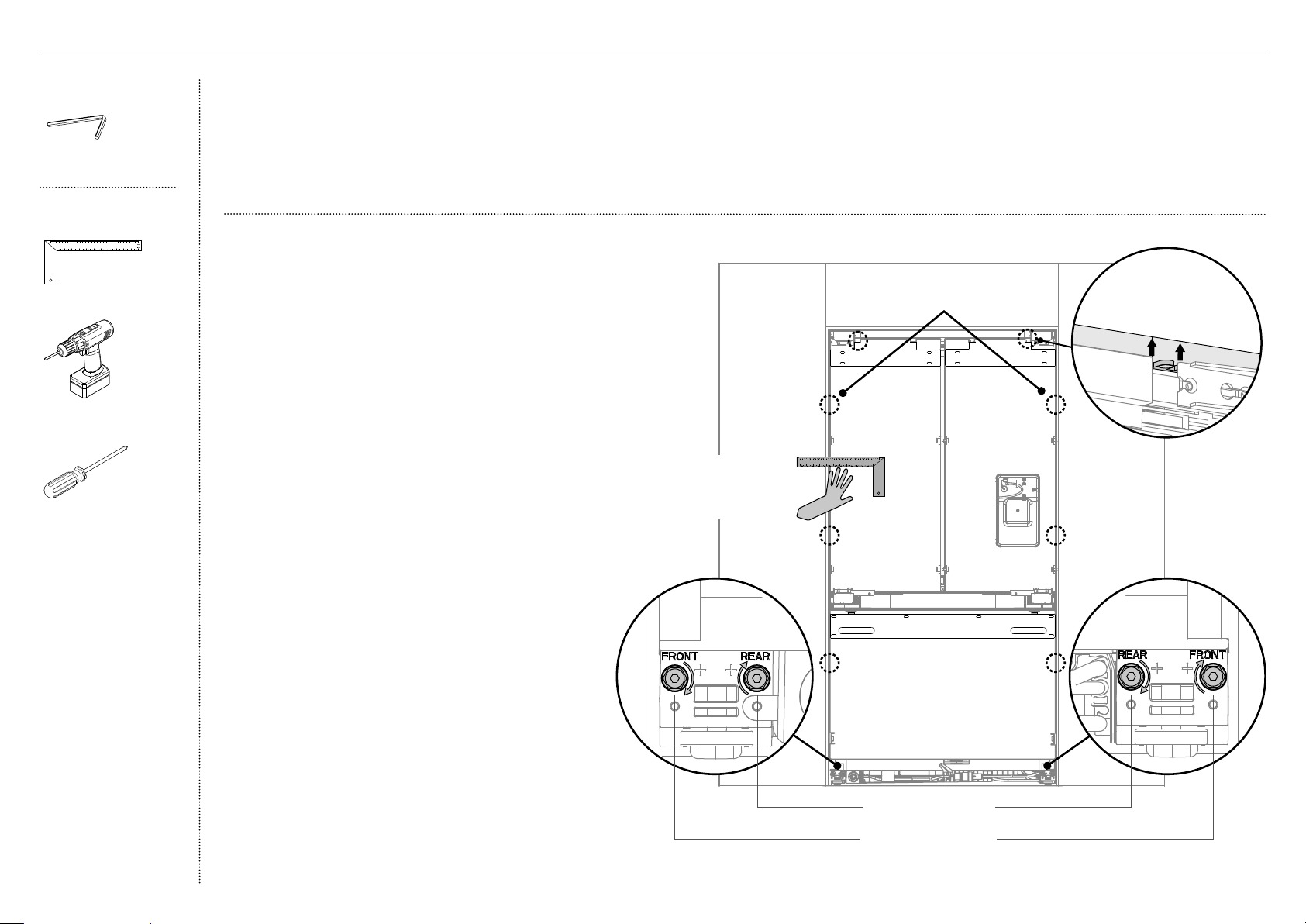

!7 POSITIONING INTO CABINETRY

IMPORTANT!

● ●

Your appliance is fitted with front and rear rollers designed for moving the appliance in

the forwards and backwards direction.

● ●

Avoid moving the appliance in a sideways direction as this may damage the rollers or

the floor covering/surface.

●

Position the appliance into the cabinetry

Ensure the power cord are secured to the clip at the back

1

of the appliance (A) and the excess water hose coiled flat

behind the appliance.

Push the appliance into the cabinetry until the anti-tip bracket

2

overlaps the rear top edge of the appliance (B).

– Ensure the appliance is centered.

