Fisher & Paykel FPRADW724, FPRADW728, OR36SCI6B1 Installation manual

FREESTANDING RANGE

OR6S Gas Gas & OR6S Dual Fuel

models

INSTALLATION GUIDE

US CA

WARNING!

If the information in this manual is not

followed exactly, a fire or explosion

may result causing property damage,

personal injury or death.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

NEVER use this appliance as a space heater

to heat or warm the room. Doing so may result

in carbon monoxide poisoning and overheating

of the appliance.

WHAT TO DO IF YOU SMELL GAS:

z

Do not try to light any appliance.

z

Do not touch any electrical switch.

z

Do not use any phone in your building.

z

Immediately call your gas supplier from

a neighbor’s phone.

Follow the gas supplier’s instructions.

z

If you cannot reach your gas supplier,

call the fire department.

Installation and service must be performed

by a qualified installer, service agency or the

gas supplier.

C

SAFETY AND WARNINGS

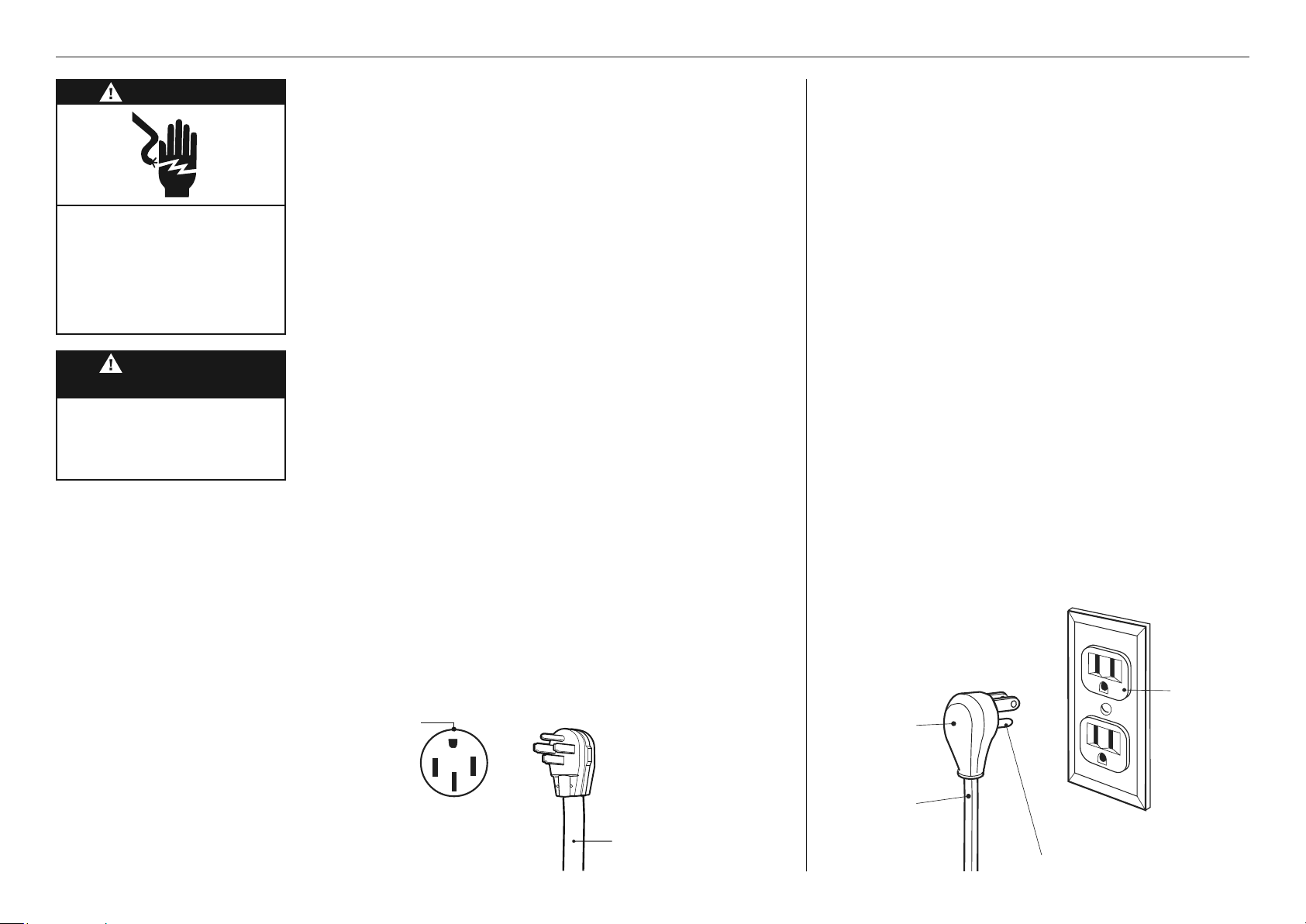

WARNING!

Electrical shock hazard

Before carrying out any work on the electrical section of

the appliance, it must be disconnected from the mains

electricity supply.

Connection to a good ground wiring system is absolutely essential

and mandatory.

Alterations to the domestic wiring system must only be made

by a qualified electrician

Failure to follow this advice may result in electrical shock

or death.

WARNING!

Cut Hazard

Take care – some edges are sharp.

Failure to use caution could result in injury or cuts.

WARNING!

Tip-Over Hazard

A child or adult can tip the range and be killed.

z

Install anti-tip device to range and/or structure per

installation instructions.

z

Engage the range to the anti-tip device installed

to the structure.

z

Re-engage anti-tip device if range is moved.

Failure to follow these instructions can result in death or serious

burns to children and adults.

The product data plate is attached below the bottom drawer.

To check the label, it is necessary to remove the drawer

(see ‘Setting the pressure regulator’ for instructions on drawer removal).

DATA PLATE

CONVERSION LABEL

SAVE THESE INSTRUCTIONS

The models shown in this installation guide may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country,

please go to our website fisherpaykel.com or contact your local Fisher & Paykel dealer.

3

IMPORTANT!

SAFETY AND WARNINGS

IMPORTANT SAFETY INSTRUCTIONS!

z

Save these instructions for the local inspectors use.

z

To avoid hazard, follow these instructions carefully before installing or using this appliance.

z

Please make this information available to the person installing the appliance – doing so could reduce

your installation costs.

z

This range is to be installed and connected to the electricity supply only by an authorized person.

z

If the installation requires alterations to the domestic electrical system, call a qualified electrician.

The electrician should also check that the socket cable section is suitable for the electricity

drawn by the range.

z

The range must be grounded.

z

Installation must comply with your local building and electricity regulations.

z

This appliance must be installed and connected to the mains power supply only by a suitably

qualified person according to these installation instructions and in compliance with any applicable

local building and electricity regulations. Failure to install the appliance correctly could invalidate

any warranty or liability claims.

z

Installation of any gas-fired equipment should be made by a licensed plumber. A manual shut-off

valve must be installed in an accessible location in the gas line external to the appliance for the

purpose of turning on or shutting off gas to the appliance (In Massachusetts such shutoff devices

should be approved by the Board of State Examiners of Plumbers & Gas Fitters).

z

Ensure the installer shows the customer where the gas supply shut-off valve is located.

z

If the power supply cable is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified person in order to avoid a hazard.

z

A circuit breaker is recommended.

z

Do not use adaptors, reducers or branching devices to connect the oven to the mains electricity

supply, as they can cause overheating and burning.

z

Improper installation, adjustment alteration, service or maintenance can cause property damage,

injury or death. Read the installation, operating and maintenance instructions thoroughly before

using, installing or servicing this appliance.

z

A risk of the appliance tipping over exists if the appliance is not installed in accordance with

installation instructions.

z

DO NOT obstruct the flow of combustion or ventilation air to the appliance. Be sure a fresh air

supply is available.

z

California Proposition 65 – The burning of gas cooking fuel generates some by-products which

are known by the State of California to cause cancer or reproductive harm. California law requires

businesses to warn customers of potential exposure to such substances. To minimize exposure to

these substances, always operate this unit according to the manufacturer’s instructions and provide

good ventilation to the room when cooking with gas.

z

Check local building codes for the proper method of range installation. Local codes vary. Installation,

electrical connections, and grounding must comply with all applicable codes. In the absence of local

codes, the range should be installed in accordance with the latest edition of National Fuel Gas Code

ANSI Z223.1 and National Electrical Code ANSI/NFPA 70.

z

In Canada: Installation must be in accordance with the current CAN/CGA B149.1 & 2 Gas Installation

codes and/or local codes. Electrical installation must be in accordance with the current CSA C22.1

Canadian Electrical Codes Part 1 and/or local codes. Be sure that the unit being installed is set up for

the kind of gas being used. The gas range is shipped from the factory set and adjusted for Natural

Gas. It can be converted for use with LP (propane) following the instructions in this manual.

z

Some models are supplied with a protective film on steel and aluminum parts.

