Fisher & Paykel DOUBLE DISHDRAWER DD603I, DS603I Accessory Installation Manual

open

5

/16

(8mm)

gap between

panels

BEFORE YOU START

FOR INTEGRATED DOUBLE MODELS DD603I

(NOTE: FOR SINGLE

R

MODELS, REFER TO BACK OF THIS BOOK)

DOUBLE

R

INTEGRATED PANEL PREPARATION

part number 526608 J

06/2004

(page 1 of 6)

US

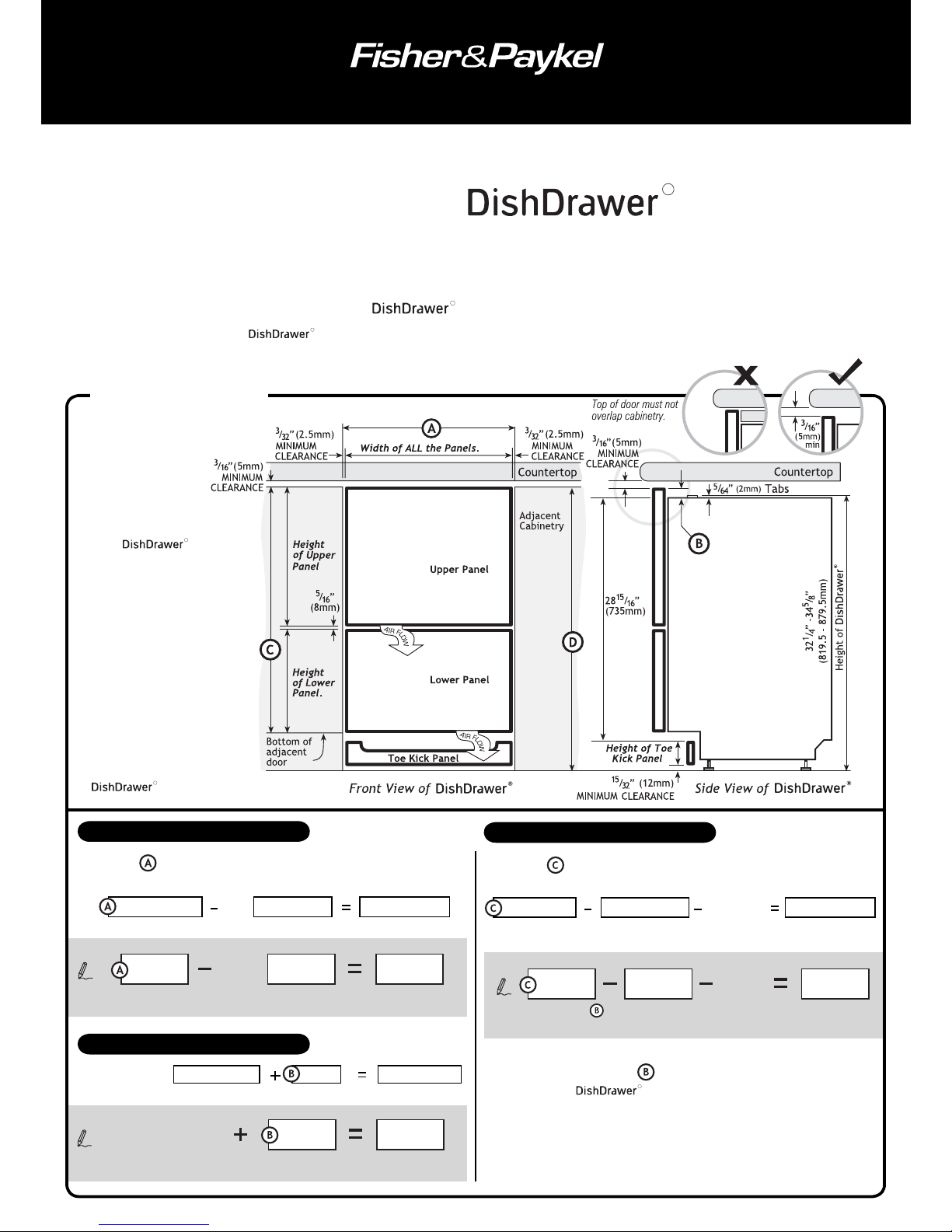

WIDTH OF ALL PANELS

Measure the width between adjacent door/drawer fronts and write it

in the first box below, then complete the equation. For example:

2x

door clearance

(

3

/32” (2.5mm) MIN)

HEIGHT OF UPPER PANEL

For example: 155/8” (398mm) 0mm 155/8” (398mm)

155/8 (398mm)

door extension

(0” recommended)

height of upper panelstandard height

HEIGHT OF LOWER PANEL

Measure

door/drawer height (or equivalent) and write it in the first

box below, then complete the equation. For example:

height of lower panel

(12

17

/64” (311.5mm) MIN)

MIN 28

1

/4” (717.5mm) + height of upper panel

Note: The ‘Door Extension’ allows for the top of the Upper Panel

to be above the

R

where required.

Important!

The air vent between the Upper and Lower Panels must not be

covered. An air gap of

5

/16” (8mm) MUST be provided.

PLEASE NOTE: Your model of

R

may differ from the model shown in the diagrams. Diagrams have been simplified to enable clearer instruction.

FOLLOW THESE INSTRUCTIONS BEFORE REFERRING TO PRODUCT INSTALLATION INSTRUCTION SHEET P/N 526607.

The Door and Toe Kick Panels

of the

R

can be

made to match your kitchen

cabinetry. This diagram,

with the addition of your own

measurements will help you

calculate the required panel

sizes.

CABINETRY ALIGNMENT

The following calculations

assume:

The top of the Upper Panel is

to be aligned with the top of

the adjacent cabinetry. The

final panel/cabinetry alignment

is achieved by adjusting the

R

’s feet

door clearance

standard height

door extension

width of all panels

width of all panels

(23

7

/16” (595mm) MIN)

height of upper panel

height of upper panel air gap height of lower panel

241/4” (616mm)

2 x

3

/32” (2.5mm)

24

1

/16” (611mm)

30” (762mm)

15

5

/8” (398mm)

14

1

/16” (356mm)

5

/16” (8mm)