– Ensure there is firm contact between the appliance and

anti-tip bracket withamin.2 3/8" (60mm) overlap (C).

● ●

Ensure the hose is not run over by the appliance when pushing into the cabinetry to

prevent damage and possible water leaks.

● ●

Ensure water tubing is routed away from any sharp objects, sharp corners (beware of

kinking the tube as this will stop water flow), and not in a location where it can be kinked

or squashed.

Min. 2 3/8"

(60mm) overlap

Anti-tip

bracket

Refer to 'Attach anti-tip bracket' (page19) for more information.

B

A

24

Page 27

!8 ALIGNING INSIDE CABINETRY

Supplied tools

Hex key

Tools

Ruler

Powered driver (optional)

Cross-head screwdriver

IMPORTANT!

●

Ensure all four corners of the appliance is supported firmly onto the floor

to eliminate any movement.

●

DO NOT install the appliance on a soft, uneven, or unlevelled floor

toavoidtwisting the appliance and poor door sealing.

●

We recommend to use A 4mm hex key.

●

One turn of height adjusting nuts is equivalent to 1mm heightadjustment.

Note: Maximum height adjustment is 13/16" (20mm).

Align appliance inside the cabinetry

1 Centre the appliance within the alcove, using the adjacent

walls as a guide.

2 Raise the front of the appliance until the fixing brackets

contact the ceiling of the enclosure (A).

z

Turn the front and rear adjusting nuts (B) clockwise to

raise the roller or counter-clockwise to lower the roller.

3 To achieve correct alignment between front of the doors

and adjacent cabinetry panels, turn the adjusting nuts

alternately between front and rear rollers.

4 Check the gaps top and bottom, left and right by placing a

ruler on the front of the appliance.

z

Ensure the gaps between appliance and adjacent

cabinetry are even on both sides (C).

z

This step will help ensure the appliance is level with the

adjacent cabinetry

5 Gently push the front of the appliance to check

the stability

●

●

●

Place a ruler on the

front of the appliance to

check flushness top and

bottom, left and right

If using a powered driver, use low torque setting to avoid the nut

disengaging from the rod and damaging theleveling system. If the nut

disengages, use the hex key to realign with rod.

Ensure that the top, bottom and side gap differences are not greater than

1.5mm to achieve correct alignment.

Finalalignment will be achieved once door panels have been installed

andthe appliance is pushed back to sit flush with the cabinetry.