This film must be removed before installing/using the appliance.

z

The appliance must not be installed behind a decorative door in order to avoid overheating.

GENERAL INSTALLATION INFORMATION

Installation in manufactured (mobile) home

Installation must conform with the Manufactured Home Construction and

Safety Standard, Title 24 CFR, Part 3280 [formerly the Federal Standard

for Mobile Home Construction and Safety, Title 24, HUD (Part 280)] or,

when such standard is not applicable, the Standard for Manufactured Home

Installations, ANSI/NCSBCS A225.1, or with local codes where applicable.

Installation in recreational park trailers

Installation must conform with state or other codes or, in the absence of

such codes, with the Standard for Recreational Park Trailers, ANSI A119.5.

z

To eliminate risk of burns or fire by reaching over heated surface units,

cabinet storage located above the surface units should be avoided.

z

Air curtain or other overhead range hoods, which operate by blowing

a downward air flow on to a range, shall not be used in conjunction

with gas ranges other than when the hood and range have been

designed, tested and listed by an independent test laboratory for use

in combination.

Cleaning and servicing

z

Service should only be performed by an authorized/qualified technician.

z

Disconnect the electrical supply to the appliance before servicing.

z

When removing appliance for cleaning and/or service:

z

Shut off gas at main supply.

z

Disconnect AC power supply.

z

Disconnect gas line to the inlet pipe.

z

Carefully remove the range by pulling outward.

z

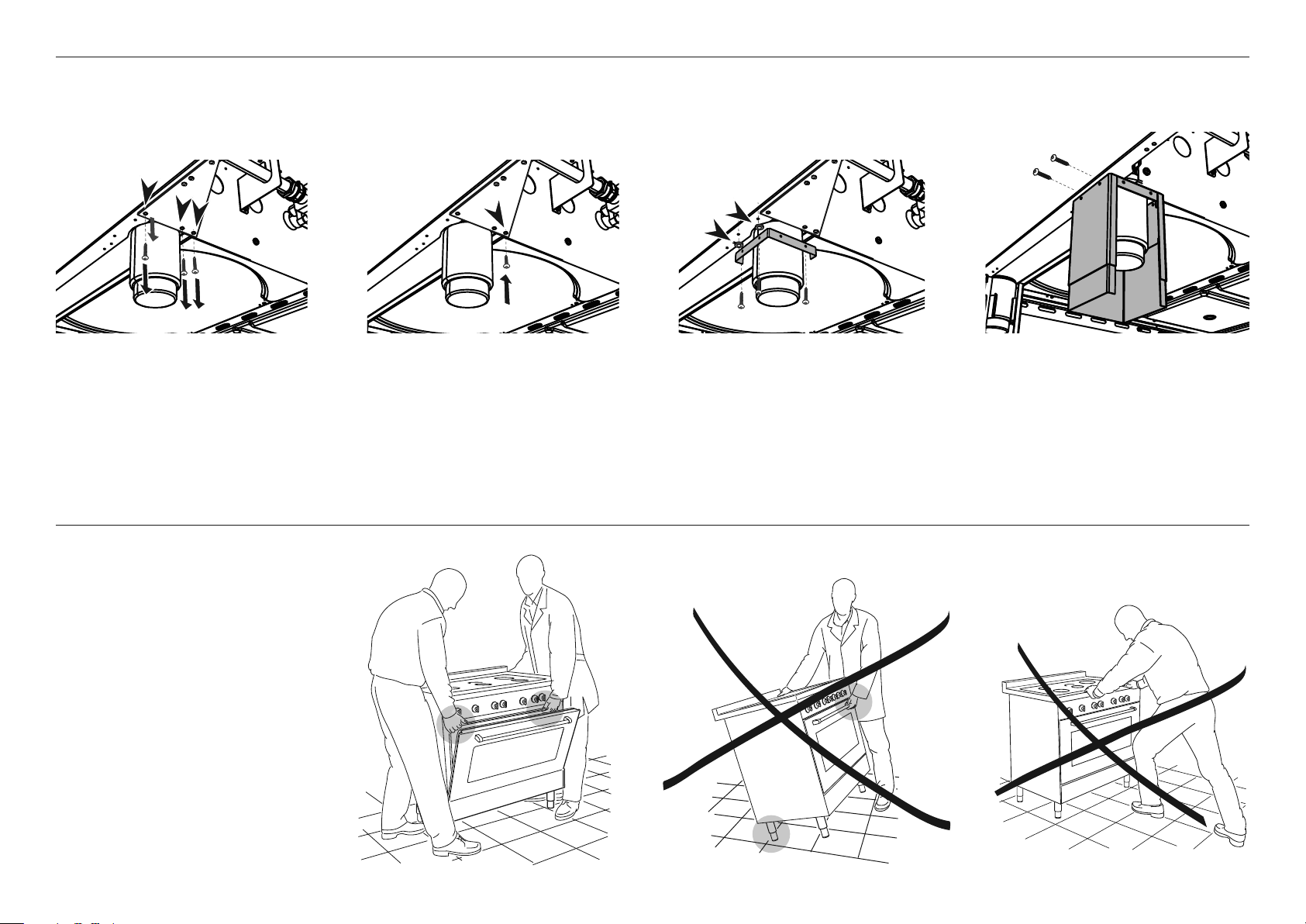

CAUTION: Range is heavy; use care in handling.

z

Do not lift the range by the oven door handle or hob rail

z

The misuse of oven door (eg stepping, sitting, or leaning on them) can

result in potential hazards and/or injuries.

z

When installing or removing the range for service, a rolling lift jack

should be used. Do not push against any of the edges of the range in

an attempt to slide it into or out of the installation.

z

Pushing or pulling a range (rather than using a lift jack) also

increases the possibility of bending the leg spindles or the internal

coupling connectors.

Replacement parts

Only authorized replacement parts may be used in performing service on

the range. Replacement parts are available from factory authorized parts

distributors. Contact the nearest parts distributor in your area.

4

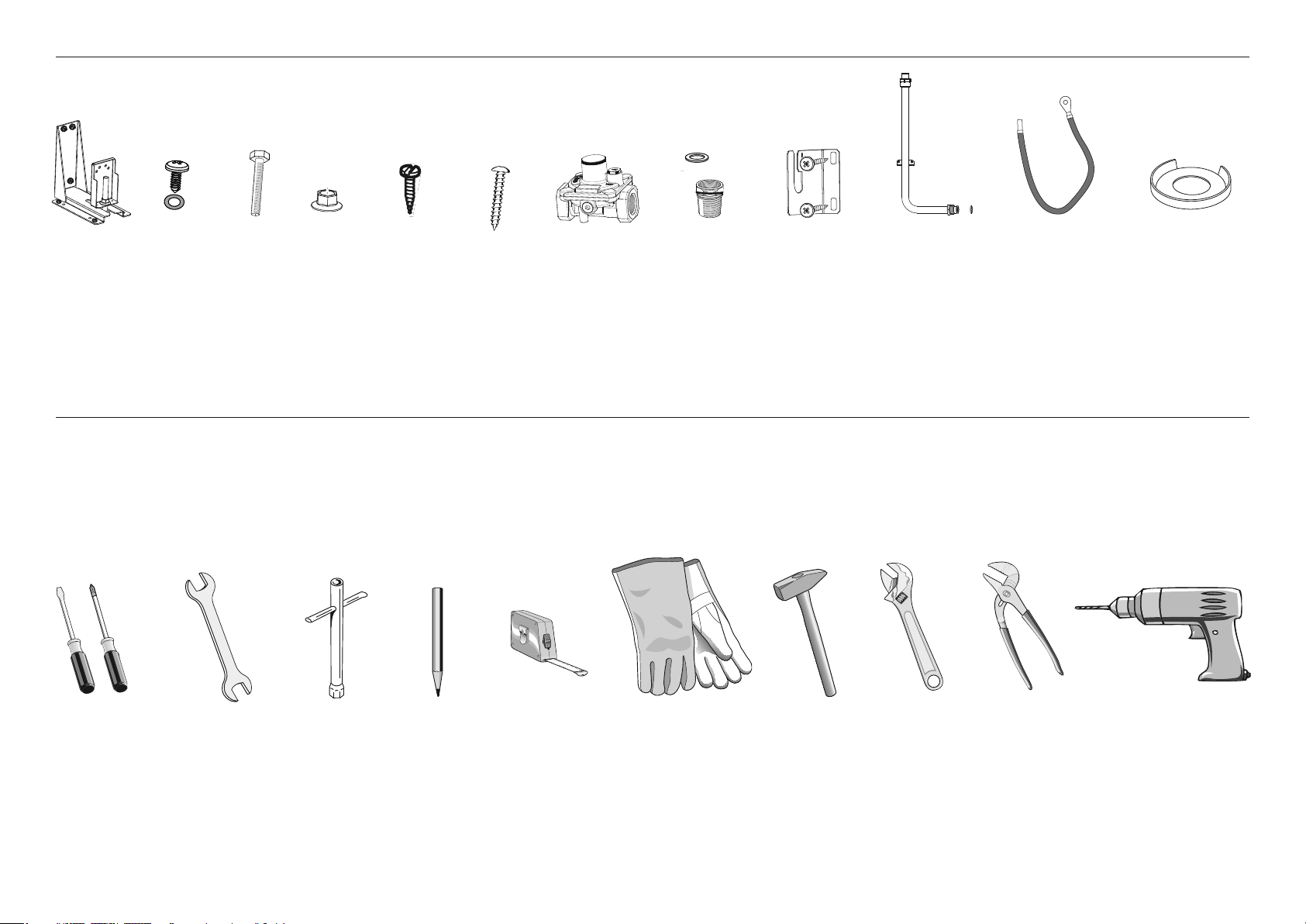

PARTS SUPPLIED FOR INSTALLATION

Anti-tip

bracket (1)