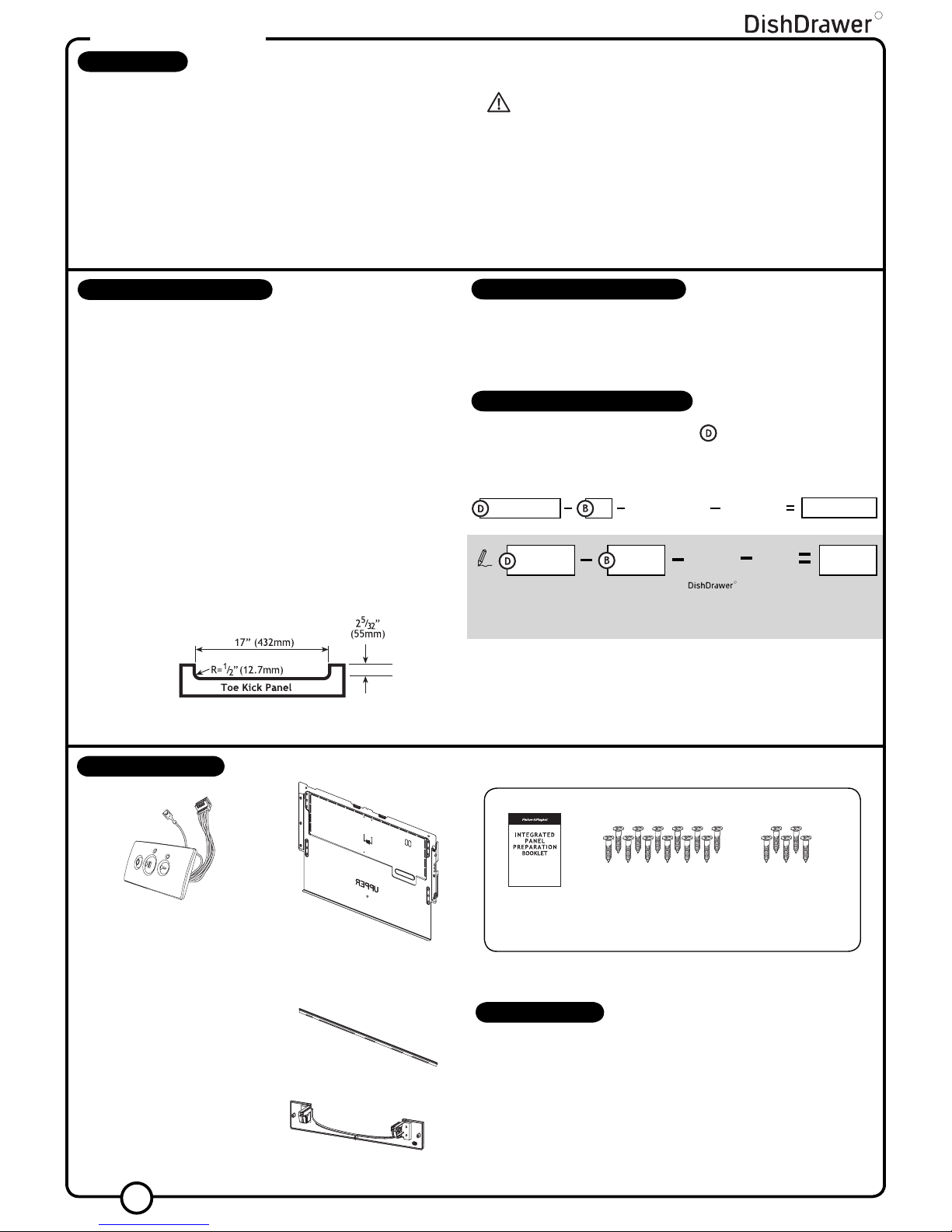

BEFORE YOU START

PARTS SUPPLIED

INTEGRATED PARTS KIT part no. 526674

Panel

Preparation

Booklet (1)

TOOLS NEEDED

Safety Glasses, Tape Measure, Pencil, Needle-Nose Pliers, Drill & Phillips

Bit or Phillips Screwdriver,

ø 1” (25.4mm) Boring Bit or ø 1” (25.4mm)

Hole Saw, Small Hand or Jig Saw.

IMPORTANT

INTEGRATED PANEL THICKNESS

Upper and Lower Panel minimum thickness is 5/8” (16mm). Panel

thicknesses above

11

/16” (18mm) can be accommodated but product depth

will increase accordingly.

INTEGRATED PANEL MATERIAL

Drawer Front material must be suitable for damp conditions

(122

o

F/50oC @ 80% RH) and adequately sealed to withstand moisture.

Additional protection can be provided by using a “Moisture Resistant

Board”. Taping edges alone may not provide adequate sealing. For

painted panels, radius all rear edges to improve sealing.

2

R

TOE KICK PREPARATION

TOE KICK OPTIONS

A) The Black Prefinished Toe Kick Panel is supplied. Refer to Installation

Instructions for preparation.

B) The Black Prefinished Toe Kick Panel can also have a front panel of

your choice attached to it using screws or an adhesive.

C) A Toe Kick panel of any material with thickness from

3

/8” - 3/4”

(9-19mm) can be screwed to a plastic Toe Kick Mounting Bracket

(supplied).

TOE KICK PANEL INSTALLATION DEPTH

When using a rectangular Toe Kick, the maximum depth, excluding the

Toe Kick Panel is 2

5

/8” (67mm).

To move the Toe Kick deeper the Toe Kick Panel must have the profile

shown in the diagram below cut out of it. The maximum Toe Kick depth

with the cut out excluding the Toe Kick Panel is 5” (127mm).

WIDTH OF TOE KICK PANEL

Refer to “Width of All Panels” on page 1.

[Height of adjacent

cabinetry]

HEIGHT OF TOE KICK PANEL

Refer to the diagram on page 1. Measure the height from the top of the

adjacent cabinet door fronts to the floor and write it in the first box below,

then complete the equation.