C

A

Rear roller adjustment

Front roller adjustment

BB

25

Page 28

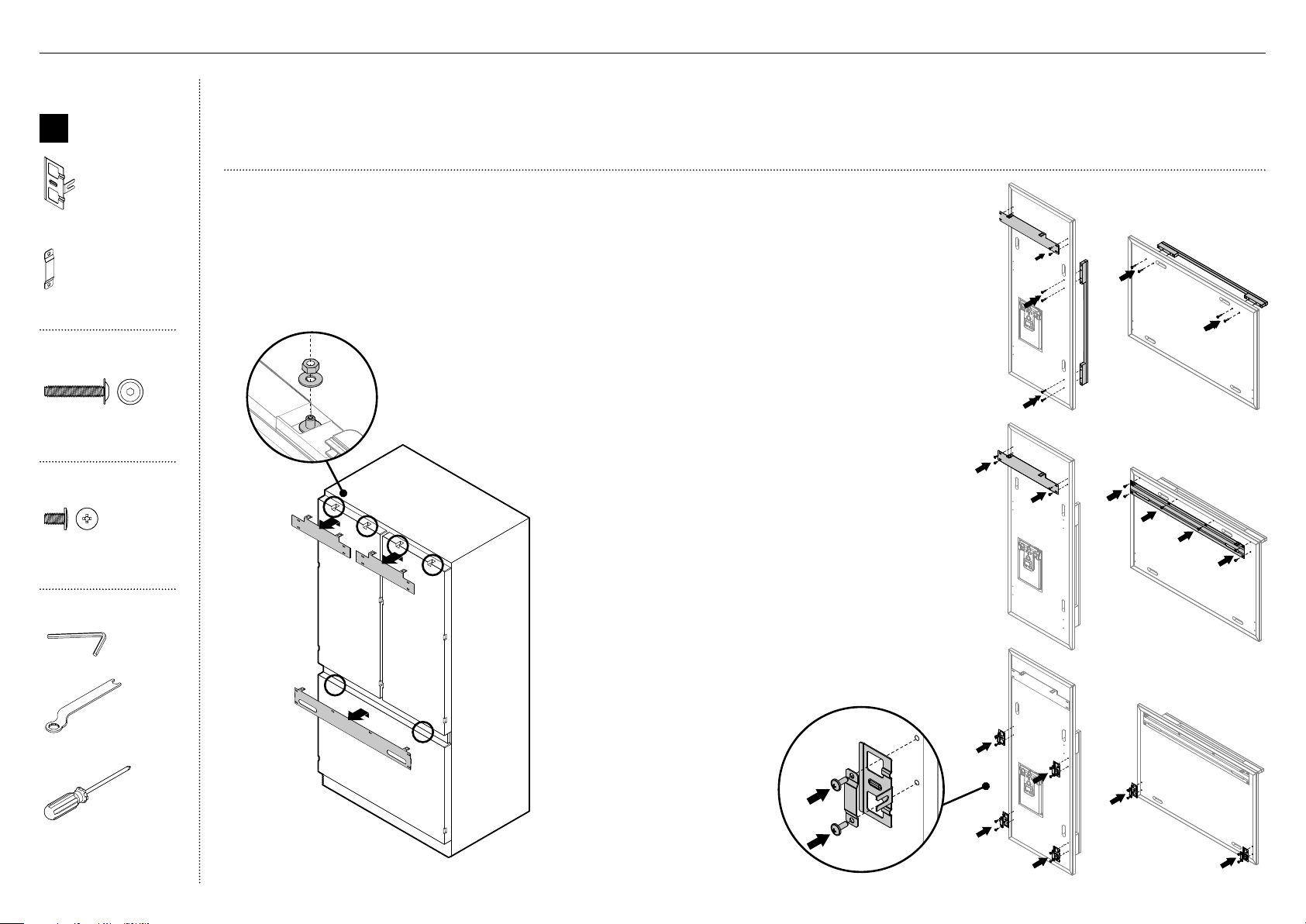

!9 DOOR PANEL INSTALLATION — STAINLESS STEEL

Internal box

Door panel

B

attachment kit

Side bracket (10)

Side strap (10)

Door handle kit

M5x25 pan head socket

screw (12x)

Door panel set

IMPORTANT!

●

Follow these steps to avoid difficulties in door panel adjustment and cosmetic cap fitment.

●

Ensure to protect the finish of the Stainless steel door panels.

●

For non-water dispensing door panels: Leave the protective film on the panels when hanging and remove the film only when installation is complete.

Remove hanging brackets

Remove the M8 washers and M8 nuts

1

fromtheM8 studs at the top the door (A).

Keepthe washers and nuts to reuse later.

Remove the hanging bracket from the top of

2

each door and set aside (B) for later installation.

A

Attach the door and drawer handles (A)

Remove the plastic plugs from the handle holes

3

(4 per each door panel).

Align the handle holes with the door panel

4

holes and secure with M5x25 pan head socket

screws (4 per each door panel).

Note: Door handle kit available and must be

purchased separately. Refer to 'Components'

(page 5) for more details.

Attach the hanging brackets (B)

Align the bracket to the holes and secure

5

withM5x14 mush cross-head SS screws (14).

A

B

B

A

M5x14 mush cross-head

(SS) screw (34)

Tools

Hex key

FPA spanner

Cross-head screwdriver

26

B

Attach side brackets and straps (C)

Align the brackets and straps to the holes on

6

the side of the panel and secure with M5x14

mush cross-head SS screws (20).

C

C

Page 29

!9 DOOR PANEL INSTALLATION — STAINLESS STEEL

Ice and Water display

(Ice and Water models

only)

External display module

(1)

IMPORTANT!

●

Failure to follow these steps can lead to difficulties in door panel adjustment and cosmetic cap fitment.

●

For water dispensing door panels: Remove the protective film from the appliance doors before hanging door panels.

Connect the external display module

(for Water dispensing model only)

Locate the external display

1

module from inside the appliance.

Thread the display harness

2

through the door panel cavity (A).

– Ensure the grommet

isengaged.

Turn the top display tabs at an

3

angle into the door panel (B).

– Ensure the harness is free

ofpinching.

Push firmly against the bottom

4

display tabs and insert into

the door panel until you feel

itclipsecurely.

– Ensure the display is flush

with the door panel.

A

B

Connect the display harness onto the

7

appliance door by inserting firmly until you feel

it clip securely (D).

– On the external display, enable the

dispenser lock to

prevent any water

from dispensing

during water

connection.

– To lock, press the

button for 4 seconds.

The LED above the

button will illuminate.

D

Remove water tube

5

from the holder on

the appliance door

(C).

Hang the door panel

6

onto M8 studs.

– Ensure the

panel is free to

pivot for water

connections.