Small

screws &

washers

(2)

Bolt (1) Pressure

Threaded

nuts (2)

Wood

screws (8)

Screws

and plastic

sleeve

anchors (8)

regulator (1)

1/2" (12.7mm)

NPT connector

and gasket (1)

TOOLS NEEDED FOR INSTALLATION (NOT SUPPLIED WITH THE APPLIANCE)

IMPORTANT!

This appliance must be installed by a qualified installer.

z

Improper installation, adjustment, alteration, services, or maintenance can cause injury or property damage.

Consult a qualified installer, service agent, or the gas supplier.

z

The use of suitable protective clothing/gloves is recommended when handling or installing this appliance.

Gas extension

pipe support

bracket (1) and

screws (2)

Gas extension

pipe and

gasket (1)

Ground lead*

(3 wire permanent

connection)

*Can be used in US only, for Canada it is

mandatory to connect the range by using

cordset with plug supplied.

Cupped washer*

(4 wire permanent

connection)

Screwdriver 2 – Wrench T-handle

wrench

Pencil Tape measure Suitable

protective

gloves

Hammer Adjustable

wrench

Adjustable

pliers

Drill

5

Model features may vary

36" GAS GAS MODELS

OR36SCG4

OR36SDG4

MODEL IDENTIFICATION

36" DUAL FUEL MODELS

OR36SCG6

OR36SDG6

PRIOR TO INSTALLATION

Unpacking and handling

z

Inspect the range to verify that there is no shipping damage. If any damage is detected, call the shipper and initiate a damage claim. Fisher & Paykel is not responsible for shipping damage.

z

DO NOT discard any packing material until the range has been inspected.

z

Remove the outer carton and any packing material from the range. Some models are supplied with a protective film on steel and aluminum parts.

This film must be removed before installing or using the appliance.

6

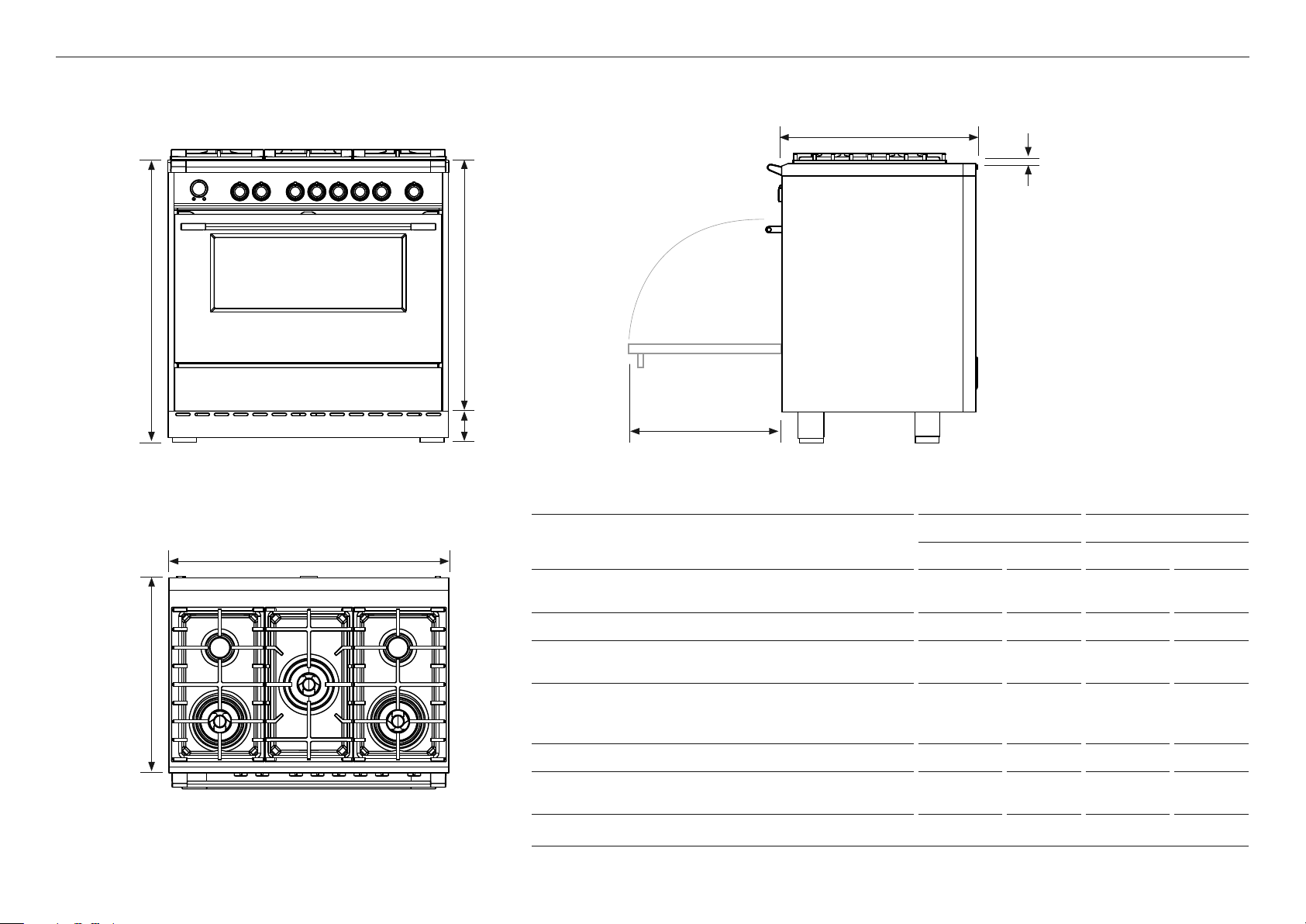

Note: Model features may vary

Optional kickstrip is available (purchased separately)

PRODUCT DIMENSIONS

C

D

EA

F

G

C

FRONT

B

PLAN

PROFILE

OR36S GAS GAS OR36S DUAL FUEL

PRODUCT DIMENSIONS

INCHES MM INCHES MM

A Overall height of product (from floor to top of cooktop,

excl. grates and island trim/backguard)

B Overall width of product

min 35 3/8

max 37 1/4

35 7/8 911 35 7/8 911

min 898

max 946

min 35 3/8

max 37 1/4

C Overall depth of range (from front of range to rear of

island trim/backguard, excl. handles and dials) 25 1/4 641 25 1/4 641

D Height from top of cooktop to top of

z

Island trim (fitted)

z

Backguard (optional)

E Height of chassis (excl. adjustable feet)

F Adjustable feet height min 3 3/8

G Depth of open door to front of range

*Level with cooktop.

7/ 8

3

22

76

Level*

3

32 813 32 813

max 5 1/4

min 85

max 133

min 3 3/8

max 5 1/4

17 3/4 451 17 3/4 451

min 898

max 946

Level*

76

min 85

max 133

7

CLEARANCE DIMENSIONS

A

E

D

B

C

Cooking surface

H

G

Electrical & gas

(see diagrams following)

F

ISO FRONT

OR36S GAS GAS OR36S DUAL FUEL

CLEARANCE DIMENSIONS

INCHES MM INCHES MM

A Width of ventilation hood installed above range min 36 min 914 min 36 min 914

B Vertical distance between countertop and cabinet extending above counter min 18 min 457 min 18 min 457

C Clearance from left and right edge of range to nearest vertical combustible surface min 11 13/16 300 min 11 13/16 300

D Clearance from cooking surface to:

z

Overhead cabinet centered above the cooktop (combustible/unprotected)*

z

Overhead cabinet centered above the cooktop (non-combustible/protected)*

z

Ventilation hood** centered above the cooking surface

min 36

min 30

min 30

min 914

min 762

min 762

See notes #1 and #2.