For example:

[

R

dimension]

[MIN

clearance]

[height of Toe

Kick Panel,

MIN 2

3

/4”

(70.5mm)]

IMPORTANT

WARNING!

BE SURE THE PRODUCT IS NOT PLUGGED IN.

Important!

The installation of the Panels requires an electrical

connection and must be performed by a suitably

qualified person.

Panel

Mounting

Screws (12)

Toe Kick

Mounting

Screws (5)

Door Front Seal (2)

p.n 526466

Mounting Bracket (2)

(Upper and Lower)

p.n 526440 & 526441

Integrated Rectangular Badge (2)

(Satin Chrome supplied)

p.n 526975

Other Badges Available

Rectangular:

Bright Chrome Kit p.n 527276

Brass Kit p.n 527277

Eliptical:

Black Kit p.n 526683

Satin Chrome Kit p.n 526684

Bright Chrome Kit p.n 527156

Brass Kit p.n 526685

Toe Kick Mounting Bracket (1)

p.n 526682

34

1

/4” (870mm)

0”

28

15

/16” (735mm)15/32” (12mm)

427/32” (123mm)

2815/16”

(735mm)

15

/32”

(12mm)

[Door extension]

R

READ THESE INSTRUCTIONS COMPLETELY AND CAREFULLY.

BADGE AND HANDLE POSITIONS

On both Panels, select the Badge position to suit the cabinetry design,

within the available badge zones.

The Badge may be centered on the edge of the badge zone.

The handle position will also need to be taken into account.