Enable the dispenser lock to prevent any water

8

from dispensing during water connection. To lock,

press the button for 4seconds. The LED above

the button will illuminate.

C

Push the water tube firmly

9

into the spigot behind

the door panel until

the marked line is not

visible(E).

– Ensure the water

tube is routed away

from any sharp

objects or corners,

and not in a location

where it can be

kinked or squashed

when the door panel

is secured, (as this

will stop water flow).

E

27

Page 30

!9 DOOR PANEL INSTALLATION — STAINLESS STEEL

Tools

Cross-head screwdriver

Powered driver (optional)

Hex key

FPA spanner

Attach the door panels

Open the door and loosen the M5x10 cross-head

1

screws (do not remove) at the sides of the doors (A).

Hang the door panel by inserting the M8 studs

2

through the holes of the hanging bracket (B).

Slide the forks of the side brackets onto the

3

screws of the door (C).

Screw the M8 washer and nut to each stud

4

(D), and re-tighten the side screws (E) using

the hex key and spanner to fix the door

panel (do not fully tighten). This will allow

opening the door without affecting

adjustment of the door panel.

E

A

B

D

28

C

Page 31

!9 DOOR PANEL INSTALLATION — STAINLESS STEEL

Door panel

B

attachment

kit

#8Gx16 countersunk

screw (2)

Tools

Hex key

FPA spanner

Cross-head screwdriver

Powered driver (optional)

Ruler

IMPORTANT!

●

Follow these steps to avoid difficulties in door panel adjustment and cosmetic cap fitment.

Adjust the door panels

Push the appliance into the cavity until the door panels are flush

1

with adjacent cabinetry surface.

Place a ruler on the front of the appliance to check flushness top

2

and bottom, left and right..

Each door panel has full axis adjustment to ensure flushness

2

with adjacent walls. To adjust the height of the panel, turn the

stud clockwise to raise or counter-clockwise to lower the door

panel (A).

Once satisfied with the alignment, secure M8 studs with

3

M8 washer and M8 nut (B). The top of the stud must remain

below the top face of the door panel.

Secure side bracket forks by tightening

4

side screws(C).

Repeat for all door panels.

Note:

– For depth adjustment, loosen the

side screws, adjustthe panels and

then retightenoncesatisfied.

– Further adjustment of door panels

can be achieved by removing door

panels then looseningthe fixing

screws for the hanging bracket and

moving the bracket sideways to suit.

Loosen the M8x16 crosshead screw (D)

5

so that locking bracket can slide freely

back to front.

– Slide the locking bracket out until it

touches the back of the door panel.

Fully tighten the screw.

– Screw in place using a #8x16 screw

through one ofthe three slotted

holes.

B

A

C

D

29

Page 32

DRAWER PANEL TOP EDGE

LH DOOR PANEL HINGE SIDE

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

DRAWER PANEL HINGE SIDE

LH DOOR PANEL HINGE SIDE

LH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

LEFT DOOR

PANEL TEMPLATE

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

LH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

DOOR PANEL

DOOR PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

LEFT DOOR

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

RH DOOR PANEL HINGE SIDE

DOOR PANEL

HANGING BRACKET HOLES

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL BOTTOM EDGE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

FLIP FOR LEFT

DOOR PANEL

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL BOTTOM EDGE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

FLIP FOR LEFT

DOOR PANEL

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HINGE SIDE

@0 DOOR PANEL INSTALLATION — CUSTOM

External box

Door panel template

(1)

Tools

Cross-head screwdriver

Powered driver (optional)

IMPORTANT!

●

The template is a single sheet with one side used for the left door

panel / drawer panel and the other side for the right door panel.

●

The template should be placed on the back side of the door panel.

Using the installation template

(for right French door panel)

2 Mark drill locations of

screw holes for the left

hanging bracket and

side brackets. Drill 3/32"

(2mm) screw holes to

the markedlocations.

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

HANGING BRACKET HOLES

DOOR PANEL

RIGHT DOOR

PANEL TEMPLATE

back side of

door panel

RH DOOR PANEL HANDLE SIDE

HANGING BRACKET HOLES

DOOR PANEL

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

front side of

door panel

5 Mark drill locations of

screw holes for the right

hanging bracket and

side brackets. Drill 3/32"

RH DOOR PANEL HANDLE SIDE

SIDE BRACKET HOLES

DOOR PANEL

DOOR PANEL

SIDE BRACKET HOLES

SIDE BRACKET HOLES

DOOR PANEL

DOOR PANEL

SIDE BRACKET HOLES

(2mm) screw holes to the

markedlocations.