E Depth of overhead cabinetry max 13 max 330 max 13 max 330

F Width of cabinetry opening 36 914 36 914

G Height of cabinetry immediately adjacent to the range

max 37 1/2 max 953 max 37 1/2 max 953

(from floor to countertop)***

H Depth from wall to cabinetry face max 25 1/4 max 641 max 25 1/4 max 641

8

C

min 36

min 30

min 30

min 914

min 762

min 762

Note #1

To eliminate the risk of burns or fire by reaching

over heated surface units, cabinet storage

space located above the surface units should be

avoided. If cabinet storage is to be provided, the

risk can be reduced by installing a rangehood

that projects horizontally a minimum of 5" (127mm)

beyond the bottom of the cabinets.

Note #2

=36" (914mm) minimum clearance between

D

the top of the cooking surface and the bottom

of an unprotected wood or metal cabinet; or

=30" (762mm) minimum when bottom of

D

wood or metal cabinet is protected by not

less than 1/4"-thick flame retardant millboard

covered with not less than No. 28 MSG sheet

steel, 0.015"-thick stainless steel, 0.024"-thick

aluminum, or 0.020"-thick copper.

Other notes:

z

This range may be installed directly adjacent

to existing 36" (914mm) high base cabinets.

z

If the range is to be placed adjacent to cabinets,

the clearances shown are required. The same

clearances apply to island installations.

z

The range can be placed in various positions

with respect to the cabinet front, with the

control panel either flush or projecting,

depending on the cabinetry depth.

z

The electrical and gas supply should be within

the zones shown in the following diagrams.

z

Any openings in the wall behind the range and

in the floor under the range must be sealed.

z

Always keep the appliance area clear and

free from combustible materials, gasoline and

other flammable vapors and liquids.

z

Do not obstruct the flow of combustion and

ventilation air to the unit.

*Non-combustible surfaces:as defined in

‘National Fuel Gas Code’ (ANSI Z223.1, Current

Edition). Clearances from non-combustible materials

are not part of the ANSI Z21.1 scope and are not

certified by UL.

**Refer to local/national codes for

ventilation requirements.

***Depending on the height of the feet adjustment.

The cooking surface must sit flush or above

countertop level.

FITTING THE OPTIONAL BACKGUARD

LOCATION OF ELECTRICAL & GAS SUPPLY

Island trim and backguard

z

It is mandatory to install and use the appliance with

either the island trim or the optional backguard

correctly in place.

z

The island trim is already fitted to the appliance while

the backguard can be purchased as a separate kit.

z

If replacing the island trim with the backguard,

assemble it by using the same screws/spacers used

for fixing the island trim.

Grounded outlet

(Gas Gas)

z

The electric cord with

3-prong ground plug

(NEMA 5-15P) has

a length of 72"

(1830mm).

Grounded outlet

(Dual Fuel)

z

The electric cord with

4-prong ground plug

(NEMA 14-50P) shall

have a minimum length

of 48" (1220mm beyond

the back of the range.

Left side

of cavity

Final position of cooker

against wall

E

GasElectricity

Floor

B

CDAA

SUPPLY AREA DIMENSIONS

INCHES MM

A Distance from either edge of product to supply area 1/4 6

B Height of supply area (from floor) 8 1/8–10 1/8* 207–257*

C Width of gas supply area 23 9/16 599

D Width of electrical supply area 11 13/16 300

E Depth of supply area (ie max. protrusion of gas and

4 1/2 115

electrical connection from wall)

*Depending on adjustment of feet.

9

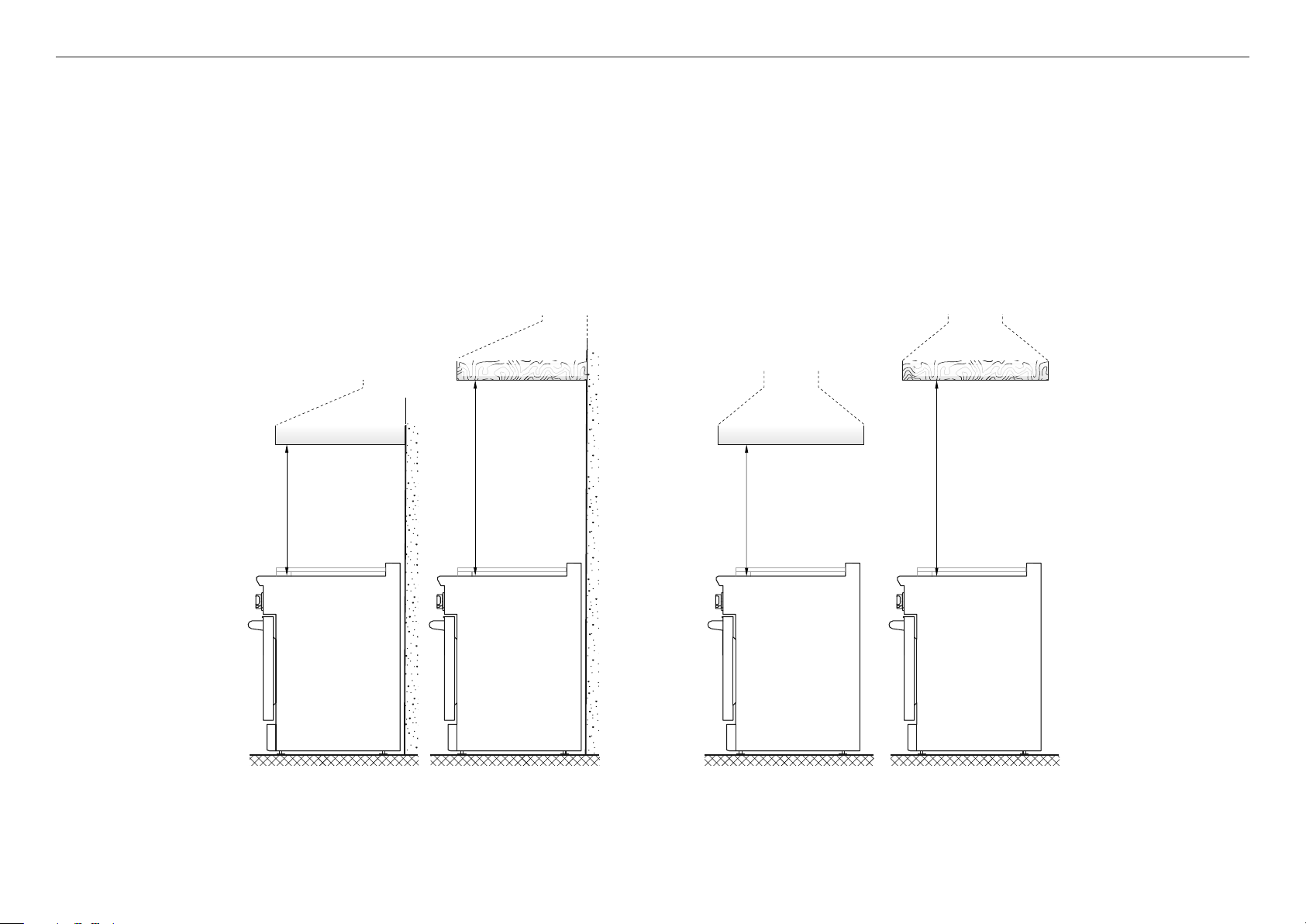

VENTILATION REQUIREMENTS

A suitable ventilation hood may be installed above the range.

Fisher & Paykel has a choice of ventilation hoods designed to match the rest of our kitchen appliance family. See fisherpaykel.com or your local dealer for more details.

IMPORTANT

z

Consult local building codes and/or local agencies, before starting, to ensure that hood and duct installation will meet local requirements.

z

Hood blower speeds should be variable to reduce noise and loss of heated or air conditioned household air when maximum ventilation is not required.

Normally, the maximum blower speed is only required when using the grill or the self-cleaning cycle.

z

If a custom hood canopy contains any combustible materials (eg a wood covering) it must be a minimum of 36" (914mm) above the cooking surface.

z

Due to a high volume of ventilation air, a source of make-up air (outside replacement air) that complies with local codes and regulations is required.