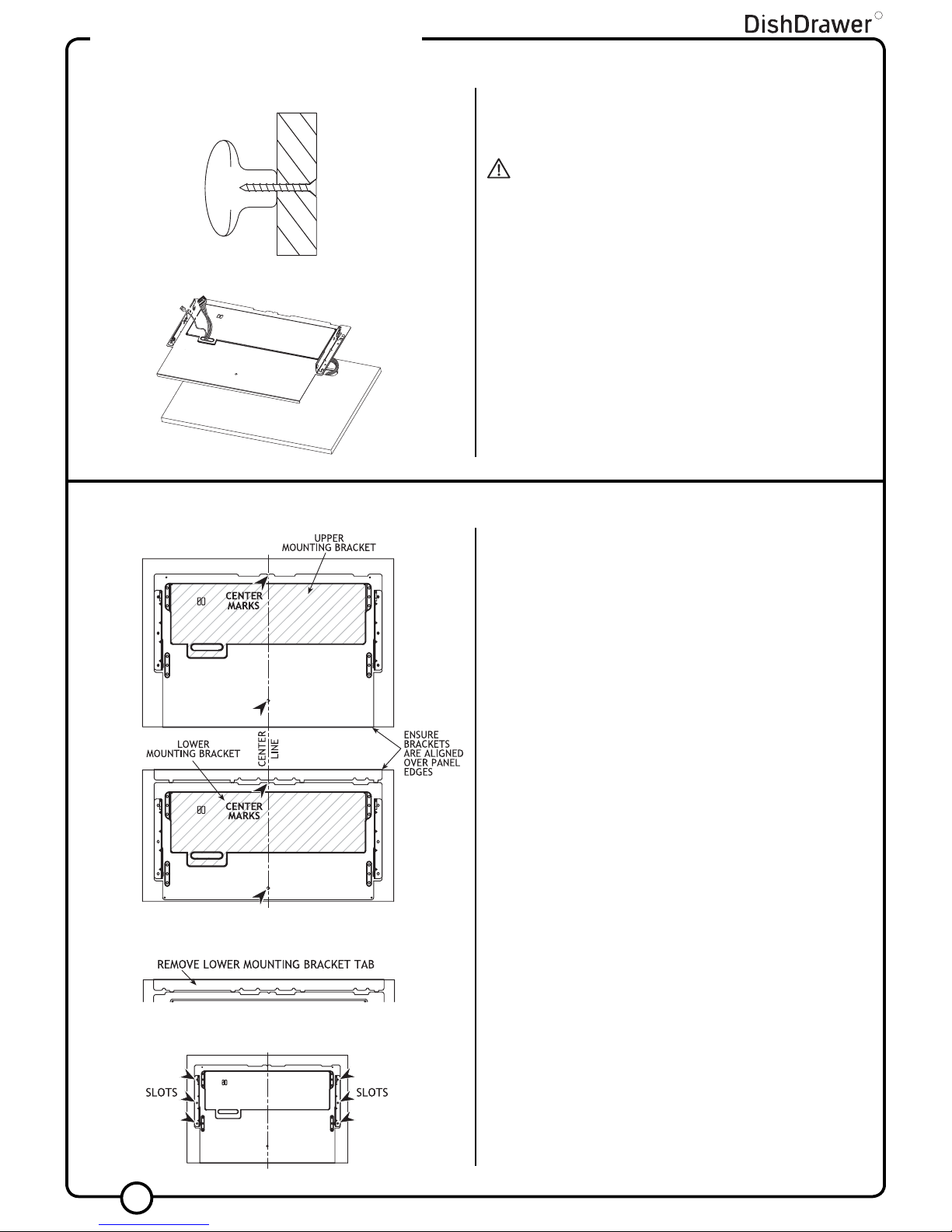

PANEL PREPARATION INSTRUCTIONS

STEP 1: BADGE AND HANDLE POSITION

STEP 2: BADGE CUT-OUT & BRACKET REMOVAL

BADGE CUT-OUT

Cut the badge slot in each Panel by drilling two 1” (25.4mm) diameter

holes and cutting out the remaining material between the holes. A hole

center to hole center template is provided on the Mounting Backet.

WARNING!

Be sure the Product is not plugged in.

Important!

Accuracy is essential when cutting the Badge slot to be sure of a

neat fit to hold the Badge.

REMOVING THE BRACKET

1) To remove the Mounting Brackets withdraw the pins from the Drawer

sides, using a pair of needle-nose pliers.

2) Gently slide the Mounting Bracket off in a downwards and outwards

motion. Disconnect the Mounting Bracket and Badge grounding

wires, also unplug the Badge harness from the Badge Isolator box.

Remove the Badge from the Mounting Bracket.

NOTE: The four

1

/8” (3.3mm) holes on the perimeter of the

rectangular recess in the Mounting Bracket can also be used

to define the badge zone.

3

(Not shown to scale)

FITTING THE HANDLE

Fit the customer supplied handle.

WARNING!

When mounting the handle, be sure fastenings do not protrude

beyond the back surface of the Panel.

FITTING THE BADGE

Fit a Badge to each Panel by feeding the wires through to the back and

pressing the Badge into the cut out. If needed adhere the Badge to the

Panel with an adhesive.

Feed the Badge wires through the slot in the Mounting Bracket. As the

Mounting Bracket is placed on the rear of the Panel the excess wire must

be pulled through.

R

PANEL PREPARATION INSTRUCTIONS

STEP 4: SECURING THE MOUNTING BRACKETS

STEP 3: FITTING THE HANDLE AND BADGE

4

Each Mounting Bracket is directly screwed to the back of each Integrated

Panel. On a soft surface centralize and align the Upper Mounting Bracket

on the Upper Panel and the Lower Mounting Bracket on the Lower Panel.

Important!

For some materials pilot holes may need to be drilled first before

screwing the Mounting Bracket onto the Panel. Be sure the drill does

not damage the face of the Panel.

Important!

The mounting bracket must not be modified in any way. It is

designed to hold the door front in the correct position to allow

venting.

Important!

The top door front must not extend beyond the bottom of the

mounting bracket. Drying problems and moisture damage may

otherwise occur.

Important!

Break off the tab at the top of the Lower Mounting Bracket, after

Panel has been secured.

Using six

of the

5

/8” (16mm) screws supplied, secure the Mounting

Bracket to each Panel at the six points shown in the diagram.

NOTE: If the the six outermost slots are not able to be used

to securely fix the Mounting Brackets to the Panel, choose

any six well spaced slots about the Panel.

Loading...

Loading...