30

1A Align left side edge

of template with

left side edge of

top door panel.

1

1B Align bottom of template with

bottom edge of top door panel.

RH DOOR PANEL HANDLE SIDE

FLIP FOR LEFT

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

RH DOOR PANEL BOTTOM EDGE

DOOR PANEL

SIDE BRACKET HOLES

RH DOOR PANEL HANDLE SIDE

FLIP FOR LEFT

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

RH DOOR PANEL BOTTOM EDGE

3 Move the same template to

right hand side of door panel.

4A Align right side

edge of template

with right side edge

of top door panel.

DOOR PANEL

SIDE BRACKET HOLES

4B Align bottom of template with

bottom edge of top door panel.

Page 33

DRAWER PANEL TOP EDGE

LH DOOR PANEL HINGE SIDE

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

DRAWER PANEL HINGE SIDE

LH DOOR PANEL HINGE SIDE

LH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

LEFT DOOR

PANEL TEMPLATE

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

LH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

DOOR PANEL

DOOR PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

LEFT DOOR

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

RH DOOR PANEL HINGE SIDE

DOOR PANEL

HANGING BRACKET HOLES

LH DOOR PANEL HINGE SIDE

LH DOOR PANEL HANDLE SIDE

DRAWER PANEL HANDLE SIDE

DRAWER PANEL HINGE SIDE

FLIP FOR RIGHT

DOOR PANEL

LH DOOR PANEL HINGE SIDE

LH DOOR PANEL HANDLE SIDE

LH DOOR PANEL BOTTOM EDGE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL BOTTOM EDGE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

LEFT DOOR

PANEL TEMPLATE

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DRAWER PANEL

SIDE BRACKET HOLES

DRAWER PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

FLIP FOR LEFT

DOOR PANEL

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL BOTTOM EDGE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

FLIP FOR LEFT

DOOR PANEL

DRAWER PANEL TOP EDGE

LH DOOR PANEL HINGE SIDE

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

RH DOOR PANEL BOTTOM EDGE

DRAWER PANEL HINGE SIDE

LH DOOR PANEL BOTTOM EDGE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL BOTTOM EDGE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

FLIP FOR LEFT

DOOR PANEL

@0 DOOR PANEL INSTALLATION — CUSTOM

IMPORTANT!

●

Flip the template over to use for the left top door panel.

●

The template should be placed on the back side of the door panel.

Using the installation template

(for left French door panel)

2 Mark drill locations of

screw holes for the left

1A Align left side edge of

hanging bracket and

side brackets. Drill 3–32

(2mm) screw holes to

the marked locations.

template with left side

edge of top door panel.

1

1B Align bottom of template with

bottom edge of top door panel.

back side of

door panel

DRAWER PANEL TOP EDGE

LH DOOR PANEL HINGE SIDE

HANGING BRACKET HOLES

DOOR PANEL

DOOR PANEL

HANGING BRACKET HOLES

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

DRAWER PANEL

DRAWER PANEL

HANGING BRACKET HOLES

HANGING BRACKET HOLES

DRAWER PANEL HINGE SIDE

LEFT DOOR

PANEL TEMPLATE

LH DOOR PANEL HINGE SIDE

SIDE BRACKET HOLES

DOOR PANEL

DOOR PANEL

SIDE BRACKET HOLES

LH DOOR PANEL HANDLE SIDE

SIDE BRACKET HOLES

DRAWER PANEL

DRAWER PANEL

SIDE BRACKET HOLES

DRAWER PANEL HANDLE SIDE

FLIP FOR RIGHT

DOOR PANEL

LH DOOR PANEL HINGE SIDE

SIDE BRACKET HOLES

DOOR PANEL

DOOR PANEL

SIDE BRACKET HOLES

LH DOOR PANEL HANDLE SIDE

3 Move the same template to

right hand side of door panel.

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

RIGHT DOOR

PANEL TEMPLATE

FLIP FOR LEFT

DOOR PANEL

front side of

door panel

DOOR PANEL

HANGING BRACKET HOLES

RH DOOR PANEL HINGE SIDE

5 Mark drill locations of screw holes

for the right hanging bracket and

side brackets. Drill 3–32 (2mm)

screw holes to the marked locations.

DOOR PANEL

SIDE BRACKET HOLES

RH DOOR PANEL HINGE SIDE

4A Align right side edge of

template with right side

edge of top door panel.

DOOR PANEL

SIDE BRACKET HOLES

RH DOOR PANEL HINGE SIDE

4B Align bottom of template with

bottom edge of top door panel.