Hood

(non-combustible)

min 30"

(762mm)

Hood (inc. combustible, for

example a wood surround)

min 36"

(914mm)

Hood

(non-combustible)

min 30"

(762mm)

Hood (inc. combustible, for

example a wood surround)

min 36"

(914mm)

10

Wall Installation

Island Installation

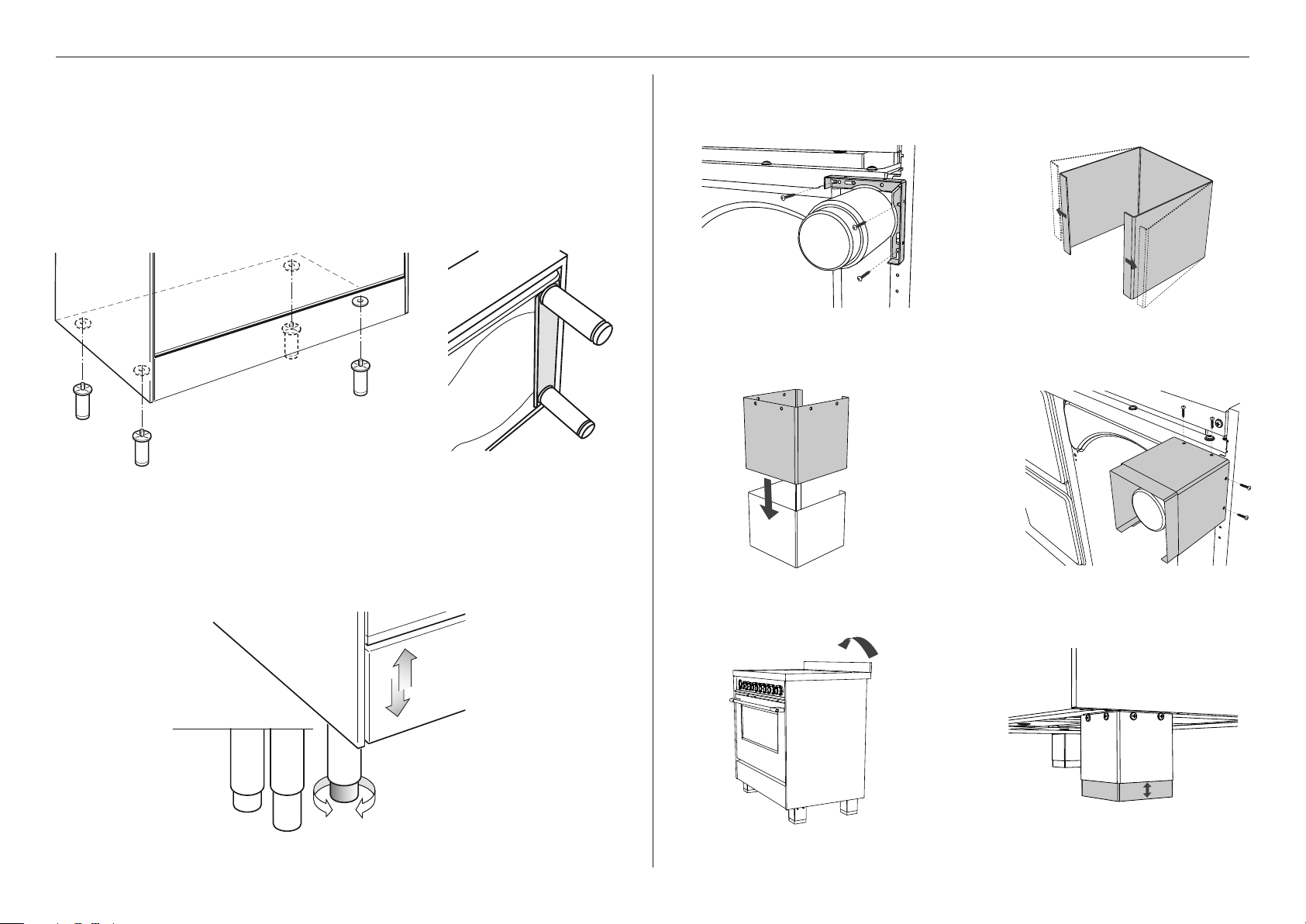

FITTING THE ADJUSTABLE FEET

Fitting the adjustable feet

The adjustable feet must be fitted to the base of the range before use.

Rest the rear of the range on a piece of the polystyrene packaging exposing

the base for the fitting of the feet.

IMPORTANT

Take care not to damage the range during this operation.

Fit the four legs by screwing them tight into the support base as shown.

Levelling the range

z

The range may be levelled by screwing the lower ends of the feet IN or OUT.

z

Small adjustments may be made to the range in the upright position, however it

may be necessary to tip the range again to make larger adjustments.

Fitting the adjustable (front) feet covers (optional)

If using the adjustable feet covers fit these while the range is tipped over.

1 Tip range onto its back and fix

brackets to mounting holes.

3 Slot the outer panels over the

tensioned inner panels.

2 Gently bend the sides of the inner

panels outwards to tension.

4 Secure covers to brackets using

the provided screws

5 Stand range back upright. 6 Adjust the inner panels of the foot

covers to suit height of range feet.

11

FITTING THE ADJUSTABLE FEET

Fitting the adjustable (rear) feet covers (optional)

If installing rear feet covers use the following instructions to attach the mounting

brackets to the base of the range.

CABB

Washers

1 Remove screws A, B and C from

the plate on the base of the range.

IMPORTANT!

z

When raising the range to upright

position always ensure two people

carry out this manoeuvre to prevent

damage to the adjustable feet.

z

Be careful: do not lift the range by

the oven door handle, the hob rail

or the cooktop trim as this may

damage the appliance.

z

When moving range to its final

position DO NOT DRAG.

Lift feet clear of floor.

2 Replace screw C with one of the

screws supplied with the feet covers.

z

This screw must be replaced before

attaching the mounting bracket to the

base of the range.

MOVING THE RANGE

3 Attach the mounting bracket to

the base of the range using the

supplied screws.

z

Ensure the two supplied washers

are fitted between the rear edge

of the bracket and the base of the

range (as shown).

4 Secure covers to brackets using the

provided screws.

12

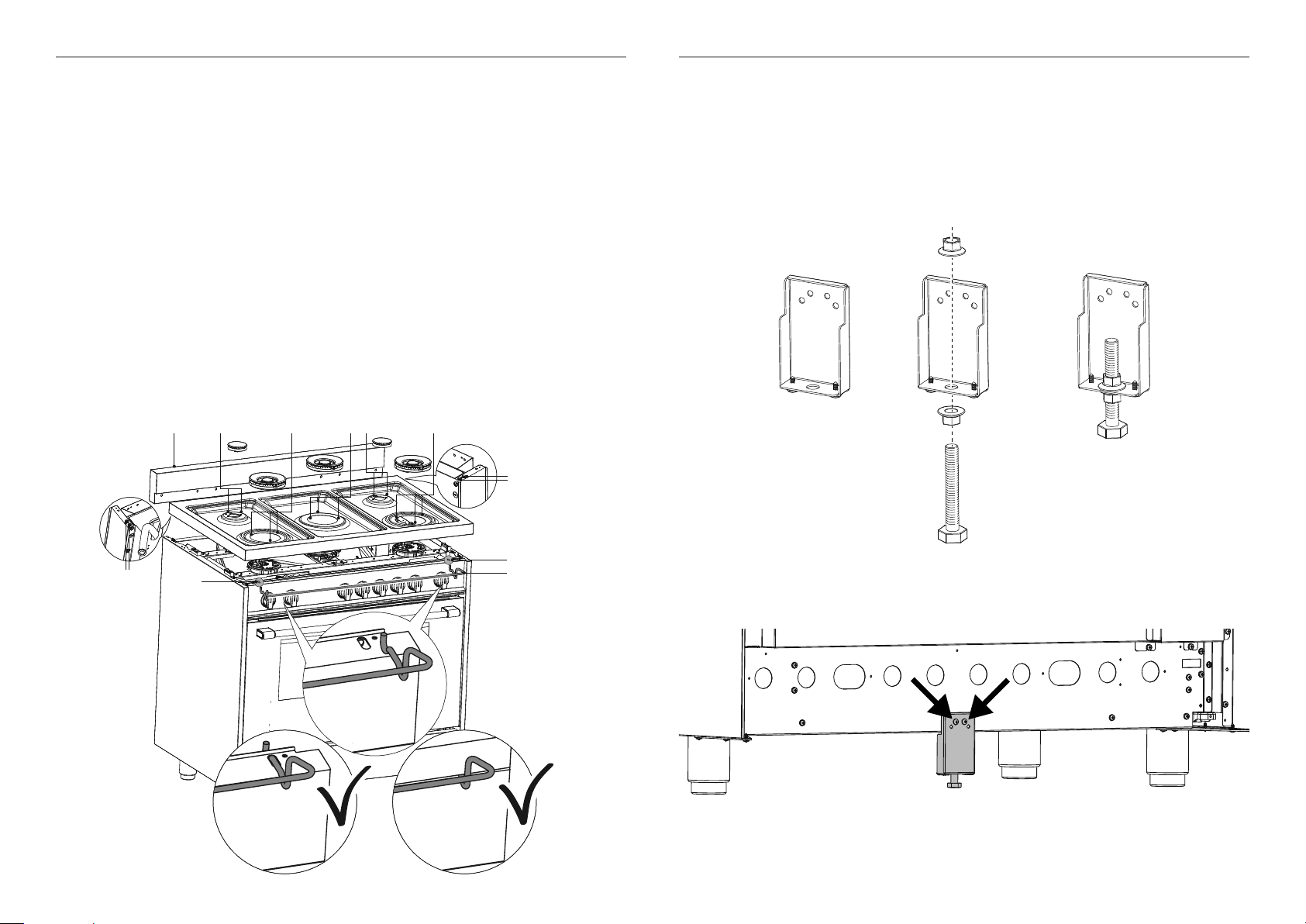

INSTALLING THE COOKTOP FRONT GUARD

INSTALLING THE ANTI-TIP BRACKET

Models without hob rail only

To increase the clearance between the front edge of the cooktop and

the burners it is possible to install the cooktop front guard supplied with the appliance.