31

Page 34

@0 DOOR PANEL INSTALLATION — CUSTOM

DRAWER PANEL TOP EDGE

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

DRAWER PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

DOOR PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

LH DOOR PANEL HINGE SIDE

DRAWER PANEL TOP EDGE

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

DRAWER PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

DOOR PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

LH DOOR PANEL HINGE SIDE

DRAWER PANEL TOP EDGE

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

DRAWER PANEL HINGE SIDE

LH DOOR PANEL HINGE SIDE

LH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

DOOR PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

LEFT DOOR

PANEL TEMPLATE

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

LH DOOR PANEL HINGE SIDE

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

LH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

DOOR PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

LH DOOR PANEL BOTTOM EDGE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL BOTTOM EDGE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

FLIP FOR LEFT

DOOR PANEL

DRAWER PANEL HINGE SIDE

LH DOOR PANEL BOTTOM EDGE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL BOTTOM EDGE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

RIGHT DOOR

PANEL TEMPLATE

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

FLIP FOR LEFT

DOOR PANEL

DRAWER PANEL TOP EDGE

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

LH DOOR PANEL HINGE SIDE

DRAWER PANEL TOP EDGE

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

RH DOOR PANEL HANDLE SIDE

RH DOOR PANEL HINGE SIDE

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

HANGING BRACKET HOLES

LH DOOR PANEL HINGE SIDE

32

IMPORTANT!

●

Use left door panel template to use for the drawer panel.

●

Place the template at the back side of the drawer panel.

Using the installation template

(for drawer panel)

2 Mark drill locations of screw

holes for the left hanging

bracket and side brackets.

Drill 3–32 (2mm) screw holes

to the marked locations.

1A Align top of template with

top edge of drawer panel.

1B Align left side edge of

template with left side

edge of drawer panel.

DRAWER PANEL TOP EDGE

LH DOOR PANEL HINGE SIDE

HANGING BRACKET HOLES

DOOR PANEL

DRAWER PANEL

DRAWER PANEL

HANGING BRACKET HOLES

HANGING BRACKET HOLES

DRAWER PANEL HINGE SIDE

LEFT DOOR

PANEL TEMPLATE

LH DOOR PANEL HINGE SIDE

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DRAWER PANEL

DRAWER PANEL HINGE SIDE

FLIP FOR RIGHT

DOOR PANEL

LH DOOR PANEL HINGE SIDE

SIDE BRACKET HOLES

DOOR PANEL

back side of

drawer panel

6 To mark the drill locations of middle

screw holes, align the screw holes of

the drawer hanging bracket with the

right and left drilled screw holes. Drill

screw holes to the marked locations.

DOOR PANEL

HANGING BRACKET HOLES

DOOR PANEL

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

SIDE BRACKET HOLES

LH DOOR PANEL HANDLE SIDE

DRAWER PANEL

SIDE BRACKET HOLES

DRAWER PANEL HANDLE SIDE

3 Move the same template to

right hand side of drawer panel.

DOOR PANEL

SIDE BRACKET HOLES

LH DOOR PANEL HANDLE SIDE

front side of

door panel

LH DOOR PANEL HINGE SIDE

DRAWER PANEL

HANGING BRACKET HOLES

DRAWER PANEL HINGE SIDE

LH DOOR PANEL HINGE SIDE

SIDE BRACKET HOLES

DOOR PANEL

SIDE BRACKET HOLES

DRAWER PANEL

LH DOOR PANEL HINGE SIDE

SIDE BRACKET HOLES

DOOR PANEL

DRAWER PANEL TOP EDGE

HANGING BRACKET HOLES

DOOR PANEL

LEFT DOOR

PANEL TEMPLATE

FLIP FOR RIGHT

DOOR PANEL

DOOR PANEL

HANGING BRACKET HOLES

DRAWER PANEL

HANGING BRACKET HOLES

4A Align top of template with

top edge of drawer panel.

4B Align right side edge of

template with right side

edge of drawer panel.

LH DOOR PANEL HANDLE SIDEDRAWER PANEL HANDLE SIDE

5 Mark drill locations of screw

holes for the left hanging

DOOR PANEL

SIDE BRACKET HOLES

LH DOOR PANEL HANDLE SIDE

bracket and side brackets.

Drill 3–32 (2mm) screw holes

to the marked locations.

DRAWER PANEL

SIDE BRACKET HOLES

DRAWER PANEL HANDLE SIDE

DOOR PANEL

SIDE BRACKET HOLES

LH DOOR PANEL HANDLE SIDE

Page 35

@0 DOOR PANEL INSTALLATION — CUSTOM

Internal box

Door panel

B

attachment kit

Side bracket

(10)

Side strap

(10)

#8x16 mush washer

(Custom) screw (34)

Door handle kit

M5x25 pan head socket

screw (12x)

Remove hanging brackets

Remove the M8 washers and M8 nuts fromthe

1

M8 studs at the top the door (A) using the hex

key and spanner. Keep the washers and nuts to

reuse later.

Remove the hanging bracket from the top of

2

each door and set aside (B) for later installation.

A

B

Attach the door and drawer handles (C)

Align the handle holes with the door panel

3

holes and secure with M5x25 pan head socket

screws (4 per each door panel).

Note: Door handle kit available and must be

purchased separately. Refer to 'Components'

(page 6) for more details.

Attach the hanging brackets (D)

Align the bracket to the holes and secure

4

with #8x16 mush washer screws (14).

C

C

D

D

Tools

Hex key

FPA spanner

Cross-head screwdriver

Attach side brackets and straps (E)

Align the brackets and straps to the holes on

6

the side of the panel and secure with #8x16

mush washer screws (20).

E

E

33

Page 36

@0 DOOR PANEL INSTALLATION — CUSTOM

Tools

Hex key

FPA spanner

(1)

Cross-head screwdriver

Powered driver (optional)

Attach the door panels

Open the door and loosen the M5x10 cross-head screws

1

(do not remove) at the sides of the doors (A).

Hang the door panel by inserting the M8 studs

2

through the holes of the hanging bracket (B).

Slide the forks of the side brackets onto the

3

screws of the door (C).

Screw the M8 washer and nut to each stud (D),

4

and re-tighten the side screws (E) to fix the

door panel (do not fully tighten). This will

allow opening the door without affecting

adjustment of the door panel.

E

A

B

D

34

C

Page 37

@0 DOOR PANEL INSTALLATION — CUSTOM

Door panel

B

attachment

kit

#8Gx16 countersunk

screw (2)

Tools

Hex key

FPA spanner

Cross-head screwdriver

Powered driver (optional)

Ruler

IMPORTANT!

●

Follow these steps to avoid difficulties in door panel adjustment and cosmetic cap fitment.

Adjust the door panels

Push the appliance into the cavity until the door panels are flush

1

with adjacent cabinetry.

Place a ruler on the front of the appliance to check flushness top

2

and bottom, left and right.

Each door panel has full axis adjustment to ensure flushness

2

with adjacent walls. To adjust the height of the panel, turn

the stud clockwise to raise or counter-clockwise to lower the

door panel (A).

Once satisfied with the alignment, secure M8 studs with M8

3

washer and M8 nut (B). The top of the stud must remain below

the top face of the door panel.

Secure side bracket forks by tightening

4

side screws(C).

Repeat for all door panels.

Note:

– For depth adjustment, loosen the

side screws, adjustthe panels and

then retightenoncesatisfied.

– Further adjustment of door panels

can be achieved by removing door

panels then looseningthe fixing

screws for the hanging bracket and

moving the bracket sideways to suit.

Loosen the M8x16 crosshead screw (D)

5

so that locking bracket can slide freely

back to front.

– Slide the locking bracket out until it

touches the back of the door panel.

Fully tighten the screw.

– Screw in place using a #8x16 screw

through one ofthe three slotted

holes.

B

A

C

D

35

Page 38

150

C

O

P

P

@1 FIXING TO CABINETRY

Internal box

Install

X

fasteners kit

#8Gx16 flat head screw

(2)

Tools

Cross-head screwdriver

Powered driver (optional)

IMPORTANT!

Lower the feet until it engages the floor to provide more stability to the

appliance and prevent back and forth movement.

A

B

C

36

Secure the top trim to cabinetry

1 Secure the top trim to the ceiling of the cabinetry

with #8Gx16 flat head screws (A).

Repeat on the opposite side.

2 Lower the feet until it engages the floor to provide

more stability to the appliance and prevent back

and forth movement.

Reattach the hinge end caps

3 Reattach the left hinge end cap (B).

z

Align hinge cap to the appliance, press

andfirmly slide the cap to the right.

z

Hold onto the corner of the end cap,

firmly push up and to the left to engage

securing hook. Ensure cap is flush

with the appliance.

Reattach right hinge end cap (C).

4

– Align hinge cap to appliance, press

and firmly slide the cap to the left.

– Ensure cap is flush with

the appliance.

Page 39

@2 WATER FILTER INSTALLATION

Miscellaneous

itemspack

Water filter

(1)

Filter cartridge tool

(1)

IMPORTANT!