IMPORTANT

To install or remove the guard it is necessary to remove the cooktop.

Attempting to install or remove the guard without disassembling the cooktop will result

in permanent damage to the appliance.

Install the front guard as shown:

1 Remove the backguard or island trim A (see ‘Fitting the optional backguard’)

2 Remove the grates, the burner caps and the flame spreaders.

3 Unscrew cooktop fixing screws B and C.

4 Remove the cooktop. Note: Take extra care not to damage the gaskets fitted above

the burner cups (below the cooktop). If they are damaged they must be replaced.

5 Install the front guard D by inserting the wire terminals into the corresponding holes

above the control panel E.

6 Reassemble the cooktop and the other components.

Note: Take extra care not to damage the gaskets fitted above the burner cups

(below the cooktop). If they are damaged they must be replaced.

A BBBBB

C

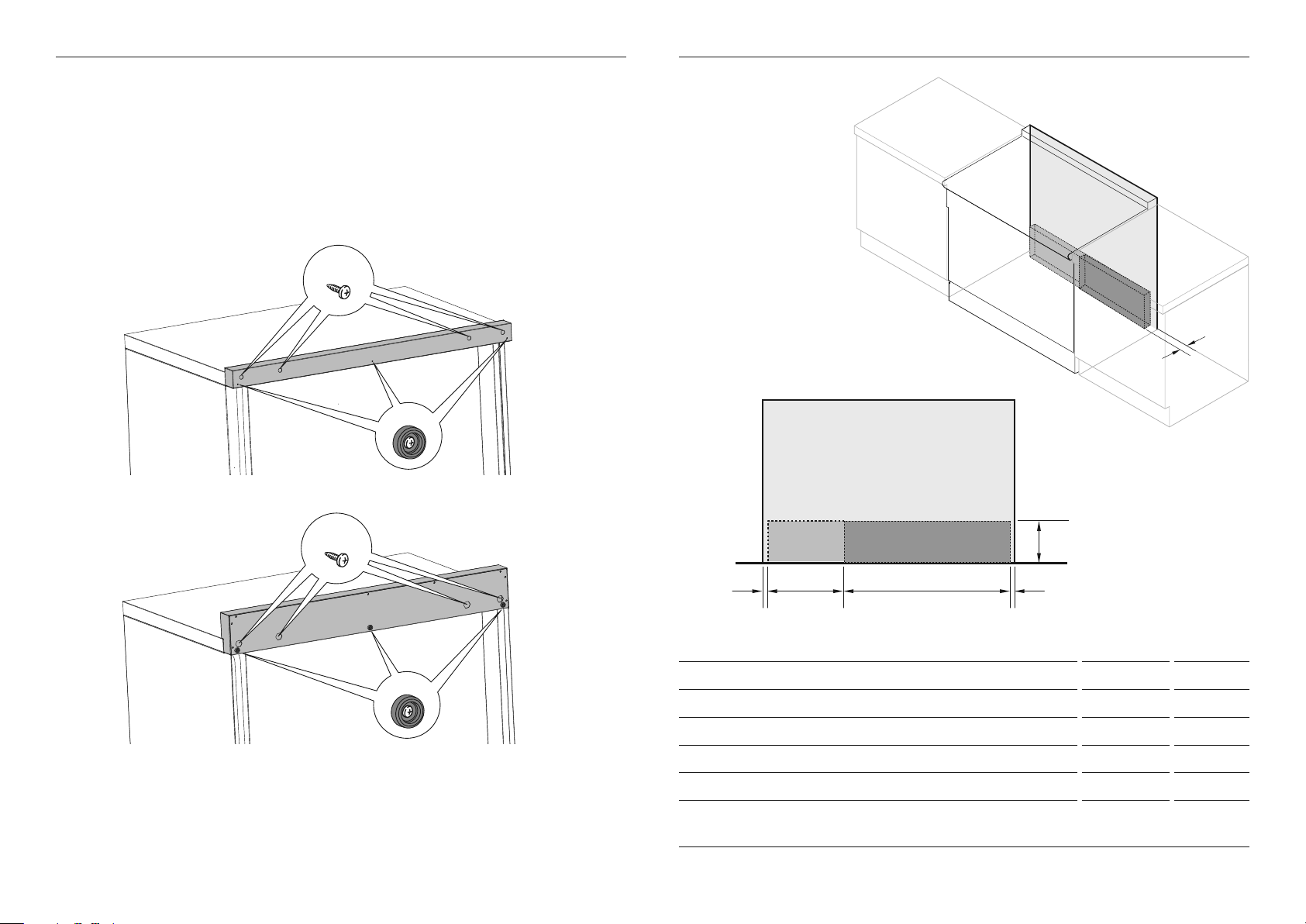

The anti-tip bracket has two components:

z

the adjustable bracket

z

the stability bracket

IMPORTANT!

You must install both parts of the anti-tip bracket and ensure they are properly fitted

together to prevent the range from tipping.

To fit the anti-tip bracket

123

CC

C

E

E

D

1 Thread the bolt through the adjustable bracket and fix in place using the two supplied

nuts. Ensure the nuts are well tightened.

2 Fix the adjustable bracket to the back of the range (centered on the lower edge) using

the two supplied screws and washers.

13

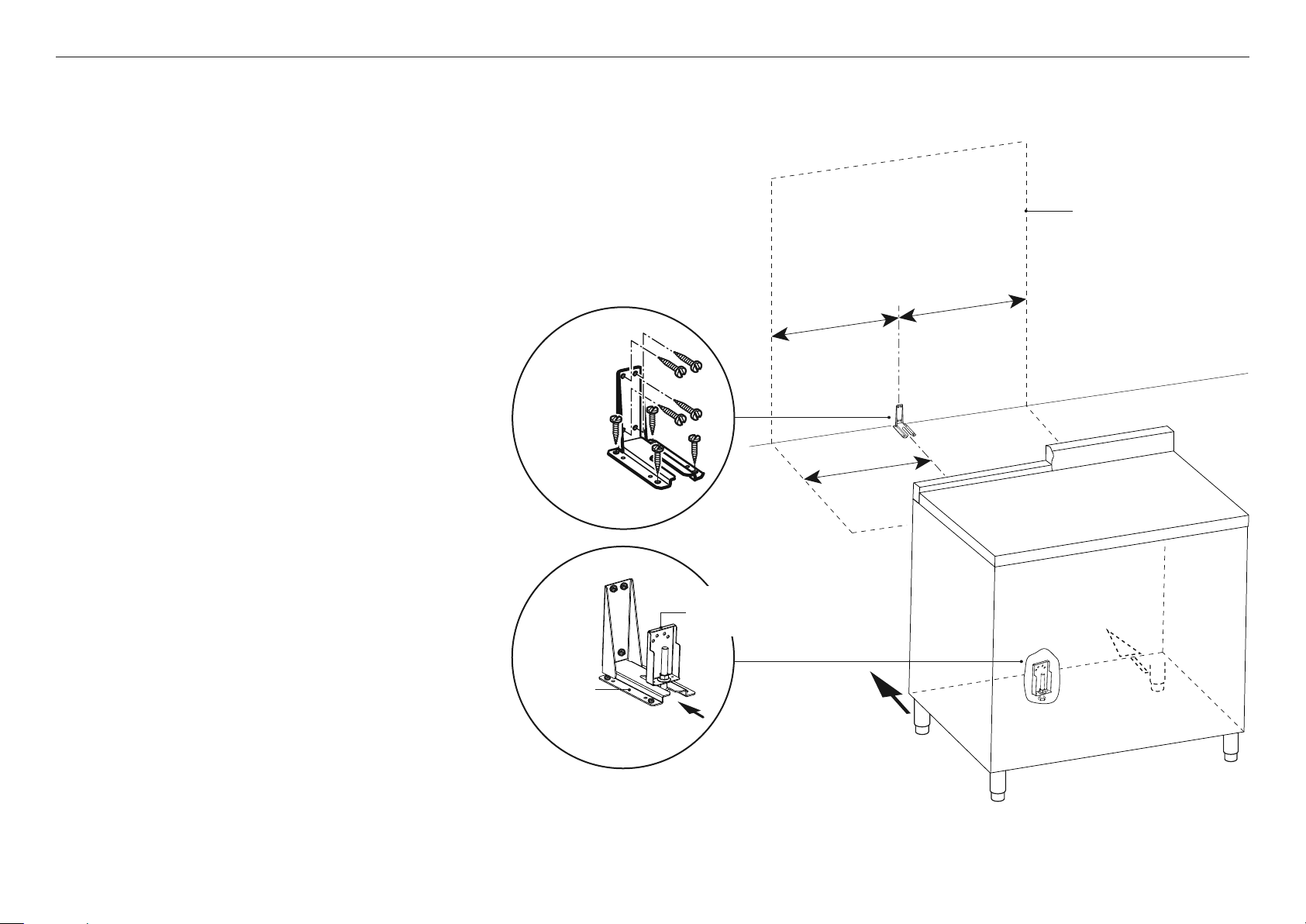

3 Fix the stability bracket in place. It can be fixed as follows:

=

=

z

To the floor OR on the rear wall by #4 screws (supplied).

z

To the floor AND on the rear wall by #8 screws (supplied).

z

There are 8 x wood screws and 8 x screws with plastic

sleeve anchors supplied with the range in two separate kits.

Use the proper screws according to the type of material on

the floor and/or wall.

z

If using the the plastic sleeve anchors: drill 5/16" (8mm)

diameter holes and insert the supplied plastic sleeve anchors

before attaching the stability bracket with the screws.

4 Slide the range into place, ensuring the bolt on the adjustable

bracket slots under the stability bracket.

z

Adjust the length of the bolt as necessary. Ensure the two nuts

are well tightened after any adjustments.

IMPORTANT!

z

Use the proper screws to fix the stability bracket in place

according to the type of material on the floor and/or wall.

z

Before drilling and holes or inserting any screws into the floor

or wall check that you will not damage any wiring or pipes.

INSTALLING THE ANTI-TIP BRACKET

Stability

bracket

17 15/16"

(456mm)

Dotted line

showing the

position of the

range when

installed

14

Adjustable

bracket with

bolt correctly

fitted

Stability

bracket

ELECTRICAL CONNECTION

WARNING!

Electrical Shock Hazard

Plug into a grounded outlet.

Do not remove ground prong.

Do not use an adapter.

Failure to follow these

instructions can result in death,

fire, or electrical shock.

WARNING!

VERY IMPORTANT

Before any operation of

maintenance disconnect

the appliance from the

electrical main supply.

OR36 Dual Fuel models ONLY

If codes permit and a separate ground wire is used, it is recommended

that a qualified electrician determine that the ground path is adequate.

Be sure that the electrical connection and wire size are adequate

and in conformance with:

O

ANSI/NFPA 70 latest edition and local codes and ordinances.

O

CSA Standard C22.1, Canadian Electrical Code, Part 1 – latest edition,

and all local codes and ordinances.

ONLY FOR CANADA:

A copy of the above code standards can be obtained from:

CANADIAN STANDARDS ASSOCIATION

178 Rexdale Boulevard, TORONTO, ON M9W 1R3, CANADA

z

Do not ground to a gas pipe.

z

Check with a qualified electrical installer if you are not sure the range

is properly grounded.

z

Do not have a fuse in the neutral or ground circuit.

z

When a 4-wire, two phase 240-208/120-volt, 60Hz, AC-only electrical

supply is available, a 30 A maximum circuit protection is required,

fused on both sides of the line.

z

A time-delay fuse or circuit breaker is recommended

Recommended ground method

z

This range is equipped with a Certified Power Cord intended to be

plugged into a standard 14-50R wall receptacle. Be sure the wall

receptacle is within reach of range’s final location.

z

Do not use an extension cord.

z

In the case of substitution of the power cord always replace it with

a suitable UL or CSA approved one (with the same technical features

of the replaced cord).

z

Tighten the power cord by using only the power cord strain relief

bracket supplied with the appliance.

z

Allow enough slack to easily attach the cord terminals to the

terminal block.

z

These operations must be carried out only by an

authorized technician.

Standard NEMA

14-50R wall

receptacle

OR36 Gas Gas models ONLY

If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that

the ground path is adequate.

Check with a qualified electrician if you are not sure whether

the range is properly grounded.

Do Not ground to a gas pipe.

z

A 120-volt, 60-Hz, AC-only, 15 A, fused electrical

supply is required.

z

A time-delay fuse or circuit breaker is recommended.

z

It is recommended that a separate circuit serving only this

appliance be provided.

z

The outlet must be checked by a qualified electrician to see

if it is wired with correct polarity.

z

This appliance, when installed, must be electrically grounded

in accordance with local codes.

Recommended ground method

z

For your personal safety, this range must be grounded.

z

This range is equipped with a 3-prong ground plug.

z

To minimize possible shock hazard, the cord must be plugged

into a mating 3-prong ground-type outlet, grounded in

accordance with the National Electrical Code ANSI/NFPA 70

latest edition and local codes and ordinances.

z

If a mating outlet is not available, it is the personal responsibility

and obligation of the customer to have a properly polarized and

grounded, 3-prong outlet installed by a qualified electrician.

IMPORTANT!

The third (ground) prong should not, under ANY circumstances,

be cut or removed.

3-prong

polarized

ground-type

3-prong

ground plug

outlet

IMPORTANT!

The fourth (ground) prong should

not, under ANY circumstances, be

cut or removed.

Power supply

cord

Power supply cord with

NEMA 14-50P plug

Ground prong

15

ELECTRICAL CONNECTION

PENL1 L2

NL1 L2

PE

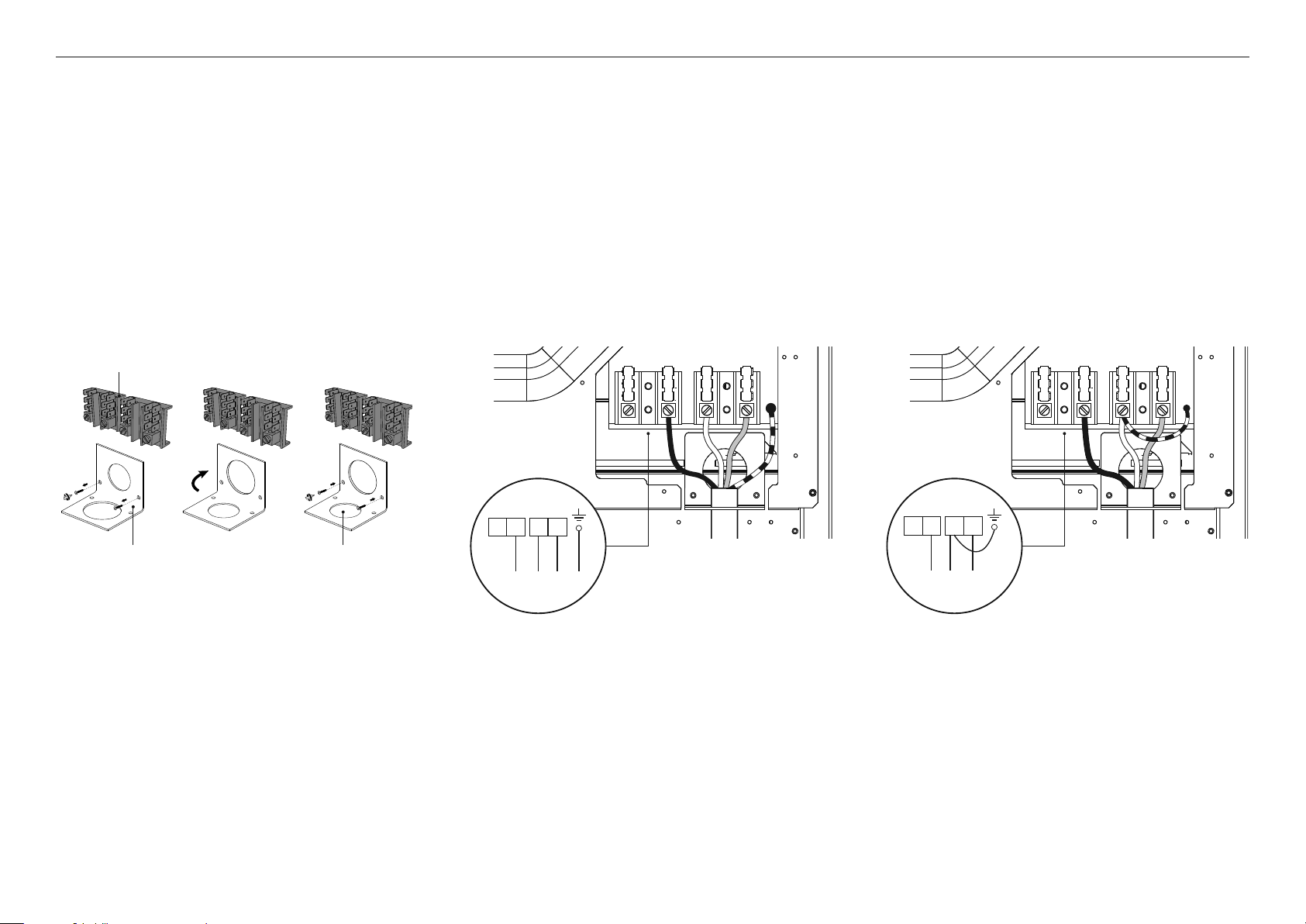

PERMANENT CONNECTION (HARD WIRING)

US only, for Canada it is mandatory to connect the range

by using cordset with plug supplied.

z

Units may be hard wired to the power supply. The

installer must provide approved flexible aluminium

conduit, 3/4" (19mm) trade size, maximum 6ft (1.8m)

long. Locate the terminal block on the rear of the unit and

remove access cover.

z

The strain relief bracket orientation must be

switched in order to accommodate for a permanent

wiring connection:

1 Remove the factory supplied power cord with plug.

2 Remove the 2 screws on the bracket.

3 Re-secure bracket with the 2 screws so that the 1 1/8"

(29mm) smaller opening is facing down.