●

The water filter head must be firmly pushed into the appliance and secured. incorrect installation can lead to water leaks.

Filter

handle

A

FRONT VIEW

Install the water filter

Remove the plastic wrapping of the new filter.

1

Pull the freezer drawer out slightly and insert the filter into the casing

2

at the bottom left corner of the appliance. Ensure the filter handle is

positioned vertically (A).

Push the cartridge firmly inside the casing all the way into the filter head.

3

Align the filter removal tool over the filter handle and turn 90° clockwise

4

to tighten (B). Remove filter removal tool and close the freezer drawer.

IMPORTANT!

●

Before turning on your automatic ice maker, the water filter must be

flushed to remove any impurities or trapped air in the water tank and

filter system.

●

Refer to the user guide ‘Operating instructions — Automatic ice maker’

for more information.

B

Filter in locked position

37

Page 40

@3 TOE KICK INSTALLATION

MI Pack

Toe kick filter

(1)

External box

Toe kick grille

(1)

Install the toe kick filter and grille

Fit the filter onto the rails and push until it clips securely (A).

1

Alignthe top grille clips to the top plinth slots. Ensure the top grille is in the correct orientation (B).

2

Push the grille firmly onto the appliance until the clips engage (C).

3

C

A

38

B

Page 41

@4 COVERS AND TRIMS INSTALLATION

Internal box

Door/drawer

C

trim install kit

Dual adhesive tabs

(12)

Top cover

(2)

Side cover

(4)

External box

Door side trim

(2)

Attach the covers

Open the French doors.

1

Attach the top covers (A) firmly

over the top studs, and the side

covers (B) to the side brackets.

A

B

Attach the door side trims

Install the side trims by inserting into the panel gaps on each

2

side of the door(s) (C). Align the trim to the top of the door

and press evenly into the panel gap until fully seated (D).

Attach the drawer top and side trims

Peel off two dual adhesive tabs and press them together

3

to form a pair (E). Remove the adhesive backing on one

side only.

Press firmly to the underside of the drawer top trim

4

inthe indicated locations (F).

C

Remove the remaining adhesive backing from the dual adhesive tabs.

5

Locate the trim against the back surface of the panel and press down firmly.

6

Ensure the trim is fully seated against the drawer surface (G).

Install the side trims by inserting into the panel gaps on each side of

7

the door(s) (H).

– Make sure the cabinet is centered to prevent the side trims

frominterfering with the cabinet.

F

Drawer side trim

(2)

Drawer top trim

(1)

G

C

H

D

39

Page 42

TWO METHODS ARE AVAILABLE FOR ATTACHING CABINET SIDE TRIMS:

[A] FLEXIBLE SPRING CLIP METHOD — RECOMMENDED METHOD

[B] FIXED SCREW METHOD — METHOD TO USE IF CABINET IS NOT TO SPECIFICATION

(Attempt method [A]. If method [A] results in poor fitment of side trims due to cabinetry that is uneven or out of specification, use method [B]).

@5 CABINET TRIMS INSTALLATION — [A] FLEXIBLE SPRING CLIP METHOD

Internal box

Cabinet side

D

trim install kit

Side trim bracket

(6)

Spring clip

(6)

External box

Cabinet side trim

(2)

Break off the datum lip of each side trim bracket and discard.

1

Discard

Place 3 side trim brackets onto each side trim.

2

Note: Measure from the top of the trim, with the short lip at

the bottom (A).

IMPORTANT!

Each bracket has two engagement points for the side trim to locate.

Ensure the trim is engaged in both points (B).

Repeat for all side trims.

Side trim

bracket

Side trim

Top view of side trim engaged

correctly in side trim bracket

~ 69" (1753mm)

~ 40" (1016mm)

A

~ 10" (254mm)

40

B

short lip

Page 43

@5 CABINET TRIMS INSTALLATION — [A] FLEXIBLE SPRING CLIP METHOD

Insert the spring clip into the gap between the side trim and side trim

3

bracket, orientation as shown in figures (C) and (D).

Open the French doors. Place the assembled side trim with brackets and spring

4

clips against the alcove side wall with the shorter lip facing the bottom (E).

IMPORTANT!

Ensure spring clip is correctly oriented with the open loop facing

theside trim lip.

Repeat for all side trims.

Spring clip

Side trim lip

IMPORTANT!

Ensure the side trim is positioned as high as it will go.

Push the side trim at each bracket location until there are no visible gaps

between the trim and cabinetry (F).

Repeat for all side trims.

F

C