Terminal Block

1 23

123

4-Wire Connection

1 Loosen the L1 (black), L2 (red) and neutral (white) screws.

2 Mount the conduit fitting to the 1 1/8" (29mm) hole in the

strain relief bracket.

3 Secure the neutral (white) power lead to the center

terminal and tighten the screw.

4 Secure the L1 (black) and the L2 (red) power leads to the

terminals immediately to the left (L1) and right (L2) of the

neutral terminal. Tighten the screws.

5 Secure the Ground (green) lead to the green screw

located to the right of the terminal block using the

supplied cupped washer. The end of the grounding

conductor must be retained by the cupped washer.

6 Check all connections are securely tightened.

7 Reinstall the Terminal Block cover.

3-Wire Connection (using supplied Ground lead)

1 Loosen the L1 (black), L2 (red) and neutral

(white) screws.

2 Mount the conduit fitting to the 1 1/8" (29mm) hole

in the strain relief bracket.

3 Secure the supplied Ground (green) lead to the

grounding screw to the right of the terminal block.

4 Secure the Neutral (white) power lead together with

the free end of the Ground (green) lead to the center

terminal. Tighten the screw.

5 Secure the L1 (black) and the L2 (red) power leads to

the terminals immediately to the left (L1) and right (L2)

of the neutral terminal. Tighten the screws.

6 Check all connections are securely tightened.

7 Reinstall the Terminal Block cover.

Strain relief bracket

z

The conduit must be installed to the terminal block using

Smaller opening

an approved conduit connector. The free end of the

conduit must be connected to a junction box provided in

the electrical supply zone.

z

Mount a strain relief (not provided) into the 1 1/8" (29mm)

diameter hole located below the terminal block. Wiring

for the unit is to be brought into the terminal block

through the conduit and through the strain relief. Make

suitable connections to the terminal block provided.

z

Installer — Show the owner the location of the circuit

breaker. Mark it for easy reference.

16

GAS CONNECTION

Gas requirements

All gas connections must be made according to national and local codes.

The gas supply (service) line must be the same size or greater than the inlet

line of the appliance. Sealant on all pipe joints must be resistant to the action

of LP/Propane gas.

z

The range is equipped for the use with NATURAL gas. It is design-certified by

CSA International for NATURAL (and LP gases with appropriate conversion).

z

Any conversion required must be performed by your dealer or a qualified licensed

technician or gas service company. Please provide the service person with this manual

before work is started on the range. (Gas conversions are the responsibility of the

dealer or end user.)

z

The model/serial rating plate, located below the bottom drawer, has information

on the type of gas that can be used.

z

If this information does not agree with the type of gas available, check with the

local gas supplier.

Natural gas

z

Supply Pressure: 4" W.C.P.

LP gas

z

Supply Pressure: 11" W.C.P.

z

A regulator is required at the LP source to provide a maximum pressure

of 14" W.C. to the range regulator.

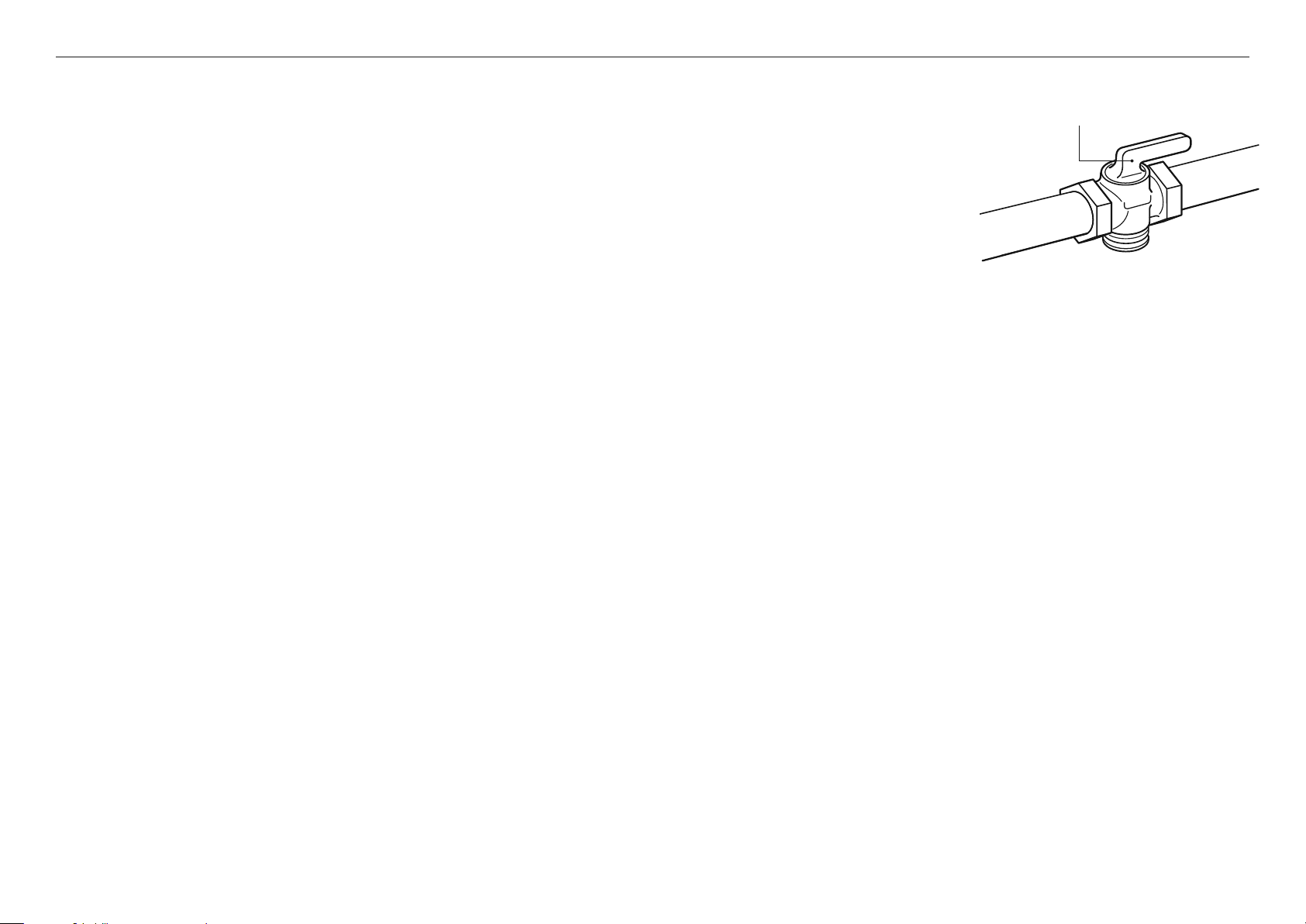

Manual shut-off valve

z

A manual shut-off valve must be installed

in an accessible location in the gas line

Shut-off valve

‘open’ position

external to the appliance for the purpose

of turning on or shutting off gas to the

appliance (In Massachusetts such shutoff

devices should be approved by the

Board of State Examiners of Plumbers

Gas supply

line

& Gas Fitters).

z

This valve should be located in the same

To range

room as the range and should be in a

location that allows ease of opening

and closing (in a position where it

can be reached quickly in the event

of an emergency).

z

Do not block access to the shutoff valve.

The valve is for turning on or shutting off gas to the appliance.

IMPORTANT!

Fisher & Paykel recommends installing the manual shutoff valve in a location readily

accessible by the customer, so that gas to the appliance can be shut off in an emergency

situation. However, the appliance must not be modified in any way to accommodate

such placement.

z

The gas supply line must not protrude beyond the back of the appliance.

z

Make sure the gas supply is turned off at the wall valve before connecting the appliance.

z

Leak-testing of the appliance shall be conducted according to the manufacturer’s

instructions. See instructions following.

z

When hooking up the gas supply from the wall hard pipe to the range hard pipe,

installation length of flex line between range/wall hard piping must accommodate range

being pulled from wall for cleaning or servicing purposes. When range is pulled from

wall, no strain should occur at range or wall hard pipe connections.

17

Loading...

Loading...